- Summary

- Table Of Content

- Methodology

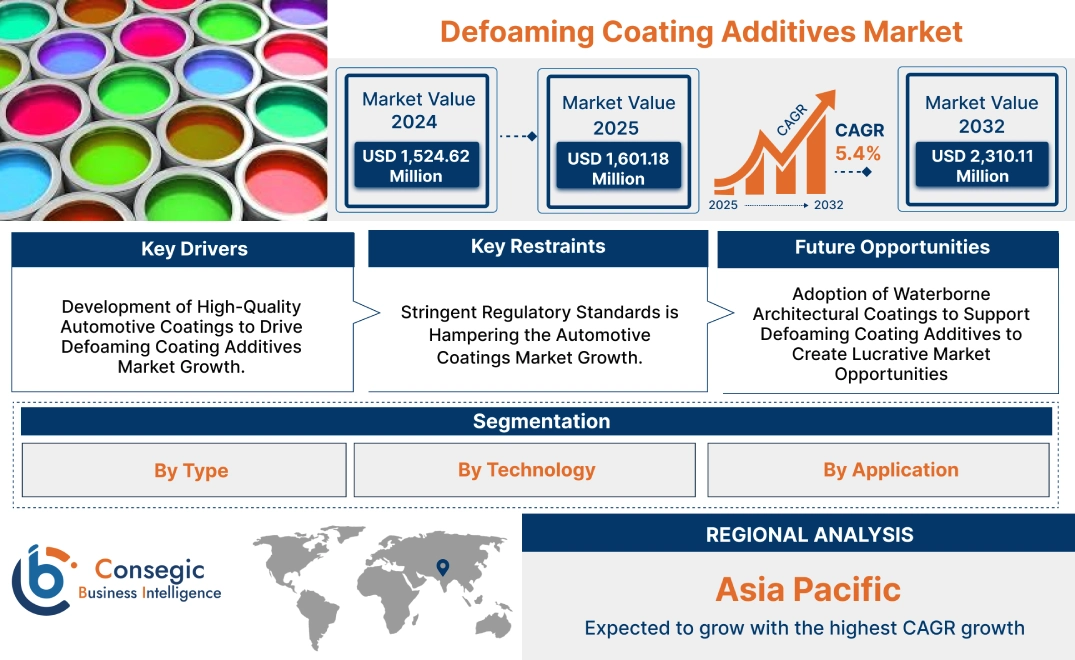

Defoaming Coating Additives Market Size:

The Defoaming Coating Additives Market size is growing with a CAGR of 5.4% during the forecast period (2025-2032), and the market is projected to be valued at USD 2,310.11 Million by 2032 from USD 1,524.62 Million in 2024. Additionally, the market value for 2025 attributed to USD 1,601.18 Million.

Defoaming Coating Additives Market Scope & Overview:

Defoaming coating additives are specialized chemical compounds designed to prevent or reduce the formation of foam during production, application, or curing of coatings. During the production and application of coatings, foam formation is a common issue that arises from factors such as air entrapment, surfactants, and the mixing process. Defoaming coating additives are incorporated into coating formulations to combat the defects caused by foam formation. Based on the formulation, these defoamers are categorized into silicone-based and silicone-free types. They are developed using water, oil, and solvent as carriers. These defoamers are incorporated into several applications such as architectural coatings, automotive coatings, industrial coatings, wood & furniture coatings, and more.

