- Summary

- Table Of Content

- Methodology

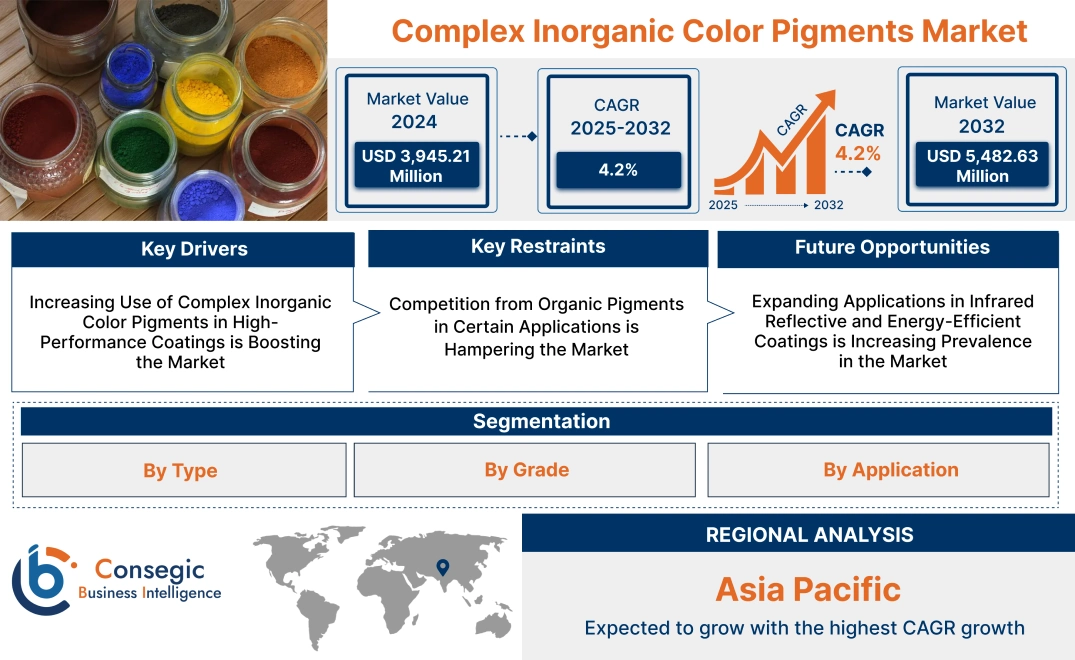

Complex Inorganic Color Pigments Market Size:

Complex Inorganic Color Pigments Market size is estimated to reach over USD 5,482.63 Million by 2032 from a value of USD 3,945.21 Million in 2024 and is projected to grow by USD 4,040.61 Million in 2025, growing at a CAGR of 4.2% from 2025 to 2032.

Complex Inorganic Color Pigments Market Scope & Overview:

Complex inorganic color pigments (CICPs) are executed as high-performance pigments known for their exceptional color stability, durability, and resistance to heat, light, and chemicals. These pigments are widely used in industries such as coatings, plastics, ceramics, and construction, where long-lasting and vibrant coloration is essential. Key characteristics of CICPs include their ability to retain color integrity under harsh conditions, excellent opacity, and compatibility with various materials. The benefits include enhanced product aesthetics, extended lifespan of colored materials, and reduced maintenance costs. Applications span automotive coatings, industrial paints, plastic coloration, ceramic glazes, and construction materials like concrete and roofing. End-users include automotive manufacturers, construction companies, and consumer goods producers, driven by increasing trends for sustainable and durable pigments, advancements in pigment technology, and growing applications in the industrial and architectural sectors.

