- Summary

- Table Of Content

- Methodology

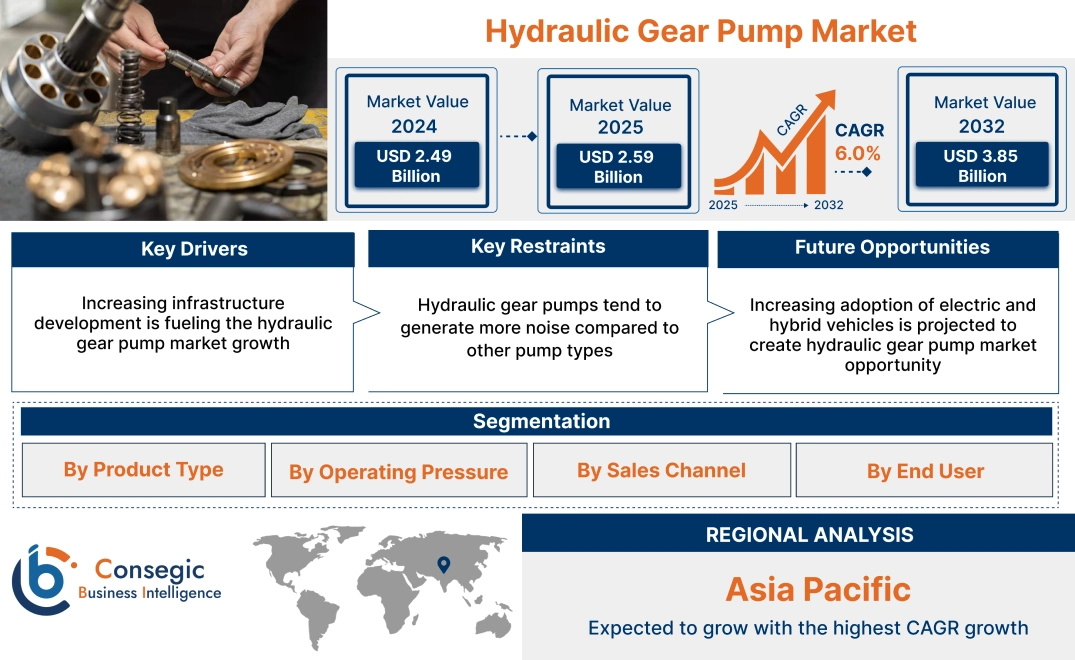

Hydraulic Gear Pump Market Size:

Hydraulic Gear Pump Market Size is estimated to reach over USD 3.85 Billion by 2032 from a value of USD 2.49 Billion in 2024 and is projected to grow by USD 2.59 Billion in 2025, growing at a CAGR of 6.0% from 2025 to 2032.

Hydraulic Gear Pump Market Scope & Overview:

A hydraulic gear pump is a positive displacement pump that utilizes the network of gears to transfer fluid. Essentially, it converts mechanical power into hydraulic fluid power. As the gears rotate, they create a vacuum at the pump's inlet, drawing in fluid and this fluid is then trapped within the gear teeth and transported to the outlet, where the meshing of the gears forces it out under pressure. These pumps are commonly used in hydraulic systems due to their simplicity, reliability, and ability to handle high pressures.