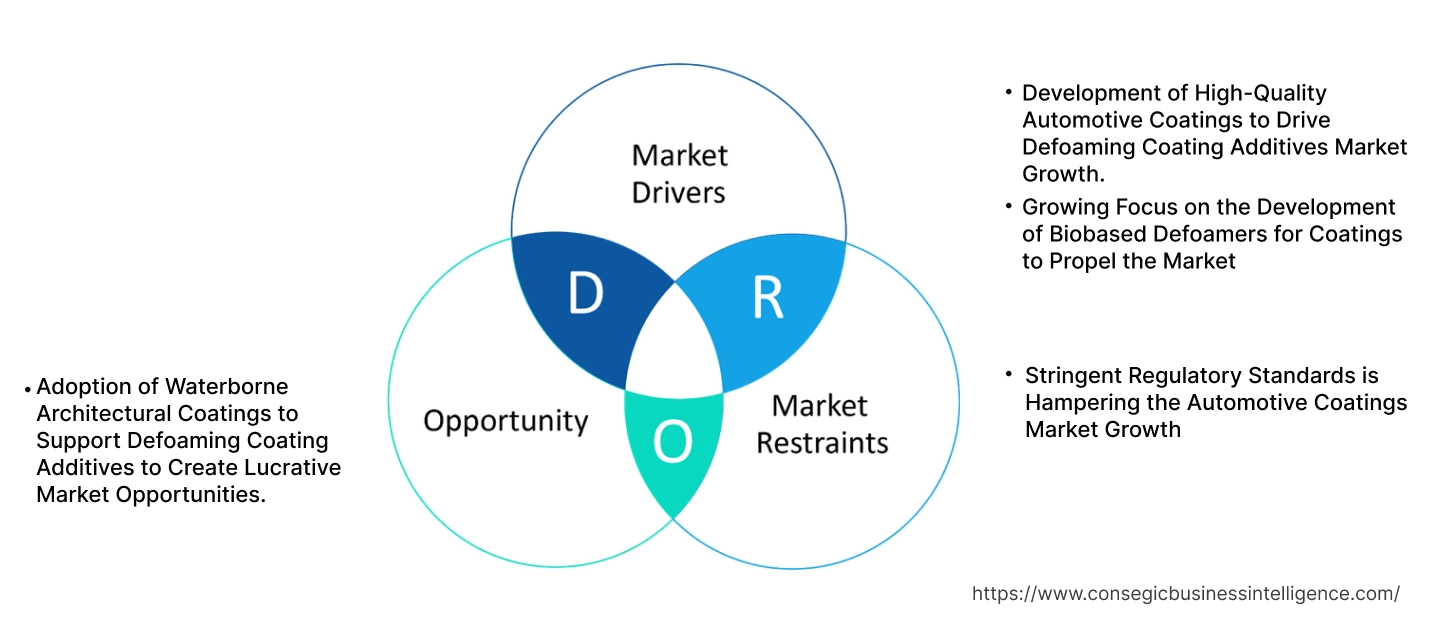

Key Drivers:

Development of High-Quality Automotive Coatings to Drive Defoaming Coating Additives Market Growth.

In the automotive industry, vehicle appearance is crucial, and consumers expect a flawless, smooth, and glossy finish. Foam during the coating process create surface defects and uneven gloss, making defoamers essential. Furthermore, automotive coatings must withstand harsh environmental conditions, including UV radiation, extreme temperatures, and chemical exposure. Given the automotive sector’s high-volume production, manufacturers need consistent, high-quality finishes, and defoamers are essential for maintaining efficiency and quality. Thus, the adoption of advanced coating technologies, such as powder coatings drives the requirement for specialized defoamers.

- For instance, in 2023, AkzoNobel launched a range of Resicoat EV powder coatings. The range is specifically designed to help improve the safety and performance of EV components. They have superior electrical insulating properties and enhanced thermal management. This drives the need for defoaming additives for coatings that are compatible with these advanced coating formulations.

This development of high-quality automotive coatings directly impacts the requirement for effective defoaming coating additives further propelling the market.

Growing Focus on the Development of Biobased Defoamers for Coatings to Propel the Market.

The coatings sector is emphasizing the reduction of its environmental footprint. Bio-based defoamers, derived from renewable resources such as plant oils, sugars, or other biomass, offer a more sustainable alternative to traditional petroleum-based defoamers. Bio-based defoamers also contribute to lower volatile organic compounds (VOCs) emissions. This aligns with increasingly stringent environmental regulations and consumer need for eco-friendly products. As a result, manufacturers are increasingly focusing on the development of biobased defoaming coating additives.