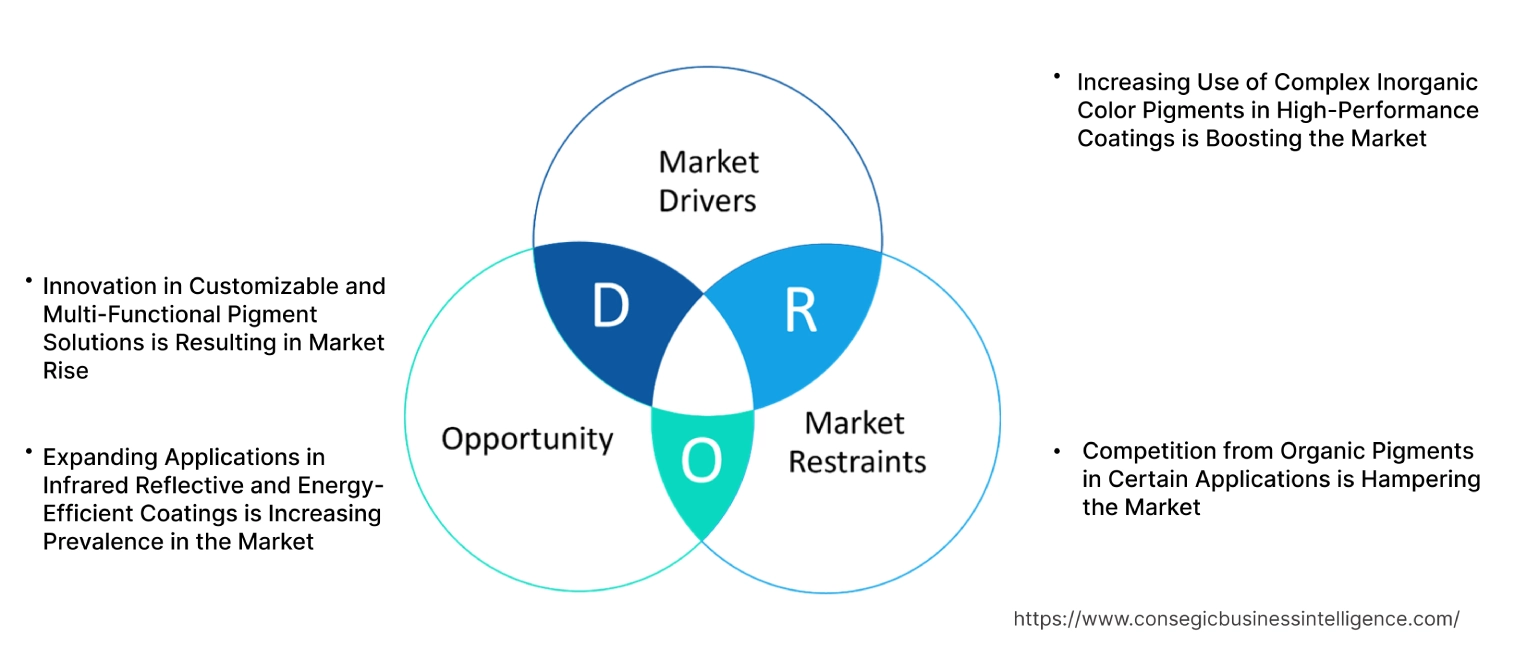

Key Drivers:

Increasing Use of Complex Inorganic Color Pigments in High-Performance Coatings is Boosting the Market

Complex inorganic color pigments (CICPs) are becoming increasingly important in high-performance coatings due to their unmatched durability, color stability, and resistance to extreme environmental conditions. Industries such as automotive, aerospace, and construction leverage these pigments in coatings to ensure long-lasting aesthetic appeal and functionality. CICPs provide superior protection against UV degradation, heat, and chemical exposure, making them ideal for applications where standard pigments fail to perform.

Trends in advanced material technology and the growing emphasis on durable and low-maintenance finishes are driving the integration of CICPs in industrial and architectural coatings. Analysis highlights that their ability to maintain color integrity and performance over extended periods aligns with the evolving requirements of high-performance applications, reinforcing their position as a preferred choice in demanding environments.

Key Restraints:

Competition from Organic Pigments in Certain Applications is Hampering the Market

While CICPs excel in durability and environmental resistance, they face competition from organic pigments, particularly in applications like printing and textiles, where vibrant colors and cost-efficiency are prioritized. Organic pigments offer a broader color range and are easier to process, making them suitable for decorative purposes and markets with price-sensitive end users.

