Cured-in-place Pipe Market Introduction :

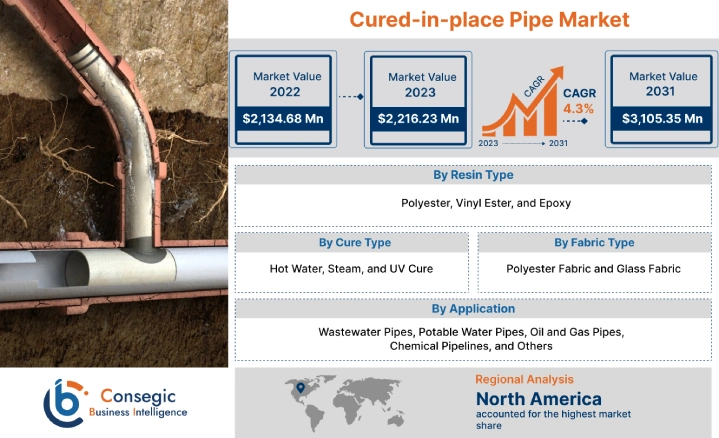

Consegic Business Intelligence analyzes that the Cured-in-place Pipe Market size is estimated to reach over USD 3,154.06 Million by 2032 from a value of USD 2,259.18 Million in 2024 and is projected to grow by USD 2,315.17 Million in 2025, growing at a CAGR of 4.30% from 2025 to 2032.

Cured-in-place Pipe Market Definition & Overview :

Cured-in-place pipe (CIPP) is a trenchless technology used to repair existing pipelines. It involves inserting a resin-impregnated liner into the existing pipe and then curing the resin to form a new pipe within the old one. CIPP is a jointless, seamless pipe lining that can be used to repair a variety of pipe defects, including cracks, holes, leaks, corrosion, root intrusion, and joint failure. It can also be used to repair pipes of different materials, including cast iron, concrete, clay, and plastic.

The technology is particularly well-suited for repairing pipes in areas where excavation is difficult or disruptive, such as under roads, buildings, and rivers. It can also be used to repair pipes in environmentally sensitive areas. It is a versatile and effective trenchless technology that can be used to repair a wide variety of pipes in a variety of applications.

Cured-in-place Pipe Market Insights :

Key Drivers :

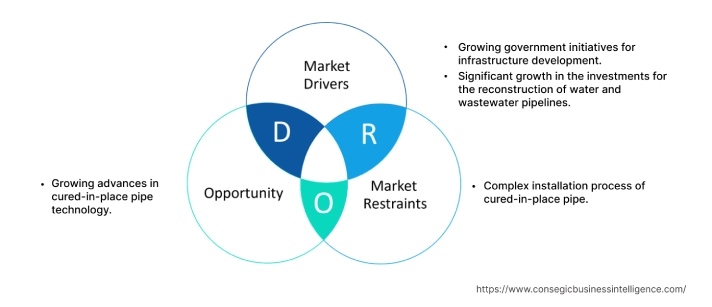

Growing government initiatives for infrastructure development Drives the Market Growth

Cured-in-place pipe is a cost-effective and sustainable solution for infrastructure development. It offers a number of advantages over traditional open-cut trenching methods. Governments around the world are investing heavily in infrastructure development to improve the quality of life for their citizens and to boost economic growth. Based on the analysis, this includes investments in pipeline rehabilitation, as pipelines are essential for delivering water, wastewater, and other essential services to communities. for instance, in September 2023, the US Environmental Protection Agency (EPA) awarded USD 7.5 billion in grants to communities to help them repair and rehabilitate their drinking water, wastewater, and stormwater infrastructure.

Furthermore, in November 2021, the European Union (EU) has also invested heavily in water and wastewater infrastructure development. The EU's Water Framework Directive requires all EU member states to achieve good ecological status for their water bodies by 2027. CIPP is playing an important role in helping EU member states meet this goal. Thus, the increasing focus of governments around the world for the invest in infrastructure development is driving the market for this technology globally.

