- Summary

- Table Of Content

- Methodology

Flexographic Printing Machine Market Size :

Flexographic Printing Machine Market is estimated to reach over USD 1,311.05 Million by 2030 from a value of USD 791.38 Million in 2022, growing at a CAGR of 6.7% from 2023 to 2030.

Flexographic Printing Machine Market Scope & Overview:

A flexographic printing machine, also known as a flexo press or flexo printer, is installed for the high-volume production of packaging materials, labels, and other flexible materials. A flexographic machine utilizes a flexible relief plate made of rubber or photopolymer material, which is mounted on a rotating cylinder. The printing process involves transferring ink from the plate onto the substrate (including paper, plastic, or film) to create the desired image or text. Additionally, flexographic machines are suitable for various applications, including food packaging, labels, corrugated cardboard, and flexible packaging to produce high-quality and durable prints.

Flexographic Printing Machine Market Insights :

Key Drivers :

Growing demand of flexographic printing machines from the packaging industry is driving the market growth

The packaging industry is witnessing substantial growth due to factors including population expansion, rising e-commerce, and changing consumer preferences. Flexographic printing machines are extensively deployed in the packaging industry to print various packaging materials namely corrugated boxes, folding cartons, flexible films, labels, and bags. Additionally, flexographic printing machines are capable of printing on a wide range of substrates, including paper, plastics, films, foils, and flexible packaging materials. The versatility offered by the machines is particularly advantageous for the packaging industry that requires the printing of different materials for various products and applications. Consequently, the expanding packaging industry is raising the demand for advanced flexographic printing machines for high-quality and durable prints. For instance, in August 2022, according to the Flexible Packaging Association (FPA), the packaging industry in the U.S. is estimated to be USD 39 Billion in 2021 in comparison to USD 34.8 Billion in 2020. In conclusion, the rapid expansion of the packaging industry is contributing significantly in accelerating the growth of the flexographic printing machine market.

Advancements in flexographic printing machines to offer high-quality prints is accelerating the market growth

Enhancements in plate technology including the introduction of high-resolution photopolymer plates and plate imaging technologies, namely digital laser imaging and direct laser engraving, to offer high-quality prints are boosting the market growth. The emergence of the aforementioned advanced technologies is enabling the flexographic printing machines to produce finer and sharper images coupled with better color production is promoting market growth. Moreover, the advent of a hot air drying system to enable quick drying of the ink is also contributing considerably in propelling the market growth. The advancements in technology have made flexographic printing a viable option for high-quality packaging and label printing, hence contributing remarkably in driving the growth of the market. For instance, in March 2023, Line O Matic launched STM 125, an automatic flexographic printing machine at Pamex 2023. The machine is ideal for printing on rolling paper, glass paper, and kraft paper and also comprises of hot air drying system to enable quick drying of the ink.

Key Restraints :

Slow printing speed of flexographic printing machines is restraining the growth of the market

The inefficiency of flexographic printing machines to print quickly with short turnaround times is hampering the growth of the market. The time required for plate mounting, ink adjustments, and other setup processes make flexographic printing less cost-effective and less efficient for short-run jobs, compared to digital printing technologies that excel in such applications. Additionally, the slower speed and setup requirements of flexographic printing machines are less suitable for applications that require frequent changes in content, such as variable data printing for promotional campaigns or personalized packaging. Consequently, the inability of flexographic printing machines to function effectively for short-run prints and variable data printing owing to the slow printing speed is hindering the growth of the market.

Presence of alternatives including digital printing machines to offer high-quality prints at shorter periods of time is impeding the market growth

Digital printing machines provide exceptional print quality with precise details, sharp images, and vibrant colors. Additionally, unlike flexographic printing, digital printing does not rely on plates, thus allowing for more accurate production of graphics and text. Furthermore, digital printing machines have minimal setup requirements, eliminating the need for plate mounting and ink adjustments, resulting in significantly shorter setup and changeover times. In conclusion, the ability of digital printing machines to offer high-quality prints in a short duration of time and with minimal setup is impeding the growth of flexographic printing machines.

