- Summary

- Table Of Content

- Methodology

Failure Analysis Market Size:

Failure Analysis Market size is estimated to reach over USD 9,423.72 Million by 2031 from a value of USD 5,074.71 Million in 2023 and is projected to grow by USD 5,467.50 Million in 2024, growing at a CAGR of 8.0% from 2024 to 2031.

Failure Analysis Market Scope & Overview:

Failure analysis (FA) refers to an analysis to examine the root cause of failure of an equipment, product, or a production mistake in manufacturing, designing, or any unseen defects in a continuous process. The process of analyzing and collecting failure data is used for the identification of product malfunction and improvement in maintenance processes and schedules. Further, a precise problem description is important for any deep analysis to overcome problems such as component design and product breakdown. It is divided into two categories including complete failure and partial failure. Additionally, it helps to develop different methods to mitigate future problems and modify design according to the requirement to develop a system or product.

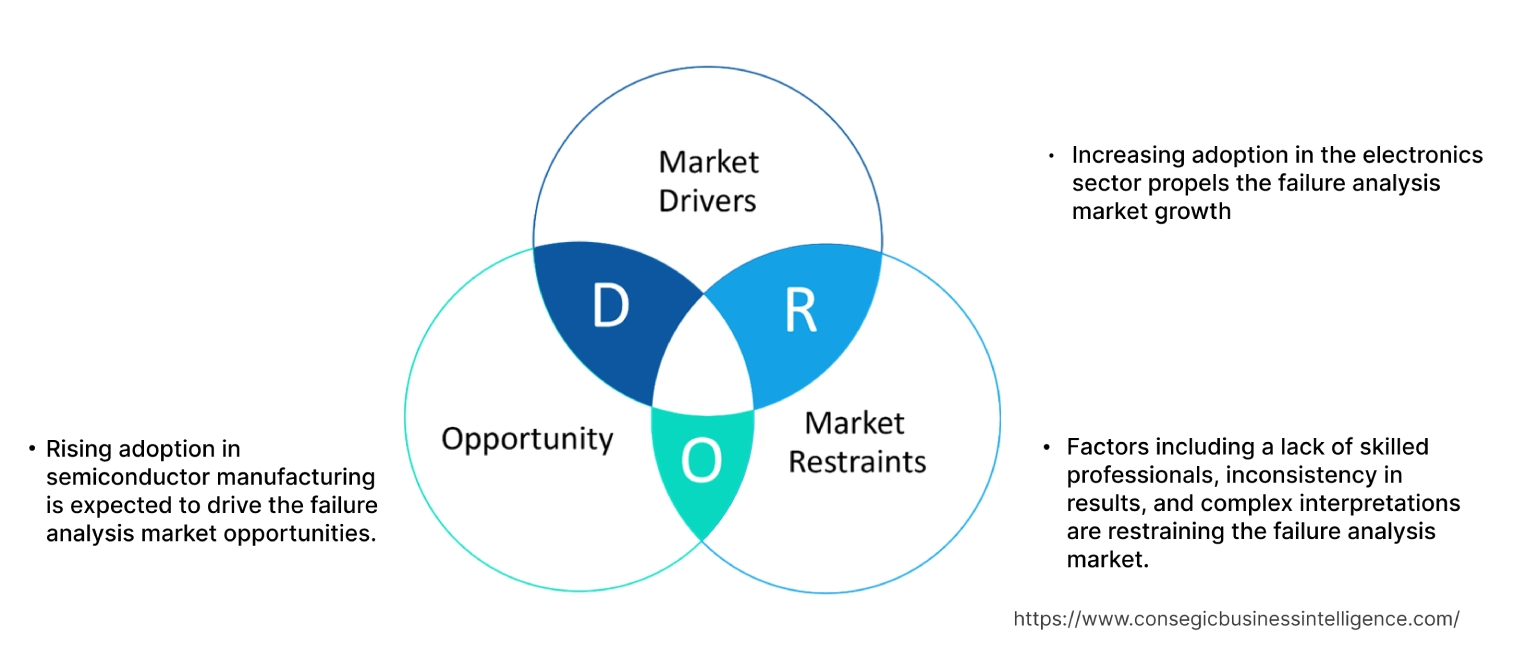

Failure Analysis MarketDynamics - (DRO) :

Key Drivers:

Increasing adoption in the electronics sector propels the failure analysis market growth

Rising demand for electronic devices such as televisions, IoT electronics, smartphones, computers, and smart wearables is increasing the complexities in printed-wiring-boards (PWBs), printed-circuit-boards (PCBs), and electronic components such as memory chips, integrated circuits (ICs), diodes, transistors, capacitors, LEDs, power modules, resistors, and others. Additionally, electronic failure analysis is used to overcome design malfunctions, which involves examination and cross-sectioning in the SEM (Scanning Electron Microscope) to provide an accurate root cause of the failure in the system.

