- Summary

- Table Of Content

- Methodology

Electric Heat Tracing Market Size:

Electric Heat Tracing Market size is estimated to reach over USD 6.29 Billion by 2032 from a value of USD 3.45 Billion in 2024 and is projected to grow by USD 3.66 Billion in 2025, growing at a CAGR of 8.5% from 2025 to 2032.

Electric Heat Tracing Market Scope & Overview:

Electric heat tracing uses electrical energy to maintain or increase the temperature of pipes, equipment, and other objects. The system is equipped with thermostats and controllers to monitor and regulate the heating process, ensuring precise temperature control. Electric heat tracing maintains specific temperatures for various processes, such as controlling liquid flow and viscosity. It prevents pipes and other equipment from freezing, which can cause damage or disruption. It is used in a wide range of applications, from industrial settings to residential and commercial buildings.

Key Drivers:

Rising adoption of electrical heat tracing in residential sector is boosting the market growth

Electrical heat tracing in residential applications refers to using specialized heating cables to maintain or raise the temperature of pipes, particularly during cold weather to prevent freezing. These systems are designed to prevent pipes from freezing and bursting, ensuring uninterrupted water supply. In addition to freeze protection, heat tracing also maintains desired temperatures for hot water distribution systems or even prevent ice and snow accumulation on roofs and walkways.

- For instance, in January 2025, Chemelex completed its separation from nVent. The company offers electrical heat tracing solutions for residential applications. These solutions are represented by brands including Raychem, Pyrotenax, Tracer, and Nuheat.

Thus, the aforementioned factors are boosting the adoption of heat tracing, in turn driving the electric heat tracing market growth.

Key Restraints:

Issues associated with electric heat tracing is hindering the market growth

Electrical heat tracing faces issues including damage to insulation, improper installation, and difficulties in monitoring and controlling the system. Insulation, which is crucial for heat retention, is damaged by wear and tear, moisture, or poor installation. Damage to the insulation render the heat trace system ineffective. Overlapping heating cables lead to uneven heat distribution, overheating, and potential damage to the cables, requiring frequent maintenance.

Moreover, many plant automation systems are not designed to monitor or control heat trace systems, making it difficult to track system performance and troubleshoot issues. Thus, the market analysis shows that the aforementioned factors are restraining the electric heat tracing market demand.

Future Opportunities :

Innovations in advanced materials and nanotechnology are expected to create new market opportunities

Electric heat tracing is being enhanced by advanced materials and nanotechnology innovations. These innovations focus on improving the efficiency, durability, and safety of heat tracing systems, particularly in demanding industrial and environmental applications. New polymers with improved strength, temperature resistance, and dielectric strength are being used in cable construction, allowing higher power outputs and wider voltage ranges. Moreover, nanomaterials can be used to create highly effective insulating layers, reducing heat loss and improving system efficiency.

- For instance, nVEnt offers self regulating heat tracing technology using nanotechnology. nVent developed a new semi-conductive polymer nanocomposite with enhanced performance.

Thus, the ongoing progressions in advanced materials and nanotechnology are projected to drive electric heat tracing market opportunities during the forecast period.

Electric Heat Tracing Market Segmental Analysis :

By Type:

Based on the type, the market is segmented into self-regulating, constant wattage, mineral-insulated, and skin effect.

Trends in the Type:

- Rising adoption of constant wattage electric heat tracing cables to provide a consistent heat output per meter is boosting the electric heat tracing market size.

- Increasing trend in adoption of skin effect electric heat tracing due to benefits including reduced maintenance, and increased safety for maintenance staff.

The self-regulating segment accounted for the largest revenue share of 43.59% in the market in 2024.

- Self-regulating electric heat tracing is a system that automatically adjusts its heat output based on ambient temperature, preventing overheating and ensuring efficient energy use.

- It uses a special conductive polymer that changes resistance depending on the temperature, delivering more heat when colder and less when warmer.

- The key benefits of self-regulating heat tracing include energy savings, safety, ease of installation, and reliability.

- Moreover, self-regulating cables inherently limit heat output, preventing overheating and reducing the risk of fire or damage, even if they overlap.

- For instance, Thermon offers HLX self-regulating heat trace to use in hot water systems for sustainable electrification. The solutions minimize overall environmental impact and complies with the latest building safety requirements.

- Therefore, the market trends analysis depicts that the aforementioned factors are driving the electric heat tracing market growth.

The mineral-insulated segment is expected to register the fastest CAGR growth during the forecast period.

- Mineral-insulated (MI) electric heat tracing systems, also known as MI cables, are used for maintaining or raising the temperature of pipes, vessels, and other equipment.

- They are particularly well-suited for high-temperature and harsh environmental conditions. The key functions of MI heat tracing include freeze protection, high-temperature process maintenance, and ensuring optimal flow and viscosity of liquids.

- MI cables prevent freezing of fluids in pipelines, which is crucial in applications such as oil and gas and power generation.

- They maintain the required temperatures for various industrial processes, such as chemical plants and power plants.

- For instance, nVent offers MI heat trace technology under its brand, Raychem. The cables are designed for high exposure temperatures in non-hazardous and hazardous areas.

