- Summary

- Table Of Content

- Methodology

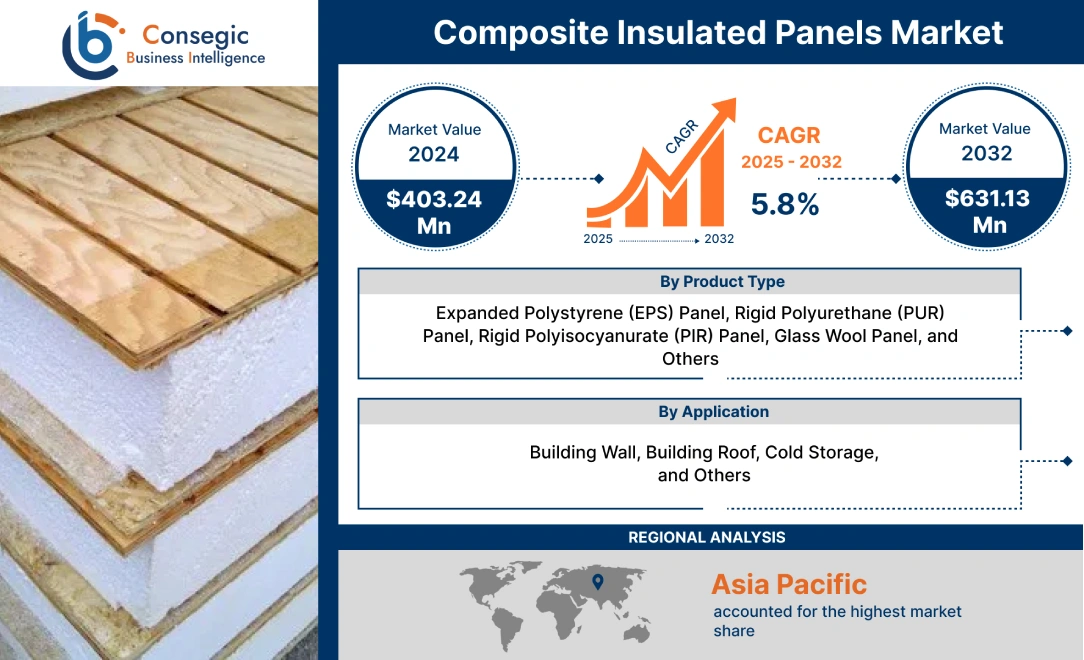

Composite Insulated Panels Market Size :

Consegic Business Intelligence analyzes that the composite insulated panels market size is growing with a healthy CAGR of 5.8% during the forecast period (2025-2032), and the market is projected to be valued at USD 631.13 Million by 2032 from USD 403.24 Million in 2024.

Composite Insulated Panels Market Scope & Overview:

Composite insulated panels are a construction material comprised of an insulation core sandwiched between two plastic facings or metal. The major product types of composite insulated panels include expanded polystyrene (EPS) panels, rigid polyurethane (PUR) panel, rigid polyisocyanurate (PIR) panel, and glass wool panel, among others. The primary benefits associated with composite insulated panels include superior thermal efficiency. The base of composite panels is effective for soundproofing. Moreover, the composite insulated panels are efficient for absorbing noises. This property makes composite insulated panels ideal for residential use, commercial construction, and drywall construction. As a result, composite insulated panels are an ideal option for various applications, including building walls, building roofs, cold storage, and others.

