- Summary

- Table Of Content

- Methodology

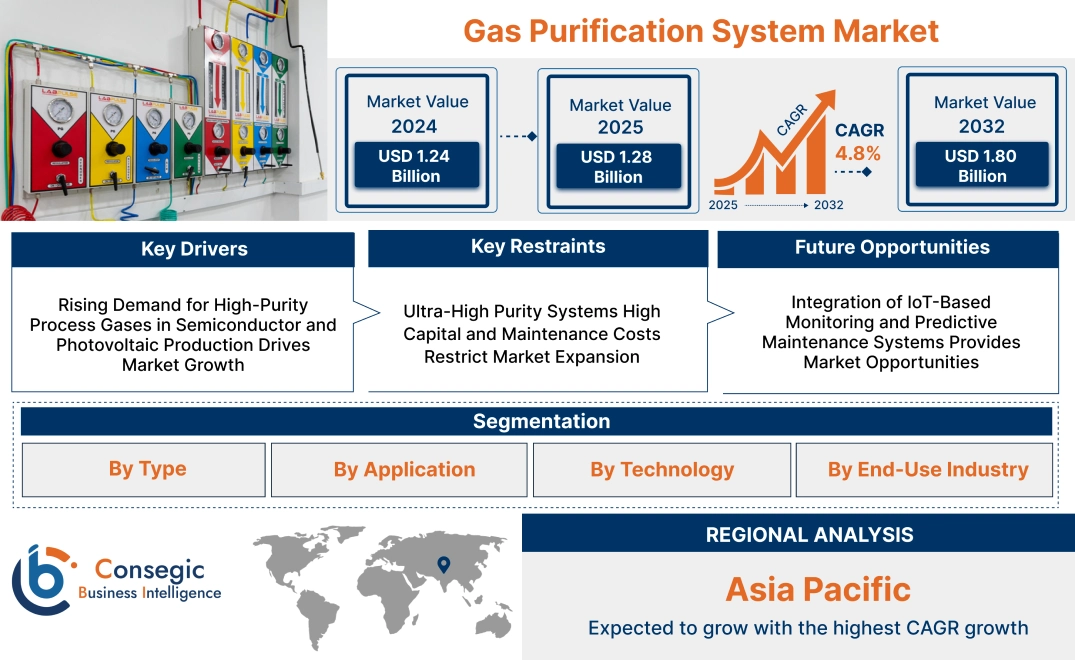

Gas Purification System Market Size:

Gas Purification System Market size is estimated to reach over USD 1.80 Billion by 2032 from a value of USD 1.24 Billion in 2024 and is projected to grow by USD 1.28 Billion in 2025, growing at a CAGR of 4.8% from 2025 to 2032.

Gas Purification System Market Scope & Overview:

A gas purification system is a custom-built apparatus used to eliminate contaminants and impurities from industrial or lab gases to guarantee a high-purity product. It is applied across applications requiring accurate gas quality, such as semiconductor fabrication, pharmaceuticals, petrochemicals, and analytical labs.

These systems combine filtration units, catalytic converters, absorbent columns, and monitoring sensors in order to provide certain purity levels customized for end-use applications. Modular configurations, automated operation, corrosion-resistant components, and continuous gas quality monitoring are important features.

The major advantages are increased equipment longevity, enhanced process productivity, and reduced chances of contamination in critical applications. Gas purification system facilitates the supply of stable and consistent gas streams, helping ensure consistent product quality and regulatory adherence. Its versatility in high-purity and high-volume conditions makes it an indispensable asset in industries where gas integrity is key to operational efficiency and safety measures.

Key Drivers:

Rising Demand for High-Purity Process Gases in Semiconductor and Photovoltaic Production Drives Market Growth

Semiconductor and photovoltaic cell manufacturing require ultra-pure gases for maintaining accuracy in deposition, etching, doping, and annealing operations. Trace amounts of contaminants like moisture, hydrocarbons, or metallic ions impair wafer yield and decrease device reliability. Gas purification systems are needed to eliminate these contaminants, making gas streams fulfill industry standards like SEMI F20 and ITRS specifications. With rising chip density and efficiency requirements in solar modules, manufacturers are investing in sophisticated purification units with catalytic, getter, and adsorptive technologies. Increasing complexity of integrated circuits and the increasing use of monocrystalline PV technologies are also heightening purity needs. As semiconductor fabs and solar panel manufacturing plants scale up worldwide, especially in Asia-Pacific and North America, the requirement for dependable gas handling and purification infrastructure is increasing. This growing dependence on ultra-pure gas streams is one of the major drivers that is driving the gas purification system market expansion.