Significant growth in the investments for the reconstruction of water and wastewater pipelines Fuels the Market Progress

Water and wastewater pipelines are essential for public health and safety, and they play a vital role in economic development. However, many water and wastewater pipelines around the world are aging and in need of repair or replacement. As per the analysis, this is due to several factors, including the long service life of pipelines, the corrosive effects of water and wastewater, and the increasing frequency of extreme weather events. the increasing investments in the development of water and wastewater pipeline network is driving the cured-in-place pipe market demand. For instance, in June 2021, The Biden-Harris administration invested USD 307 million to modernize rural drinking water and wastewater infrastructure in 34 states and Puerto Rico. The investment was announced by Agriculture Secretary Tom Vilsack. Furthermore, in December 2022, The Government of India and Asian Development Bank (ADB) today signed a USD 125 million loan to develop climate-resilient sewage collection and treatment, and drainage and water supply systems in three cities in the state of Tamil Nadu. Thus, the rise in investments for the reconstruction of water and wastewater pipeline systems is a major driver of the cured-in-place pipe market.

Key Restraints :

Complex installation process of cured-in-place pipe Hinders the Market Development

The installation process can be complex and challenging, especially for pipes with complex geometries or in difficult-to-access locations. This can make it difficult to find qualified this technology contractors and can increase the cost of this material installation. The liners are typically made from a resin-impregnated fabric. Based on the analysis, the complexity of the installation process is also a barrier to entry for new companies that are interested in entering the cured-in-place pipe market. Companies that want to offer these services need to invest in specialized equipment and training for their employees. This can be a significant investment, especially for small businesses. Moreover, the installation is a multi-step process that requires specialized equipment and expertise. This can make it difficult and expensive to find qualified contractors. thus, all these factors are hampering the trend of the global cured-in-place pipe market across the globe.

Future Opportunities :

Growing advances in cured-in-place pipe technology Opens New Doors

Cured-in-place pipe industry has advanced significantly in recent years. This has resulted in the development of new products and installation methods that are even more efficient and cost-effective. The advances in manufacturing technology are also making it possible to use cured-in-place to repair a wider range of pipe defects. According to the analysis, the increasing advances in the technologies for cured-in-place is expected to drive the market growth. For instance, in February 2020, Advanced Pipe Repair, a Texas-based commercial plumbing company, announced new UV cured-in-place pipe methods. This method, also known as LED or Light-Emitting Diode cured-in-place pipe is a process that uses UV curing technology to create a stronger, longer-lasting pipe. Thus, increasing innovation in the this technology is expected to create lucrative opportunities and trends for expansion over the forecast period.

Cured-in-place Pipe Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,154.06 Million |

| CAGR (2025-2032) | 4.3% |

| By Resin Type | Polyester, Vinyl Ester, and Epoxy |

| By Cure Type | Hot Water, Steam, and UV Cure |

| By Fabric Type | Polyester Fabric and Glass Fabric |

| By Application | Wastewater Pipes, Potable Water Pipes, Oil and Gas Pipes, Chemical Pipelines, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Aegion Corporation, Norditube Technologies, IMPREG LLC, LMK Technologies, Relining Group, SAERTEX, SEKISUI SPR AMERICAS, LLC, CIPP Corporation, PMPS Liner Technology Limited, Trelleborg Sealing Profiles Sweden AB, Arvind Composite, RTi Rohrtechnik Gruppe, Waterline Renewal Technologies, and Vortex Companies |

Cured-in-place Pipe Market Segmental Analysis :

Based on the Resin Type :

The type is categorized into polyester, vinyl ester, and epoxy. In 2024, the polyester segment accounted for the highest market share in the cured-in-place pipe market, and it is also expected to grow at the highest CAGR over the forecast period. Polyester resin is the most cost-effective of the three resin types. This makes it a popular choice for various infrastructure projects, especially in budget-constrained applications. Polyester resin offers good mechanical properties, chemical resistance, and durability. This makes it suitable for a wide range of applications, including the rehabilitation of water and wastewater pipes, oil and gas pipelines, and transportation pipelines. Furthermore, as per the analysis, polyester resin is easy to install and cure. This makes it a good choice for the contractors, as it can help to reduce the time and cost of these projects. Thus, the cost-effectiveness, good performance, and ease of installation of polyester resins is driving the segment expansion and trend across the globe.