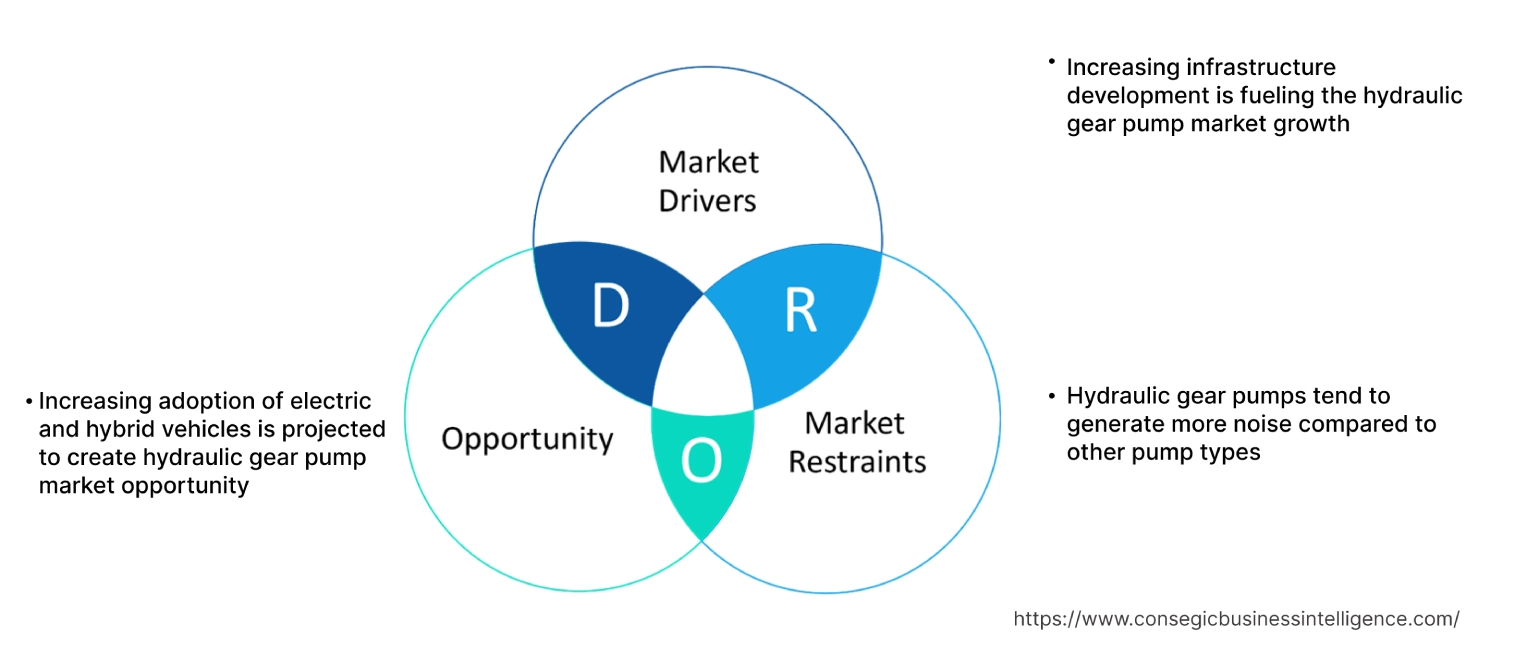

Key Drivers:

Increasing infrastructure development is fueling the hydraulic gear pump market growth

Infrastructure projects, such as building roads, bridges, dams, and large-scale buildings, require extensive use of heavy machinery. Equipment like excavators, bulldozers, cranes, and loaders heavily rely on hydraulic systems to perform their tasks. Hydraulic gear pumps are essential components in these systems, providing the necessary power to operate the machinery's functions. Additionally, government investments in infrastructure projects also play a crucial role in driving market growth. Large-scale government initiatives involve significant spending on construction and infrastructure development, which fuels the need for these equipments, thereby driving the hydraulic gear pump market size.

- For instance, India's rapid economic growth, boasting an 8.9% GDP increase in 2021, is fueled by substantial infrastructure investment. The nation plans to invest USD 1.4 trillion by 2023 in sustainable infrastructure, supported by initiatives like Gati Shakti, the National Infrastructure Pipeline, and the National Monetization Pipeline.

Consequently, increasing infrastructure development is driving the hydraulic gear pump market expansion.

Key Restraints:

Hydraulic gear pumps tend to generate more noise compared to other pump types

In industrial settings, excessive noise can pose a risk to workers' hearing and overall health. Regulations regarding workplace noise levels are becoming increasingly stringent in many regions, limiting the use of gear pumps in applications where noise control is critical. Moreover, noise pollution is recognized as an environmental hazard and in urban areas, the use of noisy machinery can be restricted. This impacts the adoption of gear pumps in applications like construction and municipal services. Further, alternative pump technologies, such as screw pumps or vane pumps, offer quieter operation and are gaining preference in various applications, further hindering the global hydraulic gear pump market size.

Therefore, as per the analysis, these combined factors are significantly hindering hydraulic gear pump market share.