- For instance, in June 2023, Elementis announced launch of DAPRO® BIO 9910. This new defoamer with 96% biobased carbon content is designed to add more sustainability and performance in coatings.

Thus, due to the above-mentioned factors, the inclination towards development of bio-based defoamers is contributing to defoaming coating additives market expansion.

Key Restraints:

Stringent Regulatory Standards is Hampering the Automotive Coatings Market Growth.

Stringent regulatory standards imposed by government bodies worldwide pose significant constraints in the defoaming coating additives market expansion. These regulations, designed to protect the environment and public health, increase production costs and slow down product development. The increasing focus on reducing the use of hazardous substances such as such as lead, mercury, and cadmium necessitates reformulation efforts, which become complex and time-consuming.

Additionally, the automotive and construction sector are subject to stringent safety standards, including those related to fire resistance and corrosion protection. Coatings additives must meet these standards to ensure the safety and durability of coatings. Moreover, evolving federal regulations accelerate annual compliance and operating costs throughout supply chains, including the defoaming coating additives industry. Thus, the impact of these stringent regulations on the automotive coatings market expansion is multifaceted.

Future Opportunities :

Adoption of Waterborne Architectural Coatings to Support Defoaming Coating Additives to Create Lucrative Market Opportunities.

The adoption of waterborne coatings in architecture is driven by a combination of factors, including environmental regulations, consumer awareness, performance improvements, sustainability goals, application advantages, and cost considerations are creating market growth over the forecast period. Governments worldwide are implementing stricter regulations on VOCs in paints and coatings. Many building projects are aiming for green building certifications. Waterborne coatings have significantly lower VOC content compared to solvent-based coatings, making them a preferred choice for compliance. This need for waterborne architectural coatings is influencing the development of water-based defoaming additives for architectural coatings.

- For instance, in November 2024, Evonik introduced two new TEGO Foamex Defoamers, TEGO Foamex 16 and TEGO Foamex 11 for waterborne architectural coatings. Both the defoamers have very low VOC and SVOC content and do not contain solvents or mineral oils.

Thus, due to the above-mentioned factors, the shift towards waterborne coatings in architectural applications is creating upward market trajectory over the upcoming period.

Defoaming Coating Additives Market Segmental Analysis :

By Type:

Based on type, the market is bifurcated into Silicon-based Defoamers and Silicone-free Defoamers.

Trends in the Type:

- Development of advanced silicone-based defoamers with improved performance characteristics, such as enhanced compatibility with specific resin systems, increased efficiency at low concentrations, and improved long-term stability is growing.

- Due to increasing environmental regulations and consumer preference for low-VOC products, the requirement for silicone-free defoamers is on the rise.

The silicone-based defoamers segment accounted for the largest market share in 2024.

- Silicone-based defoamers hold the dominant position in the market due to their exceptional effectiveness and versatility.

- Their chemical inertness and thermal stability are key features. Their low surface tension allows for rapid spreading and efficient foam breakdown.

- Moreover, silicone defoamers offer wide compatibility with a broad spectrum of coating formulations, encompassing both solvent-borne and waterborne systems.

- The need for high-performance coatings is driving the development of silicone based defoamers for coatings.

- For instance, in June 2023, Evonik expanded its TEGO Rad line of specialized silicone acrylates with the introduction of TEGO Rad 2550. This clear, low-viscosity liquid is effective in reducing both static and dynamic surface tension in formulations cured with conventional UV and LED technologies. TEGO Rad 2550 is characterized by a low coefficient of friction, high scratch resistance, effective defoaming capabilities, and the ability to impart hydrophobic properties to surfaces.

- Collectively, this analysis supports segment trajectory in the overall market for defoaming coating additives.

The silicone-free defoamers segment is expected to grow at the fastest CAGR in the forecast period.

- Silicone-free defoamers for coatings are expected to experience substantial growth rate due to demand for low-VOC products.