Key Restraints:

Ultra-High Purity Systems High Capital and Maintenance Costs Restrict Market Expansion

The installation of ultra-high purity gas purification systems necessitates high capital expenditure, mainly in applications like semiconductors and pharmaceuticals, where purity levels are high. Such systems entail sophisticated materials, corrosion-resistant fabrication, and high-precision manufacturing, resulting in higher procurement costs initially. Further, frequent replacement of purification media, regular system validation, and stringent operating procedures add to lifecycle expenses. Lower-volume facilities or companies in developing regions will be reluctant to invest in high-end systems, particularly when their operations do not require ultra-pure specifications. Cost sensitivity limits adoption in larger business segments and reduces the technology refresh pace in installed facilities. The system's purchase capital intensity, together with the expense of sustaining high-performance purification over the long term, discourages non-critical applications. These financial hurdles still restrain widespread adoption, representing a main challenge to the gas purification system market growth, even with the expanding industrial base of users.

Future Opportunities:

Integration of IoT-Based Monitoring and Predictive Maintenance Systems Provides Market Opportunities

Gas purification equipment is increasingly being combined with Industrial IoT platforms that provide real-time monitoring of performance, media saturation notifications, and sophisticated diagnostics. The digital capabilities facilitate predictive maintenance through the detection of deviations in flow rate, pressure drop, or contaminant breakthrough prior to failure. In high-throughput electronics, chemical, and pharmaceutical applications, downtime reduction and gas stream stability are essential. IoT-integrated purification units improve operational transparency, optimize maintenance cycles, and lower total cost of ownership. Process industry demand for digital infrastructure is also forcing vendors to provide cloud-capable solutions that fit into smart factory strategies. Such systems are integration-friendly with building management systems and enable multi-site monitoring from central dashboards. With industrial automation scaling, the capability to remotely manage gas purification infrastructure will fuel competitive differentiation. This intersection of digital control and gas quality assurance is generating strong gas purification system market opportunities fueled by necessity.

Gas Purification System Market Segmental Analysis :

By Type:

Based on type, the gas purification system market is segmented into point-of-use and bulk gas purifiers.

The point-of-use segment accounted for the largest gas purification system market share in 2024.

- Point-of-use gas purifiers are essential in critical operations requiring ultra-high purity gases near equipment such as gas chromatographs and semiconductor tools.

- These systems remove last-mile contaminants, including moisture, hydrocarbons, and metal ions, ensuring minimal interference in high-precision processes.

- Their compact design and modular configuration support demand in laboratories, biotech facilities, and nanofabrication labs.

- According to gas purification system market analysis, rising emphasis on purity at the point of consumption drives growth in this segment.

The bulk gas purifier segment is expected to register the fastest CAGR over the forecast period.

- Bulk gas purifiers are deployed upstream in supply chains to purify gases used across large-scale processes.

- They are widely used in semiconductors, metallurgy, and chemical manufacturing for processing nitrogen, argon, and hydrogen in high volumes.

- Advanced designs incorporating regenerative adsorption and catalytic methods support high throughput while maintaining purity.

- As per gas purification system market trends, the expansion of bulk gas distribution infrastructure is fueling the segment’s rapid growth.

By Application:

Based on application, the market is segmented into single and multi-gas purification systems.

The single gas purification system segment accounted for the largest revenue share in 2024.

- These systems are specialized to purify individual gases such as nitrogen, argon, or hydrogen to ultra-pure levels for electronics and pharmaceutical applications.

- Their simplified design allows for easier integration and targeted performance enhancement.

- High need from research labs and critical manufacturing environments supports segment expansion.

