- Summary

- Table Of Content

- Methodology

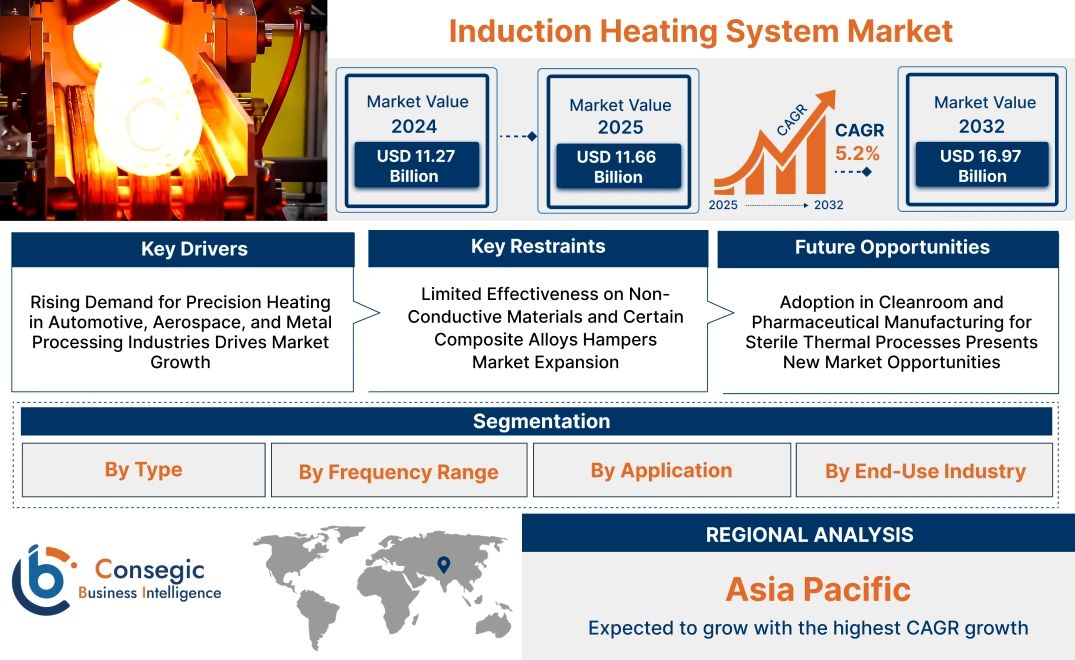

Induction Heating System Market Size:

Induction Heating System Market size is estimated to reach over USD 16.97 Billion by 2032 from a value of USD 11.27 Billion in 2024 and is projected to grow by USD 11.66 Billion in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

Induction Heating System Market Scope & Overview:

Induction heating system is a non-contact thermal processing technology that uses electromagnetic fields to heat conductive materials, primarily metals. It is widely implemented in applications such as metal hardening, brazing, forging, melting, and annealing across automotive, aerospace, electronics, and manufacturing industries.

The system comprises an induction coil, a power supply unit, a cooling assembly, and a control interface. Key features include rapid heat generation, precise temperature control, and localized heating zones without affecting adjacent components. Configurable designs enable seamless integration into automated production lines.

Induction heating system offers benefits such as high energy efficiency, reduced material distortion, minimal oxidation, and uniform heat distribution. Its ability to deliver fast, repeatable, and clean heating processes enhances productivity and product quality. Adaptable to both small-scale and high-throughput operations, it serves as a critical tool in precision-driven and thermally intensive industrial environments.

Key Drivers:

Rising Demand for Precision Heating in Automotive, Aerospace, and Metal Processing Industries Drives Market Growth

Industries such as automotive, aerospace, and heavy engineering are increasingly adopting induction heating systems to meet strict metallurgical and dimensional precision requirements. These systems provide localized, contactless heating with minimal thermal distortion, making them ideal for surface hardening, brazing, and forging applications. In automotive manufacturing, they ensure repeatable hardness profiles for drivetrain components. In aerospace, they support the integrity of critical metal joints and high-stress parts. Additionally, their rapid heat-up times and controllability reduce processing cycles and energy consumption. As these industries move toward automation and tighter quality control, the need for advanced thermal processing technologies is rising. The ability to deliver high-performance heating solutions across diverse geometries and alloys is reinforcing adoption, driving sustained induction heating system market expansion.