- Their low VOC content makes them environmentally friendly, and they are less prone to causing surface defects.

- Silicone-free defoamers encompass various chemistries, including polymer-based options and mineral oil-based defoamers.

- Other silicone-free defoamers utilize chemistries such as vegetable oils, fatty acids, and esters.

- Demand for silicone-free defoamers is especially high in applications such as architectural coatings where low VOC content is critical.

- Hence, manufacturers are actively engaged in research and development to create new and improved silicone-free defoamers with enhanced performance and sustainability.

- Thus, considering this analysis, the silicone-free defoamers segment is expected to experience greater CAGR in the forecast years.

By Technology:

The technology segment is categorized water-based, oil-based, and solvent-based.

Trends in Technology:

- Inclination towards water-based coatings due to environmental regulations and consumer preferences support the adoption of effective water-based defoamers.

- Focus on bio-based defoamers derived from renewable resources to address sustainability concerns.

The water-based segment accounted for the largest defoaming coating additives market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- Water-based defoamers represent a crucial and expanding segment within the defoaming additives market. These specialized chemical formulations utilize water as their primary carrier.

- The advantages of water-based defoamers are numerous. Their low VOC content makes them an environmentally-fervency choice compared to solvent-based alternatives.

- Increasingly stringent environmental regulations are influencing manufacturers to transition to water-based coatings, consequently driving requirement for compatible defoamers.

- For instance, in 2024, Axalta Building Products launched Cerulean, its latest generation of waterborne industrial wood coatings. This meets the needs of customers to improve environmental profiles, including the use of low-VOC products. The development of such waterborne coatings supports the adoption of water-based defoamers.

- Owing to the above-mentioned analysis, the water-based segment holds a dominant position and is growing at the fastest rate in the overall defoaming coating additives market demand.

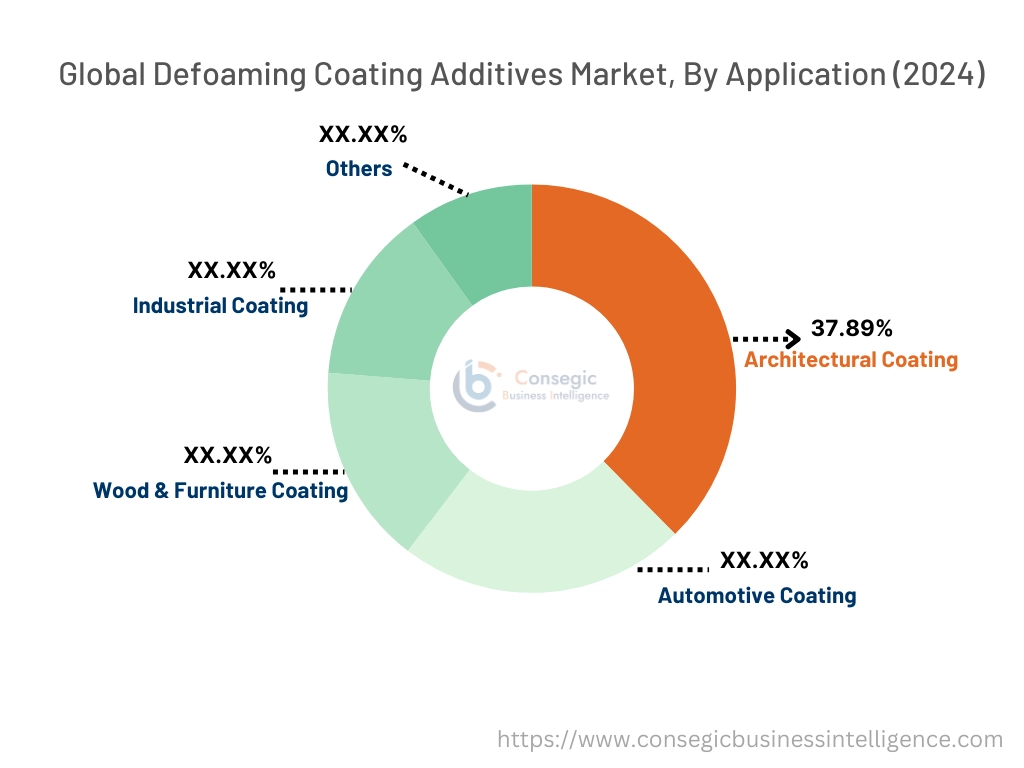

By Application:

Based on application, the market is categorized into architectural coating, automotive coating, wood & furniture coating, industrial coating, and others.