- Thus, the rising adoption of MI cables for various applications is expected to boost the electric heat tracing market trends during the forecast period.

By Connectivity Component:

Based on the connectivity component, the market is segmented into electric heat tracing cables, power connection kits, control and monitoring systems, thermal insulation materials, and others.

Trends in the Connectivity Component:

- Rising adoption of power connection kits in heat tracing to enable the secure and efficient delivery of power to the heating cables is boosting the electric heat tracing market size.

- Increasing adoption of control and monitoring systems in heat tracing due to its several benefits including reduced maintenance, energy savings, and increased system availability.

The electric heat tracing cables segment accounted for the largest revenue share in the electric heat tracing market share in 2024 and it is expected to register the fastest CAGR during the forecast period.

- Electric heat tracing cables are used to maintain or increase the temperature of pipes, tanks, and other equipment, primarily to prevent freezing or maintain a specific temperature for process requirements.

- They offer a reliable and energy-efficient way to control temperature in various applications, including industrial, commercial, and residential settings.

- Heat tracing cables are used to keep the temperature of pipes or tanks at a specific level for various processes.

- They melt snow and ice on roofs and in gutters to prevent ice dams and the potential damage they can cause.

- Therefore, the wide applications of electric heat tracing cables is driving the electric heat tracing market demand.

By Application:

Based on the application, the market is segmented into freeze protection and process temperature maintenance, roof and guttering de-icing, floor heating, and others.

Trends in the Application:

- Rising demand in heat tracing systems in roof and guttering de-icing to create pathways for melting snow and ice to drain off safely, preventing water damage and potential roof collapse.

- Increasing adoption of heat tracing systems in floor heating due to benefits including energy savings, uniform heat distribution, and ease of maintenance is boosting the market growth.

The freeze protection and process temperature maintenance segment accounted for the largest revenue share in the market in 2024 and it is expected to register the fastest CAGR during the forecast period.

- Freeze protection ensures that pipes and equipment do not freeze in cold environments. It prevents water pipes from freezing in cold weather, protecting pipelines carrying oil or chemicals in arctic climates.

- Process temperature maintenance keeps fluids or materials at a specific temperature for efficient processing or storage.

- Heat tracing ensures that pipes and equipment do not freeze, preventing costly repairs and downtime.

- Heat tracing maintains the desired temperature for optimal processing, reducing energy costs and improving product quality.

- Therefore, the market analysis depicts that the rising demand for heat tracing for freeze protection and process temperature maintenance application is boosting the electric heat tracing market trends.

By End-User:

Based on the end user, the market is segmented into oil and gas, chemical, commercial, residential, power and energy, food and beverage, pharmaceutical, water and wastewater treatment, and others.

Trends in the End User:

- Rising demand for heat tracing in pharmaceuticals to prevent freezing, viscosity issues, and condensation is boosting the electric heat tracing market expansion.

- Increasing adoption of heat tracing in water and wastewater treatment for maintaining consistent flow rates, preventing pipe damage from freezing, and enabling efficient operation of treatment processes.

The oil and gas segment accounted for the largest revenue in the electric heat tracing market share in 2024.

- Electrical heat tracing in oil and gas applications involves using heating cables to maintain or raise the temperature of pipes, tanks, and associated equipment, preventing freezing, reducing viscosity, and ensuring proper fluid flow.

- Its primary function is to prevent problems associated with cold temperatures, such as hydrate formation, wax precipitation, and increased viscosity, which hinder operations and damage equipment.

- By maintaining optimal temperatures, heat tracing ensures smooth and efficient operation of various processes, such as refining, pumping, and storage.

- Moreover, heat tracing maintains desired temperatures in storage tanks, preventing solidification and ensuring proper fluid movement.

- Therefore, the rising demand for heat tracing in oil and gas industry is boosting the electric heat tracing market expansion.

The chemical segment is expected to register the fastest CAGR during the forecast period.

- Electrical heat tracing in the chemical industry utilizes electrical heating cables to maintain or raise the temperature of pipes, tanks, and equipment.

- This system is crucial for preventing freezing, reducing viscosity, and maintaining optimal process temperatures, ensuring efficient and safe operations, especially with hazardous materials.

- Many chemical reactions and processes require specific temperature ranges to ensure efficient production and product quality.

- In hazardous material industries, maintaining safe operating temperatures is crucial to prevent accidents and explosions.

