- Summary

- Table Of Content

- Methodology

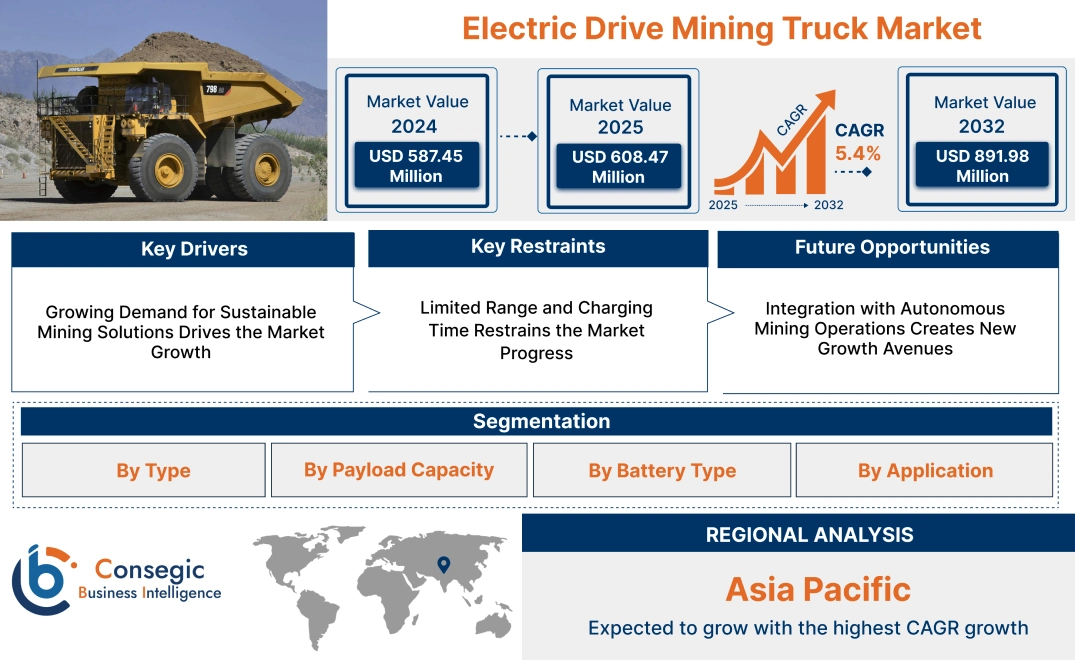

Electric Drive Mining Truck Market Size:

Electric Drive Mining Truck Market size is estimated to reach over USD 891.98 Million by 2032 from a value of USD 587.45 Million in 2024 and is projected to grow by USD 608.47 Million in 2025, growing at a CAGR of 5.4% from 2025 to 2032.

Electric Drive Mining Truck Market Scope & Overview:

An electric drive mining truck is a heavy-duty vehicle designed for transporting large volumes of materials in mining operations. Unlike traditional mechanical drive trucks, these vehicles use electric propulsion systems that combine diesel engines or battery systems with electric motors to enhance operational efficiency and load-handling capacity. They are specifically engineered to perform in harsh mining environments, offering increased durability and reliability.

These trucks are equipped with advanced electric drive components, including traction motors, inverters, and control systems, which provide better torque distribution and reduced mechanical complexity. Their robust design supports the transportation of heavy loads over uneven terrains while minimizing energy loss and wear on mechanical parts. Additionally, they are compatible with various mining operations, including open-pit and underground mining.

End-users of these trucks include large mining companies and contractors involved in mineral extraction and processing. Electric drive mining trucks play a vital role in improving material transport efficiency and operational productivity in demanding mining operations.