Composite Insulated Panels Market Insights :

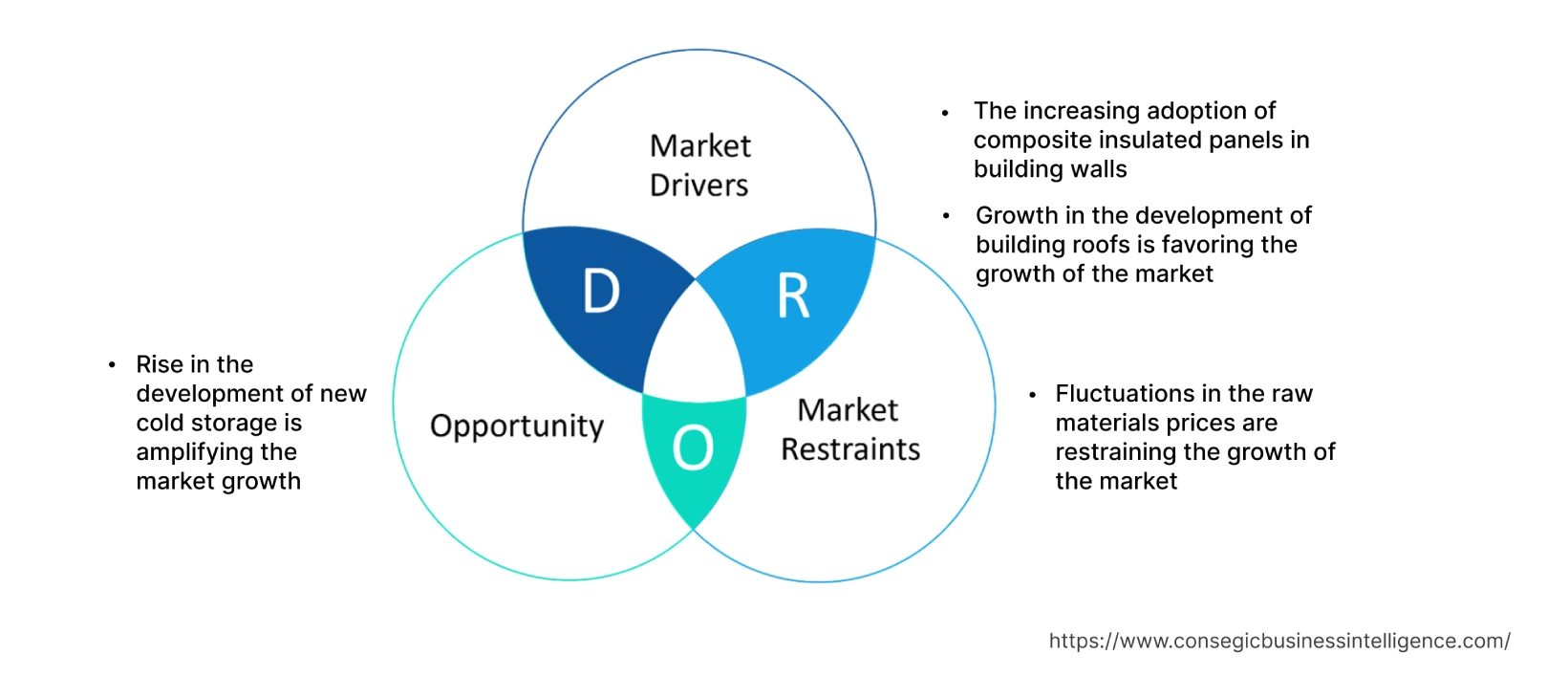

Key Drivers :

The increasing adoption of composite insulated panels in building walls

Composite insulated panels are employed in building walls to aid in efficient vapor, air, moisture, and thermal protection. Building walls are developed in various construction projects, including residential, commercial, industrial, and infrastructure. For instance, according to the recent 2022 statistics published by the European Construction Industry Federation (FIEC), in 2020, the investment in residential construction projects in the Netherlands was Euro 34,917.95 million (USD 39,883.15 million), and in 2021, it was EURO 36,175.00 million (USD 42,785.62 million). In 2021, the year-on-year growth rate of the Netherlands' residential construction industry was 3.6% as compared with the year 2020. Therefore, the growth in residential construction accelerated the construction of building walls. Hence, the increase in the development of building walls is boosting the demand for composite insulated panels to ensure superior thermal properties. This, in turn, is benefiting the market growth.

