- Summary

- Table Of Content

- Methodology

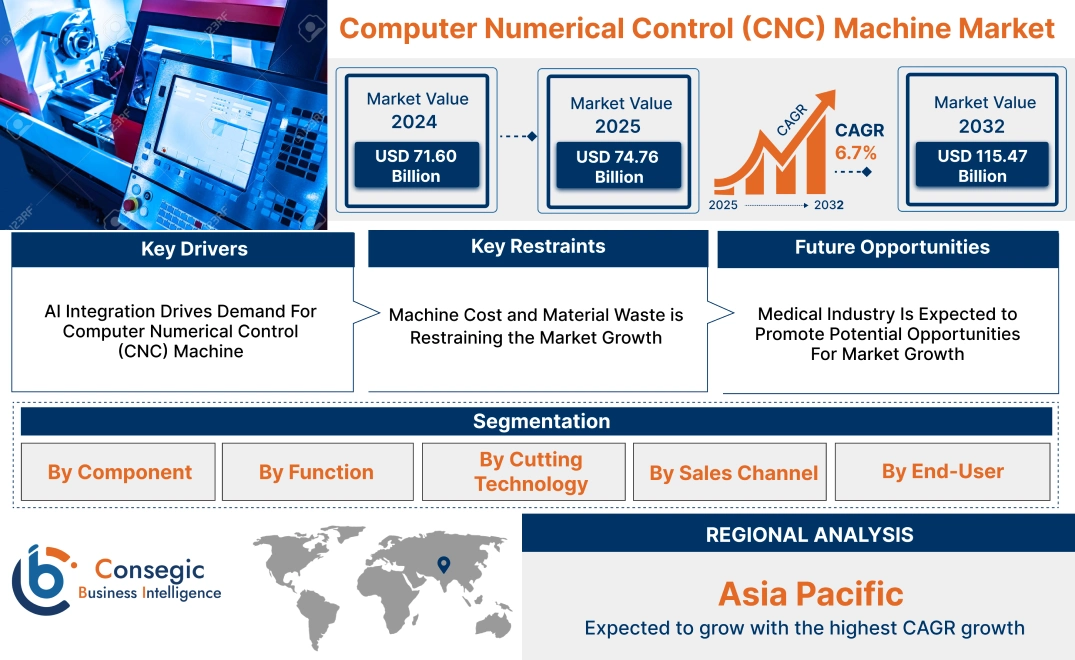

Computer Numerical Control (CNC) Machine Market Size:

Computer Numerical Control (CNC) Machine Market is estimated to reach over USD 115.47 Billion by 2032 from a value of USD 71.60 Billion in 2024 and is projected to grow by USD 74.76 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

Computer Numerical Control (CNC) Machine Market Scope & Overview:

Computer numerical control (CNC) machine is an automatic technology that dictates the movement of factory tools and machinery.The machine is segmented into hardware, software and services in which hardware operates various components via numerical control. Also, various functions in the machine are pre-programmed with the help of software which determines the functioning of machine. Additionally, the machine is utilized in applications such as part manufacturing, carving and decoration, mold manufacturing, part finishing and automating production processes among others. Moreover, the key benefits of adopting these machines include improved accuracy, enhanced precision, scalability, versatility, speed, enhanced capabilities, and reduced dependability among others in turn boosting the computer numerical control (CNC) machine market demand. Further, superior efficiency and production rate drives the computer numerical control (CNC) machine market growth.

