- Summary

- Table Of Content

- Methodology

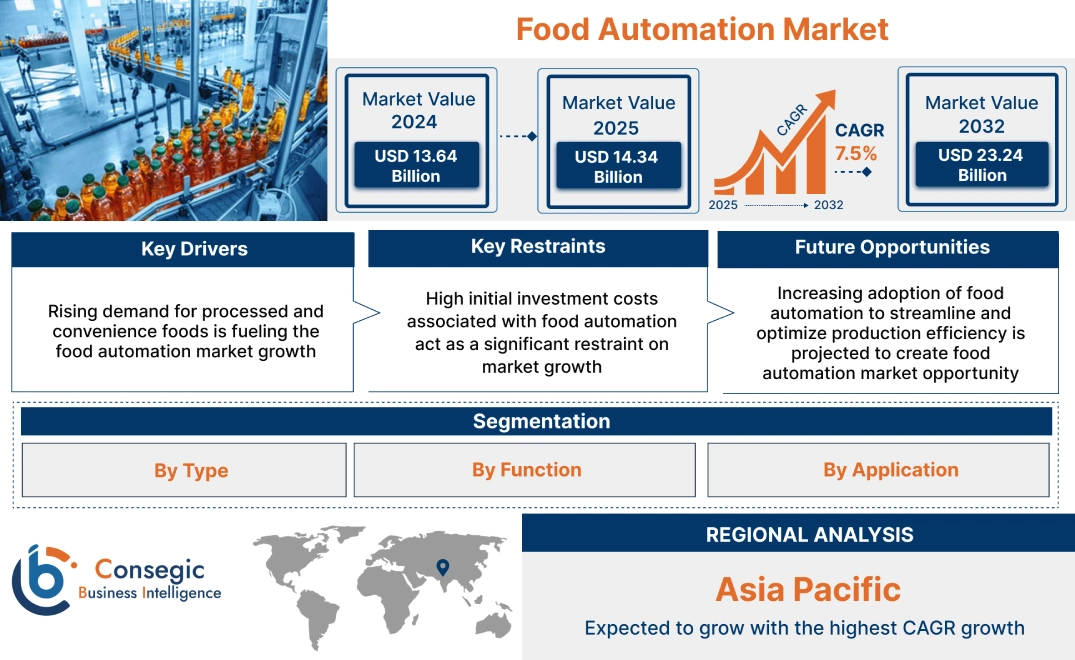

Food Automation Market Size:

Food Automation Market Size is estimated to reach over USD 23.24 Billion by 2032 from a value of USD 13.64 Billion in 2024 and is projected to grow by USD 14.34 Billion in 2025, growing at a CAGR of 7.5% from 2025 to 2032.

Food Automation Market Scope & Overview:

Food automation refers to the application of technology, machinery, and control systems to automate various processes within the food industry. This encompasses a wide range of activities, from the initial stages of agriculture and food processing to packaging, quality control, material handling, and even food service.