Based on the Cure Type :

The cure type segment is categorized into hot water, steam, and UV cure. In 2024, the steel curing segment accounted for the highest market share in the overall cured-in-place pipe market. Steam cured-in-place pipe has a faster curing time than other curing methods, such as hot water curing and UV curing. This makes it ideal for projects where time is critical. the liners of these cure types offer better performance than other liners cured using other methods. Steam cured-in-place pipe liners are stronger, more durable, and have better adhesion to the existing pipe. This cure type is increasingly used to rehabilitate oil and gas pipelines. This is because steam liners are resistant to the corrosive chemicals found in oil and gas pipelines. Based on the analysis, the increasing investment for the refinery upgrade is also driving the segment expansion across the globe. For instance, in June 2020, Iraq's oil ministry announced plans to upgrade the country's 20,000 b/d Qayyarah refinery, with the aim of adding a second 70,000 b/d. Thus, the high benefits of steam curing over other cure type and increasing initiative for oil refinery development is driving the segment expansion.

Based on the Fabric Type :

The polyester fabric segment is categorized into polyester fabric and glass fabric. In 2024, the polyester fabric segment accounted for the highest revenue in the overall cured-in-place pipe market. The increasing steel production across various parts of the globe is driving the segment expansiom worldwide. Polyester fabric is the most popular fabric for these technology liners due to its cost-effectiveness, good performance, ease of installation, and high popularity. Polyester fabric offers good mechanical properties, chemical resistance, and durability. the increasing innovations in polyester fabrics are driving the segment expansion across the globe. For instance, in November 2021, Toray Industries, Inc. announced the development of Qile, a polyester filament fabric. The fabric combines the structure of hair and wool with a smooth and supple texture and functionality. Thus, the high benefits of polyester fabrics and increasing innovations in polyester fabric are driving the segment rise globally.

Moreover, the glass fabric segment is expected to hold the highest CAGR over the forecast period. Glass fabric has superior performance characteristics compared to polyester fabric; the most common fabric used in these liners. Glass fabric has higher tensile strength, better chemical resistance, and a longer service life than polyester fabric. This makes glass fabric a better choice for demanding for these applications, such as the rehabilitation of pipes in corrosive environments or in areas with high temperatures. The superior performance characteristics are creating lucrative cured-in-place pipe market opportunities and trends over the forecast period.

Based on the Application :