- For instance, in February 2025, BGR Tech launched its 100kW Hydrogen Purification System to enhance electrolysis-based hydrogen purification. This system delivers 99.999% pure, fuel cell grade hydrogen and operates under pressures up to 30 bar. This purified hydrogen finds application in fuel cells and combustion engines, as well as in industrial processes like steel annealing.

- The growing need for specific gas control is a key trend driving the gas purification system market demand.

The multi-gas purification system segment is projected to register the fastest CAGR during the forecast period.

- Multi-gas systems allow simultaneous purification of multiple gases in centralized setups, improving cost efficiency and scalability.

- These are widely adopted in semiconductor fabs and industrial gas distribution systems.

- Advancements in modular purification units and real-time gas monitoring technologies support operational efficiency.

- As per gas purification system market analysis, rising multipurpose industrial applications are accelerating adoption.

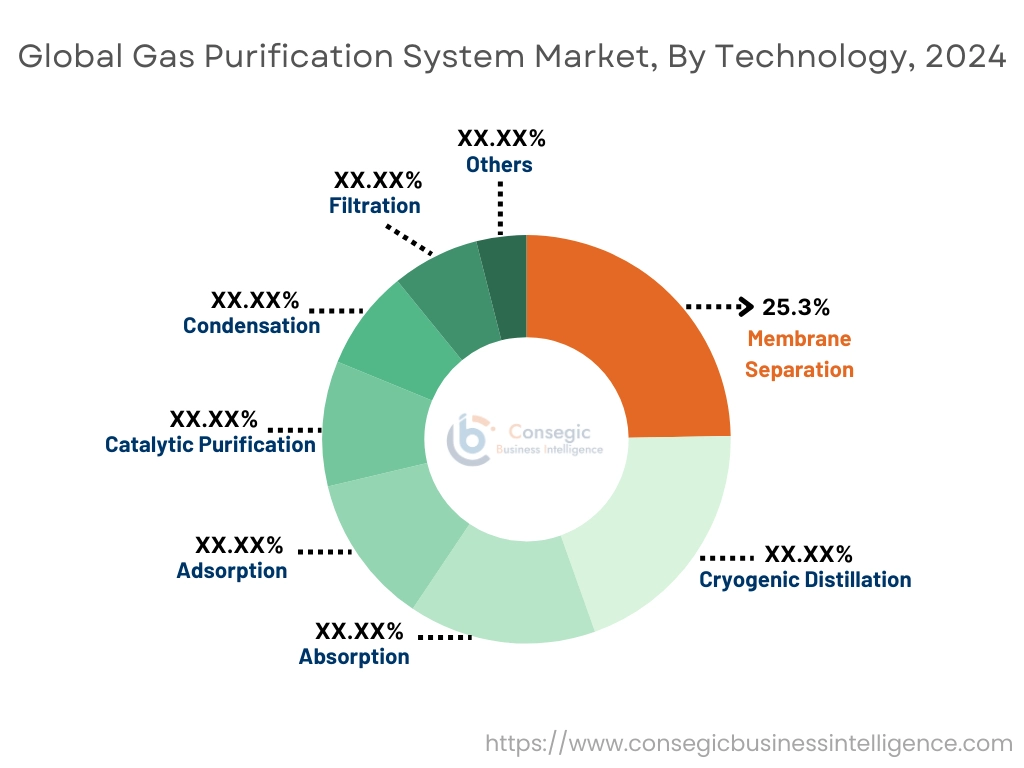

By Technology:

Based on technology, the market is segmented into membrane separation, cryogenic distillation, absorption, adsorption (PSA, TSA, regenerative), catalytic purification, condensation, filtration, and others.

The membrane separation segment formed the dominant gas purification system market share of 25.3% in 2024.

- Membrane separation is widely preferred due to its continuous operation capability, compact system footprint, and relatively low energy consumption.

- This technology is increasingly used in the electronics, petrochemical, and medical gas industries for removing contaminants like moisture, CO₂, and hydrocarbons from industrial gases.

- Advanced polymeric and ceramic membranes offer selective permeability and long-term stability, improving system reliability and process economics.