Trends in the Application:

- There is growing trend of architectural coatings with high durability, that withstand various weather conditions and maintain their appearance over time.

- The automotive sector is increasingly focusing on lightweighting to improve fuel efficiency. This trend is driving the development of defoamers that are compatible with lightweight coating materials.

The architectural coating segment accounted for the largest market share of 37.89% in 2024.

- Architectural coating represents the largest application segment within the market

- These coatings encompass a wide range of products, including interior and exterior paints, primers, and varnishes, all of which require defoaming additives to ensure smooth application and appropriate finish.

- Need for architectural coatings is driven by construction activity, with rise in residential and commercial building directly impacting consumption. Rise in renovation and remodeling projects also contribute significantly.

- For instance, according to the Renovation Nation Report provided by Money Co UK, it is stated that over 77% of UK homeowners spent money on changing or improving their properties in 2021. The average UK homeowner spent an average of USD 1,593.19 on home renovations.

- Increasing consumer and business requirement for durable coatings in renovation and remodeling projects necessitates performance-enhancing additives such as defoamers, boosting market growth.

- This analysis positions the architectural coating as a application segment within the dynamic demand for defoaming additives.

The industrial coating segment is expected to grow at the fastest CAGR in forecast years.

- Industrial coatings are specialized formulations designed for robust protection in harsh environments and demanding applications.

- These coatings are used in manufacturing, transportation, and infrastructure to protect equipment and structures from corrosion, chemicals, and harsh environments. This segment includes coatings for machinery, pipelines, bridges, and more.

- Their primary function is protecting substrates from corrosion, abrasion, chemicals, weathering, and other damage, extending the lifespan of equipment, machinery, and structures.

- The development of the manufacturing sector globally contributes to the increased use of industrial coatings. This need for high-performance coatings drives the need for effective defoaming additives.

- Thus, based on the defoaming coating additives market analysis, the aforementioned factors contribute to industrial coating as fastest growing application.