Future Opportunities :

Growing focus on sustainability in printing practices is projected to create opportunities for market growth

Drying systems in flexographic printing machines have been improved to enhance energy efficiency, thus expected to create potential opportunities for the market growth. The development of advanced drying technologies including LED-UV or low-temperature drying, reduces energy consumption and the overall carbon footprint of the printing process. Flexographic printing machines incorporate energy-efficient drying systems to allure environmentally conscious customers and contribute to sustainable printing practices. Additionally, flexographic printing machines take advantage of advancements in environmentally friendly ink formulations to accelerate market growth. For instance, water-based inks have lower levels of volatile organic compounds (VOCs) compared to solvent-based inks, reducing the environmental impact. Flexographic printing machines are expected to be designed or upgraded to accommodate water-based inks, providing a more sustainable printing solution for packaging and other applications. In conclusion, the integration of the drying system and environmentally friendly ink is anticipated to achieve the sustainability goals in printing practices, creating opportunities for market growth.

Flexographic Printing Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,311.05 Million |

| CAGR (2023-2030) | 6.7% |

| By Type | Stack Type Press, Inline Type Press, Central Impression Type Press, and Others |

| By Substrate | Papers, Polyethylene, Plastic film, Paperboard, and Others |

| By Ink Type | Solvent-based, Water based, UV-based, and Oil-based |

| By Technology | Automatic and Semi-Automatic |

| By Coloring Capacity | 2 color, 4 color, 6 color, and 8 color |

| By Application | Printing Media, Office and Admin, and Industrial Applications |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Apex International, Bobst, Comexi Group, Azul 3D, Donghang Precision Machinery Limited Company, Heidelberger Druckmaschinen AG, Lohia Corp Limited, Mark Andy (MAI Holdings, Inc.), Nilpeter India Pvt Ltd, Taiyo Kikai Ltd., Windmöller & Hölscher, Xi'An Aerospace-Huayang Mechanical & Electrical Equipment Co., Ltd |

Flexographic Printing Machine Market Segmental Analysis :

By Type :

The type of segment is classified into stack type press, inline type press, central impression type press, and others. The inline type of press accounted for the largest market share of 35.4% in 2022 as inline type presses are designed to efficiently handle large print volumes and are suitable for long print runs. In addition, the inline configuration allows for efficient and continuous printing without frequent stops or interruptions, resulting in increased productivity and faster turnaround times. Moreover, inline type presses offer versatility to print several products including folding cartons, labels, and flexible packaging, to cater to the diverse needs of different industries. For instance, in March 2022, Mondi Group launched a state-of-the-art flexographic printing line in Germany. The new machinery encompasses inline embossing solutions and inline siliconization to offer high-quality prints without interruptions in femcare pouch wrapping film designs and materials. Consequently, the increasing adoption of inline prints in various sectors to provide precise and sharp prints is contributing notably in propelling the growth of the inline type presses segment.

Central Impression (CI) type segment is predicted to witness the fastest CAGR in the flexographic printing machine during the forecast period. CI flexographic presses are known for excellent print accuracy as the central drum of the machine allows for precise control of the printing plates and substrates, resulting in superior print quality. Furthermore, modern CI presses have incorporated advanced automation features namely automatic plate mounting systems, robotic workflows, and digital controls. The automation enhancements improve operational efficiency, reduce setup times, and increase productivity. The automated systems in CI flexo press also enable faster job changeovers, reducing downtime and enhancing overall production efficiency. Consequently, the aforementioned factors are collectively responsible in driving the growth of the central impression flexographic machines during the forecast period.

By Substrate :

The product segment is classified into paper, polyethylene, plastic film, paperboard, and others. Paper accounted for the largest market share in 2022 and is also projected to witness the fastest CAGR in the upcoming years. The growth is attributed to the high versatility of paper substrate to be utilized in various applications, including packaging, labels, newspapers, books, and promotional materials. Flexographic printing machines are well-suited for printing on paper due to the ability to effectively handle the characteristics of paper, namely absorbency and flexibility. Moreover, paper is a cost-effective substrate compared to other materials used in printing such as plastics and polyethylene, further driving the growth of the paper substrate.

Furthermore, paper is a renewable and recyclable material and aligns with the increasing focus on sustainability in printing practices. Consequently, the rising demand for eco-friendly and recyclable packaging materials is contributing significantly in accelerating the growth of the paper segment. For instance, in February 2021, Walki Group Oy launched an advanced flexo printing machine in Jatne to cater to the company's sustainable food packaging goals by using the recyclable paper. In conclusion, the increasing application of paper in packaging and labeling is contributing significantly in driving the growth of the paper segment.

