Heat Seal Coatings Market Introduction :

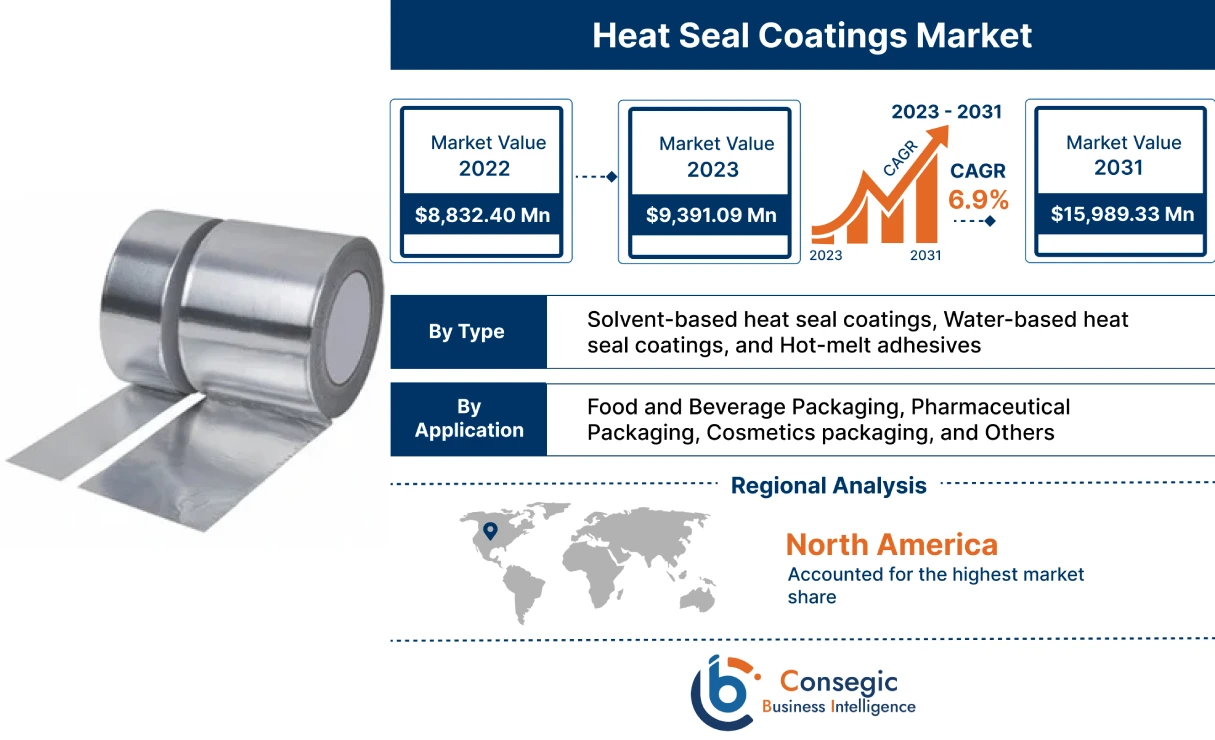

Consegic Business Intelligence analyzes that the heat seal coatings market size is growing with a CAGR of 6.9% during the forecast period (2023-2031), and the market is projected to be valued at USD 15,989.33 million by 2031 USD 9,391.09 million in 2023 from USD 8,832.40 million in 2022.

Heat Seal Coatings Market Definition & Overview:

Heat seal coatings are thermoplastic adhesive coatings that are used to bond two substrates together using heat and pressure. They are typically applied to flexible substrates, such as film, foil, paper, or non-woven material. They are used in a wide range of applications, including food packaging, pharmaceutical packaging, personal care and cosmetics packaging, and industrial packaging. As per the analysis, they work by melting when heated and then re-solidifying when cooled, forming a strong bond between the two substrates.

The strength and durability of the bond will depend on the type of heat seal coating used, the substrates being bonded, and the heat and pressure conditions used during the sealing process. As per the analysis, they are a critical component in many packaging applications. They help to ensure that products are packaged securely and that the packaging remains intact throughout the distribution chain and on the shelf.