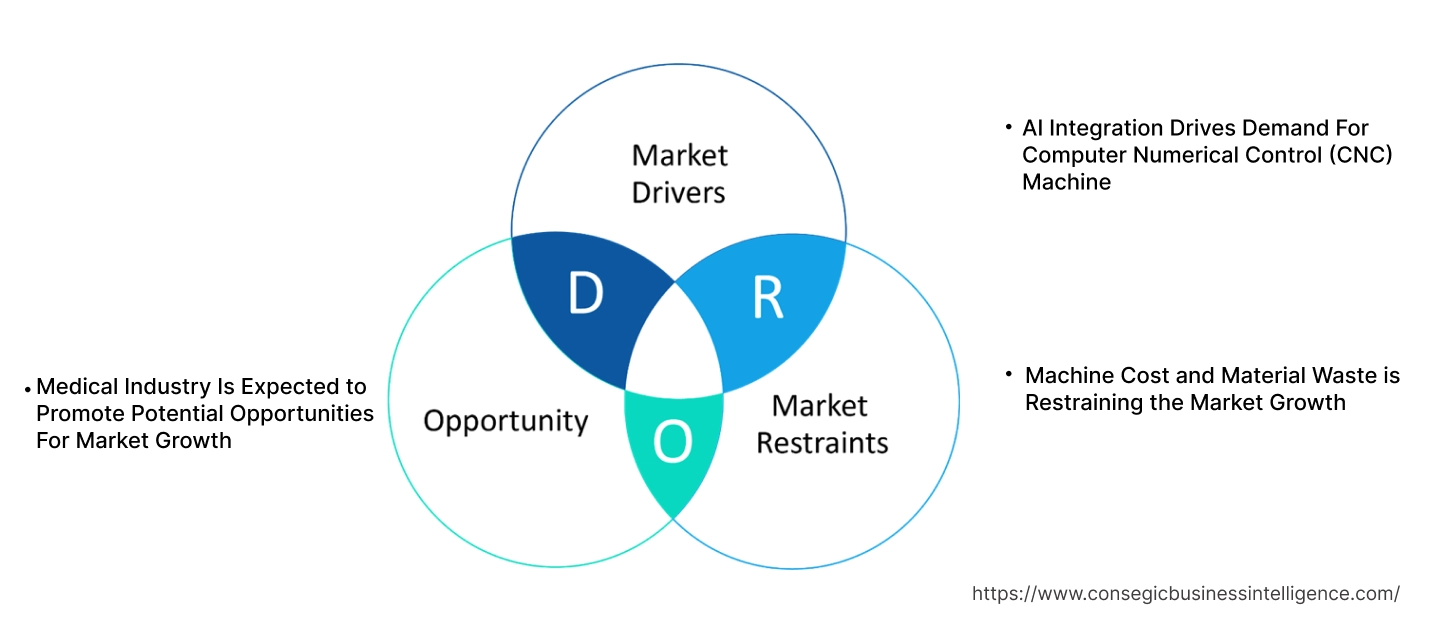

Key Drivers:

AI Integration Drives Demand For Computer Numerical Control (CNC) Machine

Integration of AI into computer numerical control machine significantly enhances efficiency, performance, and cost-effectiveness which drives the computer numerical control (CNC) machine market growth. Additionally, the AI integration helps in real time data analysis which significantly improves maintenance procedures, potentially resulting in considerable cost and time savings for manufacturers. Further, AI enables greater flexibility in production, allowing for more customized designs in turn boosting the computer numerical control (CNC) machine market demand.

- For instance, in October 2024, Hurco Companies, Inc. launched control software for CNC control technology by leveraging emerging AI technology directly into the software.

Therefore, the ability to enhance efficiency, performance, and cost-effectiveness is driving the integration of AI into the machine, in turn proliferating the growth of the market.

Key Restraints:

Machine Cost and Material Waste is Restraining the Market Growth

CNC machine involves the process of removing materials for creating finished products resulting in material wastage, which in turn is hindering the computer numerical control (CNC) machine market expansion. Also, the machine leverages advanced technology precision engineering, thus increasing the cost of the machine, hampering the adoption in small and medium-sized businesses. Further, unexpected breakdowns lead to high maintenance cost and downtime, hence impeding the computer numerical control (CNC) machine market expansion.

Therefore, the high costs of machine and increased material wastage in the manufacturing of components are restraining the market growth.

Future Opportunities:

Medical Industry Is Expected to Promote Potential Opportunities For Market Growth

The medical devices and components are advancing rapidly due to increased accuracy and efficiency in manufacturing is driving the computer numerical control (CNC) machine market opportunities. Additionally, the key features driving the adoption of these machines in medical sector include increased production volume, high precision and accuracy, versatility and others is driving the adoption of these machines. Further, These machines are leveraged in various medical applications such as prosthetics and orthotics, medical implants, and surgical instruments among others is also expected to propel the computer numerical control (CNC) machine market opportunities.