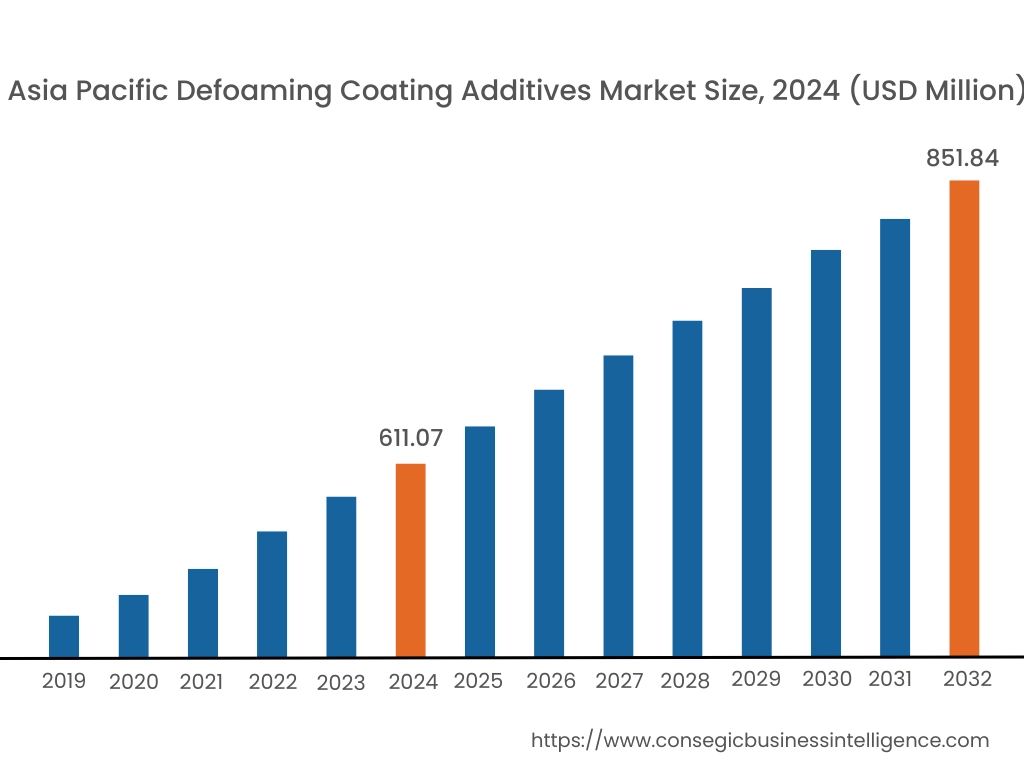

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

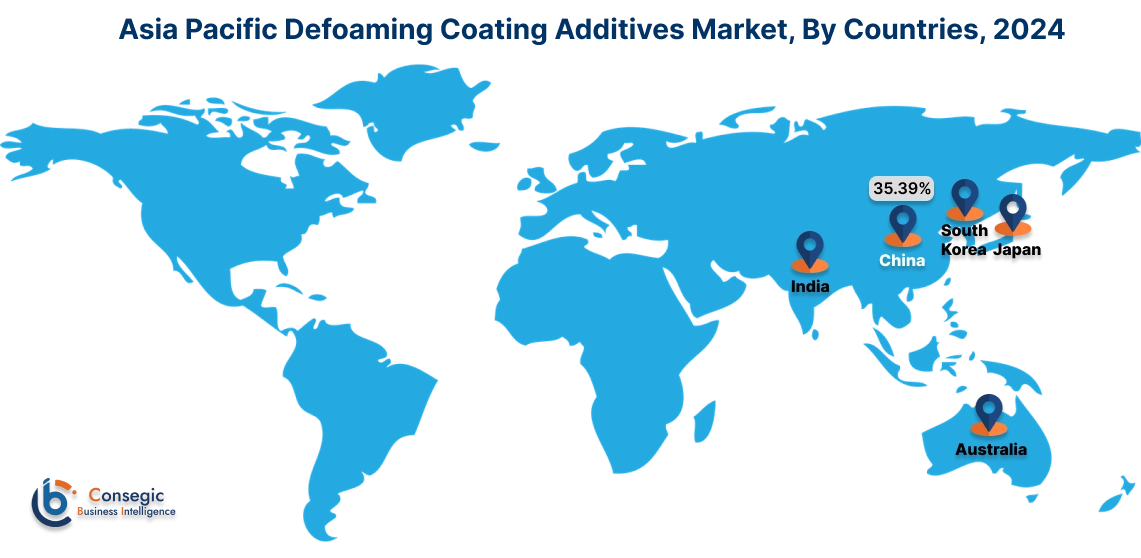

In 2024, Asia Pacific accounted for the highest Defoaming Coating Additives market share at 40.08% and was valued at USD 611.07 Million and is expected to reach USD 851.84 Million in 2032. In Asia Pacific, the China accounted for the largest share of 35.39% during the base year of 2024.

Asia Pacific dominates the global defoaming coating additives market, primarily due to the rapidly accelerating automotive manufacturing in countries such as China, India, and South Korea. Governments in the region are promoting infrastructure development and automotive manufacturing, further boosting the automotive coatings sector. This need for automotive coatings consequently creates the high adoption of defoamers.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with 11.6% year-on-year growth.