- Thus, the electric heat tracing market analysis depicts that the aforementioned factors are expected to the electric heat tracing market opportunities during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

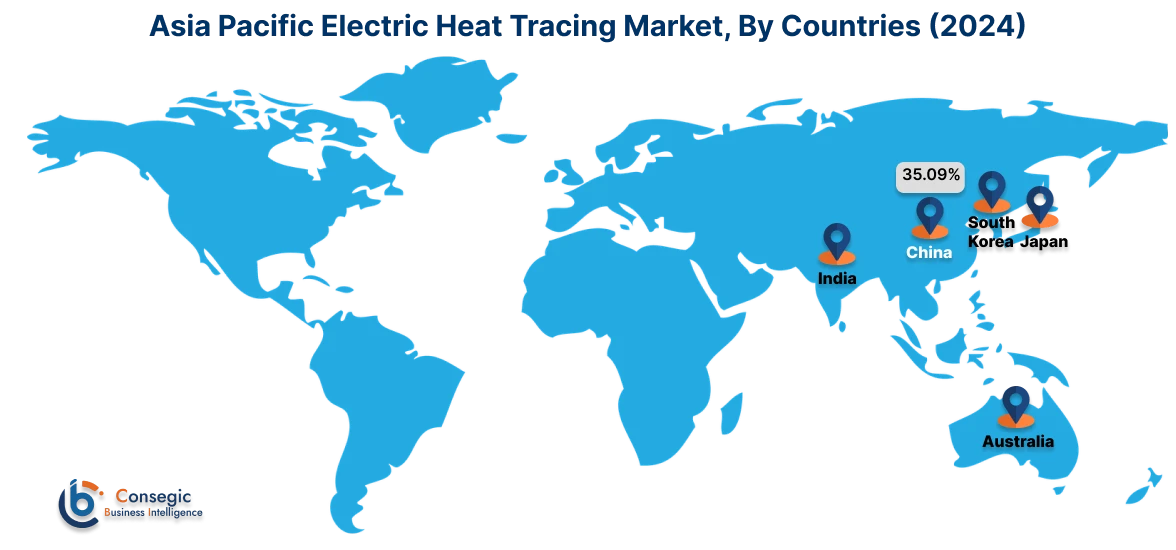

Asia Pacific region was valued at USD 0.84 Billion in 2024. Moreover, it is projected to grow by USD 0.90 Billion in 2025 and reach over USD 1.60 Billion by 2032. Out of this, China accounted for the maximum revenue share of 35.09%. The electric heat tracing market analysis shows that the market in the region is growing due to increasing adoption of heat tracing solutions in power & energy and food & beverage industries to maintain desired temperatures in pipes, equipment, and vessels, to prevent freezing and ensure efficient operations.

- For instance, in the Union Budget 2025-26, the Indian Ministry of Food Processing Industries (MoFPI) was allocated USD 505.70 million. This showcases the rising government investment in the food processing industries, in turn leading to the adoption of heat tracing for aforementioned applications.

North America is estimated to reach over USD 2.28 Billion by 2032 from a value of USD 1.26 Billion in 2024 and is projected to grow by USD 1.34 Billion in 2025. The market analysis shows that the market in the region is growing due to usage of heat tracing in commercial, residential, and power and energy sectors among others.

- For instance, according to the S Energy Information Administration (EIA), the energy production in the U.S. reached around 102.83 quads in 2023 while the consumption was 93.59 quads. The total annual energy production surpassed the total annual energy consumption since 2019. Thus, the growing power & energy sector is driving the market growth in North America.

In Europe, the market is driven by the wide applications of heat tracing in pharmaceutical and food & beverage sectors that utilize it for preventing freezing, ensuring smooth flow of substances, and maintaining process temperatures. Moreover, in Latin America, Middle East and Africa, the market is primarily driven by the rising adoption of heat tracing in oil and gas and chemical sectors to maintain or elevate the temperature of pipes, vessels, and equipment. Thus, the aforementioned factors are boosting the electric heat tracing market in the regions.

Top Key Players and Market Share Insights:

The electric heat tracing industry is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global electric heat tracing market. Key players in the electric heat tracing industry include -

- BARTEC Top Holding GmbH (Germany)

- Danfoss (Denmark)

- Drexan Energy System, Inc. (Canada)

- Eltherm GmbH (Germany)

- Emerson Electric Co (United States)

- nVent Electric plc (United Kingdom)

- Spirax-Sarco Engineering plc (United Kingdom)

- Thermon Group Holding, Inc. (United States)

- Watlow Electric Manufacturing Company (United States)

Electric Heat Tracing Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6.29 Billion |

| CAGR (2025-2032) | 8.5% |

| By Type |

|

| By Connectivity Component |

|

| By Application |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the electric heat tracing market? +

Electric Heat Tracing Market size is estimated to reach over USD 6.29 Billion by 2032 from a value of USD 3.45 Billion in 2024 and is projected to grow by USD 3.66 Billion in 2025, growing at a CAGR of 8.5% from 2025 to 2032.

What are the major segments covered in the electric heat tracing market report? +

The segments covered in the report are type, connectivity component, application, end user, and region.

Which region holds the largest revenue share in 2024 in the electric heat tracing market? +

North America holds the largest revenue share in the electric heat tracing market in 2024.

Who are the major key players in the electric heat tracing market? +

The major key players in the market are BARTEC Top Holding GmbH (Germany), Danfoss (Denmark), Drexan Energy System, Inc. (Canada), eltherm GmbH (Germany), Emerson Electric Co (United States), nVent Electric plc (United Kingdom), Spirax-Sarco Engineering plc (United Kingdom), Thermon Group Holding, Inc. (United States), and Watlow Electric Manufacturing Company (United States).