- For instance, according to the India Brand Equity Foundation (IBEF), investments of USD 1.06 billion are secured under the scheme for the promotion of manufacturing of electronic components and semiconductors.

Thus, the rising investment in the electronics sector is further increasing the adoption of failure-detecting tools, in turn, driving failure analysis market size.

Key Restraints :

Factors including a lack of skilled professionals, inconsistency in results, and complex interpretations are restraining the failure analysis market.

Accidents in heavy equipment failures are growing due to a shortage in skilled professionals for repair workings, which in turn is driving the overall cost of businesses in terms of training and recruitment. Additionally, the predictions of failure for each asset are often inconsistent because it is based on the physical and environmental properties of elements. Rising complexity in interpretations of fault detection in machinery is restricting the efficiency of system reliability, in turn hindering the adoption of failure detection tools.

Hence, factors including a lack of skilled professionals, inconsistency in results, and complex interpretations are hindering the failure analysis market expansion.

Future Opportunities :

Rising adoption in semiconductor manufacturing is expected to drive the failure analysis market opportunities.

Rising demand for smaller, faster, and more efficient semiconductor chips is growing for both AI and IoT applications. Additionally, high-performance and fast computing devices are in trend due to the implementation of 5G network infrastructure. Further, the identification and rectifying defects of in chips are essential for ensuring the quality of chip design. Failures in semiconductor devices are typically mechanical, electrical, visual, and thermal, which are identified using electronic failure analysis equipment. Electronic defect analysis includes various electrical tests such as parameter checks, microscopy investigations, switching timing control tests, and thermal emission analysis for the identification of defects.

- For instance, in October 2024, QuantumDiamonds GmbH launched a quantum sensing technology that utilizes quantum microscopy for detecting faults in IC (Integrated Circuits).

Thus, as per the analysis, the rising advancements associated with failure detection tools for detecting semiconductor faults are driving the global failure analysis market opportunities.

Failure Analysis Market Segmental Analysis :