This competition can limit the adoption of CICPs in areas where their enhanced properties, such as thermal stability and non-toxicity, are less critical. Trends in cost optimization and the availability of low-cost organic alternatives pose challenges for CICPs in penetrating segments where vividness and affordability outweigh performance considerations. Addressing this challenge requires the strategic positioning of CICPs in applications where their unique advantages deliver significant value.

Future Opportunities :

Expanding Applications in Infrared Reflective and Energy-Efficient Coatings is Increasing Prevalence in the Market

CICPs are finding expanding applications in infrared reflective and energy-efficient coatings, particularly for sustainable construction and green building projects. These pigments reduce heat absorption by reflecting infrared radiation, contributing to energy savings in cooling systems and enhancing building sustainability. Infrared reflective coatings incorporating CICPs are widely used in cool roofing systems, façade coatings, and industrial applications requiring thermal management.

Trends in energy efficiency and sustainable design present significant opportunities for CICPs in the construction and industrial sectors. Analysis indicates that their role in enabling eco-friendly and high-performance coatings makes them a key component in addressing the increasing emphasis on reducing carbon footprints and improving energy conservation across industries.

Innovation in Customizable and Multi-Functional Pigment Solutions is Resulting in Market Rise

Advancements in pigment technology are driving the development of CICPs with enhanced functionalities and customizable characteristics, catering to evolving industry requirements. Modern CICPs offer tailored color solutions with improved environmental performance, such as lower toxicity and compliance with stringent regulations. Additionally, innovations in multi-functional coatings, including self-cleaning, anti-corrosion, and thermal insulating properties, are expanding the use of CICPs in applications like automotive finishes, consumer goods, and industrial equipment.

Trends in material customization and high-performance coatings highlight the growing preference for pigments that deliver both aesthetic appeal and added functionality. By investing in innovative pigment formulations, manufacturers can cater to diverse market needs, establishing a competitive edge in industries prioritizing advanced and sustainable solutions.

Complex Inorganic Color Pigments Market Segmental Analysis :

By Type:

Based on type, the market is segmented into mixed metal oxide pigments, titanium-based pigments, and others. The mixed metal oxide pigments segment is further sub-segmented into cobalt-based pigments, chromium-based pigments, and iron-based pigments.

The mixed metal oxide pigments segment accounted for the largest revenue in complex inorganic color pigments market share in 2024.

- Mixed metal oxide pigments are widely recognized for their versatility, offering superior durability, heat resistance, and color stability across various industries.

- Cobalt-based pigments are highly valued for their vibrant colors and exceptional performance under high-temperature conditions, making them indispensable in industrial coatings and ceramics.

- Chromium-based pigments stand out for their corrosion-resistant properties, finding extensive use in protective coatings for machinery, marine equipment, and architectural applications.

- Iron-based pigments, being cost-effective and weather-resistant, are predominantly used in construction materials, such as colored concrete and roofing tiles.

- The rising focus on long-lasting pigments with minimal environmental impact has further boosted the complex inorganic color pigments market demand for mixed metal oxide pigments, particularly in the automotive, construction, and industrial sectors.

The titanium-based pigments segment is anticipated to register the fastest CAGR during the forecast period.

- Titanium-based pigments, such as titanium dioxide, are integral to numerous applications due to their high opacity, brightness, and UV resistance.

- These pigments play a crucial role in architectural coatings by delivering weather-resistant finishes that enhance both functionality and aesthetics.

- In the automotive sector, titanium pigments contribute to superior gloss and durability, ensuring enhanced visual appeal and prolonged performance.

- Additionally, their adoption in the plastics sector has surged due to their ability to maintain color stability under prolonged sunlight exposure.

- The growing focus on sustainable production methods for titanium pigments, coupled with their increasing applications in printing inks for high-quality and durable prints, is driving their rapid expansion in the market.

By Grade:

Based on grade, the market is segmented into ceramic grade, construction grade, and industrial grade.

The construction grade segment accounted for the largest revenue share in 2024.