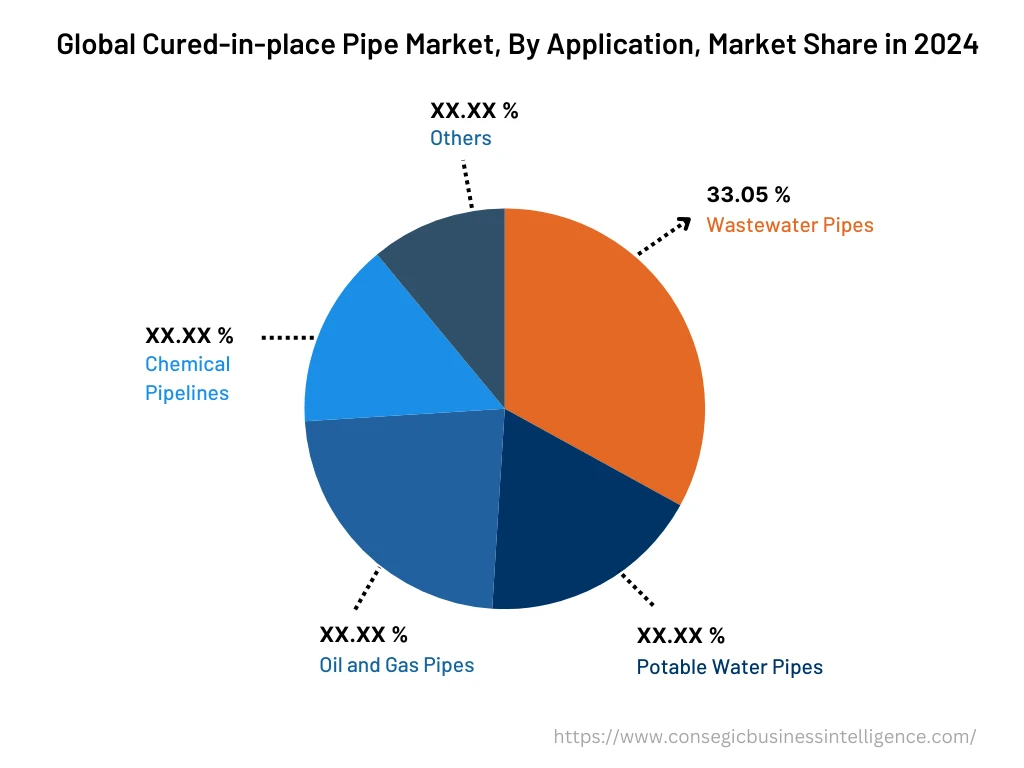

The application segment is categorized into wastewater pipes, potable water pipes, oil and gas pipes, chemical pipelines, and others. In 2024, the wastewater pipes segment accounted for the highest market share of 33.05% in the overall cured-in-place pipe market. The increasing launch of new wastewater treatment projects across the globe is driving the demand for these for wastewater pipe application. For instance, in June 2021, The Los Angeles County Sanitation Districts announced USD the launch of 630 million project to replace two aging wastewater pipes under the South Bay and Harbor Area in California. The project is estimated to be completed in December 2026. Thus, the significant development in such a project is creating a lucrative trend and driving the segment growth across the globe.

Moreover, the oil and gas pipes segment is expected to hold the highest CAGR over the forecast period. It is a versatile element that has several applications in solar energy. the increasing oil and gas pipeline projects are expected to drive the segment expansion. For instance, in August 2023, Argentina's Energy Secretary Flavia Rayon announced the launch of the project to convert a pipeline in northern Argentina. The project will transport natural gas north from the Vaca Muerta shale play. The growing initiative for oil and gas transportation is creating lucrative opportunities and trends for these elements for oil and gas pipes application over the forecast period.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