- For instance, in December 2024, Tuofa CNC Machining expanded the services focus towards medical industry by delivering high-quality medical parts. Also, the company supports a wide range of medical products, such as implants, surgical tools, diagnostic devices, and more.

Hence, the rising adoption in medical sector is anticipated to increase the utilization of these machines in turn promoting prospect for market development.

Computer Numerical Control (CNC) Machine Market Segmental Analysis :

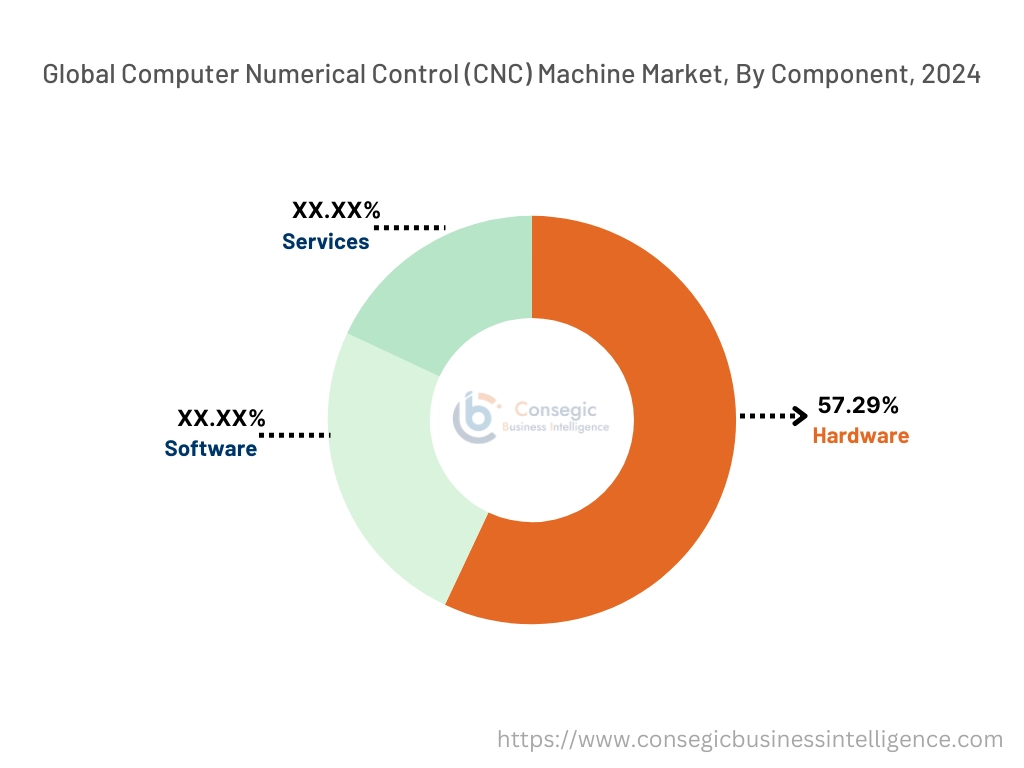

By Component:

Based on the component, the market is segmented into hardware, software and services.

Trends in the Component:

- The CNC control unit are increasingly leveraging high-speed interpolation technology for continuous feeding of small program segments fueling the computer numerical control (CNC) machine market trend.

- Industrial sector leveraging digital twins to gather more insight into the performance of machines and processes.

Hardware accounted for the largest revenue share of 57.29% in the year 2024.

- The hardware components in these machines collectively works together to perform precise machining tasks.

- The major hardware components include central processing unit (CPU), input devices, machine control panel, display unit, programmable logic controller (PLC) and others.

- Furter, the rising demand for ensuring precision and accuracy in every operation is driving the adoption of machine control unit which drives the computer numerical control (CNC) machine market size.

- Furthermore, the integration of AI into machines for improving efficiency and precision as well as creates data base for predictive maintenance is driving the computer numerical control (CNC) machine market share.

- For instance, in March 2024, FANUC America Corporation launched PLC/CNC motion controller. The controllers have the ability to run multiple programs simultaneously and independently by controlling multiple pieces of industrial equipment.

- Thus, according to the computer numerical control (CNC) machine market analysis, integration of AI into the machines is driving the hardware segment.

Services are anticipated to register the fastest CAGR during the forecast period.

- The services segment consists of maintenance, support and training, consulting and others.