Key Drivers:

Growing Demand for Sustainable Mining Solutions Drives the Market Growth

The mining industry is under increasing pressure to reduce its environmental footprint, particularly regarding carbon emissions and air quality. As a result, there is a growing demand for sustainable, low-emission solutions, which is driving the adoption of electric drive systems in mining trucks. These trucks, powered by electricity, offer a significant reduction in carbon emissions compared to traditional diesel-powered vehicles. By utilizing electric power, mining companies reduce their reliance on fossil fuels, cut greenhouse gas emissions, and comply with stricter environmental regulations. Electric drive systems also contribute to improved air quality within mining operations, creating a safer and healthier work environment. As sustainability becomes a key focus in the mining sector, the shift to electric drive trucks aligns with the broader trend towards green technologies, improving the environmental performance of mining operations and contributing to global efforts to mitigate climate change. Thus, the aforementioned factors are driving the electric drive mining truck market growth.

Key Restraints:

Limited Range and Charging Time Restrains the Market Progress

Despite significant advancements in battery technology, the range and charging time of electric drive trucks continue to pose constraints, particularly in large mining operations. These trucks are required to travel long distances and carry heavy loads, which places high demands on battery capacity. Current battery technologies, though improved, still limit the range of electric trucks, requiring frequent recharging during extended shifts. The need for long charging times between operations leads to downtime, affecting the overall operational efficiency of the fleet. In large mining environments, where trucks need to operate continuously, this limitation hinders productivity. Moreover, charging infrastructure are not readily available or capable of handling the power needs of multiple trucks at once, further reducing operational efficiency. Until battery technologies improve to provide longer range and faster charging times, these constraints limit the electric drive mining truck market demand.

Future Opportunities :

Integration with Autonomous Mining Operations Creates New Growth Avenues

The rise of automation in the mining industry presents a significant opportunity for integrating electric drive trucks with autonomous driving systems. Autonomous mining operations, where trucks will perform tasks without human intervention, significantly improve operational efficiency and reduce human error. By integrating electric drive systems with autonomous technologies, mining companies will optimize fuel and energy consumption, enhancing the sustainability of their operations. Electric trucks equipped with autonomous systems will be able to operate continuously with minimal downtime, reduce maintenance needs, and ensure precise, optimized routes for transporting materials. This integration also leads to improved safety, as autonomous trucks will reduce the risk of accidents caused by human factors. Furthermore, autonomous systems will be programmed to efficiently manage energy use, ensuring that electric trucks operate at their optimal energy levels throughout the work cycle. This makes electric drive trucks an essential component of the future of autonomous, energy-efficient, and cost-effective mining operations. Therefore, the above mentioned factors are creating new electric drive mining truck market opportunities.

Electric Drive Mining Truck Market Segmental Analysis :

By Type:

Based on type, the market is segmented into battery electric drive mining trucks and hybrid electric drive mining trucks.

The battery electric drive mining trucks segment accounted for the largest revenue of the total electric drive mining truck market share in 2024.

- The dominance of this segment is due to the rising focus on reducing carbon emissions and transitioning to cleaner mining operations.

- These trucks offer lower operating costs by eliminating fuel expenses and reducing maintenance requirements compared to traditional diesel-powered trucks.

- Increasing government regulations on emissions and incentives for adopting electric vehicles further drive the adoption of battery electric mining trucks.

- Growth in investments in electric vehicle (EV) infrastructure in the mining sector support the widespread deployment of these trucks, contributing to the electric drive mining truck market expansion.

The hybrid electric drive mining trucks segment is projected to grow at the fastest CAGR during the forecast period.

- Hybrid models combine electric and diesel power, offering better fuel efficiency and operational flexibility in challenging mining environments.

- These trucks provide extended operational ranges and lower emissions, balancing performance and sustainability.

- Hybrid systems reduce fuel consumption while maintaining high payload capacities, appealing to mining companies focused on efficiency.

- As per the electric drive mining truck market analysis, advancements in hybrid technology, including better energy management systems, are driving the segment's rapid expansion.