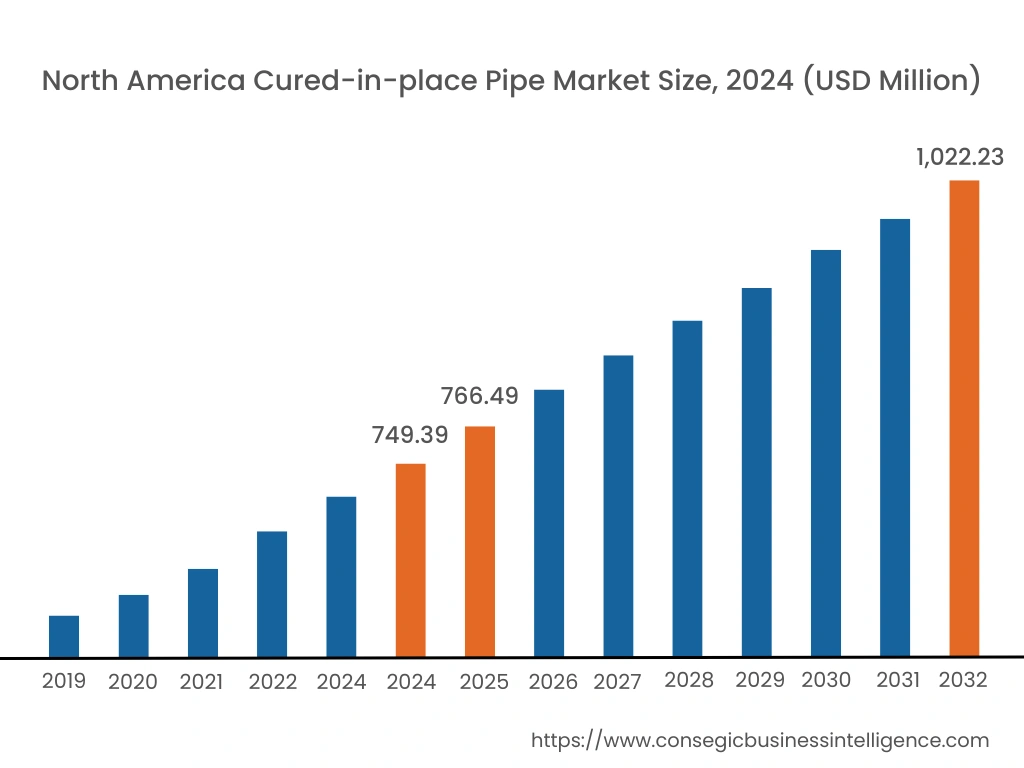

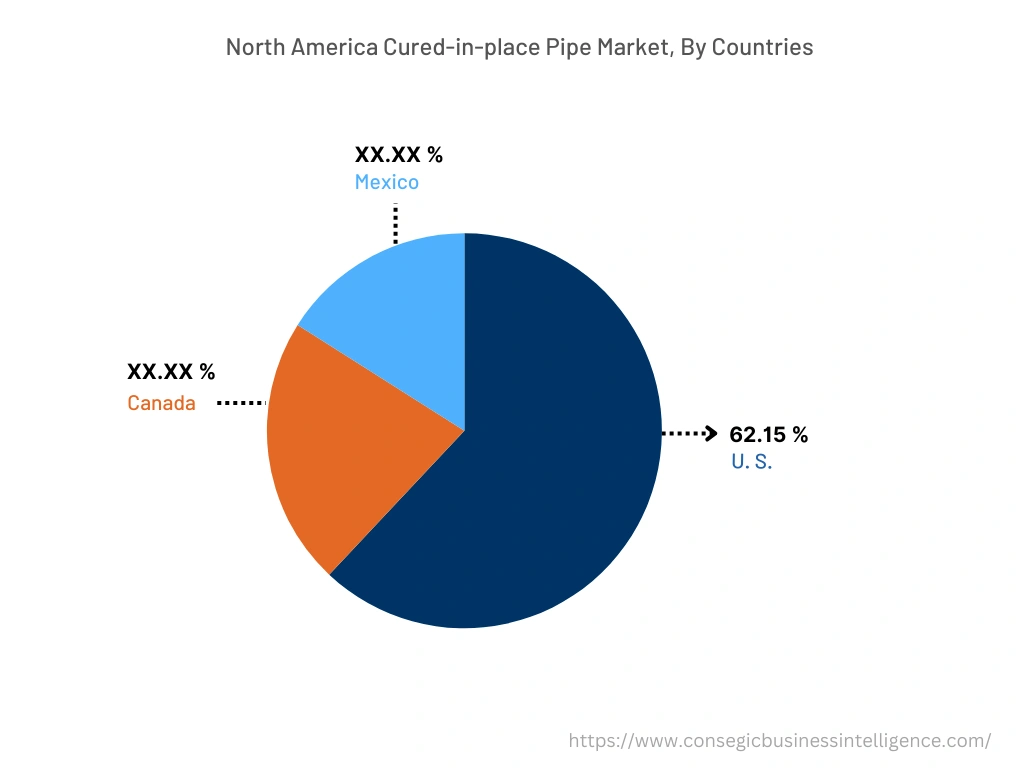

North America is estimated to reach over USD 1,022.23 Million by 2032 from a value of USD 749.39 Million in 2024 and is projected to grow by USD 766.49 Million in 2025. In North America, the U.S. accounted for the highest cured-in-place pipe market share of 62.15% in the base year 2024. North America has a large and aging pipeline infrastructure that needs to be rehabilitated. These elements are a popular choice for pipeline rehabilitation in North America because it is a trenchless technology that can be used to repair pipes without the need for disruptive excavation. The increasing number of pipe rehabilitation projects across the region is driving market demand and the cured-in-place pipe market trend across North America. For instance, in June 2022, The City of Concord Water Resources Department contract crews announced the launch annual Sewer Cured in Place Pipe (CIPP) Lining project. The project helps to improve the durability of a city's infrastructure. The project involves inserting a resin-saturated tube into an existing pipe and then curing it using UV light. The cured material bonds tightly to the inner walls of the existing pipe, creating a pipe within a pipe. This rehabilitated pipe restores the integrity and water flow of the original pipeline. thus, the increasing launch of such projects are driving the cured-in-place pipe market growth across the North America region.

Furthermore, the Asia Pacific region is expected to witness significant development over the forecast period, growing at a CAGR of 4.9% during 2025-2032. As per the cured-in-place pipe market analysis, this growth is being driven by the rapid urbanization and industrialization in Asia, which is leading to increased demand for water and wastewater infrastructure industry. In May 2022, Singapore announced the expansion of its recycling system. It is planning to invest around USD 7.4 billion in upgrading its water treatment infrastructure. It also plans to add an underground tunnel and a major water reclamation plant to serve the western half of the island. Thus, the significant growth in wastewater infrastructure development is expected to create opportunities and trends in the etanercept market over the forecast period.