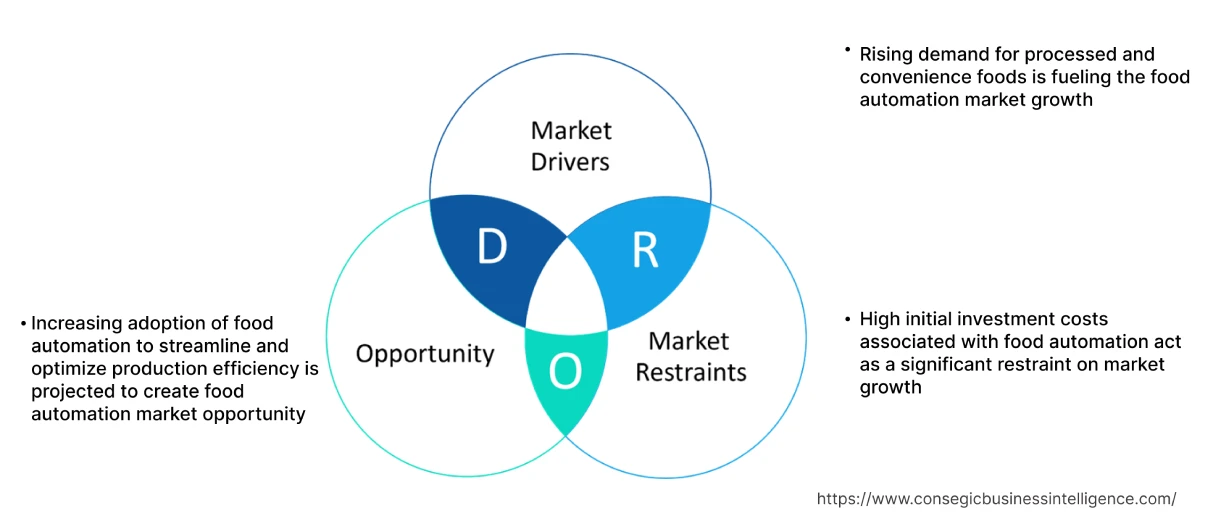

Key Drivers:

Rising demand for processed and convenience foods is fueling the food automation market growth

Processed and convenience foods are produced on a large scale to meet consumer demand and automation provides the necessary speed and efficiency to handle these high volumes. Automated systems like robotic arms, conveyor belts, and automated packaging lines can operate continuously and at high speeds, ensuring a consistent supply of products. Additionally, many processed and convenience foods undergo specific treatments like canning, freezing, or the addition of preservatives to extend their shelf life. Automation plays a crucial role in these processes, ensuring they are carried out under controlled conditions to maintain food safety and quality over extended periods, thereby driving the food automation market size.

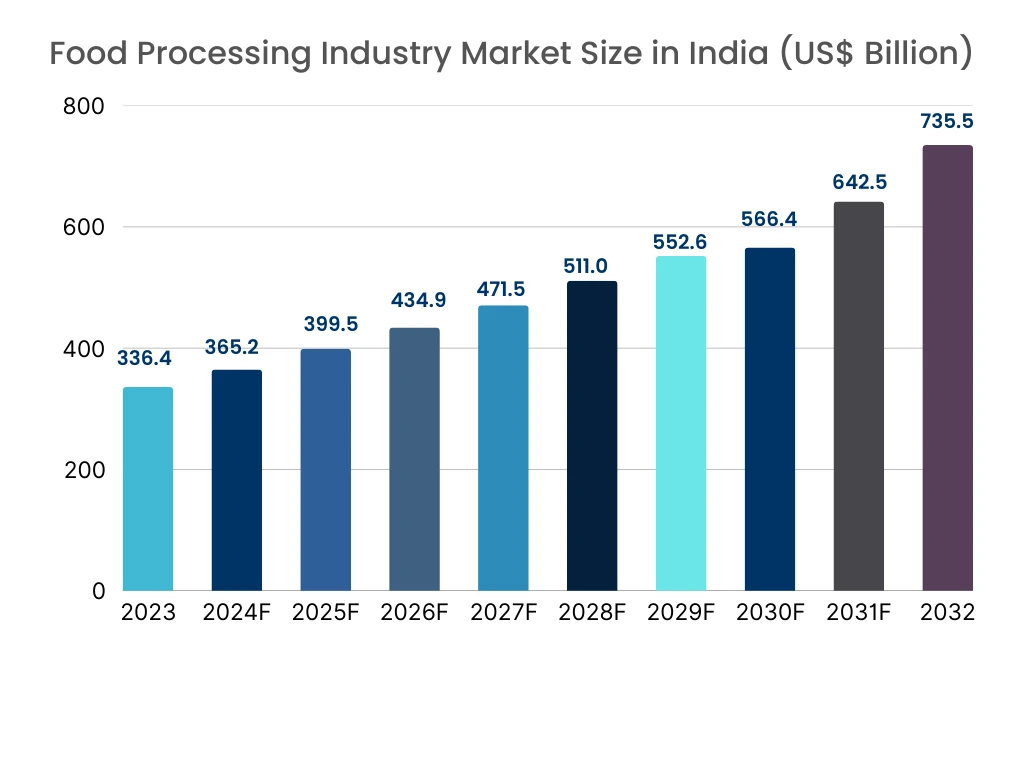

- For instance, the Indian food processing industry is experiencing substantial growth, reaching USD 336.4 billion in 2023 and projected to grow at an 8.8% CAGR to USD 735.5 billion by 2032, as reported by IMARC.

Consequently, rising demand for processed and convenience foods is driving the food automation market expansion.