Growth in the development of building roofs is favoring the growth of the market

The key features of composite insulated panels include excellent weather & temperature resistance, minimum maintenance, lightweight, easy installation, and others. These vital characteristics enable higher functioning property for building roofs, which are critical for commercial buildings, including office buildings, hospitals, cinema halls, museums, and others. The development of new commercial construction projects is increasing due to the growing demand for larger commercial spaces. For illustration, in October 2022, Foster + Partners completed the construction of Varso Tower, a commercial building in Poland. Thus, the development of new commercial construction projects is driving the development of building roofs. As a result, the demand for composite insulated panels is increasing to ensure superior material flexibility, thereby proliferating market growth.

Key Restraints :

Fluctuations in the raw materials prices are restraining the growth of the market

The overall cost of composite insulated panels is primarily dependent on the cost of production, followed by the cost of raw materials such as polystyrene, polyurethane, and others. As a result, fluctuations in the prices of raw materials are posing a bottleneck for the growth of the market. Additionally, the above-mentioned materials are downstream derivatives of crude oil. For instance, Brent crude prices increased up to USD 139 per barrel in 2022. In addition to this, the Crude Oil Basket (COB) increased significantly by 35% from its initial budget estimate as per revised estimates for 2020-21. Hence, the volatility in the prices of raw materials including polystyrene, polyurethane, and others that are used in the production of composite insulated panels impacts the overall pricing of these chips. This, in turn, is restraining the growth of the market.

Future Opportunities :

Rise in the development of new cold storage is amplifying the market growth

Composite insulated panels are ideal for cold storage applications as the panels are equipped with excellent thermal performance. This makes composite insulated panels for use in a diverse range of cold storage applications such as refrigerated vehicles, temperature-controlled environments, and others. For instance, in April 2023, Cypress Cold Storage commenced the development of a new cold storage plant in Springdale, United States. The Cypress Cold Storage facility will be spread across 207,285-square-foot. This facility will consist of over 170,000 square feet of temperature-controlled space. The construction of the new Cypress Cold Storage facility will be completed by the end of 2024. Thus, the rising development of new cold storage facilities will boost the demand for composite insulated panels as these panels are utilized in cold storage ceilings, walls, cold store partitions, and others. This prime factor will boost the demand for the composite insulated panels market.

Composite Insulated Panels Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 631.13 Million |

| CAGR (2025-2032) | 5.8% |

| By Product Type | Expanded Polystyrene (EPS) Panel, Rigid Polyurethane (PUR) Panel, Rigid Polyisocyanurate (PIR) Panel, Glass Wool Panel, and Others |

| By Application | Building Wall, Building Roof, Cold Storage, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Kingspan Group, Alubel SpA., ArcelorMittal, DANA Group of Companies, Balex-Metal, PFB Corporation, Jiangsu Jingxue Insulation Technology Co. Ltd, METECNO, Zamil Steel Pre-Engineered Buildings Co. Ltd, and Tata Steel |

Composite Insulated Panels Market Segmental Analysis :

By Product Type :

The product type segment is categorized into expanded polystyrene (EPS) panel, rigid polyurethane (PUR) panel, rigid polyisocyanurate (PIR) panel, glass wool panel, and others. In 2024, the expanded polystyrene (EPS) panel segment accounted for the highest market share in the composite insulated panels market. Expanded polystyrene (EPS) panel is equipped with various beneficial features such as measurable energy savings, modular in nature, multiple finishing options, constant thermal resistance, and lightweight, among others. These features ensure an optimal weight-to-strength ratio. Expanded polystyrene (EPS) panel is utilized in commercial construction projects. For instance, in 2022, various office building projects were started in the United States such as USD 476 million for The Eight Office Tower project (completion year 2024), USD 400 million for 1900 Lawrence Street Office Tower (completion year 2024), USD 276 million El Segundo Headquarters and Training Facility (completion year 2024), and others. Hence, the ongoing commercial development projects will create a lucrative opportunity for expanded polystyrene (EPS) panel demand growth to ensure energy-efficient insulation. This, in turn, will boost the segment growth in the upcoming years.