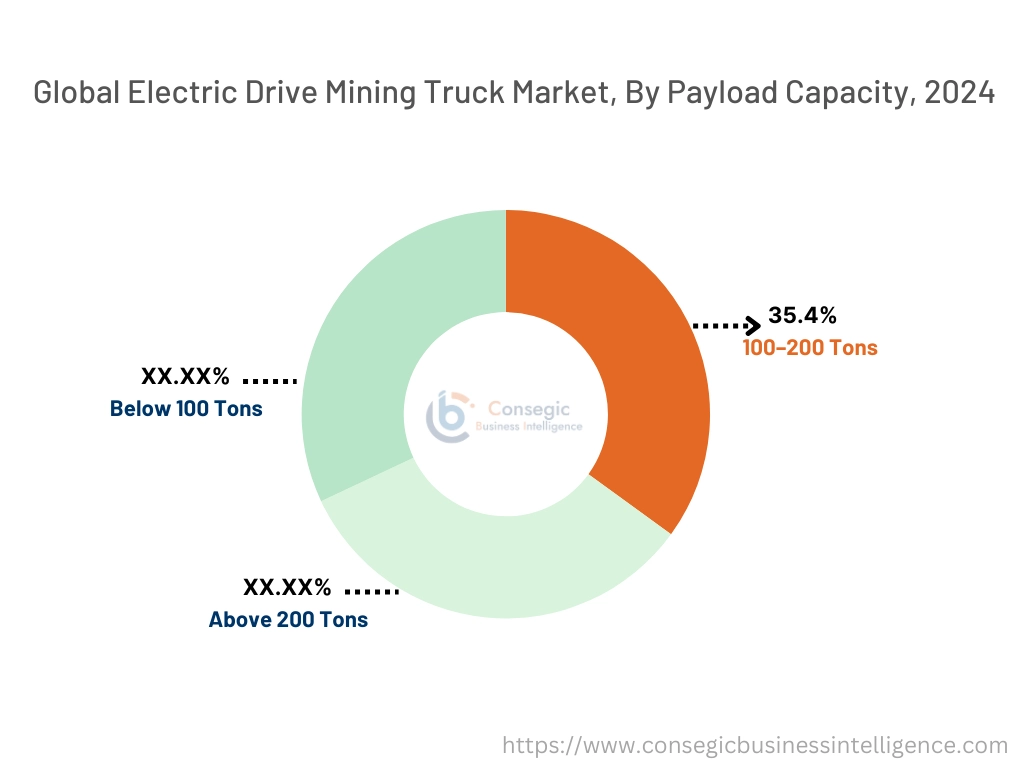

By Payload Capacity:

Based on payload capacity, the market is segmented into below 100 tons, 100–200 tons, and above 200 tons.

The 100–200 tons segment held the largest revenue share of 35.4% of the total electric drive mining truck market share in 2024.

- Trucks in this payload range are widely used in large-scale mining operations for their balance of capacity and maneuverability.

- Mining companies prefer this segment for its efficiency in transporting bulk materials while maintaining fuel efficiency.

- Established infrastructure in major mining regions supports the widespread use of these trucks.

- As per the electric drive mining truck market trends, technological advancements in this segment have improved operational safety and productivity.

The above 200 tons segment is anticipated to register the fastest CAGR during the forecast period.

- Increasing need for high-capacity trucks in large-scale mining operations is driving growth in this segment.

- These trucks offer significant cost savings by reducing the number of trips required for material transport.

- Continuous advancements in battery and electric motor technologies support the deployment of larger-capacity electric mining trucks.

- Thus, mining companies are investing in large-capacity electric trucks to improve operational efficiency and reduce carbon emissions, which further fuels the electric drive mining truck market demand.

By Battery Type:

Based on battery type, the market is segmented into lithium-ion batteries, lead-acid batteries, nickel-metal hydride batteries, and others.

The lithium-ion batteries segment accounted for the largest market share in 2024.

- Lithium-ion batteries offer high energy density, longer life cycles, and faster charging capabilities, making them ideal for mining applications.