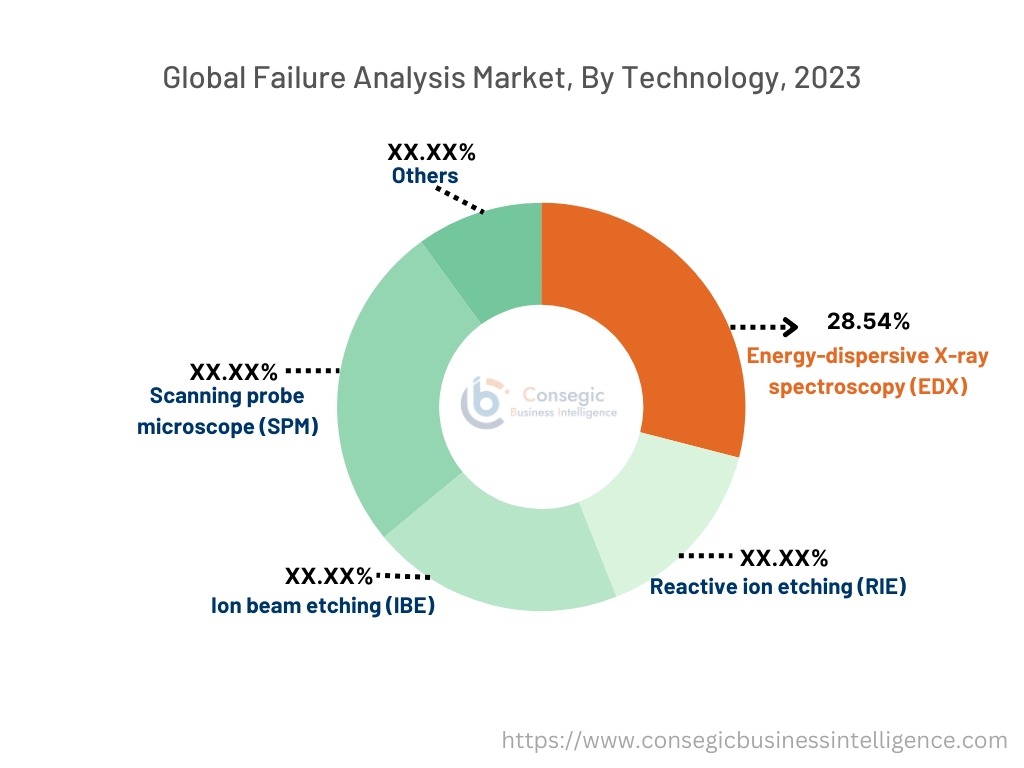

By Technology:

Based on the technology, the market is segmented into energy-dispersive X-ray spectroscopy (EDX), reactive ion etching (RIE), ion beam etching (IBE), scanning probe microscope (SPM), and others.

Trends in the technology:

- There is an increasing adoption of ion beam etching (IBE) for etching various dielectric materials and metals.

- Rising utilization of reactive ion etching (RIE) in the semiconductor sector for manufacturing devices.

Energy dispersive X-ray spectroscopy (EDX) accounted for the largest revenue share of 28.54% of the total failure analysis market share in 2023.

- X-ray spectroscopy uses high-energy radiation from surroundings to excite core electrons from lower energy states to higher energy states for the characterization of the elemental composition.

- Due to the conservation of energy, electrons emit X-rays that are measured by using X-ray spectroscopy. The collected charge pulse in X-ray spectroscopy is converted to a voltage pulse and then sorted based on the voltage.

- X-ray spectroscopy is used in various applications such as cement production, environmental studies, mining, ceramic and glass manufacturing, petroleum industry, metallurgy, and others.

- For instance, in March 2023, Gatan collaborated with EDAX, an X-ray microanalysis provider, to offer microscopy tools and enhance the operation and productivity of microscopes.

- According to the analysis, the rising developments associated with X-ray spectroscopy are driving the failure analysis market growth.

Scanning probe microscope (SPM) is anticipated to register the fastest CAGR during the forecast period.

- Scanning probe microscopy (SPM) is used in semiconductor failure analysis to detect leakage currents, doping defects, isolation faults, and open circuits.

- Various physical parameters such as doping, oxide thickness, current, or temperature at sub-micron to nanometer resolution insights are gathered in two-dimensional maps using scanning probe microscopy.

- Scanning probe microscopy is used for finding nanoscopic construction details of semiconductors to enhance processes and find faults.

- Scanning probe microscope is used in biophysical and biological research to identify the properties and structure of cells, biomolecules, and tissues.

- For instance, in June 2022, Hitachi High-Tech Corporation launched the AFM100 Pro high-sensitivity scanning probe microscope, which is equipped with a high sensitivity optical head for measuring physical properties.

- According to the failure analysis market analysis, the rising advancements in scanning probe microscopes are driving the failure analysis market size.

By Equipment:

Based on the equipment, the market is segmented into scanning electron microscope (SEM), transmission electron microscope (TEM), energy dispersive X-ray microanalyzer (EDS), thermomechanical analyzer (TMA), inductively coupled plasma spectrometer (ICP).

Trends in the equipment:

- There is an increasing trend towards the adoption of thermomechanical analyzers (TMA) for measuring the glass transition temperature of polymers.

- Rising adoption of inductively coupled plasma spectrometer (ICP) for tracing elements in liquid samples.

Scanning electron microscope (SEM) accounted for the largest revenue of the overall market share in 2023

- Scanning electron microscope (SEM) produces images by scanning the surface using a beam of electrons.

- Detailed and magnified images of an object can be produced by using a scanning electron microscope (SEM), which leads to the creation of high-resolution images.

- Scanning electron microscope is used in various applications such as semiconductor inspection, microchip assembly, microchip assembly, microchip assembly, and others.

- For instance, in July 2024, JOEL launched scanning electron microscopes for detecting images, live 3d microscopy, live EDS analysis, and others.

- Therefore, the rising developments and advancements in scanning electron microscopes are driving the failure analysis market trends.

Energy dispersive X-ray microanalyzer (EDS) is anticipated to register a significant CAGR during the forecast period.

- Energy dispersive X-ray microanalyzer (EDS) is an analysis process that is used for identifying compositions of various elements.