Heat Seal Coatings Market Insights :

Heat Seal Coatings Market Dynamics - (DRO) :

Key Drivers :

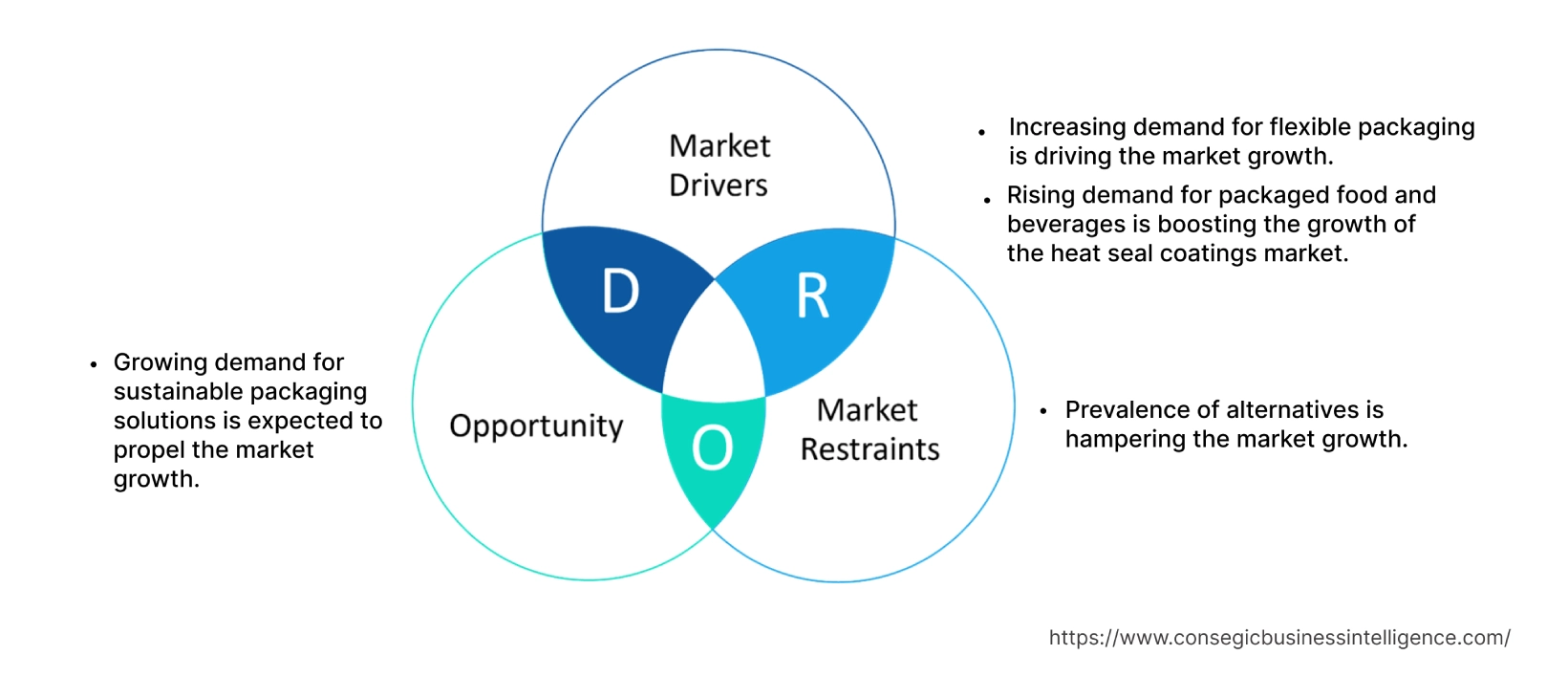

Increasing demand for flexible packaging is driving the market

Heat seal coatings are essential for flexible packaging, as they allow for strong and durable seals that can protect the product from moisture, contamination, and other environmental factors. Flexible packaging is becoming increasingly popular due to its advantages over rigid packaging, such as lighter weight, lower cost, and reduced environmental impact.

Hence, it is widely demanded in food and beverage packaging, pharmaceutical packaging, personal care and cosmetics packaging, industrial packaging, and medical device packaging. Heat seal coating packaging offers light weight and greater versatility to the products. Furthermore, Based on the analysis, the coatings lead to significant savings on shipping costs owing to light weight and help to reduce the overall cost of packaging a product. Hence, due to increasing requirement for flexible packaging, the heat seal coatings market is experiencing significant.