Key Restraints:

High initial investment costs associated with food automation act as a significant restraint on market growth

Implementing advanced automation systems, including robotics, AI-driven systems, and sophisticated machinery, demands significant capital investment. This includes the cost of purchasing the equipment, software licensing, installation, and system integration. Estimates for initial investment range from USD 500,000 to USD 2 million, depending on the complexity and scale of the automation. For SMEs in the food processing sector, these high upfront costs can be a major barrier to entry. Approximately 25% of small businesses in the food industry are estimated to delay automation adoption due to the significant initial capital required, hindering the global food automation market size.

Therefore, as per the analysis, these combined factors are significantly hindering food automation market share.

Future Opportunities :

Increasing adoption of food automation to streamline and optimize production efficiency is projected to create food automation market opportunity

Automation enables food processing and packaging to occur at much higher speeds and with greater consistency than manual labor. Automated machinery can operate continuously, leading to increased production volumes and the ability to meet growing consumer need more effectively. Additionally, automated systems can be programmed to execute tasks with precision, ensuring uniformity in product dimensions, weight, and appearance. This minimizes human error and leads to more consistent product quality, enhancing brand reputation and reducing waste from defects, hence boosting food automation market demand.

- For instance, in Dec 2024, Forpak Automation introduced LayerPak, a new automated solution designed to boost production efficiency for high-volume food products requiring stacking or paper insertion. This mechanical, non-robotic system integrates servo grouping, automated paper insertion, machine vision inspection, and rapid multi-layer stacking to provide unparalleled precision.

Hence, based on the analysis, increasing adoption of food automation to streamline and optimize production efficiency is expected to create food automation market opportunities.

Food Automation Market Segmental Analysis :

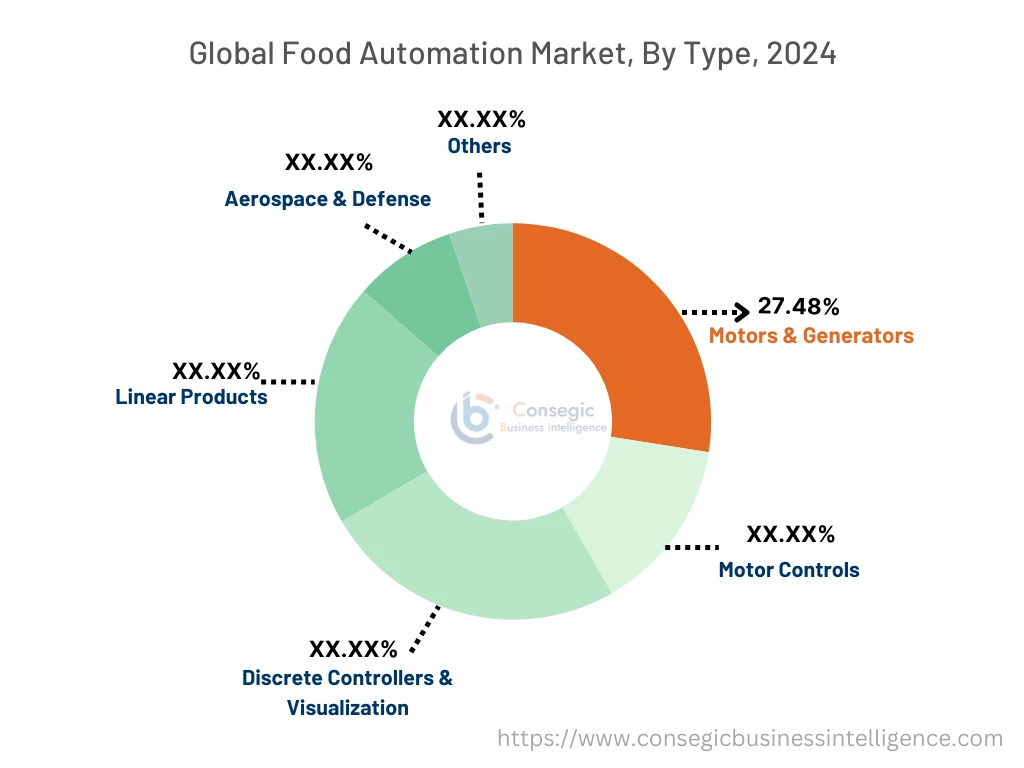

By Type:

Based on the Type, the market is categorized into Motors & Generators, Motor Controls, Discrete Controllers & Visualization, Rotary Products, Linear Products, and Others.