- EDS offers advantages including quantitative information and qualitative information on elemental composition with minor and major elements, impurities, and race elements.

- Energy dispersive X-ray microanalyzer (EDS) is used in different applications including detecting sulfur content of petroleum products, identifying particulate matter in air, geological studies, and others.

- For instance, in October 2024, Gatan launched the EDAX Elite T Ultra EDS (Energy Dispersive X-Ray Spectroscopy) system for scanning transmission electron microscopes.

- Therefore, the rising advancements in energy-dispersive X-ray microanalyzers (EDS) for scanning and analyzing element composition are driving the failure analysis market trends.

By Application:

Based on the application, the market is segmented into automotive, IT & telecom, semiconductor, manufacturing, oil & gas, metallurgy, and others.

Trends in the application:

- Rising trend towards the adoption of failure analysing equipment in oil and gas sector for analyzing the chemical composition and molecule structure.

- There is an increasing trend towards the adoption of low-power stereo microscopes in metallurgy for detecting failure and defects.

The automotive segment accounted for a significant revenue share of the total failure analysis market share in 2023.

- Automotive failure analysis is the process of identifying the root cause for damage, misuse, degradation, weathering, stress, aging, malfunction, processing, and others of automobile components.

- Automotive analysis helps in avoiding unplanned downtime, component damage, and scheduled maintenance.

- Additionally, analyses are used for determining specific requirements and identifying existing component conditions, and system failure.

- For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), production of automobiles including passenger and commercial vehicles in 2023 increased by 10% as compared to 2022.

- According to the analysis, the rising production of automotive is driving the adoption of defect analysis, in turn driving the FA market.

Semiconductor is anticipated to register the fastest CAGR during the forecast period.

- Rising demand for compact and efficient semiconductor chips is growing for different industries including consumer electronics and others.

- Identifying defects in semiconductor chips is important for ensuring the proper functioning of electronic products.

- In semiconductor devices, electronic failure equipment is used for detecting visual, mechanical, electrical, and other defects.

- For instance, in October 2024, TESCAN GROUP launched SOLARIS 2, SOLARIS X 2, and AMBER X 2 for semiconductor failure analysis.

- Therefore, the rising advancements associated with analysis systems for semiconductor defect analysis are driving the FA market.