Rising demand for packaged food and beverages is boosting the market

Heat seal coatings are used in a wide range of food and beverage packaging applications, such as bags, pouches, and cartons. They are used to create seals on bags and pouches that contain food and beverages. This helps to keep the product fresh and protected from contamination. Also, as per the analysis, these coatings are used to seal cartons that contain food and beverages. This helps to protect the product from moisture and other environmental factors. The coatings are used to seal lids on food and beverage containers, such as cups, bottles, and jars. This helps to prevent the product from leaking or spilling. Furthermore, the growing food and beverage industry is leading to increasing demand for these coatings. For instance, according to a recent report by Invest India in 2023, India's food processing sector is one of the largest in the world and its output is expected to reach USD 535 billion by 2025-26. Hence, due to the increasing food and beverage industry, the market is showcasing positive development.

Key Restraints :

Prevalence of alternatives is hampering the market growth

There are a number of other packaging solutions that compete with heat seal coatings, such as cold seal coatings, pressure-sensitive adhesives, and mechanical seals. Hence, these alternatives are posing challenges for the development of the heat seal coatings industry. As per the analysis, these alternative packaging solutions are more cost-effective and offer other advantages, such as being recyclable or compostable. Thus, due to the wide prevalence of alternatives, the heat seal coatings market growth is being hampered.

Future Opportunities :

Growing demand for sustainable packaging solutions is expected to propel the market

The growing requirement for sustainable packaging solutions are creating lucrative heat seal coatings market opportunities and trends in the coming years. The coating is made from sustainable materials, such as bio-based polymers, and they can also be used to reduce the amount of packaging material required. Consumers are becoming increasingly aware of the environmental impact of packaging and are demanding more sustainable packaging solutions. Thus, as per the analysis, key players in the market are developing new coatings with improved performance characteristics, such as higher peel strength, better heat resistance, and lower VOC emissions. For instance, in 2020, Henkel developed a new heat seal coating that is made from bio-based polyethylene terephthalate (PET). This heat seal coating is recyclable and offers comparable performance to traditional seal coatings made from petroleum-based PET. Hence, these advancements are leading to the development of new and improved materials with better performance characteristics. This is expected to drive the development and trends of the heat seal coatings market in the forecast period.

Heat Seal Coatings Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2031 |

| Market Size in 2031 | USD 15,989.33 Million |

| CAGR (2023-2031) | 6.9% |

| By Type | Solvent-based heat seal coatings, Water-based heat seal coatings, and Hot-melt adhesives |

| By Application | Food and Beverage Packaging, Pharmaceutical Packaging, Cosmetics packaging, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Henkel AG & Co. KGaA, Bostik, Michelman, Dow Inc., Flint Group, Ashland Global Holdings Inc., Avery Dennison Corporation, 3M, Bemis Company, and Amcor plc |

Heat Seal Coatings Market Segmental Analysis :

Based on the Type :