- According to gas purification system market trends, membrane-based units are favored for their operational flexibility, minimal maintenance, and scalability, especially in compact and modular plant configurations.

The cryogenic distillation segment is projected to witness the fastest CAGR during the forecast period.

- Cryogenic distillation provides ultra-high separation efficiency for gas mixtures like air and hydrocarbon streams.

- It is critical in gas liquefaction and recovery processes in industries like LNG and medical oxygen supply.

- The segment benefits from advancements in insulated systems and energy-efficient compressors.

- According to segmental analysis, the increasing demand for liquefied industrial gases is accelerating the adoption of this technology and, in turn, driving gas purification system market growth.

By End-Use Industry:

Based on end-use industry, the market is segmented into semiconductors & electronics, chemicals & petrochemicals, pharmaceuticals & biotechnology, food & beverage, metal processing, aerospace & defense, research & academic institutions, and others.

The semiconductors & electronics segment held the largest share in 2024.

- Semiconductor fabrication requires ultra-pure gases for etching, deposition, and doping processes, making gas purification systems indispensable.

- The requirement is reinforced by the global expansion of chip manufacturing facilities and advanced packaging lines.

- Key gases such as hydrogen, nitrogen, and argon require purification to ppb levels to prevent yield loss.

- According to market trends, the semiconductor boom continues to bolster the gas purification system market demand.

The pharmaceuticals & biotechnology segment is expected to register the fastest CAGR.

- Pharmaceutical manufacturing requires clean gases for sterile production environments, fermentation, and lyophilization.

- Biotechnology applications include controlled bioreactor environments and preservation systems, where purified gases ensure product stability.

- Stringent regulatory frameworks by agencies like FDA and EMA mandate validated gas purity levels.

- The increasing need for high-throughput biologics manufacturing is a key factor in the gas purification system market expansion.