Key Restraints:

Limited Effectiveness on Non-Conductive Materials and Certain Composite Alloys Hampers Market Expansion

Induction heating systems operate by inducing eddy currents in conductive materials, which limits their applicability to metals like steel, copper, and aluminum. Materials such as polymers, ceramics, glass, and most composite alloys do not respond to electromagnetic induction, restricting the use of these systems in industries adopting alternative materials for lightweighting or insulation. As sectors like aerospace and consumer electronics integrate carbon composites and non-metallic structures, traditional induction technologies face compatibility challenges. This limitation reduces the addressable market and discourages investment in induction-based infrastructure for mixed-material processing lines. Despite increasing demand for efficient and clean heating methods, these material constraints continue to limit the scope of induction heating system market growth.

Future Opportunities :

Adoption in Cleanroom and Pharmaceutical Manufacturing for Sterile Thermal Processes Presents New Market Opportunities

The pharmaceutical and biotechnology sectors require precise, contamination-free heating solutions for processes like cap sealing, tube bonding, and container sterilization. Induction heating systems meet these demands with localized, flame-free operation and minimal mechanical contact—ideal for cleanroom environments where hygiene and control are critical. Their ability to deliver uniform heat without introducing particulates or gas emissions supports regulatory compliance in sterile production settings. As requirement rises for injectable drug packaging, bioprocessing systems, and advanced medical device assembly, manufacturers are adopting induction-based solutions to enhance quality and reduce validation time. This shift opens new application segments beyond traditional metal processing, supported by growth in pharmaceutical manufacturing, cleanroom expansion, and regulatory-driven process optimization, creating significant induction heating system market opportunities.

Induction Heating System Market Segmental Analysis :

By Type:

Based on type, the induction heating system market is segmented into induction heating equipment and induction heating services.

The induction heating equipment segment accounted for the largest revenue share in 2024.

- This segment includes generators, coils, transformers, and power supplies designed for heating metals and other conductive materials.

- Equipment is widely adopted in automotive and metal processing sectors for operations like surface hardening, forging, and annealing.

- Technological advancements in IGBT-based systems and power electronics have improved heating precision and energy efficiency.

- As per the induction heating system market analysis, long-term investments in process automation and electrification are driving equipment demand.

The induction heating services segment is projected to grow at the fastest CAGR during the forecast period.

- Services include on-site installation, system calibration, repair, preventive maintenance, and retrofitting of existing setups.

- Industries lacking internal expertise prefer outsourcing these tasks to ensure uptime and maximize operational efficiency.

- The segment is also supported by increasing adoption of rental-based models and contract-based system monitoring.

- Hence, the expansion of offerings by service providers through remote diagnostics and digital monitoring platforms is bolstering the rising induction heating system market demand.

By Frequency Range:

Based on frequency range, the market is segmented into low frequency (LF), medium frequency (MF), radio frequency (RF), and very high frequency (VHF).

The medium frequency segment held the largest induction heating system market share in 2024.

- MF systems (1–10 kHz) are ideal for heat treatment, forging, and billet heating due to deep heat penetration and uniformity.

- These systems are commonly used in heavy-duty industrial operations where larger workpieces require consistent heating.

- The balance of energy efficiency and flexibility makes MF suitable across diverse end-use applications.

- As per the induction heating system market analysis, MF technology remains dominant due to its versatility and proven performance.

The very high frequency segment is projected to witness the fastest CAGR.

- VHF systems (above 100 kHz) are gaining traction in precision applications such as soldering of micro-components and semiconductor bonding.

- These systems provide shallow penetration, high control, and rapid response—ideal for electronics and medical device industries.

- Increasing miniaturization in electronics manufacturing is fueling the adoption of high-frequency systems.

- As per induction heating system market trends, the rise in high-precision fabrication supports VHF system innovation.

By Application:

Based on application, the induction heating system market is segmented into metal hardening, heat treatment, annealing, bonding, welding, soldering & brazing, melting & casting, and heating of polymer.

The metal hardening segment accounted for the largest revenue share in 2024.

- Induction hardening improves surface strength and wear resistance of components like gears, shafts, and automotive parts.

- The non-contact, localized heating enables fast processing with minimal distortion, improving product quality.

- It is widely adopted in automotive and machinery manufacturing due to its ability to enhance fatigue life.

- Induction heating system market demand in this segment is driven by increasing focus on lightweight and high-performance parts.

The soldering and brazing segment is expected to grow at the fastest CAGR.

- Induction heating allows precise and clean joining of dissimilar metals, improving joint strength and reducing contamination.

- It is widely used in electronics, HVAC, and aerospace sectors where compact and reliable connections are required.

- Energy-efficient heating, repeatability, and reduced oxidation make it ideal for high-throughput assembly lines.