Future Opportunities :

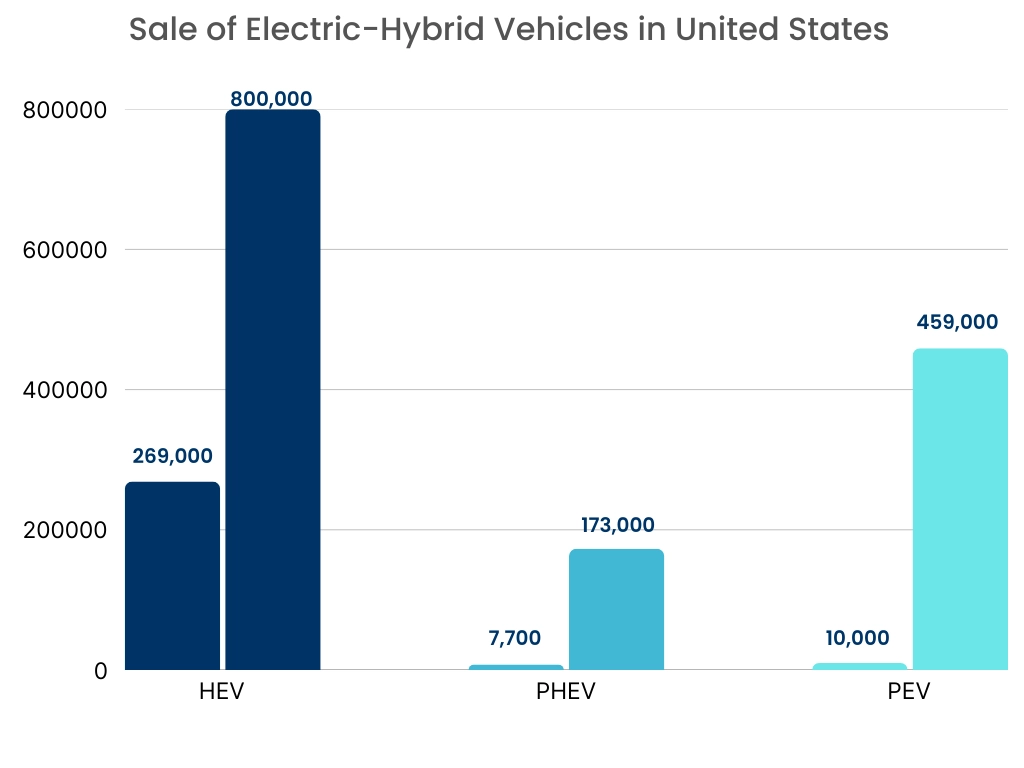

Increasing adoption of electric and hybrid vehicles is projected to create hydraulic gear pump market opportunity

Electric and hybrid vehicles utilize Electro-hydraulic power steering (EHPS) systems, which replace traditional engine-driven hydraulic power steering pumps. EHPS systems use an electric motor to drive a hydraulic gear pump, providing power steering assistance only when needed, thus improving energy efficiency. Additionally, electric and hybrid commercial vehicles and heavy-duty equipment require hydraulic systems for various auxiliary functions, such as braking, lifting, and material handling. Gear pumps can be used in these systems, and their compact size and efficiency make them well-suited for integration into electric and hybrid platforms. Furthermore, in traditional hydraulic systems powered by combustion engines, hydraulic pumps can create parasitic losses. In electric and hybrid systems, where energy efficiency is paramount, electrically driven gear pumps allow for "power on demand," minimizing these losses, thus significantly boosting hydraulic gear pump market demand.

- For instance, in the United States, the decade from 2011 to 2021 saw a significant surge in electric vehicle adoption. Hybrid-electric vehicle (HEV) sales nearly tripled, rising from approximately 269,000 to almost 800,000. Plug-in hybrid-electric vehicle (PHEV) sales experienced dramatic growth, jumping from roughly 7,700 to over 173,000. Similarly, plug-in electric vehicle (PEV) sales saw a substantial increase, climbing from about 10,000 to over 459,000.

Hence, based on the analysis, increasing adoption of electric and hybrid vehicles is expected to create hydraulic gear pump market opportunities.