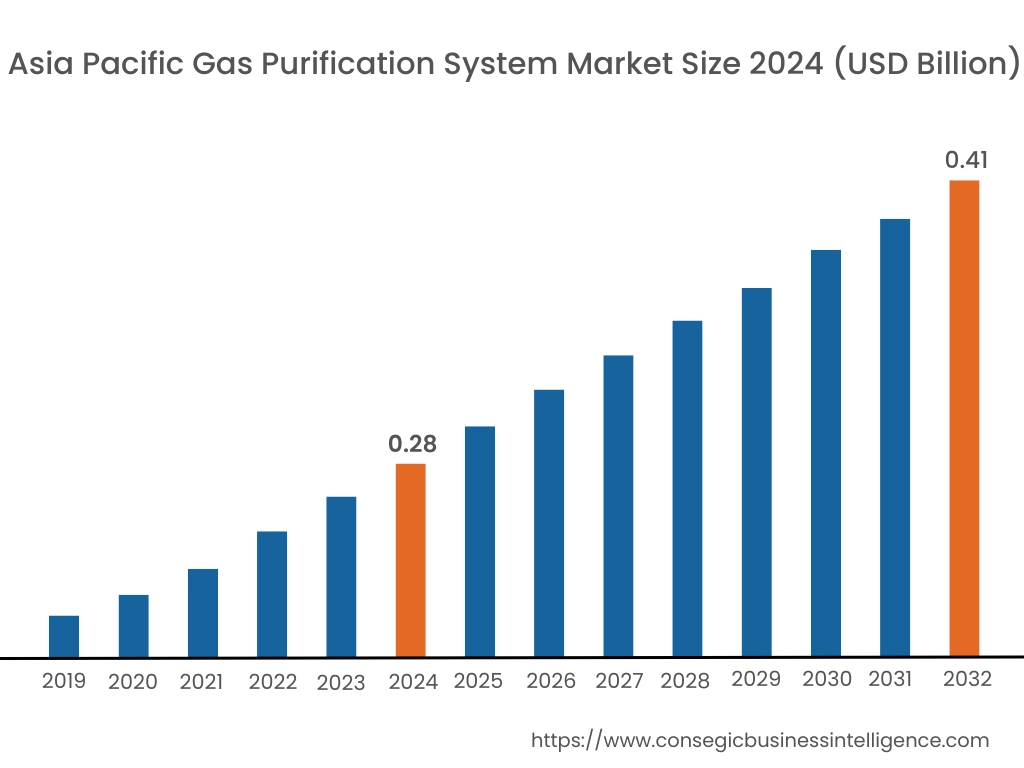

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

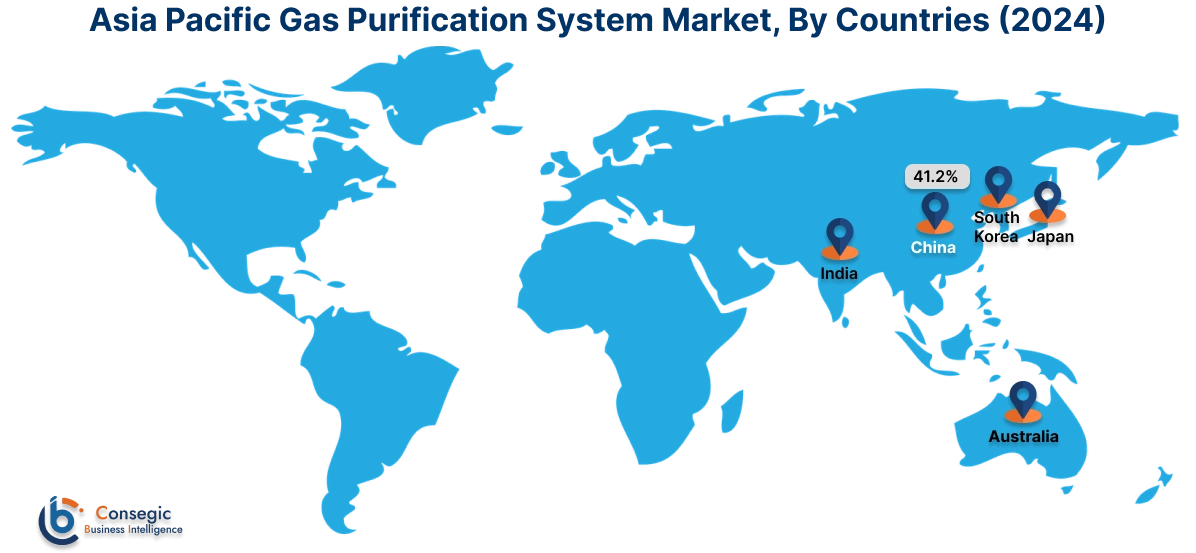

Asia Pacific region was valued at USD 0.28 Billion in 2024. Moreover, it is projected to grow by USD 0.29 Billion in 2025 and reach over USD 0.41 Billion by 2032. Out of this, China accounted for the maximum revenue share of 41.2%. Asia-Pacific is experiencing rapid growth in the gas purification system market, led by fast-paced industrialization, rising environmental concerns, and technological improvement in high-growth economies such as China, Japan, South Korea, and India. Regional analysis identifies fast-track adoption in electronics production, petrochemicals, and specialty gases, where purity levels are key to operational consistency and safety. Governments in the region are also clamping down on emissions and funding cleanroom infrastructure development in semiconductors and pharmaceuticals, thus further supporting market growth. As domestic producers increase capacity, the need for cost-efficient yet high-performance systems is generating strong opportunities.

North America is estimated to reach over USD 0.62 Billion by 2032 from a value of USD 0.42 Billion in 2024 and is projected to grow by USD 0.44 Billion in 2025. North America leads the gas purification system industry, backed by a developed manufacturing base, stringent emission standards, and stringent environmental responsibility in industries like semiconductors, chemicals, and energy. The United States and Canada use purification systems on a widespread basis to meet air quality standards and to facilitate precision manufacturing. Analysis indicates investments in hydrogen manufacture, clean energy infrastructure, and pharmaceutical processing are broadening the use of sophisticated gas purification technology. Furthermore, the incorporation of purification systems within high-purity gas delivery systems indicates a transition toward increased process control and efficiency.