Top Key Players & Market Share Insights :

The global cured-in-place pipe market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market revenue through mergers, acquisitions, and partnerships. The key players in the market include-

- Aegion Corporation

- Norditube Technologies

- Trelleborg Sealing Profiles Sweden AB

- Arvind Composite

- RTi Rohrtechnik Gruppe

- Waterline Renewal Technologies

- Vortex Companies

- IMPREG LLC

- LMK Technologies

- Relining Group

- SAERTEX

- SEKISUI SPR AMERICAS, LLC

- CIPP Corporation

- PMPS Liner Technology Limited

Recent Industry Developments :

- In June 2022, Aegion Corporation announced the acquisition of EN-TECH Corporation's cured-in-place pipe (CIPP) lining division. Aegion is a leading provider of infrastructure maintenance, rehabilitation, and technology-enabled water solutions.

- In November 2020, Vortex Companies, LLC, the nation's fastest growing trenchless infrastructure solutions provider, launched Vortex Technology Group, LLC to support its recent acquisition of proprietary Cured-In-Place-Pipe sensor technology developed to verify the curing process of the popular relining system.

Key Questions Answered in the Report

What was the market size of the cured-in-place pipe market in 2024? +

In 2024, the market size of cured-in-place pipe was USD 2,259.18 million.

What will be the potential market valuation for the cured-in-place pipe industry by 2032? +

In 2032, the market size of cured-in-place pipe will be expected to reach USD 3,154.06 million.

What are the key factors driving the growth of the cured-in-place pipe market? +

Growing government initiatives for infrastructure development across the globe are fueling market growth at the global level.

What is the dominant segment in the cured-in-place pipe market for the application? +

In 2024, the wastewater pipes segment accounted for the highest market share of 33.05% in the overall cured-in-place pipe market.

Based on current market trends and future predictions, which geographical region is the dominating region in the cured-in-place pipe market? +

North America accounted for the highest market share in the overall market.