Trends in the Type:

- Growing trend towards the adoption of VFDs (Variable Frequency Drives) is integrated with IoT for real-time data analytics and energy optimization.

- Integration of smart sensors for predictive maintenance is enhancing the reliability and lifespan of rotary products.

Motors & Generators accounted for the largest revenue share of 27.48% in 2024.

- Motors provide the motive force for machinery involved in tasks such as mixing, blending, conveying, sorting, slicing, packaging, and material handling, thereby driving food automation market.

- Additionally, many processes in food automation require precise motion control for tasks like robotic handling, filling, and cutting, which necessitates the use of advanced motors and related control systems.

- Food processing environments involve challenging conditions such as high-pressure washdowns, exposure to caustic cleaning agents, and varying temperatures. This requires specialized motors and generators built with robust materials and protective features, which can have a higher value, further boosting the food automation market trend.

- For instance, in May 2023, Kollmorgen released its AKMA servo motor, engineered for durability, cleanability, and versatility in medium to heavy washdown environments. Utilizing a hardened anodized aluminum surface, the AKMA provides machine designers with a cost-efficient hygienic alternative to stainless steel.

- Thus, as per the food automation market analysis, the aforementioned factors are driving the motors & generators segment growth.

Discrete Controllers & Visualization are predicted to register the fastest CAGR during the forecast period.

- Discrete controllers (like PLCs) are essential for managing the sequential and logical operations of various automated tasks, ensuring precise control over mixing times, temperatures, filling levels, and packaging sequences.

- Additionally, visualization systems provide operators with real-time insights into the status of various automated processes, including temperature monitoring, equipment performance, and potential contamination risks.

- Discrete controllers integrated with sensors and data acquisition systems collect crucial information at each stage of processing and packaging. Visualization tools then present this data in an understandable format, enabling manufacturers to track products, identify potential issues, and comply with regulations regarding origin and handling.

- Discrete controllers act as the central "brain" coordinating various other automation components like robots, sensors, and actuators.

- In conclusion, the above-mentioned factors are contributing significantly in spurring the market growth.

By Function:

Based on the Function, the market is classified into Processing, Packaging & Repackaging, Palletizing, Sorting & Grading, Picking & Placing, and Others.

Trends in the Function:

- Increased trend towards the adoption of robots for various packaging tasks due to their speed, precision, and ability to handle diverse packaging materials and formats.

- Use of cobots for palletizing tasks in environments where interaction with human workers is required, offering flexibility and safety.

Processing accounted for the largest revenue share in 2024 and is also projected to witness the fastest growth.

- A shift towards continuous flow processing systems for higher efficiency, consistency, and reduced downtime compared to batch processing is driving the food automation market demand.

- Increased use of real-time sensors and sophisticated control systems to optimize processing parameters and ensure quality.

- Strong emphasis on equipment designed for easy cleaning and sanitation (following standards like NSF/3A), often utilizing stainless steel and smooth surfaces to prevent contamination.

- Moreover, the integration of digitalization is also contributing significantly in accelerating the global food automation market.

- For instance, in Mar 2024, GEA launched GEA InsightPartner, a new cloud-based web application designed to optimize food processing lines. This digital tool analyzes machine data to help food manufacturers maximize machine uptime, minimize downtime, prevent shutdowns, and manage resources effectively.

- Thus, as per the food automation market analysis, the aforementioned factors are driving processing segment.

By Application:

Based on the Application, the market is categorized into Dairy, Bakery, Confectionery, Fruit & Vegetable, Meat, Poultry, and Seafood, and Beverages.

Trends in the Application:

- Increasing trend towards the adoption of robots and automated systems to precisely measure and dispense ingredients, ensuring consistency and reducing waste in dough preparation.

- Robots with specialized grippers gently handle chocolates, candies, and other delicate confectionery items without damage.