Hydraulic Gear Pump Market Segmental Analysis :

By Product Type:

Based on the Product Type, the market is categorized into External Gear Pump and Internal Gear Pump.

Trends in the Product Type:

- Internal gear pumps are gaining traction in applications requiring smoother flow, lower noise levels, and higher viscosity fluid handling.

- Growing adoption of external gear pump in diverse applications, including construction, agriculture, and industrial machinery, where high-pressure capabilities are essential.

External Gear Pump accounted for the largest revenue share in the market in 2024.

- External gear pumps are highly prevalent due to their simplicity, robustness, and cost-effectiveness, thereby driving hydraulic gear pump market.

- Additionally, manufacturers are focusing on improving the efficiency of external gear pumps to meet energy conservation demands, which in turn is boosting market.

- Noise reduction is another key trend, with advancements in gear design and materials aimed at minimizing operational noise.

- Further, the increasing utilization of external gear pumps in mobile hydraulics is also driving the market trend.

- For instance, THM Huade Hydraulics Pvt Ltd introduced the THM-TPF2G3 Series, a high-pressure external gear pump engineered for sustained operation at up to 250 bars. This pump features a specialized sealing design, robust alloy bushes with a unique locking mechanism for increased rigidity, and modified gear teeth to minimize operating torque.

- Thus, as per the hydraulic gear pump market analysis, the aforementioned factors are driving the external gear pump segment.

Internal Gear Pump are predicted to register the fastest CAGR during the forecast period.

- Internal gear pump are employed in industries including chemical processing, food and beverage, and pharmaceuticals, where precise and gentle fluid transfer is critical.

- Additionally, demand for pumps with minimal pulsation and precise flow control is driving the adoption of internal gear pumps, important in applications involving delicate fluids or sensitive processes.

- Internal gear pumps are well suited for high viscosity fluids, thus are widely used in polymers and food processing industries.

- Moreover, internal gear pump are known for their quiet operation, which in turn, is accelerating the market demand.

- In conclusion, the above-mentioned factors are contributing significantly in spurring the market.

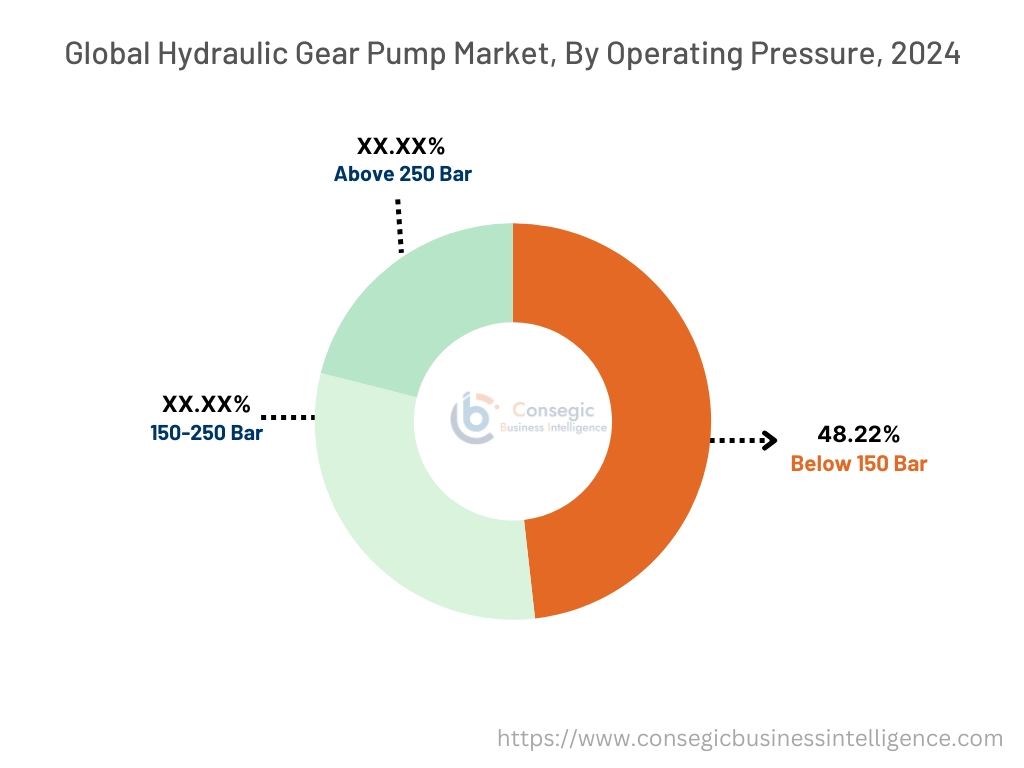

By Operating Pressure:

Based on the Operating Pressure, the market is classified into Below 150 Bar, 150-250 Bar, and Above 250 Bar.