However, the glass wool panel segment is expected to be the fastest-growing segment during the forecast period. This is due to the vital features of ceramics such as excellent fire resistance, superior sound absorption, anti-corrosive properties, and others.

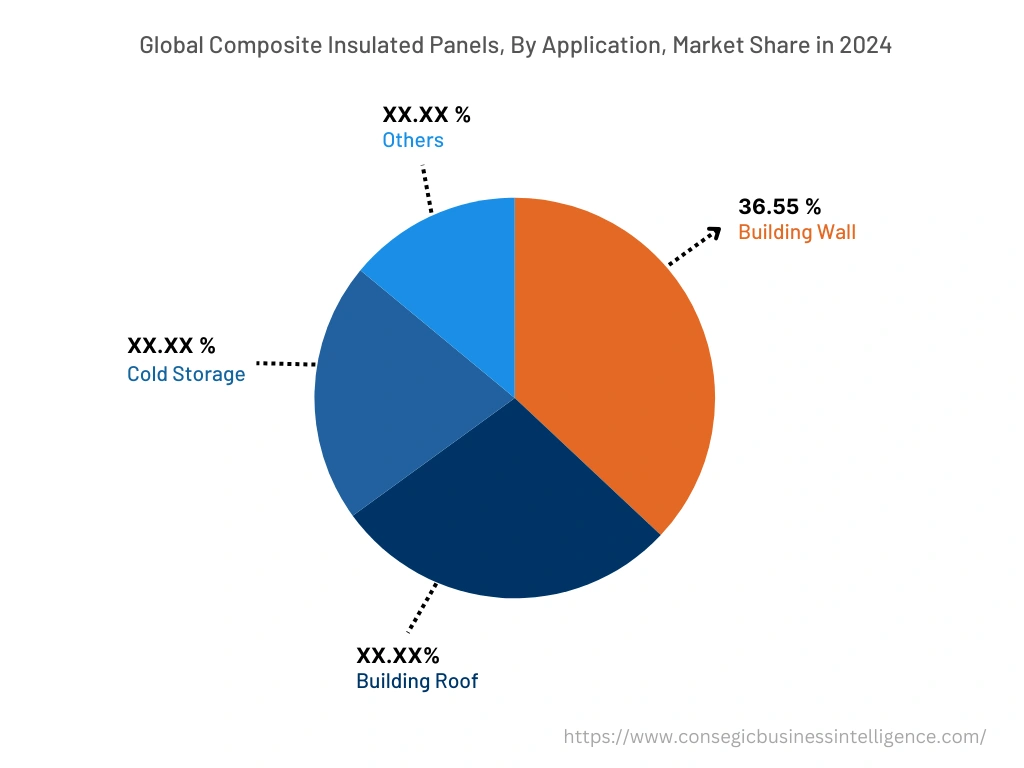

By Application :

The application segment is categorized into building wall, building roof, cold storage, and others. In 2024, the building wall segment accounted for the highest market share of 36.55% in the overall composite insulated panels market. In various building and construction projects, including residential, commercial, infrastructure, and industrial, the deployment of composite insulated panels ensures a superior building wall structure. Furthermore, the deployment of composite insulated panels in building walls ensures superior design flexibility, excellent thermal property, and others. For instance, according to recent data published by Statistics Canada, in 2020, the development of new residential projects was 201,981 units, and in 2021, it was 244,025 units. In 2021, the annual growth rate of Canada's residential construction projects was 20.8% as compared with 2020. The increase in residential projects such as row houses, residential buildings, and others is fueling the demand for composite insulated panels in building walls to ensure excellent insulation core. This, in turn, is fostering the growth of the composite insulated panels market.