- Advancements in battery technology have significantly reduced the costs associated with lithium-ion batteries, boosting adoption.

- Growing investments in battery manufacturing facilities ensure the availability and affordability of lithium-ion batteries.

- As per the electric drive mining truck market analysis, these batteries support the operational needs of high-capacity mining trucks, enhancing overall efficiency.

The nickel-metal hydride batteries segment is projected to witness the fastest CAGR during the forecast period.

- Nickel-metal hydride batteries offer improved safety and stability compared to lithium-ion batteries.

- Their ability to operate efficiently in extreme temperatures makes them suitable for mining environments.

- The segment benefits from ongoing research and development aimed at enhancing battery performance.

- As per the electric drive mining truck market trends, mining companies are exploring these batteries as an alternative to lithium-ion technology for safer and more sustainable operations.

By Application:

Based on application, the market is segmented into coal mining, metal mining, stone mining, and others.

The metal mining segment accounted for the largest revenue share in 2024.

- The increasing global need for metals such as copper, iron, and aluminum fuels the adoption of electric mining trucks.

- Metal mining operations prioritize reducing operational costs and carbon footprints, driving the shift to electric trucks.

- Technological advancements in mining equipment support the deployment of electric trucks in metal mining.

- Government regulations targeting sustainability and emissions reduction encourage the use of electric vehicles in this sector, creating significant substantial electric drive mining truck market opportunities.

The coal mining segment is expected to grow at the fastest CAGR during the forecast period.

- The segment’s growth is driven by the demand for sustainable mining practices and the transition to cleaner energy sources.

- Electric mining trucks help coal mining companies comply with stringent environmental regulations.

- These trucks offer cost savings by reducing fuel dependency and operational costs.

- Thus, advancements in battery technology enhance the suitability of electric trucks for coal mining operations, fueling the electric drive mining truck market growth.