- As per induction heating system market trends, automated brazing stations are being integrated with robotics and vision systems for enhanced accuracy.

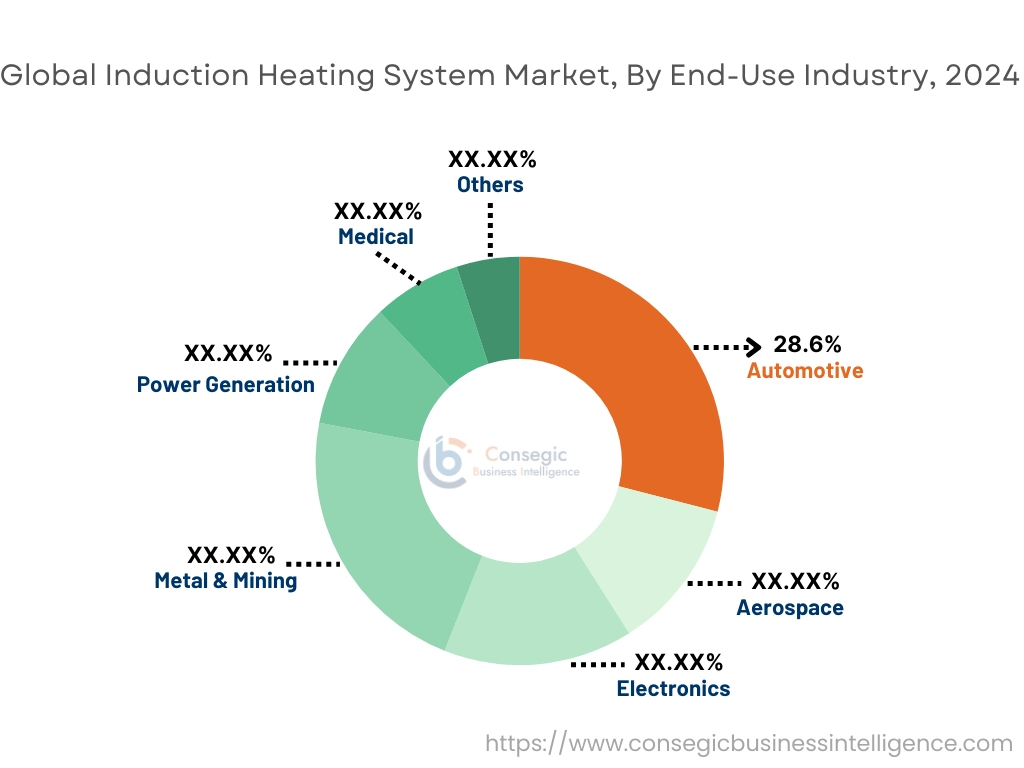

By End-Use Industry:

Based on end-use industry, the market is segmented into automotive, aerospace, electronics, metal & mining, power generation, medical, and others.

The automotive segment accounted for the largest induction heating system market share of 28.6% in 2024.

- Induction heating is heavily used in automotive manufacturing for gear hardening, camshaft tempering, bearing races, and exhaust treatment.

- EV production also utilizes induction systems for joining battery components, powertrain parts, and structural reinforcements.

- Speed, energy efficiency, and environmental compliance support strong adoption across OEM and tier suppliers.

- As per induction heating system market growth forecasts, electrification trends will further boost system integration in automotive lines.

The electronics segment is expected to grow at the fastest CAGR.

- Electronics manufacturing requires precise and localized heating for soldering chips, bonding wires, and curing adhesives.

- VHF induction systems are used for component encapsulation and assembly of sensors and micro-electromechanical systems (MEMS).

- The increasing complexity of electronic devices is creating want for highly controlled, non-contact heating solutions.

- Induction heating system market expansion in this segment is supported by miniaturization trends and the rise of high-performance computing.