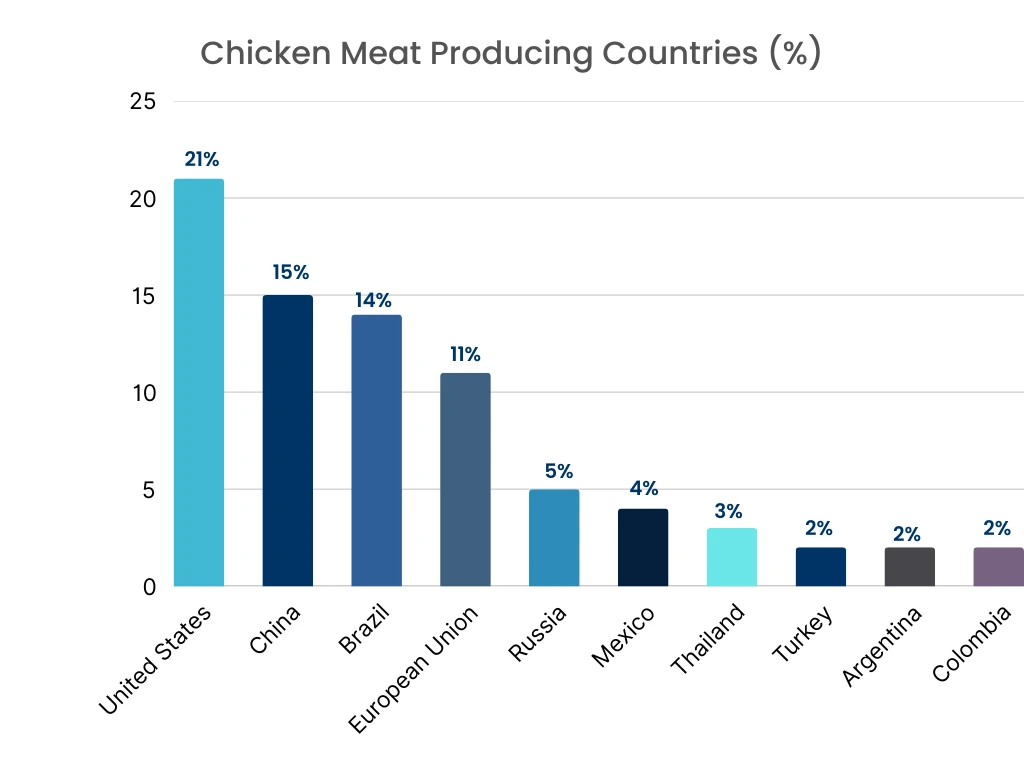

Meat, Poultry, and Seafood accounted for the largest revenue share in 2024.

- Advanced robotic systems are being developed to automate tasks like cutting, deboning, and trimming meat and poultry, improving yield.

- High-speed packaging systems handle various meat, poultry, and seafood products while maintaining hygiene standards.

- Integration of automation with technologies like blockchain to track products from farm/sea to consumer, ensuring food safety and transparency.

- Equipment designed for easy and thorough cleaning to meet stringent food safety regulations in meat and seafood processing.

- In conclusion, the aforementioned factors are contributing to the growth of global food automation market expansion.

Dairy is predicted to register the fastest CAGR during the forecast period.

- Robotic milking systems are becoming increasingly popular for increased milk yield, improved animal welfare, and reduced labor costs.

- Growing trend of using sensors, data analytics, and AI monitor cow health, milk yield, feeding patterns, and reproduction cycles for optimized farm management.

- Further, advanced filtration technologies like ultrafiltration and reverse osmosis are used for component separation (fat, protein, lactose) with higher efficiency.

- Moreover, packaging with embedded sensors monitors temperature, humidity, and freshness, providing real-time data to consumers and retailers, ensuring product quality and reducing waste.

- Robots and vision systems are used for quality checks, ensuring consistent texture, color, and identifying defects in dairy products.

- For instance, India boasts the world's largest dairy industry, responsible for 23% of global milk production. This vital sector contributes 5% to the nation's economy and provides direct livelihood support to over 80 million farmers.