- Moreover, the advantages of predictive maintenance include cost saving, safety improvements, improved quality, reduced downtime and improved reliability among others is driving the demand for maintenance services.

- Further, the support and training services increases employee performance, reduces costs associated to errors, and others is driving the services segment which in turn propels the computer numerical control (CNC) machine market size.

- Therefore, according to the computer numerical control (CNC) machine market analysis, the ability to improve performance, efficiency and reduce downtime are anticipated to boost the market during the forecast period.

By Function:

Based on the function, the market is segmented into milling, turning, grinding, routing, boring, punching and others.

Trends in the Function:

- Advancements in achieving superior surface finishes are driving the progress of grinding function which in turn fuels the computer numerical control (CNC) machine market trend.

- Automation and robotics adoption in these machines for performing automated tasks such as routing, boring and other is driving the market progress.

The milling function accounted for the largest revenue share in the year 2024 and is anticipated to register the fastest CAGR during the forecast period.

- The milling function in machine is widely utilized in aerospace, automotive, and electronics sectors for producing high-quality components with minimal human intervention.

- Moreover, the machines with milling function range from simple 3-axis machines to more complex 5-axis models for improving precision and accuracy which in turn is driving the computer numerical control (CNC) machine market share.

- Further, the companies key focus towards reducing these machine size and weight is fueling market progress. Additionally, companies are integrating AI into machines to minimize waste and enhance precision of component manufactured is driving the market progress for milling function.

- For instance, in September 2022, Bantam Tools launched desktop CNC machine which has a key function of milling and weight less than 50 pounds making it a portable solution for milling function.

- Thus, as per the market analysis, integrating AI into the machines is driving the CNC milling machines adoption which in turn is fueling the market progress.

By Cutting Technology:

Based on the cutting technology, the market is bifurcated into water and laser.

Trends in the Cutting Technology:

- The increased power and speed with accuracy is driving the adoption of laser cutting technology in the market.

- The increasing focus towards sustainability and ecofriendly solution is driving the adoption of water-based technology in the market.

The water based machine accounted for the largest revenue share in the year 2024.

- The water based machines are utilized in cutting metals, composites, plastics and rubbers among others.

- Moreover, the water based cutting technology is majorly utilized in industries such as aerospace, automotive, medicine, electronics and others is driving the market development.

- Further, the key factor driving the adoption of water based machines include no heat-affected zones, preserves material integrity, precision, and versatility among others.

- For instance, in November 2023, WAZER partnered with TriMech to sell and support by adding desktop CNC waterjet cutter into existing lineup of advanced design and manufacturing software, hardware, and services.

- Thus, as per the market analysis, aforementioned factors is driving the water based cutting technology segment.

Laser is anticipated to register the fastest CAGR during the forecast period.

- The laser based machines are utilized for cutting metals, plastics, rubbers and woods among others.

- Moreover, there are various types of laser cutter such as CO2, crystal and fiber among others for cutting specific materials in turn driving the market progress.

- Further, the machine is utilized in automotive sector for precise shaping of sheet metal parts and others. Also, laser cutting machines are utilized for production of surgical tools, medical devices, and other materials in healthcare sector.

- Therefore, the rising adoption in automotive and healthcare sector is anticipated to boost the market during the forecast period.

By Sales Channel:

Based on the sales channel, the market is bifurcated into direct and indirect.

Trends in the Sales Channel:

- The trend towards digital sales and growing e-commerce businesses is driving the progress of indirect sales channel.

- The trend towards customization in machines is driving the adoption of direct sales channels in the market.

Direct sales accounted for the largest revenue share in the year 2024.

- The model involves personal selling, through online or offline stores, with vendors engaging directly with buyers.

- Further, digital revolution plays a significant role in influencing direct sales of machines in various end use sectors.

- Furthermore, subscription-based models are gaining popularity across a variety of industries is driving the direct sales channel in the market.

- Thus, as per the market analysis, digital revolution and subscription-based models is driving the direct sales segment.

Indirect Sales is anticipated to register the fastest CAGR during the forecast period.

- Indirect sales involve resellers, brokers, and distributors to generate new sales. Also, businesses leverage indirect sales channel to allow scale quickly and efficiently by keeping costs down.