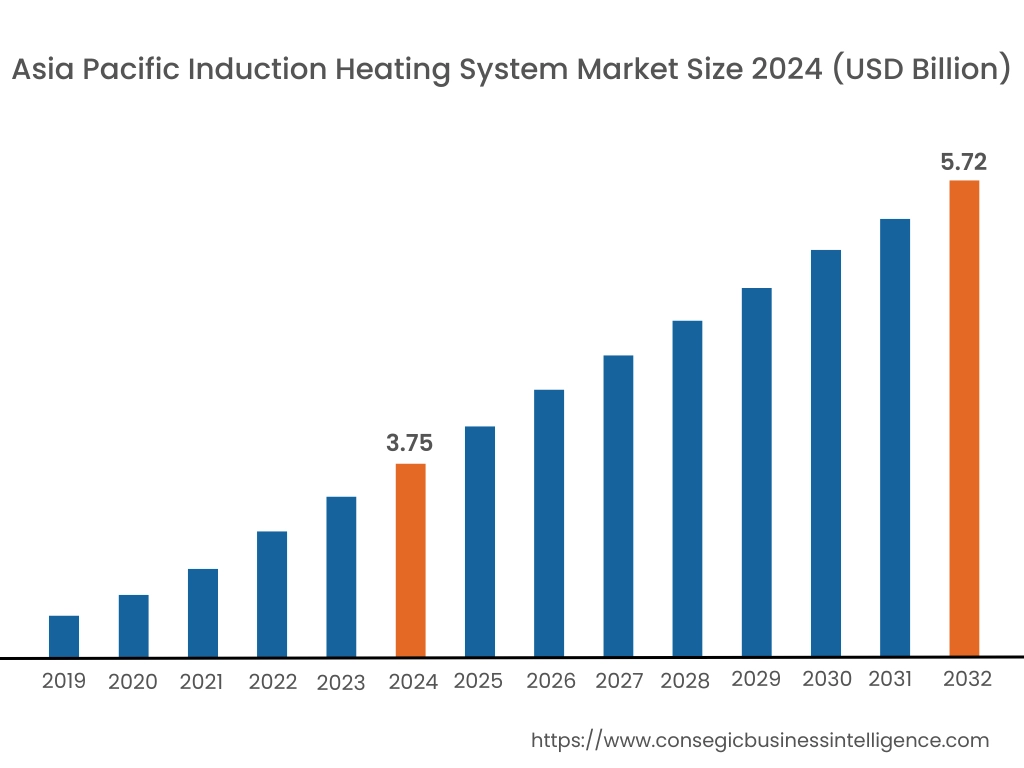

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

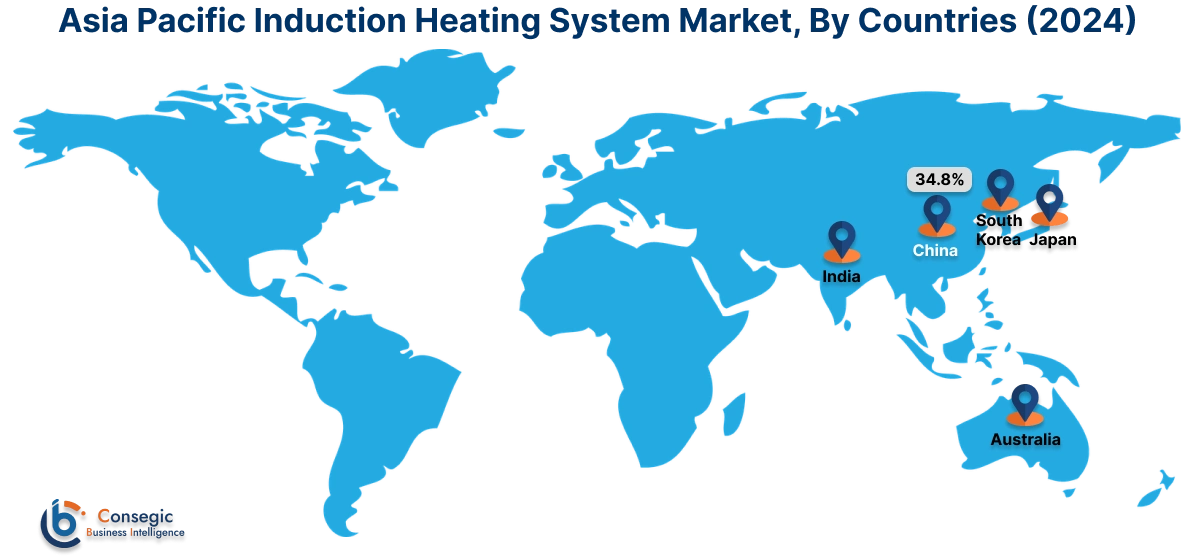

Asia Pacific region was valued at USD 3.75 Billion in 2024. Moreover, it is projected to grow by USD 3.88 Billion in 2025 and reach over USD 5.72 Billion by 2032. Out of this, China accounted for the maximum revenue share of 34.8%. Asia-Pacific is witnessing rapid growth in the induction heating systems industry, driven by industrial expansion, rising labor costs, and increasing focus on automation. In China, Japan, South Korea, and India, the shift toward high-efficiency heating technologies is particularly strong in automotive parts manufacturing, semiconductor fabrication, and precision machining sectors. Market analysis highlights that domestic production capacity, supportive industrial policies, and strong OEM presence are accelerating the adoption of flexible and modular heating systems. s manufacturing processes become more sophisticated, demand for programmable and multi-zone induction solutions is expected to rise, reinforcing the region’s position as both a consumer and producer hub for induction technologies.