Trends in the Operating Pressure:

- Below 150 bar pressure range is adopted in several applications, including general machinery and agricultural equipment.

- Growing trend towards the adoption of below 150 bar pumps primarily for optimizing efficiency and minimizing production costs.

150-250 Bar accounted for the largest revenue share of 48.22% in 2024.

- This range is used in applications requiring moderate to high pressure, such as construction equipment and heavy-duty machinery, thereby driving the hydraulic gear pump market demand.

- Manufacturers are focusing on striking a balance between performance, durability, and cost-effectiveness in this segment.

- Due to the increased workload, and stress on the pumps, manufacturers are implementing new technologies to increase the longevity of the pumps.

- Increasing trend towards the adoption of 150-250 bar range pumps to handle higher loads and operate in more demanding environments.

- Thus, as per the hydraulic gear pump market analysis, the aforementioned factors are driving 150-250 Bar segment.

Above 250 Bar is predicted to register the fastest CAGR during the forecast period.

- Above 250 bar range is primarily used in applications requiring extremely high pressure, such as heavy-duty hydraulic presses and mining equipment.

- Manufacturers are focusing on using high-strength materials and advanced manufacturing techniques to ensure long-term reliability.

- In addition, durability and reliability are essential in this segment, as pumps are subjected to extreme stress and operating conditions.

- In conclusion, as per the analysis, the above-mentioned factors are contributing significantly in spurring the market.

By Sales Channel :

Based on the Sales Channel, the market is categorized into Direct Sales and Indirect Sales.

Trends in the Sales Channel:

- Direct sales are common in large-scale industrial applications, such as heavy machinery, mining, and aerospace.

- Manufacturers provide comprehensive after-sales service and support through direct sales.

Indirect Sales accounted for the largest revenue share in 2024 and is also predicted to register the fastest growth.

- Indirect sales channels, involving distributors, dealers, and retailers, enable manufacturers to reach a wider customer base.

- This channel is effective for reaching small and medium-sized enterprises (SMEs) and customers in diverse geographical locations.

- The rise of e-commerce platforms is expanding indirect sales channels, enabling manufacturers to reach customers online.

- Indirect sales channels offer convenience to consumers to purchase from a local dealer, or distributor.

- In conclusion, the aforementioned factors are contributing to the increase of indirect sales segment in the global hydraulic gear pump market.

By End-User:

Based on the End User, the market is categorized into Automotive, Chemicals and Petrochemicals, Food and Beverage, Metal and Mining, Oil and Gas, Power Generation, Water and Wastewater, and Others.

Trends in the End User:

- Growing trend towards the adoption of hydraulic systems in the control of wastewater processing.

- Growing need for hydraulic gear pump in wind turbines and hydroelectric power plants.