However, the cold storage segment is expected to be the fastest-growing segment during the forecast period because of the development of new cold storage facilities, increasing government investments, and others.

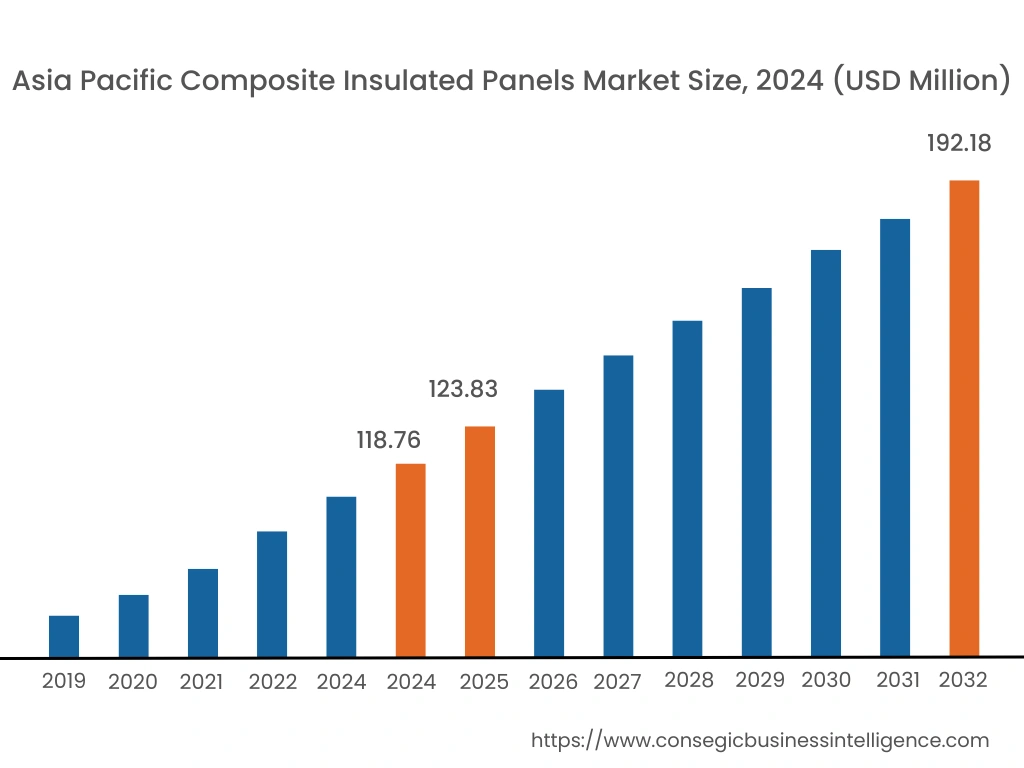

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

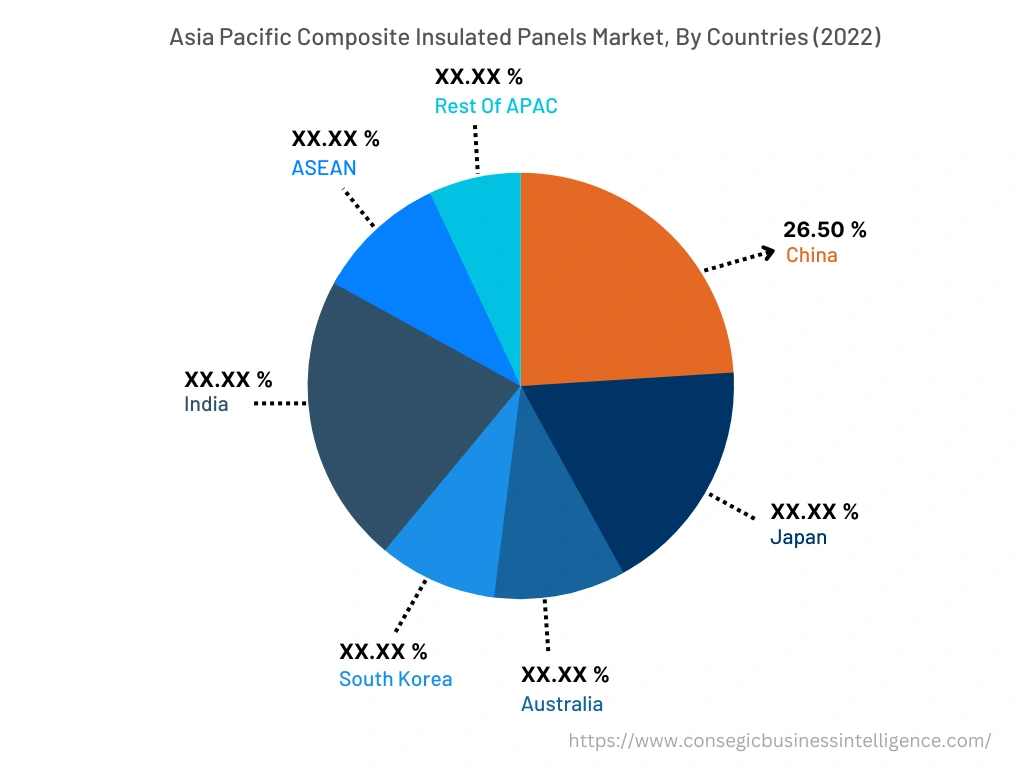

In 2024, Asia Pacific accounted for the highest market share at 34.55% and was valued at USD 118.76 million, and is expected to reach USD 192.18 million in 2032. In Asia Pacific, China accounted for the highest market share of 26.50% during the base year of 2024. This is due to the increase in the development of new buildings and construction projects in the region. For instance, as of June 2023, various commercial projects are under the development phase in the Asia Pacific region, including USD 900 million Commerz III Commercial Office Complex in India (the completion year 2027), USD 500 million Shibaura 1-Chome Mixed-Use Complex in Japan (the completion year 2030), USD 92 million Cangnan County People's Hospital Phase II in China (the completion year 2024), and others. Henceforth, the increase in the development of new construction projects in the Asia Pacific region is proliferating the growth of the market.

Furthermore, North America is expected to witness significant growth over the forecast period, growing at a CAGR of 6.4% during 2025-2032. This is due to the increasing development of new buildings & construction projects in the region.

Top Key Players & Market Share Insights :

The composite insulated panels market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market share through mergers, acquisitions, and partnerships. The key players in the market include-