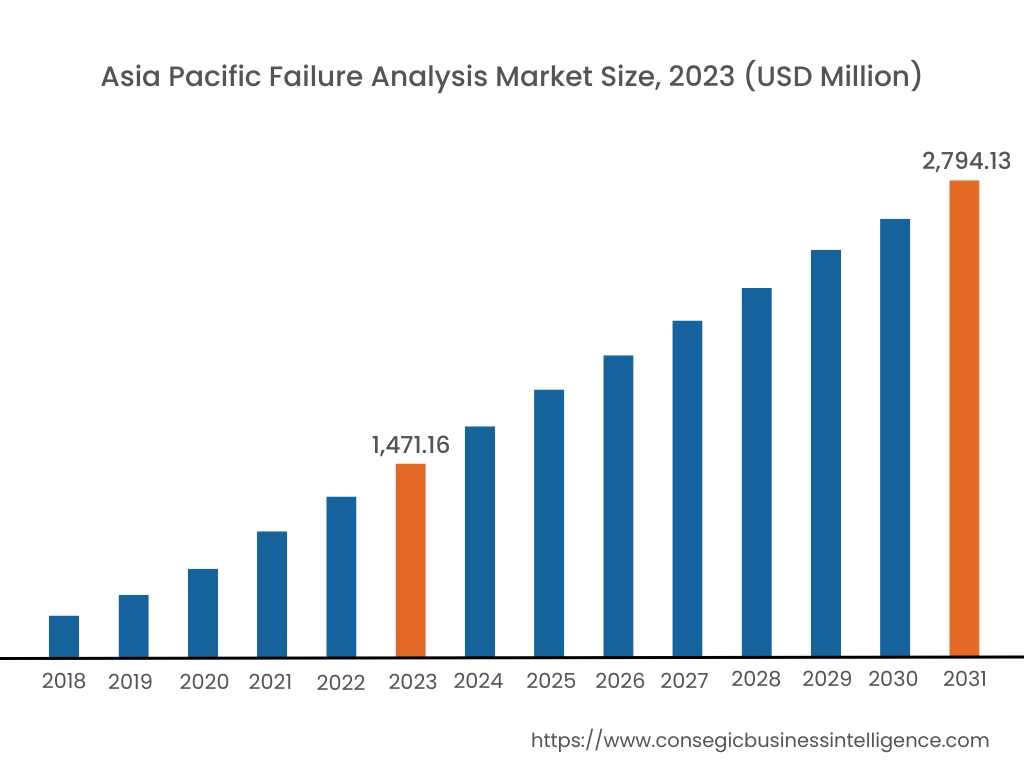

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

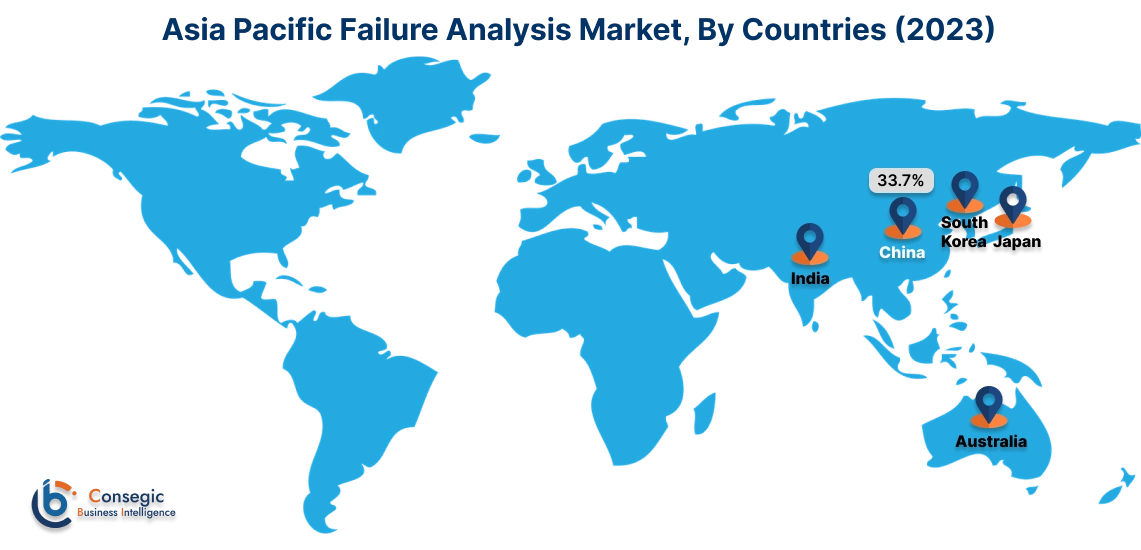

Asia Pacific region was valued at USD 1,471.16 Million in 2023. Moreover, it is projected to grow by USD 1,588.03 Million in 2024 and reach over USD 2,794.13 Million by 2031. Out of this, China accounted for the maximum revenue share of 33.7%. As per the failure analysis market analysis, there is a significant growth in the adoption of failure-detecting tools, specifically in countries such as China, India, and Japan, due to growing demand in IT & telecom sectors among others. The rapid development, growing advancements, and investments in the information services and telecommunication industry are accelerating the failure analysis market expansion.

- For instance, according to Invest India, 20,980 base stations are installed in the network infrastructure across India for quick rollout of 5G services, in turn propelling the need for failure detection tools.

North America is estimated to reach over USD 3,121.14 Million by 2031 from a value of USD 1,689.12 Million in 2023 and is projected to grow by USD 1,819.10 Million in 2024.

In North America, the growth of the failure analysis industry is driven by the rising manufacturing activities in various industries including transportation equipment, chemicals, machinery, computer and electronic products, petroleum and coal products, and others. The rising trend for increasing manufacturing output is also driving the market growth. Hence, the increased investment in manufacturing is massively contributing to the failure analysis market demand.

- For instance, in September 2024, Hitachi Energy invested over USD 155 Million in developing factories for manufacturing transformers and high-voltage switchgear and breakers.

The regional analysis depicts that the rising electric vehicle initiatives and increasing automotive production are driving the adoption of failure analysis market demand in Europe. Further, as per the market analysis, the primary factor driving the market growth in the Middle East and African regions is the increasing investment in the oil & gas sector for improving productivity and development of oil & gas infrastructure projects. The rising investments in mining projects are accelerating the demand for FA in metallurgy processes, in turn driving the market growth in the Latin America region.