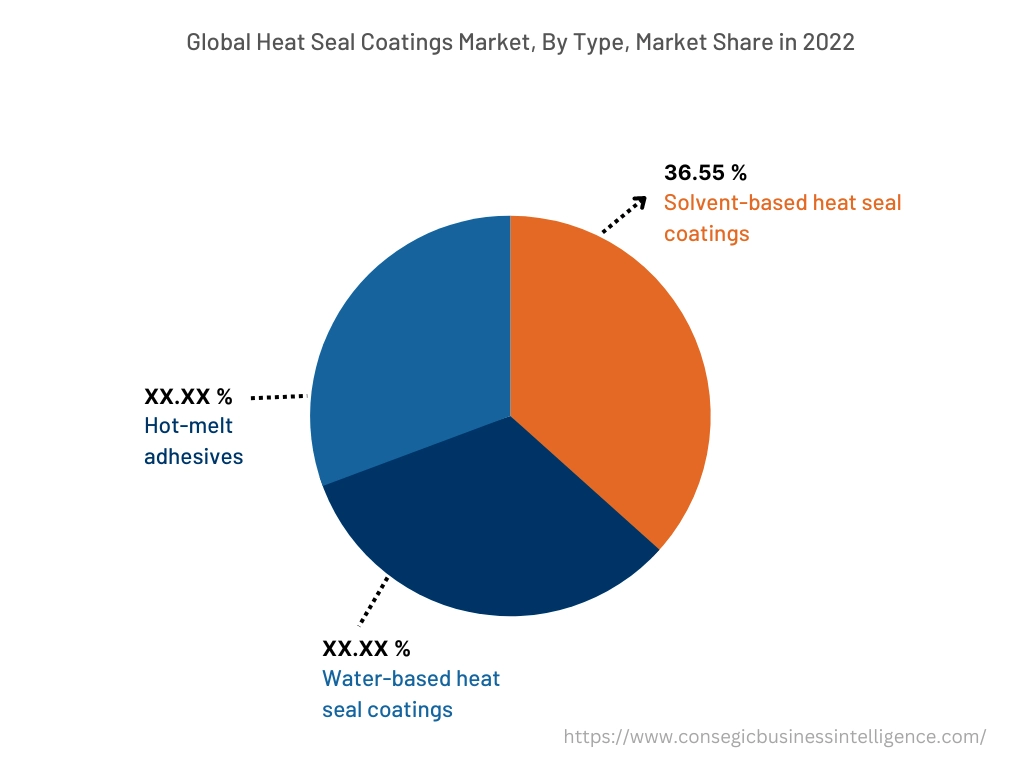

The type segment is categorized into solvent-based heat seal coatings, water-based heat seal coatings, and hot-melt adhesives. In 2022, the solvent-based heat seal coatings segment accounted for the highest heat seal coatings market share of 36.55% in the market. Solvent-based heat seal coatings are the most common type of heat seal coating. They are made with solvents, such as toluene and xylene, which dissolve the resins and polymers in the coating.

Solvent-based heat seal coatings offer several advantages, including high performance, good adhesion, and wide versatility. Also, new product launches by the key players in the market are propelling the segment expansion further. For instance, Flint Group launched chlorine-free heat sealable coatings range in Europe in 2021. The launch features solvent-based coatings that are sealable even against soft or hard aluminium, polyolefin, and PET films as well as a portfolio of completely repulpable paper packaging structures. Hence, due to the key product launches by the top players in the market, the segment is experiencing significant trends in the heat seal coatings market.

Moreover, the water-based heat seal coatings segment is expected to grow at the fastest CAGR over the forecast period in the heat seal coatings market. Water-based heat seal coatings are made with water instead of solvents, which makes them more environmentally friendly and less flammable. This coating is widely required in food packaging, beverage packaging, pharmaceutical packaging, personal care and cosmetics packaging, and others. Thus, due to the aforementioned factors, water-based heat seal coatings are showcasing positive development and trends in the market.

Based on the Application :

The application segment is categorized into food and beverage packaging, pharmaceutical packaging, cosmetics packaging, and others. In 2022, the food and beverage packaging segment accounted for the highest market share in the heat seal coatings market. They are essential for packaging a wide range of food and beverage products, such as bags, pouches, cartons, and lids. These coatings help to protect food and beverage products from moisture, contamination, and other environmental factors. Furthermore, increasing population, rising disposable income, and others are influencing larger requirement for packaged food and beverages globally. Hence, due to the wide usage and applications of these materials in food and beverage packaging, the segment is witnessing significant trends in the market.

Moreover, the pharmaceutical packaging segment is expected to grow at the fastest CAGR over the forecast period in the heat seal coatings market. They are used to package a wide range of pharmaceutical products, including prescription drugs, over-the-counter medications, and medical devices. The coatings help to protect pharmaceutical products from contamination and ensure that they remain sterile. They are also used to seal blisters, vials, and other packaging for pharmaceutical products. Furthermore, the increasing pharmaceutical sector globally is driving the developemnt of the global heat seal coatings market. For instance, according to a report by India Brand Equity Foundation in 2022, the market size of India pharmaceuticals sector is expected to reach USD 65 billion by 2024, and around USD 130 billion by 2030. Hence, due to the aforementioned factors, the pharmaceutical packaging segment is experiencing positive heat seal coatings market trends.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