By Ink Type :

The ink type segment is categorized into solvent-based, water-based, ultraviolet and electron beam, and oil-based. Solvent-based ink accounted for the largest market share in 2022 as the inks offer excellent print quality, providing vibrant and sharp colors. Additionally, solvent-based inks have good ink flow and wetting properties, allowing for precise and detailed printing. Moreover, solvent-based inks are compatible with a wide range of substrates, including various types of plastics, films, and foils, and thus are suitable for different packaging materials and applications. Furthermore, solvent-based inks also exhibit excellent resistance to abrasion, moisture, and chemicals, ensuring the longevity of the printed materials. Consequently, the ability of solvent-based inks to offer high-quality prints, durability, and versatility are contributing collectively in driving the growth of the market.

UV-based inks are expected to witness the fastest CAGR in the flexographic printing machine market during the forecast period. UV-based inks dry instantly upon exposure to ultraviolet light, allowing for faster production speeds and increased efficiency. Additionally, UV-based inks are considered more environmentally friendly compared to solvent-based inks as UV-based inks have lower VOC emissions that help to reduce air pollution and comply with stricter environmental regulations. Moreover, the rising demand of UV-based inks for commercial and packaging printing due to the ability of the ink to improve the recyclability of the paper is further contributing remarkably in bolstering the market growth. For instance, in September 2020, Siegwerk Druckfarben AG & Co. KGaA launched UV flexo varnishes and UV offset inks to deliver high-quality prints in commercial and packaging printing. The advanced ink enhances the recyclability of UV-coated paper, thus contributing notably in spurring the market growth.

By Technology :

The technology segment is divided into automatic and semi-automatic. Automatic segment accounted for the largest market share in 2022 and is also projected to witness the fastest CAGR during the forecast period. Automatic machines are designed for high-speed production and handle large print volumes efficiently. Additionally, automatic flexographic printing machines also offer faster setup times and continuous printing without frequent manual interventions. The automation features of flexographic machines result in increased productivity, allowing for higher production output and shorter lead times. Moreover, the advancements in technology to minimize human error and power consumption are also contributing remarkably in propelling the market growth. For instance, in July 2021, Soma introduced SOMA IRIS (intelligent register and impression setting) an advanced technology for automatic flexographic printing machines. SOMA IRIS is responsible for providing improved automation with fewer human errors and minimum power consumption, thus contributing considerably in accelerating the growth of the automatic flexographic printing machine segment.

By Coloring Capacity :

The coloring capacity segment is divided into 2 color, 4 color, 6 color, and 8 color. 6 color flexographic printing machine accounted for the largest market share in 2022 owing to the vast range of colors and shades that are utilized to produce high-quality images and designs. The additional color options provide greater flexibility and accuracy in matching specific color requirements and are ideal for industries such as packaging, labels, and high-quality graphics. Additionally, the ability to print with six colors offers increased versatility and flexibility for various printing applications. Different combinations of colors are used to create gradients, shading effects, and realistic images. The flexibility allows the 6-color machines to be deployed for a wide range of products, including flexible packaging, corrugated boxes, labels, and promotional materials. Furthermore, with six color stations, a flexographic printing machine produces multi-color prints in a single pass, reducing the need for multiple printing processes, leading to improved production efficiency, shorter lead times, and cost savings. Consequently, the ability to print multiple colors in one pass is contributing significantly in driving the growth of 6-color capacity flexographic printing machines.

8 color segment is projected to witness the fastest CAGR in the flexographic printing machines during the forecast period. An 8-color flexographic printing machine offers a broader range of colors and shades compared to a 6-color machine. The expanded color gamut enables more accurate color matching and production of complex designs that increase the demand of 8-color gamut in industries for high-quality and visually stunning prints. Additionally, with two additional color stations, an 8-color machine provides greater flexibility in design options by incorporating more intricate details, gradients, special effects, and finer color transitions. For instance, in September 2022, BOBST launched the CI flexo press at DFTA's Technology Center with an 8-color gamut to offer premium quality, clear, and detailed prints. The 8-color gamut enables more precise color matching and the production of complex designs, thus contributing notably in bolstering the market growth.