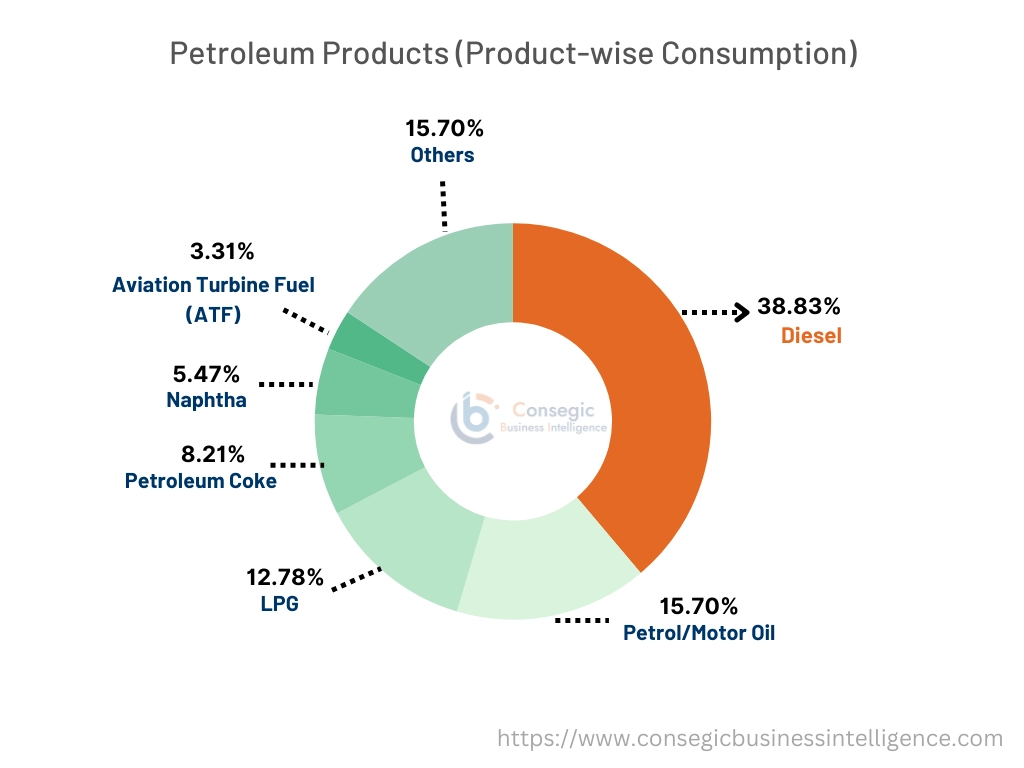

Oil and Gas accounted for the largest revenue share in the market in 2024.

- Increasing need for high-pressure and explosion-proof pumps for offshore and onshore applications is boosting market expansion.

- Additionally, growing emphasis on reliable and durable pumps for critical operations is also driving the market.

- For instance, in the 2022-23 fiscal year, India's energy consumption showed varied trends. Crude oil usage rose to 255.2 million metric tonnes, a 5.6% increase, while natural gas consumption declined by 6.5% to 60 billion cubic meters. Petroleum product consumption saw a moderate increase of 10.6%, reaching 223 million metric tonnes.

- Consequently, the expanding oil and gas sector is contributing notably in driving the hydraulic gear pump market.

Automotive are predicted to register the fastest CAGR during the forecast period.

- Increasing adoption of electro-hydraulic power steering (EHPS) in electric and hybrid vehicles is driving the need for hydraulic gear pump market.

- Rising focus on compact and efficient gear pumps for auxiliary systems in commercial vehicles is also spurring the market.

- For instance, in India's automotive sector has attracted significant foreign investment, with approximately USD 36.21 billion in equity FDI between April 2000 and September 2024. Furthermore, the nation is poised for substantial increase in the electric vehicle (EV) market, projected to become the largest by 2030, presenting an investment opportunity exceeding USD 200 billion.

- Therefore, the expanding automotive sector is contributing notably in driving the growth of hydraulic gear pump market during the forecast period.

Regional Analysis:

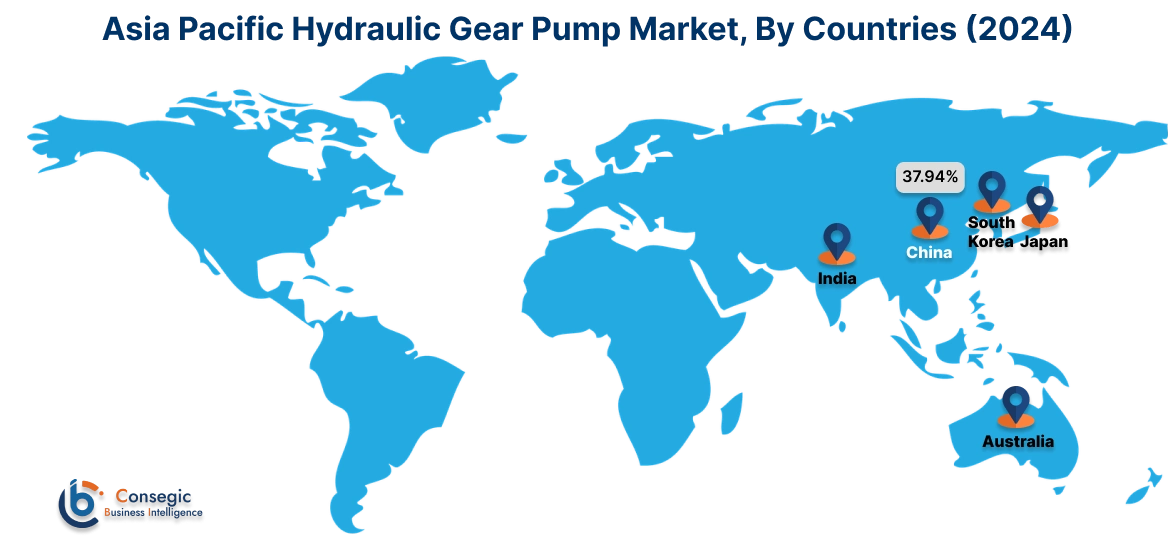

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

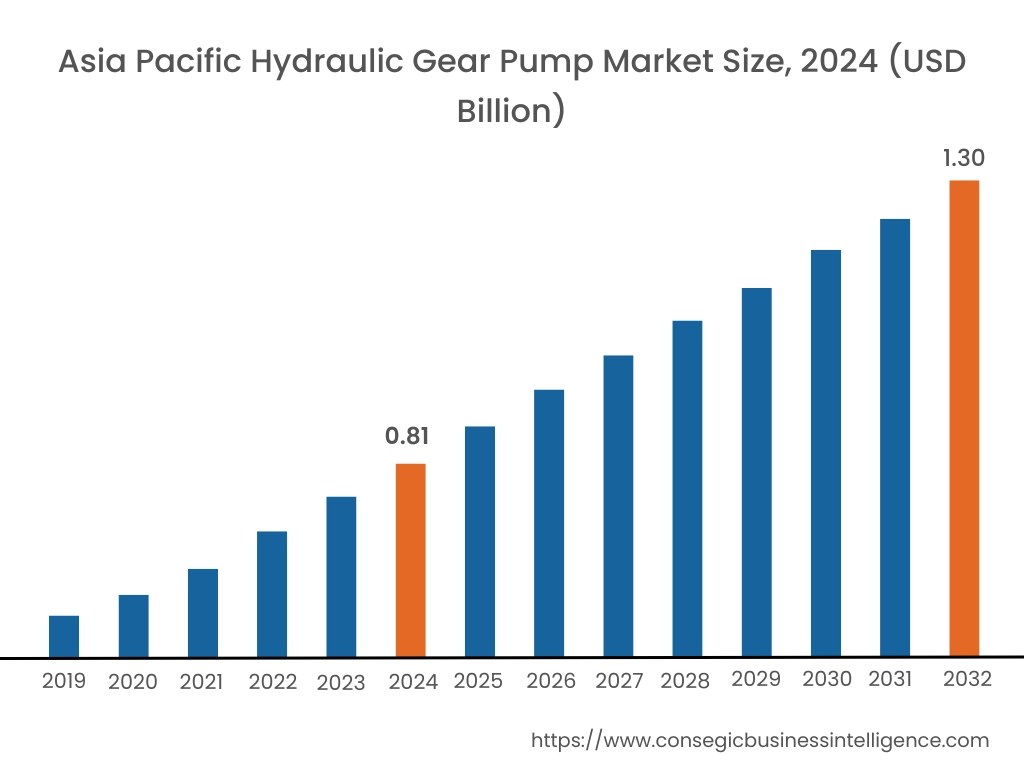

Asia Pacific was valued at USD 0.81 Billion in 2024. Moreover, it is projected to grow by USD 0.85 Billion in 2025 and reach over USD 1.30 Billion by 2032. Out of these, China accounted for the largest revenue share of 37.94% in 2024. Increasing number of infrastructure projects across countries like China, India, and Southeast Asian nations are driving need for construction equipment, which heavily relies on hydraulic gear pumps. Additionally, investments in roads, railways, and urban development also contribute significantly to market extension. Moreover, the increasing adoption of mechanized farming practices is driving the use of hydraulic gear pumps in agricultural machinery like tractors and harvesters. Consequently, the expanding agricultural sector in Asia Pacific countries is contributing significantly in driving the hydraulic gear pump market growth.