- Moreover, the key factor driving the adoption of indirect sales channel involves expanded reach, reduced cost and overheads, knowledge, relationships, and resources among others.

- Further, businesses leverage indirect sales channel to provide full solution package as well as close deals faster, which drives the indirect sales channel segment.

- For instance, EMEC Machine Tools Inc. is a leading distributor of Okuma America Corporation which is a CNC machine manufacturer. EMEC Machine Tools Inc both selling and servicing Okuma products and services.

- Therefore, the aforementioned key factors is anticipated to boost the market during the forecast period.

By End-User:

Based on the end-user, the market is segmented into automotive, aerospace, electronics, construction, healthcare, textiles, military and others.

Trends in the End-User:

- The increasing adoption of advanced brake system components is driving the adoption of market in automotive sector.

- The trend towards ensuring proper fit, stability and biocompatibility of medical component is driving the market progress.

Automotive accounted for the largest revenue share in the year 2024.

- The automotive sector leverage CNC Lathe Machines, CNC Milling Machines, CNC Drilling Machines, and CNC Grinding Machines among others for producing high-quality and consistent parts.

- Further, the increasing production and export of vehicles is in turn driving the adoption of these machines in the automotive sector.

- Furthermore, the rising adoption of electric vehicles is propelling the adoption of machine for precise cutting of various parts and panels utilized in the manufacturing of vehicles.

- For instance, according to IBEF, total automobile exports from India reached 47,61,487 units which include 36,52,122 units of two-wheelers in FY23.

- Thus, as per the market analysis, rising adoption of electric vehicles is driving the market adoption in automotive sector.

Healthcare is anticipated to register the fastest CAGR during the forecast period.

- The high level of precision and accuracy associated with machines is driving the adoption in medical sector.

- Moreover, the machines are utilized in manufacturing of implants, prosthetics, surgical instruments, and others in healthcare sector is driving the market progress.

- Further, ongoing advancements in technology and advancing materials are driving market progress. Additionally, stringent rules and regulations associated with the manufacturing of products utilized in the healthcare sector are boosting the computer numerical control (CNC) machine industry.

- Therefore, the ongoing advancements and rising adoption in various surgical tools is anticipated to boost the market during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 19.55 Billion in 2024. Moreover, it is projected to grow by USD 20.48 Billion in 2025 and reach over USD 32.70 Billion by 2032. Out of this, China accounted for the maximum revenue share of 34.5%. The market growth for machines is mainly driven by its deployment in automotive, electronics and other industries. Furthermore, factors including rising adoption of electric vehicles are projected to drive the market progress in Asia Pacific region during the forecast period.

- For instance, according to IBEF, Nissan and Renault planned to invest USD 600 million for expanding passenger cars and electric vehicles in India.

North America is estimated to reach over USD 37.61 Billion by 2032 from a value of USD 23.53 Billion in 2024 and is projected to grow by USD 24.55 Billion in 2025. The North American region's growing aerospace sector offer lucrative growth prospects for the market. Additionally, the progressing automotive sector is driving the market progress. Further, businesses leverage these machines to ease operations, enhance security and improve efficiency and precision among other is driving the adoption of market in North American region.

- For instance, in August 2024, FANUC America launched FANUC Series 500i-A CNC. The launch aims to provide easier operations, increase security and optimize efficiency.

The regional evaluation depicts that the increasing adoption of machines in healthcare sector is driving the market in Europe. Additionally, the primary factor driving the market is infrastructure development in the Middle East and African region. Further, the growing automotive and electronics sector is paving the way for the progress of market in Latin America region.