- Construction-grade pigments are extensively used in concrete, roofing tiles, and other building materials, where they enhance aesthetic appeal and provide long-lasting durability.

- These pigments are particularly valued for their exceptional weather resistance and UV stability, which ensure consistent color retention even in harsh environmental conditions.

- The rising complex inorganic color pigments market trends for decorative and sustainable construction materials, particularly in emerging economies undergoing rapid urbanization, has further propelled the complex inorganic color pigments market growth of this segment.

- Moreover, the increasing focus on infrastructure development and eco-friendly architectural practices has bolstered the adoption of construction-grade pigments in modern building designs.

The ceramic grade segment is anticipated to register the fastest CAGR during the forecast period.

- Ceramic-grade pigments are gaining traction due to their application in high-temperature processes, such as the production of tiles, sanitaryware, and decorative pottery.

- These pigments ensure vibrant colors and thermal stability, making them indispensable in the ceramics industry.

- The growing popularity of customized and decorative ceramic products for residential and commercial interiors has significantly driven trends for ceramic-grade pigments.

- Advancements in ceramic manufacturing technologies, including the use of eco-friendly pigment formulations, are expected to further boost development in this segment.

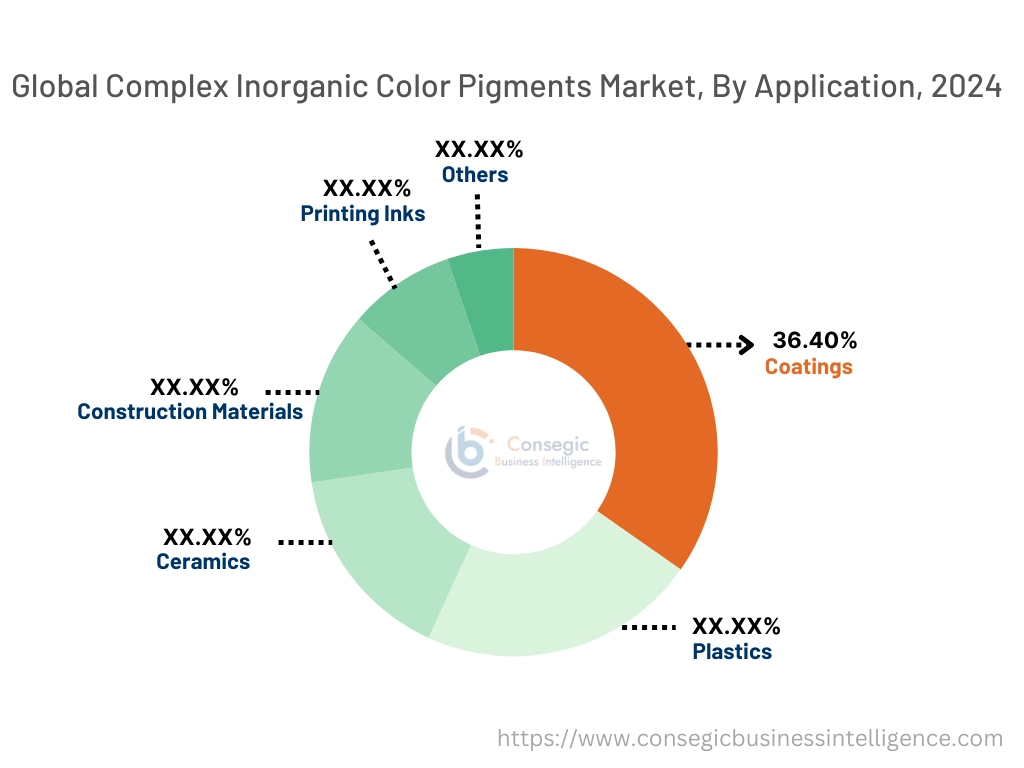

By Application:

Based on application, the market is segmented into coatings, plastics, ceramics, construction materials, printing inks, and others. The coatings segment is further sub-segmented into automotive coatings, industrial coatings, and architectural coatings, while the construction materials segment is divided into concrete and roofing tiles.