By Application :

The application segment is categorized into printing media, office and admin, and industrial applications. Printing media accounted for the largest market share in 2022 as the printing media industry requires high-volume production capabilities to meet the demand for newspapers, magazines, books, catalogs, and other printed materials. Flexographic printing machines excel in high-volume printing due to the ability to print rapidly and efficiently, thus driving the growth of the market. Additionally, flexographic printing machines are capable of handling large print runs, offering faster turnaround times and cost-effective production. Furthermore, flexographic printing machines offer cost-effective solutions for printing media applications as the machines are known for efficient ink utilization, allowing for reduced ink consumption and lower ink costs. For instance, in June 2022, Kodak launched Kodak Prosper 7000 Turbo Press to deliver high-quality prints for printing newspapers, magazines, and specialty papers. The machine offers 35% faster printing speed and utilizes water-based Kodak ink, thus contributing notably in spurring the market growth.

The industrial applications are projected to witness the fastest CAGR in the flexographic printing machine during the forecast period. The growth of the market is credited to the increasing demand of flexographic printing machines in packaged food and beverages sector. Flexographic printing machines play a crucial role in the packaging of food and beverages, providing attractive labels, packaging materials, and ensuring product safety and information. Additionally, flexographic printing machines offer high-quality and customizable prints, enabling businesses to create visually appealing and unique packaging and labeling solutions. Consequently, the ability of flexographic printing machines to deliver vibrant colors accurately and precisely increases the demand of the machines in the packaging and labeling sector.

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America accounted for the largest revenue share in the year 2022 as the region has a well-established printing industry that increases the demand of flexographic printing machines to deliver high-quality prints. Additionally, the advancements in printing technology including digital flexography, improved plate-making processes, and automated systems also contribute significantly in driving the market growth in the region. The integration of automation, computerization, and digital workflow solutions is enhancing the efficiency, accuracy, and productivity of flexographic printing machines in North America, further accelerating the market dominance.

Moreover, the rising demand for packaging and labeling solutions, particularly from food and beverages industry is propelling the market growth as flexographic printing machines are ideal for producing high-quality, cost-effective packaging materials, labels, and tags. For instance, according to the Michigan State University, United States was the largest exporter and importer of food and beverage accounted for USD 2,279,806,476, and USD 2,570,226,465 respectively in the year 2021. Consequently, the expanding food and beverage industry is increasing the demand for flexographic printing machines to provide clear print for packaged food and beverage products, thus contributing in driving the market growth.