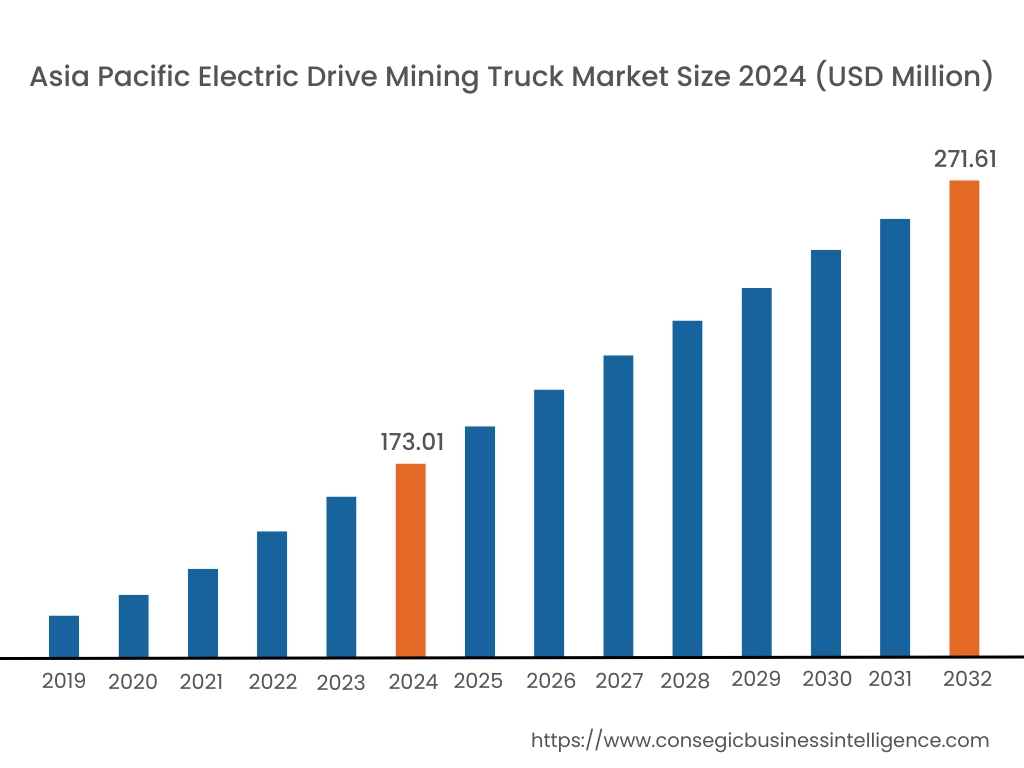

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

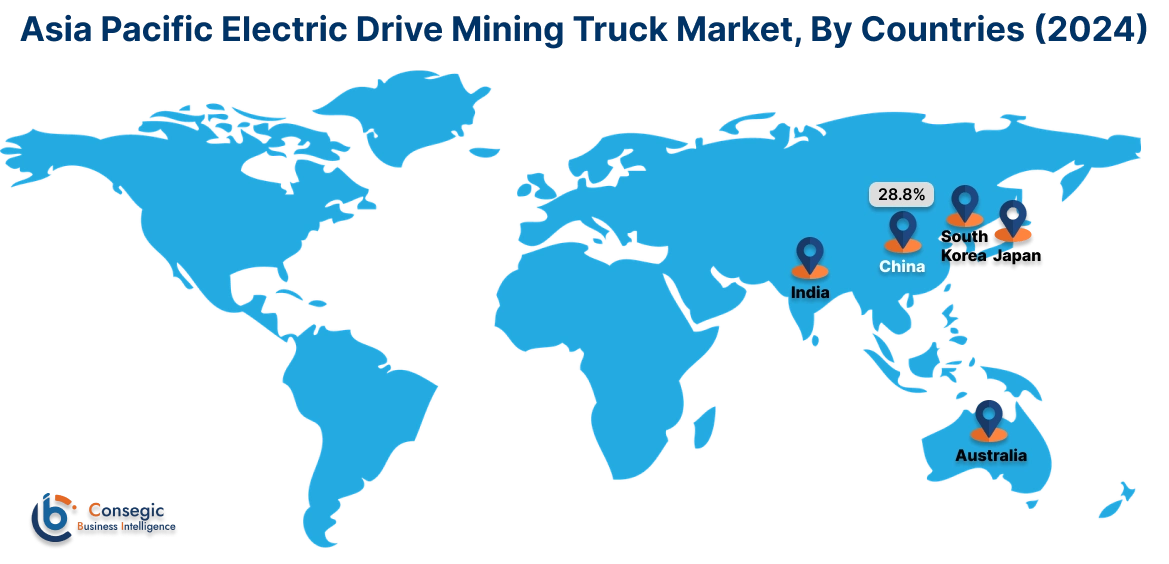

Asia Pacific region was valued at USD 173.01 Million in 2024. Moreover, it is projected to grow by USD 179.71 Million in 2025 and reach over USD 271.61 Million by 2032. Out of this, China accounted for the maximum revenue share of 28.8%. The Asia-Pacific region is emerging as a key market for electric drive mining trucks, supported by rapid industrialization and growing energy consumption. Countries like China and India are investing in electric mining equipment to reduce dependency on fossil fuels and improve operational efficiency. A major trend in the region is the development of locally manufactured electric mining trucks to meet domestic mining needs. Analysis reveals that government policies favoring clean energy and mining sector modernization are propelling electric drive mining truck market expansion.

North America is estimated to reach over USD 289.09 Million by 2032 from a value of USD 194.86 Million in 2024 and is projected to grow by USD 201.45 Million in 2025. The North American electric drive mining truck market is significantly driven by stringent environmental regulations and a well-established mining sector. The region is witnessing a shift toward electrification to reduce operational costs and minimize carbon emissions. Technological advancements in battery systems and electric drivetrains are key trends enhancing the performance and efficiency of mining trucks. Analysis suggests that increased investment in sustainable mining practices and the modernization of mining fleets are accelerating market adoption.