- For instance, India's agriculture sector has shown strong increase, averaging 5% annually from FY17 to FY23, and grew at 3.5% in the second quarter of FY25, demonstrating resilience. The sector's contribution to India's economy, as measured by Gross Value Added (GVA), has also increased significantly, rising from 24.38% in FY15 to 30.23% in FY23.

North America region was valued at USD 0.74 Billion in 2024. Moreover, it is projected to grow by USD 0.76 Billion in 2025 and reach over USD 1.12 Billion by 2032. The thriving construction sector in North America, encompassing residential, commercial, and industrial construction, is a major consumer of hydraulic gear pumps. The need for construction machinery such as excavators, loaders, cranes, and bulldozers, which rely on hydraulic systems, fuels market growth. Therefore, increase in the construction sector is contributing notably in spurring the global hydraulic gear pump market.

- For instance, according to S. Census Bureau, in February 2025 construction spending in the U.S. climbed to an estimated USD 2,195.8 billion, marking a 0.7% rise from January and a 2.9% year-over-year increase. The cumulative spending for the first two months of 2025 totalled USD 311.1 billion, reflecting a 2.1% growth compared to the same period in 2024, indicating continued expansion in the construction sector.

As per the hydraulic gear pump market analysis, Europe's market is driven by the region's strong focus on industrial automation, high-precision engineering, and a well-established automotive sector. Additionally, Latin America presents significant potential for hydraulic gear pumps, fueled by increasing investments in construction activities, mining operations, and agricultural development, as the region continues to develop its infrastructure. Further, Middle East and Africa are experiencing development in the hydraulic gear pump market due to substantial investments in infrastructure projects, the development of the oil & gas sector, and increased construction activities in countries like the UAE, Qatar, and South Africa.

Top Key Players and Market Share Insights:

The market is highly competitive with major players providing hydraulic gear pump to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the hydraulic gear pump industry include-

- Bosch Rexroth (Germany)

- Parker Hannifin (USA)

- Kawasaki Heavy Industries (Japan)

- Danfoss (Denmark)

- Eaton (USA)

- Hydac (Germany)

- Permco (USA)

- Bucher Hydraulics (Switzerland)

- Linde Hydraulics (Germany)

- Haldex (Sweden)

Recent Industry Developments :

Product Launch:

- In May 2024, Techman Robot launched TM30S robotic arm, which offers maximum payload capacity of 35kg with a reach of 1702mm across six joints.

Collaborations and Partnerships:

- In January 2025, NTT DATA collaborated with ITOCHU Techno-Solutions Corporation and Mitsubishi Chemical Group Corporation to conduct an experiment by using IOWN All-Photonics Network and AI technologies for smart maintenance through remote-controlled robots and AI-driven video analysis.

Hydraulic Gear Pump Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3.85 Billion |

| CAGR (2025-2032) | 6.0% |

| By Product Type |

|

| By Operating Pressure |

|

| By Sales Channel |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the hydraulic gear pump market? +

The hydraulic gear pump market size is estimated to reach over USD 3.85 Billion by 2032 from a value of USD 2.49 Billion in 2024 and is projected to grow by USD 2.59 Billion in 2025, growing at a CAGR of 6.0% from 2025 to 2032.

What specific segmentation details are covered in the hydraulic gear pump report? +

The hydraulic gear pump report includes specific segmentation details for product type, operating pressure, sales channel, end user, and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the hydraulic gear pump market, automotive is the fastest-growing segment during the forecast period.

Who are the major players in the hydraulic gear pump market? +

(Germany), Parker Hannifin (USA), Kawasaki Heavy Industries (Japan), Danfoss (Denmark), Eaton (USA), Hydac (Germany), Permco (USA), Bucher Hydraulics (Switzerland), Linde Hydraulics (Germany), Haldex (Sweden), and Others.