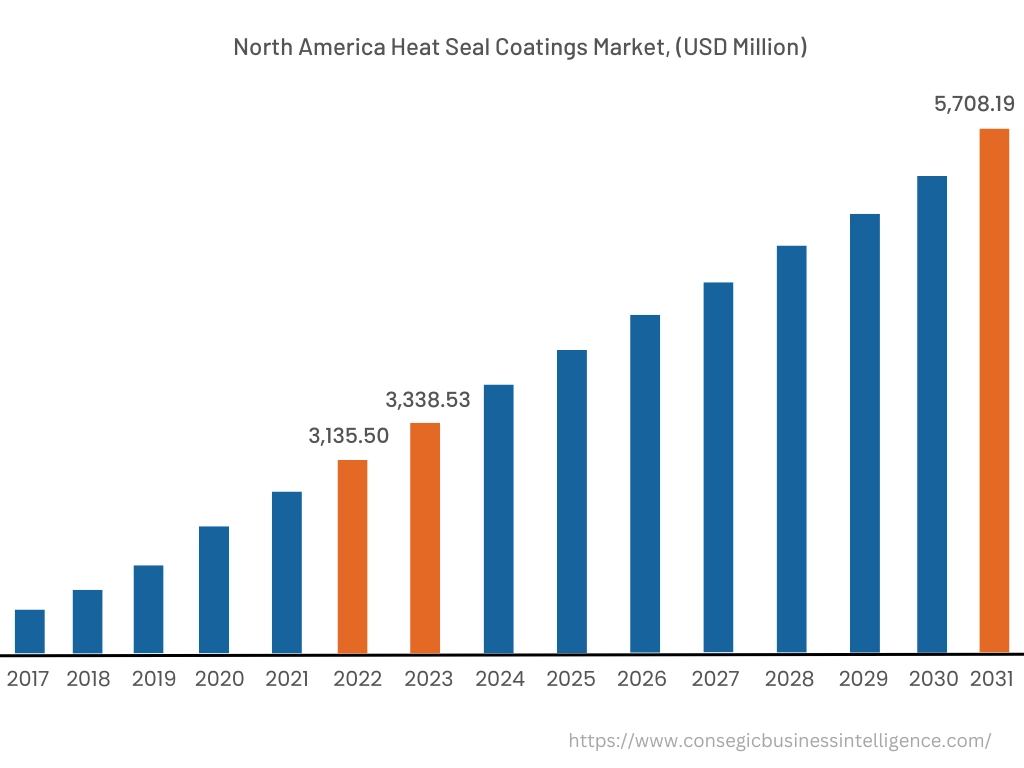

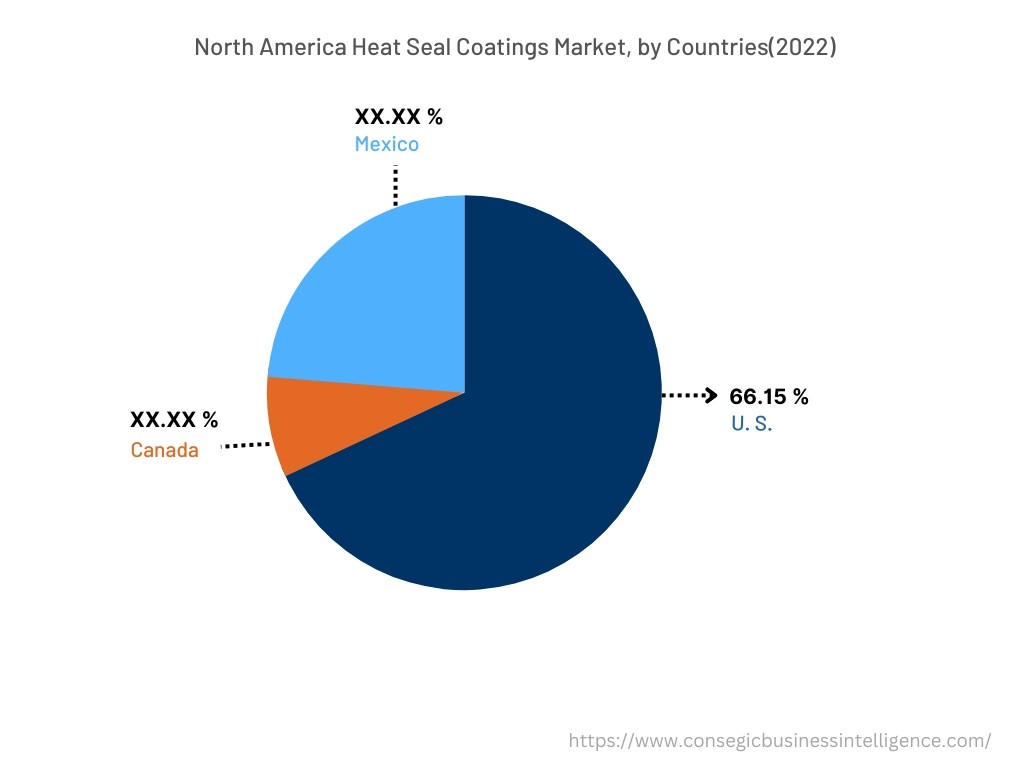

In 2022, North America accounted for the highest market share at 35.50%, valued at USD 3,135.50 million in 2022 and USD 3,338.53 million in 2023, it is expected to reach USD 5,708.19 million in 2031. In North America, U.S. accounted for the highest market share of 66.15% during the base year 2022 owing to large and well-developed food and beverage, pharmaceutical, and other industrial sectors. The North American e-commerce market is growing rapidly, and this is driving larger heat seal coatings market demand as they can protect products during shipping and handling. Hence, due to the aforementioned factors, the market is witnessing significant growth and trends in the region.

Moreover, Asia Pacific is expected to witness significant growth over the forecast period, growing at a CAGR of 7.4% during 2023-2031. The population in the region is growing and becoming increasingly urbanized, which is driving greater requirement for packaged food and beverages. The food and beverage sector in Asia Pacific is growing rapidly, driven by factors such as population growth, rising disposable incomes, and changing lifestyles. As per the heat seal coatings market analysis, the expanding food and beverage sector in the region is fostering a larger requirement for seal coating products. For instance, according to a report by the Ministry of Food Processing Industries in 2021, total agri-food exports in India have grown from USD 36.18 billion in 2014-15 to USD 38.32 billion in 2020-21 at a compounded annual growth rate of 0.96 percent. Thus, expanding food and beverage sector is directly impacting the growth and trends of the heat seal coatings market in the region.

Top Key Players & Market Share Insights:

The heat seal coatings market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market revenue through mergers, acquisitions, and partnerships. The key players in the market include-