Europe is a technologically leading and regulation-oriented region, wherein environmental policy and industrial innovation direct market activity. Countries like Germany, the Netherlands, and the UK are emphasizing cleanroom applications, research in laboratories, and integration of renewable energy—particularly in green hydrogen and carbon capture schemes. Market analysis reveals that there is growing demand for modular and automated purification systems that can treat a broad spectrum of gases with high-purity requirements. The region's drive for industrial decarbonization and compliance with strict air quality regulations further enhance long-term gas purification system market opportunities for suppliers.

Latin America exhibits steady adoption progress, especially in the oil refining, food & beverage, and healthcare industries in Brazil, Mexico, and Chile. Though investment in purification technologies is just emerging, research indicates that increasing industrial safety requirements and the upgrade of old infrastructure are driving incremental traction. International technology transfer and environmental collaborations focused on industrial emission reduction and process integrity will contribute to market growth.

In the Middle East and Africa region, market activity is picking up pace, driven by rising demand in gas processing plants, petrochemical complexes, and desalination plants. Countries such as South Africa, the UAE, and Saudi Arabia are developing their industrial capability and upgrading their gas purity management standards. Analysis indicates that as energy diversification and hydrogen economy initiatives take shape, gas purification systems are increasingly essential to ensure reliability and compliance. Nevertheless, uneven regulatory enforcement and domestic production capacity constraints need to be resolved in order to fully realize long-term growth.

Top Key Players & Market Share Insights:

The gas purification system market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global gas purification system market. Key players in the gas purification system industry include –

- Agilent Technologies, Inc. (USA)

- Air Liquide S.A. (France)

- Praxair, Inc. (Linde plc) (Ireland)

- SAES Getters S.p.A. (Italy)

- VICI Metronics (USA)

- Entegris, Inc. (USA)

- Japan Pionics Co., Ltd. (Japan)

- Matheson Tri-Gas, Inc. (USA)

- Merck KGaA (Sigma-Aldrich) (Germany)

- Parker Hannifin Corporation (USA)

Recent Industry Developments :

Product Launches:

- In February 2025, Asahi Kasei inaugurated a new biogas purification system (the System) at a sewage treatment plant in Kurashiki, Okayama Prefecture, Japan. The System uses the company’s innovative CO2 separation/recovery technology utilizing zeolites installed at a sewage treatment plant. The ultimate goal of this partnership is to achieve carbon neutrality.

Partnerships:

- In June 2024, TSMC collaborated with Suppliers to optimize the hydrogen production process and enhance sustainability. TSMC encouraged the recycling of carbon dioxide emitted from the natural gas production process into electronic-grade liquid carbon dioxide for reuse at the plant. The company also assisted suppliers in purchasing carbon-neutral natural gas and adopted underground pipelines for the direct supply of hydrogen to the Southern Taiwan Science Park.

Gas Purification System Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1.80 Billion |

| CAGR (2025-2032) | 4.8% |

| By Type |

|

| By Application |

|

| By Technology |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Gas Purification System Market? +

Gas Purification System Market size is estimated to reach over USD 1.80 Billion by 2032 from a value of USD 1.24 Billion in 2024 and is projected to grow by USD 1.28 Billion in 2025, growing at a CAGR of 4.8% from 2025 to 2032.

What specific segmentation details are covered in the Gas Purification System Market report? +

The Gas Purification System market report includes specific segmentation details for type, technology, application and end-use industry.

What are the end-use industries in the Gas Purification System Market? +

The end-use industries of the Gas Purification System Market are semiconductors & electronics, chemicals & petrochemicals, pharmaceuticals & biotechnology, food & beverage, metal processing, aerospace & defense, research & academic institutions and others (power generation, water treatment, etc.).

Who are the major players in the Gas Purification System Market? +

The key participants in the Gas Purification System market are Agilent Technologies, Inc. (USA), Air Liquide S.A. (France), Entegris, Inc. (USA), Japan Pionics Co., Ltd. (Japan), Matheson Tri-Gas, Inc. (USA), Merck KGaA (Sigma-Aldrich) (Germany), Parker Hannifin Corporation (USA), Praxair, Inc. (Linde plc) (Ireland), SAES Getters S.p.A. (Italy) and VICI Metronics (USA).