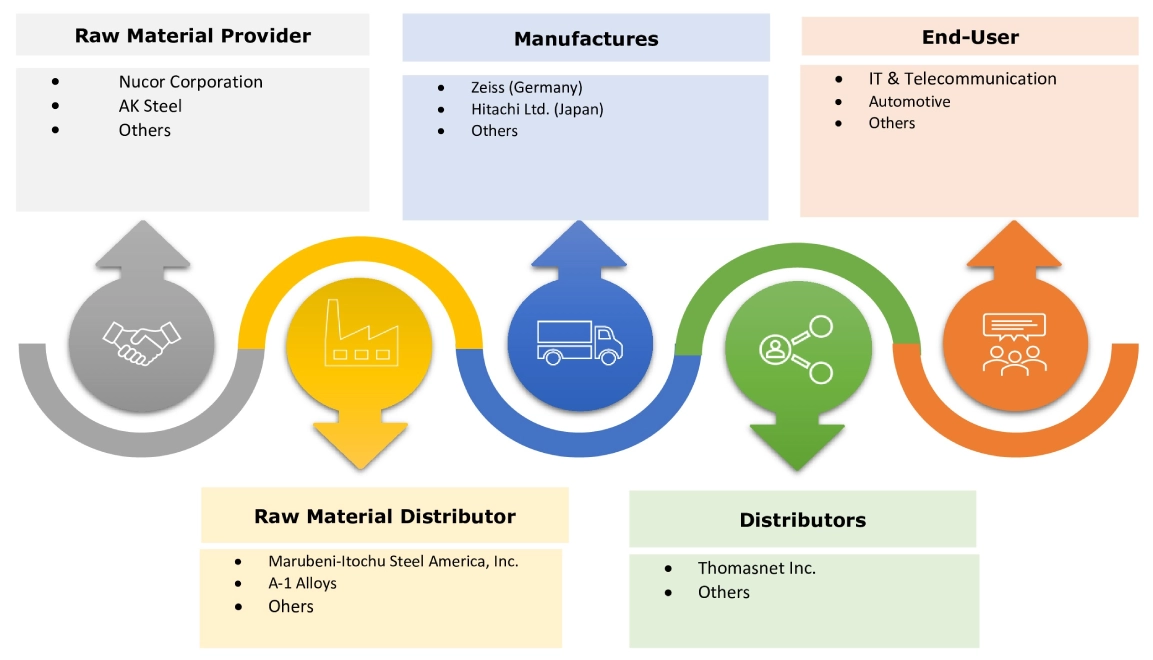

Top Key Players & Market Share Insights:

The failure analysis market is highly competitive with major players providing services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global failure analysis market. Key players in the failure analysis industry include -

- Thermo Fisher Scientific, Inc. (US)

- Oxford Instruments (UK)

- JEOL Ltd. (Japan)

- Veeco Instruments (US)

- A&D Company Ltd. (Japan)

- EAG (US)

- Zeiss (Germany)

- Hitachi Ltd. (Japan)

- Horiba Ltd. (Japan)

- Intertek Group PLC (UK)

Recent Industry Developments :

Product launches:

- In July 2024, JOEL launched JSM-IT810, a Schottky field emission SEM (Scanning Electron Microscope) with features including analysis function and automatic observation.

- In January 2024, Nanosurf, a provider of high-precision nanotechnology solutions, participated in the TOPOCOM project to provide expertise in scanning probe microscopy.

Failure Analysis Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 192,200.11 Million |

| CAGR (2024-2031) | 12.2% |

| By Technology |

|

| By Equipment |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the failure analysis market? +

The failure analysis market was valued at USD 5,074.71 Million in 2023 and is projected to grow to USD 9,423.72 Million by 2031.

Which is the fastest-growing region in the failure analysis market? +

Asia-Pacific is the region experiencing the most rapid growth in the failure analysis market.

What specific segmentation details are covered in the failure analysis system report? +

The failure analysis system report includes specific segmentation details for technology, equipment, application, and region.

Who are the major players in the failure analysis market? +

The key participants in the failure analysis market are Thermo Fisher Scientific, Inc. (US), Oxford Instruments (UK), EAG (US), Zeiss (Germany), Hitachi Ltd. (Japan), Horiba Ltd. (Japan), Intertek Group PLC (UK), JEOL Ltd. (Japan), Veeco Instruments (US), and A&D Company Ltd. (Japan).