Europe’s electric drive mining truck market is influenced by strong environmental policies aimed at reducing industrial emissions. The region's focus on sustainability and carbon neutrality is pushing mining companies to transition from diesel-powered to electric drive systems. Trends in Europe include the adoption of autonomous electric trucks and the development of high-capacity charging infrastructure. Analysis highlights that government incentives for green technologies and the mining industry’s sustainability targets are crucial factors driving the market.

The Middle East and Africa are gradually adopting electric drive mining trucks as part of efforts to improve energy efficiency and reduce carbon footprints in mining operations. The focus is on integrating electric solutions into mining fleets to address rising environmental concerns. A prominent trend in the region is the deployment of hybrid electric systems to balance energy efficiency with operational reliability. Analysis indicates that infrastructure development and foreign investments in mining projects are pivotal for market advancement.

Latin America’s electric drive mining truck market is driven by the region’s rich mineral resources and the need for sustainable mining operations. There is a growing preference for electric mining equipment to improve productivity while complying with environmental regulations. Key trends include the modernization of mining fleets and the implementation of energy-efficient technologies. Analysis suggests that supportive regulatory frameworks and strategic partnerships with technology providers are essential for market development in this region.

Top Key Players and Market Share Insights:

The Electric Drive Mining Truck market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global Electric Drive Mining Truck market. Key players in the Electric Drive Mining Truck industry include -

- Caterpillar Inc. (USA)

- Komatsu Ltd. (Japan)

- Xuzhou Construction Machinery Group (XCMG) (China)

- SANY Group (China)

- Volvo Construction Equipment (Sweden)

- Liebherr Group (Switzerland)

- Hitachi Construction Machinery Co., Ltd. (Japan)

- BelAZ (Belarus)

- Epiroc AB (Sweden)

- Sandvik AB (Sweden)

Recent Industry Developments :

- In July 2024, SANY launched the SET320S, a diesel-electric hybrid mining truck with a 300-ton capacity, at its Shenyang industrial park. The 7-meter-tall truck features advanced multi-power coupling technology, a 4,500-liter fuel tank, and safety systems like a panoramic camera, automatic weighing, and tire monitoring. Designed for open-pit mines, the SET320S marks a milestone in SANY's mining equipment development.

Electric Drive Mining Truck Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 891.98 Million |

| CAGR (2025-2032) | 5.4% |

| By Type |

|

| By Payload Capacity |

|

| By Battery Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the size of the Electric Drive Mining Truck Market? +

The Electric Drive Mining Truck Market size is estimated to reach over USD 891.98 Million by 2032 from a value of USD 587.45 Million in 2024 and is projected to grow by USD 608.47 Million in 2025, growing at a CAGR of 5.4% from 2025 to 2032.

What are the key segments in the Electric Drive Mining Truck Market? +

The market is segmented by type (battery electric drive mining trucks, hybrid electric drive mining trucks), payload capacity (below 100 tons, 100–200 tons, above 200 tons), battery type (lithium-ion batteries, lead-acid batteries, nickel-metal hydride, others), and application (coal mining, metal mining, stone mining, others).

Which segment is expected to grow the fastest in the Electric Drive Mining Truck Market? +

The above 200 tons payload capacity segment is expected to grow at the fastest CAGR during the forecast period, driven by increasing demand for high-capacity trucks in large-scale mining operations.

Who are the major players in the Electric Drive Mining Truck Market? +

Key players in the Electric Drive Mining Truck market include Caterpillar Inc. (USA), Komatsu Ltd. (Japan), Liebherr Group (Switzerland), Hitachi Construction Machinery Co., Ltd. (Japan), BelAZ (Belarus), Epiroc AB (Sweden), Sandvik AB (Sweden), Xuzhou Construction Machinery Group (XCMG) (China), SANY Group (China), Volvo Construction Equipment (Sweden).