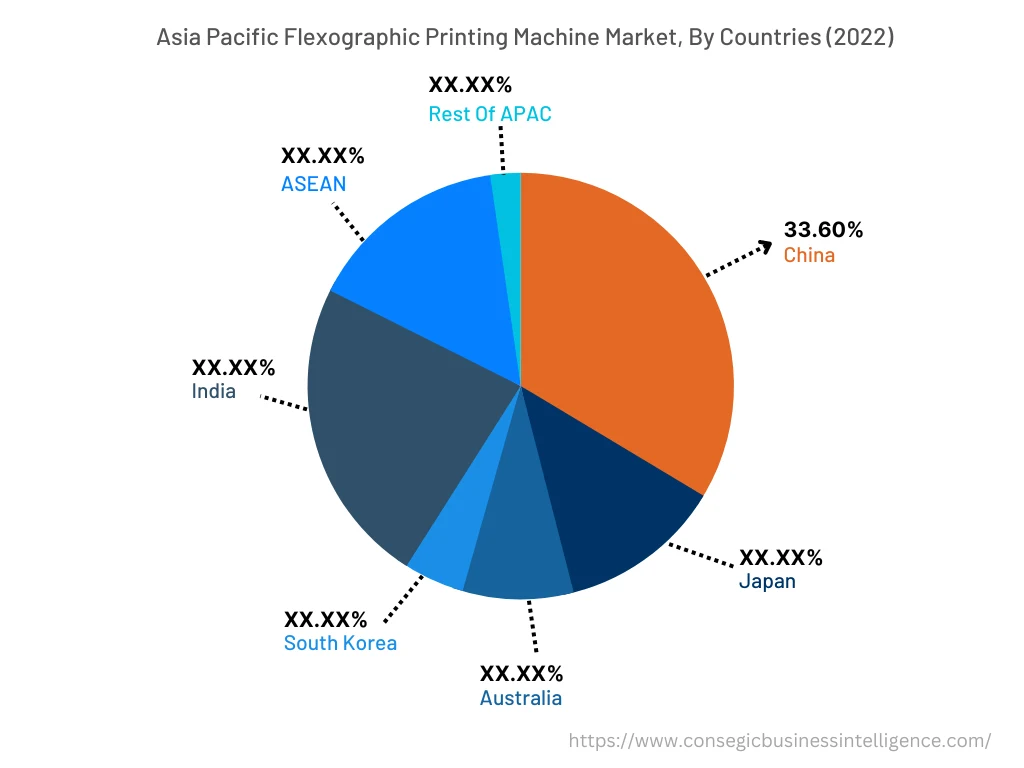

Asia Pacific accounted for USD 235.04 Million in 2022 and is anticipated to witness the fastest CAGR of 6.8% accounting to USD 393.18 Million in the flexographic printing machine market. In addition, in the region, China accounted for the maximum revenue share of 33.6% in the year 2022. The growth is attributed to the expanding e-commerce sector in countries including China, India, Japan, and South Korea that increases the demand of flexographic printing machines to print labels and packages. Additionally, the changing lifestyle of people and inclination toward packaged food also increases the demand of printing machines to offer high-quality prints. Moreover, the presence of key players in the region that invest heavily in research and development to launch advanced technologies to improve the accuracy and speed of flexographic printing machines also contributes significantly in promoting the growth of the market in the Asia Pacific.

Top Key Players & Market Share Insights:

The competitive landscape of the flexographic printing machine market has been analyzed in the report, along with the detailed profiles of the major players operating in the industry. Further, the surge in Research and Development (R&D), product innovation, various business strategies, and application launches have accelerated the growth of the flexographic printing machine market. Key players in the flexographic printing machine market include-

- Apex International

- Bobst

- Nilpeter India Pvt Ltd

- Taiyo Kikai Ltd.

- Windmöller & Hölscher

- Xi'An Aerospace-Huayang Mechanical & Electrical Equipment Co., Ltd

- Comexi Group

- Azul 3D

- Donghang Precision Machinery Limited Company

- Heidelberger Druckmaschinen AG

- Lohia Corp Limited

- Mark Andy (MAI Holdings, Inc.)

Recent Industry Developments :

- In February 2022, Paper Converting Machine Company (PCMC) partnered with Fox Valley Flexo Services to offer flexographic printing education and training to the print industry through PCMC's Packaging Innovation Center.

- In November 2020, Apex International launched FlexoKITE in India and Netherlands to offer premium-quality prints to businesses and organizations. The product is manufactured by the collective contribution of five industry leaders namely MacDermid, Apex International, ESKO, BOBST, and DuPont.

Key Questions Answered in the Report

What is a flexographic printing machine? +

A flexographic printing machine, also known as a flexo press or flexo printer, is deployed for the high-volume production of packaging materials, labels, and other flexible materials.

What specific segmentation details are covered in the flexographic printing machine market report, and how is the dominating segment impacting the market growth? +

The inline type of press accounted for the largest market share in 2022 as the machines are designed for high-speed production to handle large print volumes and are suitable for long print runs. In addition, the inline configuration allows for efficient and continuous printing without frequent stops or interruptions, resulting in increased productivity and faster turnaround times.

What specific segmentation details are covered in the flexographic printing machine market report, and how is the fastest segment anticipated to impact the market growth? +

The industrial applications are projected to witness the fastest CAGR in the flexographic printing machine due to the increasing demand of flexographic printing machines in packaged food and beverages sector. Flexographic printing machines play a crucial role in the packaging of food and beverages, providing attractive labels, packaging materials, and ensuring product safety and information.

What specific segmentation details are covered in the flexographic printing machine market report, and how does each dominating segment is influencing the demand globally? +

Each dominating segment is influencing the demand globally due to growing industrial needs. Moreover, fluctuation in demand being witnessed from different sectors is responsible for driving the flexographic printing machine market.