- Subsequently, as per the market analysis, the aforementioned factors are collectively responsible in accelerating the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

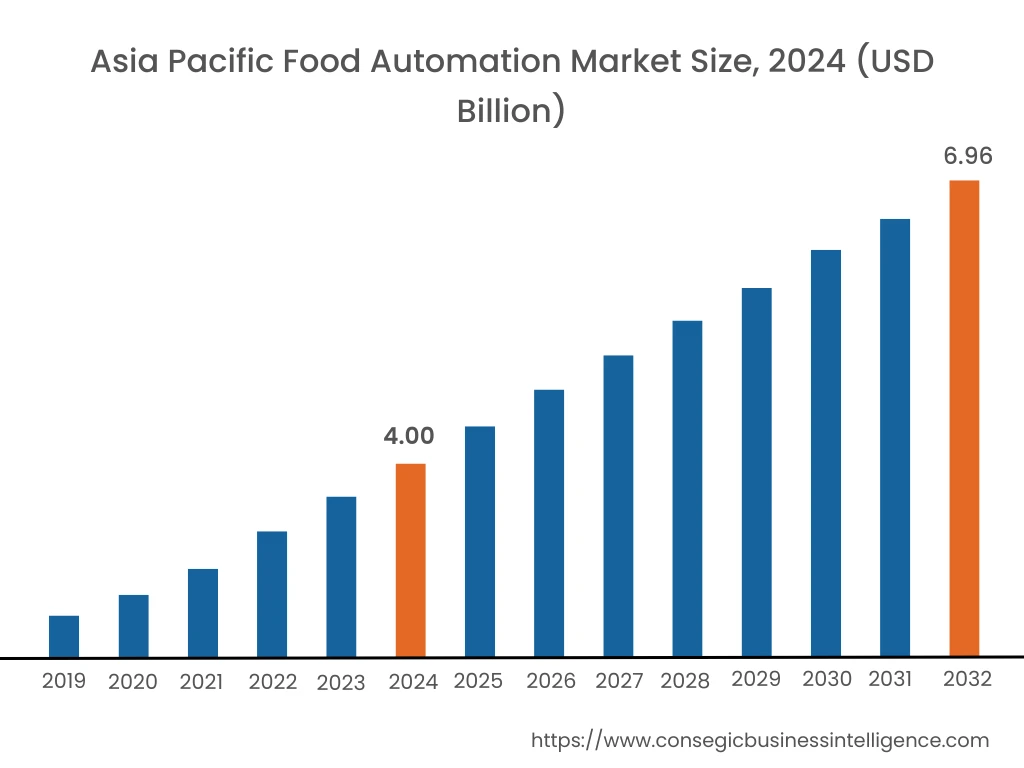

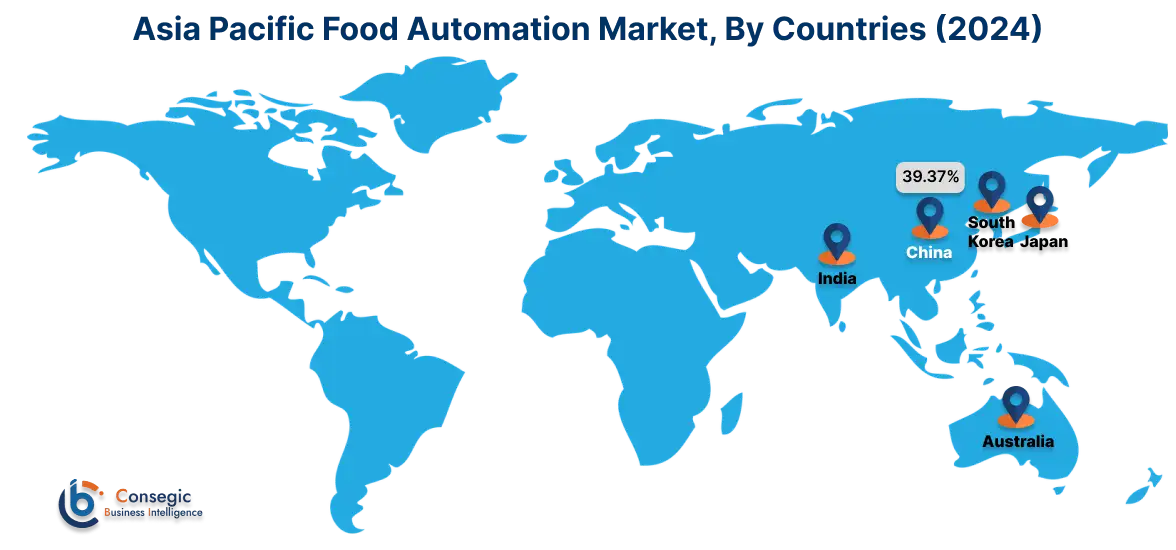

Asia Pacific was valued at USD 4.00 Billion in 2024. Moreover, it is projected to grow by USD 4.21 Billion in 2025 and reach over USD 6.96 Billion by 2032. Out of these, China accounted for the largest revenue share of 39.37% in 2024. Several governments in the Asia Pacific region are actively promoting the modernization of their food processing industries through investments and supportive policies. Rapid urbanization, a growing middle-class population with increasing disposable incomes, and changing lifestyles across Asia Pacific are fueling a surge in need for processed and ready-to-eat food products. Automation is crucial for meeting this need efficiently and consistently. Also, the expanding food processing sector is also contributing notably in driving the market share.

- For instance, PHD Chamber of Commerce and Industry (PHDCCI) has released a report projecting significant expansion in India's food processing sector. The market size is anticipated to be more than double an estimated USD 307 billion in 2023 to over USD 700 billion by the year 2030.

North America region was valued at USD 5.09 Billion in 2024. Moreover, it is projected to grow by USD 5.35 Billion in 2025 and reach over USD 8.64 Billion by 2032. Rising need for convenience foods and the push towards ready-to-eat meals and snacks is driving the market in North America. Additionally, technological advancements, such as automation and advanced processing equipment, are improving efficiency and productivity. These factors are contributing to a dynamic market with a focus on innovation and meeting consumer need for convenience, health, and quality, further fuel the food automation market demand.

As per the food automation market analysis, Europe is a significant market for food automation, driven by stringent food safety regulations, high labor costs, and increasing need for high-quality, processed foods. The region is characterized by the presence of many leading food processing companies that are early adopters of automation technologies. Countries like Brazil and Mexico are witnessing significant investments in food automation, particularly in sectors such as meat processing, dairy, and beverages. Moreover, governments in the Middle East and Africa region are investing in food processing technologies to improve food security, reduce reliance on imports, and diversify their economies.