- Kingspan Group

- Alubel SpA.

- Tata Steel

- Zamil Steel Pre-Engineered Buildings Co. Ltd

- Jiangsu Jingxue Insulation Technology Co. Ltd

- ArcelorMittal

- DANA Group of Companies

- Balex-Metal

- PFB Corporation

- METECNO

Recent Industry Developments :

- In November 2022, All Weather Insulated Panels, a leading manufacturer of foam composite insulated metal panels in the United States launched DM44 Mesa Panel. The product is ideal for building wall applications. Hence, the development of a new range of products will supplement the market growth in the upcoming years.

Key Questions Answered in the Report

What was the market size of the composite insulated panels industry in 2024? +

In 2024, the market size of composite insulated panels was USD 403.24 million

What will be the potential market valuation for the composite insulated panels industry by 2032? +

In 2032, the market size of composite insulated panels will be expected to reach USD 631.13 million.

What are the key factors driving the growth of the composite insulated panels market? +

The increasing adoption of composite insulated panels in building walls is driving market growth.

What is the dominating segment in the composite insulated panels market by application? +

In 2024, the building wall segment accounted for the highest market share of 36.55% in the overall composite insulated panels market.

Based on current market trends and future predictions, which geographical region is the dominating region in the composite insulated panels market? +

Asia Pacific accounted for the highest CAGR in the overall composite insulated panels market.