Additionally, the region's focus on lightweight materials and fuel-efficient vehicles is driving the requirement for specialized coatings further supporting the development of specialized defoamers. The combination of the aforementioned factors is driving the defoaming coating additives market trend in Asia Pacific region.

In Europe the defoaming coating additives market analysis is experiencing the fastest growth with a CAGR of 7.57% over the forecast period. Shift towards development of waterborne coatings is creating defoaming coating additives market growth in Europe. European consumers and businesses are highly conscious of environmental issues. This high awareness results in a preference for eco-friendly products, including coatings with low VOC content. Waterborne coatings align with this need. This results in the increasing utilization of water-based defoamers for coating tailored for waterborne coating formulations, further enhancing their performance and applicability. As a result, key players are focusing on developing water-based defoamers for coating further supporting defoaming coating additives market opportunities in Europe.

The increasing focus on using sustainable coatings in the construction sector is one of the primary factors creating upward market trajectory across North America. Growing construction activity, encompassing both new projects and renovations of existing structure fuels a consistent requirement for highly durable coatings. Furthermore, the region's increasing emphasis on high-performance coatings, driven by consumer expectations and industry standards, necessitates the use of specialized additives like defoamers to achieve desired finishes and durability. In addition to this, North America's strong focus on sustainability is supporting the defoaming coating additives market demand. This commitment to environmentally responsible practices is influencing a marked shift towards bio-based defoamers derived from renewable resources.

The rise in the adoption of industrial coatings is a prominent trend that drives the defoaming coating additives market trend in the Middle East and Africa. Many countries in the MEA region are experiencing industrialization with investments in manufacturing, infrastructure, and energy sectors. This rise in industrial activity leads to increased requirement for protective coatings to safeguard machinery, equipment, and structures. The MEA region presents established oil and gas sector. This sector relies heavily on industrial coating to protect pipelines, storage tanks, offshore platforms, and other equipment from harsh environmental conditions. The ongoing activities in this sector create a consistent demand for defoaming additives. Consequently, the above-mentioned factors support the market in MEA.

The Latin America sector is led by the rising adoption of coatings in wood and furniture applications. Latin America has a growing furniture manufacturing sector, both for domestic consumption and export. As this sector expands, it creates the need for coatings to protect and enhance wood products. Coatings are essential for achieving the desired aesthetic appeal of wood furniture, including color, gloss, and finish. Consumers are increasingly demanding high-quality finishes on their wood furniture, driving manufacturers to use advanced coating technologies and additives. Owing to these factors, the defoaming coating additives market opportunities in Latin America are growing at a considerate rate.

Top Key Players and Market Share Insights:

The global Defoaming Coating Additives Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Defoaming Coating Additives market. Key players in the Defoaming Coating Additives industry include-

- Allnex GMBH (Germany)

- BYK (Germany)

- BASF SE (Germany)

- Milliken & Company (United States)

- CHT Group (Germany)

Recent Industry Developments :

Product Launches:

- In November 2024, Evonik introduced TEGO Foamex 16 and TEGO Foamex 11 for waterborne architectural coatings. Both the defoamers have very low VOC and SVOC content and do not contain solvents or mineral oils.

- In June 2023, Elementis announced launch of DAPRO® BIO 9910. This new defoamer with 96% biobased carbon content is designed to add more sustainability and performance in coatings.

Defoaming Coating Additives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,310.11 Million |

| CAGR (2025-2032) | 5.4% |

| By Type |

|

| By Technology |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Defoaming Coating Additives market? +

In 2024, the Defoaming Coating Additives market is USD 1,524.62 Million.

Which is the fastest-growing region in the Defoaming Coating Additives market? +

Europe is the fastest-growing region in the Defoaming Coating Additives market.

What specific segmentation details are covered in the Defoaming Coating Additives market? +

By Type, Technology, and Application segmentation details are covered in the Defoaming Coating Additives market.

Who are the major players in the Defoaming Coating Additives market? +

Allnex GMBH (Germany), BYK (Germany), Syensqo (Belgium), Evonik (Germany) are some of the major players in the market.