- Henkel AG & Co. KGaA

- Bostik

- 3M

- Bemis Company

- Amcor plc

- Michelman

- Dow Inc.

- Flint Group

- Ashland Global Holdings Inc.

- Avery Dennison Corporation

Recent Industry Developments :

- In November 2022, Henkel entered a strategic partnership with the packaging certification body cyclos-HTP Institute (CHI). The partners aim to simplify accessibility to sustainable packaging and consumer goods solutions for all stakeholders.

- In October 2022, Dow Inc. and CAS, a division of the American Chemical Society, established a strategic collaboration focused on digital capabilities that accelerate research and development and identify new opportunities within key growth areas around the world. Dow and CAS have been longtime collaborators with a shared vision to facilitate innovation and discovery.

Key Questions Answered in the Report

What was the market size of the heat seal coatings industry in 2022? +

In 2022, the market size of heat seal coatings was USD 8,832.40 million.

What will be the potential market valuation for the heat seal coatings industry by 2031? +

In 2031, the market size of heat seal coatings will be expected to reach USD 15,989.33 million.

What are the key factors driving the growth of the heat seal coatings market? +

Increasing demand for flexible packaging is fueling market growth at the global level.

What is the dominating segment in the heat seal coatings market by type? +

In 2022, the solvent-based heat seal coatings segment accounted for the highest market share of 36.55% in the overall heat seal coatings market.

Based on current market trends and future predictions, which geographical region is the dominating region in the heat seal coatings market? +

North America accounted for the highest market share in the overall heat seal coatings market.