Top Key Players and Market Share Insights:

The market is highly competitive with major players providing food automation to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the food automation industry include-

- ABB (Switzerland)

- Siemens AG (Germany)

- Rockwell Automation Inc. (USA)

- Mitsubishi Electric Corporation (Japan)

- Schneider Electric SE (France)

- GEA Group (Germany)

- Emerson Electric Co. (USA)

- Yokogawa Electric Corporation (Japan)

- FANUC (Japan)

- KUKA AG (Germany)

- Honeywell International Inc. (USA)

- Omron Automation (Japan)

- Yaskawa Electric Corporation (Japan)

- Rexnord Corporation (Regal Rexnord Corporation) (USA)

- Fortive Corporation (USA)

Food Automation Market Ecosystem:

Recent Industry Developments :

Product Launch:

- In Sep 2024, Tetra Pak and the National Institute of Food Technology Entrepreneurship and Management, Kundli (NIFTEM-K), are collaborating to advance innovation in the Indian food processing industry via a newly signed MoU.

Food Automation Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 23.24 Billion |

| CAGR (2025-2032) | 7.5% |

| By Type |

|

| By Function |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the food automation market? +

The food automation market size is estimated to reach over USD 23.24 Billion by 2032 from a value of USD 13.64 Billion in 2024 and is projected to grow by USD 14.34 Billion in 2025, growing at a CAGR of 7.5% from 2025 to 2032.

What specific segmentation details are covered in the food automation report? +

The food automation report includes specific segmentation details for type, function, application, and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the food automation market, dairy is the fastest-growing segment during the forecast period.

Who are the major players in the food automation market? +

The key participants in the food automation market are ABB (Switzerland), Siemens AG (Germany), Rockwell Automation Inc. (USA), Mitsubishi Electric Corporation (Japan), Schneider Electric SE (France), GEA Group (Germany), Emerson Electric Co. (USA), Yokogawa Electric Corporation (Japan), FANUC (Japan), KUKA AG (Germany), Honeywell International Inc. (USA), Omron Automation (Japan), Yaskawa Electric Corporation (Japan), Rexnord Corporation (Regal Rexnord Corporation) (USA), Fortive Corporation (USA), and Others.