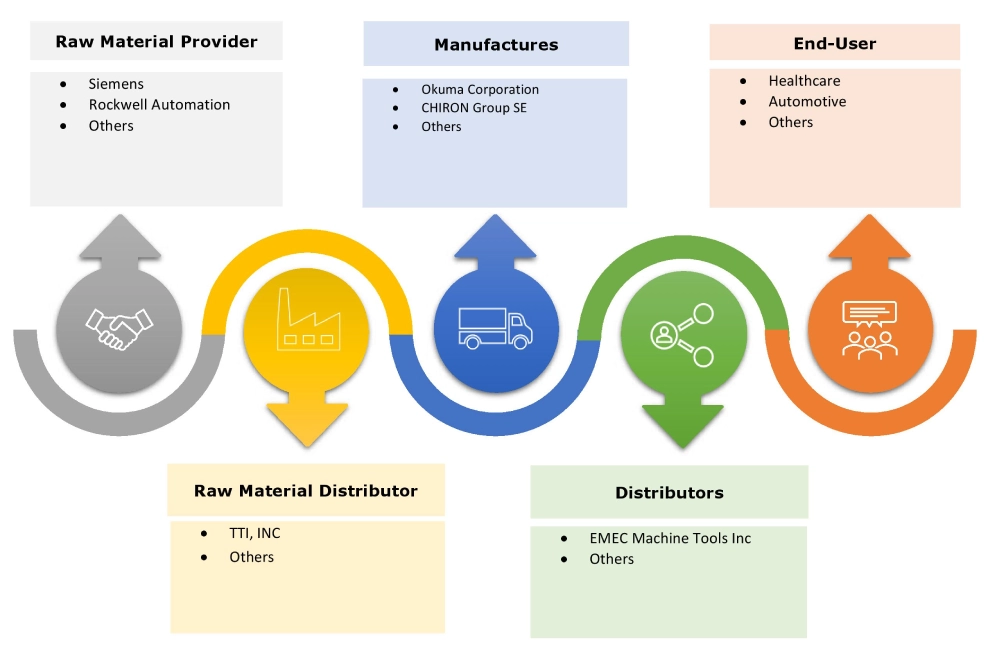

Top Key Players and Market Share Insights:

The global computer numerical control (CNC) machine market is highly competitive with major players providing computer numerical control (CNC) machine to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the computer numerical control (CNC) machine industry.Key players in the computer numerical control (CNC) machine market include-

- DMG MORI. (Japan)

- Waycon Manufacturing Ltd. (USA)

- FANUC America Corporation (USA)

- Trevisan Machine Tool. (USA)

- Jaewoo CNC Machine (India)

- Esprit Automation Ltd (UK)

- KTM Technology & Innovations (India) Pvt. Ltd. (India)

- Okuma Corporation (Japan)

- Makino Milling Machine Co., Ltd. (Japan)

- CHIRON Group SE (Germany)

Recent Industry Developments :

Product launches:

- In January 2023, Rockwell Automation, Inc. provided ThingWorx IIoT platform to Falcon Group, which is a Dubai based CNC company for enhancing machine utilization by 162.5%.

Fundings:

- In February 2024,Advantage Capital provided USD 3 million to Malone’s CNC Machining, Inc. The fund aims to support the purchase of new equipment and address working capital needs.

Computer Numerical Control (CNC) Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 115.47 Billion |

| CAGR (2025-2032) | 6.7% |

| By Component |

|

| By Function |

|

| By Cutting Technology |

|

| By Sales Channel |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the computer numerical control (CNC) machine market? +

The Computer Numerical Control (CNC) Machine Market is estimated to reach over USD 115.47 Billion by 2032 from a value of USD 71.60 Billion in 2024 and is projected to grow by USD 74.76 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

What specific segmentation details are covered in the computer numerical control (CNC) machine report? +

The computer numerical control (CNC) machine report includes specific segmentation details for component, function, cutting technology, sales channel, end-user, and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the computer numerical control (CNC) machine market, the healthcare sector is the fastest-growing segment during the forecast period due to ongoing advancements in technology and rising adoption in manufacturing of implants, prosthetics, surgical instruments, and others.

Who are the major players in the computer numerical control (CNC) machine market? +

The key participants in the computer numerical control (CNC) machine market are DMG MORI (Japan), Waycon Manufacturing Ltd. (USA), FANUC America Corporation (USA), Trevisan Machine Tool. (USA), Jaewoo CNC Machine (India), Esprit Automation Ltd (UK), KTM Technology & Innovations (India) Pvt. Ltd. (India), Okuma Corporation (Japan), Makino Milling Machine Co., Ltd. (Japan), CHIRON Group SE (Germany) and others.

What are the key trends in the computer numerical control (CNC) machine market? +

The computer numerical control (CNC) machine market is being shaped by several key trends including trend towards industrial sector leveraging digital twins to gather more insight into the performance of machines and processes and other are the key trends driving the market.