North America is estimated to reach over USD 5.00 Billion by 2032 from a value of USD 3.31 Billion in 2024 and is projected to grow by USD 3.43 Billion in 2025. North America continues to hold a significant position due to its strong industrial base and early adoption of advanced heating technologies. In the United States and Canada, induction systems are widely used in heat treating, metal hardening, and welding applications across automotive and aerospace industries. Market analysis reveals that manufacturers are investing in modernizing facilities with compact and digitally controlled induction equipment to reduce energy consumption and improve process repeatability. Growth in this region is further supported by strict emission norms and incentives for energy-efficient industrial technologies, especially in states prioritizing clean manufacturing practices and electrification of industrial processes.

Europe represents a regulation-driven and technology-rich environment for the induction heating system industry. Countries such as Germany, Italy, France, and the United Kingdom are integrating high-frequency heating equipment in forging, annealing, and surface treatment applications to align with EU directives on energy use and sustainable production. Market analysis shows that manufacturers are adopting closed-loop control systems and hybrid power modules to meet increasingly precise quality standards in electronics and tool manufacturing. The induction heating system market opportunity in Europe is closely tied to modernization of foundries and investment in zero-emission heat treatment lines, with increased focus on electrification and phasing out of fossil-fuel-based furnaces.

Latin America is an emerging market with growing interest in induction heating technologies, particularly in Brazil, Mexico, and Argentina. Market analysis indicates that need is largely driven by localized automotive production and metal component manufacturing, where precision and cost-efficiency are crucial. Although conventional heating technologies are still widely used, the adoption of induction systems is increasing in facilities focused on export-grade production and energy optimization. The market opportunity here lies in supporting industrial upgrades with scalable and easy-to-integrate solutions, while addressing gaps in technical expertise and after-sales support infrastructure.

The Middle East and Africa region is showing gradual adoption, mainly concentrated in South Africa, the UAE, and Saudi Arabia. Demand is emerging from mining equipment fabrication, pipeline construction, and energy sector applications requiring controlled heating environments. Market analysis suggests that while traditional methods remain prevalent, industrial diversification and investment in manufacturing clusters are prompting interest in efficient and clean heating technologies. As sustainability goals become more prominent, especially in Gulf nations, growth is expected in sectors that benefit from low-maintenance and environmentally compliant induction systems.

Top Key Players and Market Share Insights:

The induction heating system market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global induction heating system market. Key players in the induction heating system industry include-

- Inductotherm Group (USA)

- EFD Induction (Norway)

- Electrotherm (India) Ltd. (India)

- ABP Induction Systems GmbH (Germany)

- Ultraflex Power Technologies (USA)

- Ambrell Corporation (USA)

- Ajax Tocco Magnethermic (USA)

- GH Induction Group (Spain)

- eldec Induction GmbH (Germany)

- Fuji Electric Co., Ltd. (Japan)

Induction Heating System Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 16.97 Billion |

| CAGR (2025-2032) | 5.2% |

| By Type |

|

| By Frequency Range |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Induction Heating System Market? +

Induction Heating System Market size is estimated to reach over USD 16.97 Billion by 2032 from a value of USD 11.27 Billion in 2024 and is projected to grow by USD 11.66 Billion in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

What specific segmentation details are covered in the Induction Heating System Market report? +

The Induction Heating System market report includes specific segmentation details for type, frequency range, application and end-use industries.

What are the end-use industries of the Induction Heating System Market? +

The end-use industries of the Induction Heating System Market are automotive, aerospace, electronics, metal & mining, power generation, medical, and others.

`Who are the major players in the Induction Heating System Market? +

The key participants in the Induction Heating System market are Inductotherm Group (USA), EFD Induction (Norway), Ambrell Corporation (USA), Ajax Tocco Magnethermic (USA), GH Induction Group (Spain), eldec Induction GmbH (Germany), Fuji Electric Co., Ltd. (Japan), Electrotherm (India) Ltd. (India), ABP Induction Systems GmbH (Germany) and Ultraflex Power Technologies (USA).