The coatings segment accounted for the largest revenue of 36.40% in complex inorganic color pigments market share in 2024.

- Inorganic pigments are a cornerstone of the coatings sectors, contributing to enhanced color vibrancy, durability, and weather resistance.

- Automotive coatings benefit from these pigments' ability to withstand extreme temperatures and UV exposure, ensuring long-lasting finishes and reduced maintenance.

- Industrial coatings rely on inorganic pigments for their corrosion resistance and protective properties, essential for equipment and infrastructure exposed to harsh environments.

- In architectural coatings, inorganic pigments are used to create visually appealing and durable finishes that can withstand prolonged exposure to sunlight and environmental pollutants.

- The increasing complex inorganic color pigments market trends for eco-friendly and high-performance coatings across the automotive, industrial, and construction sectors have cemented the dominance of this segment.

The plastics segment is anticipated to register the fastest CAGR during the forecast period.

- Inorganic pigments are extensively utilized in plastics for both functional and aesthetic purposes.

- They provide color stability, UV resistance, and heat tolerance, making them ideal for applications in packaging, consumer goods, and automotive components.

- The rising trends for sustainable plastic products, driven by regulatory frameworks and consumer preferences, have spurred the adoption of inorganic pigments in this sector.

- Technological advancements in pigment dispersion and formulation have further enabled their use in lightweight and recyclable plastic solutions, aligning with the global push for sustainability.

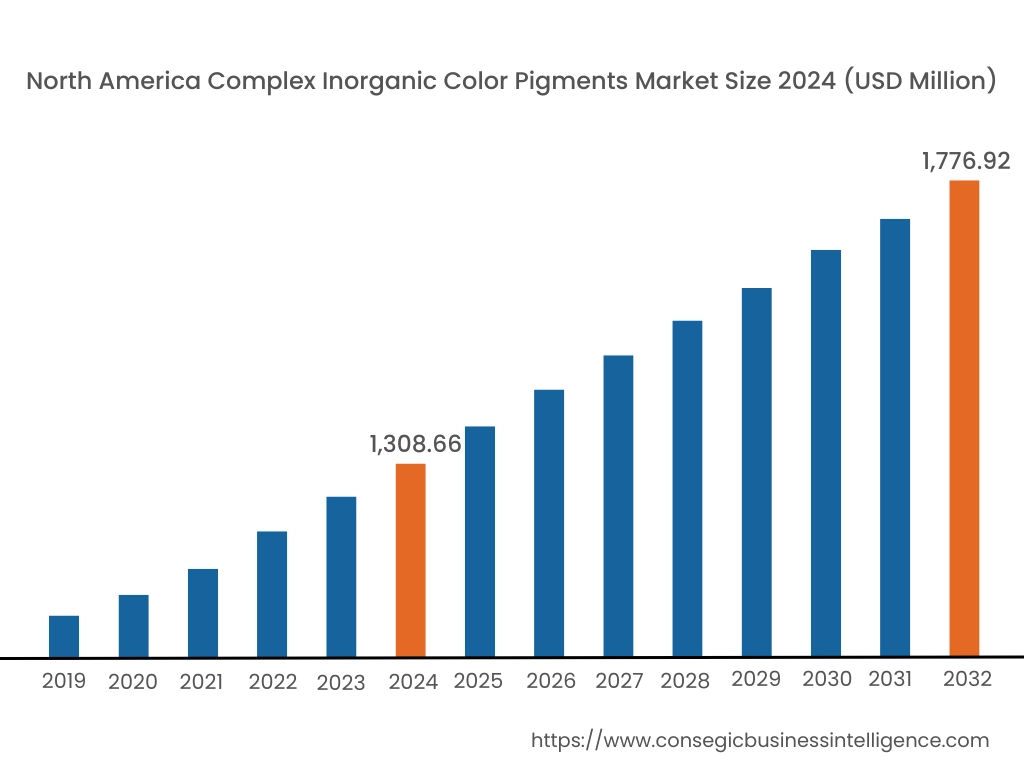

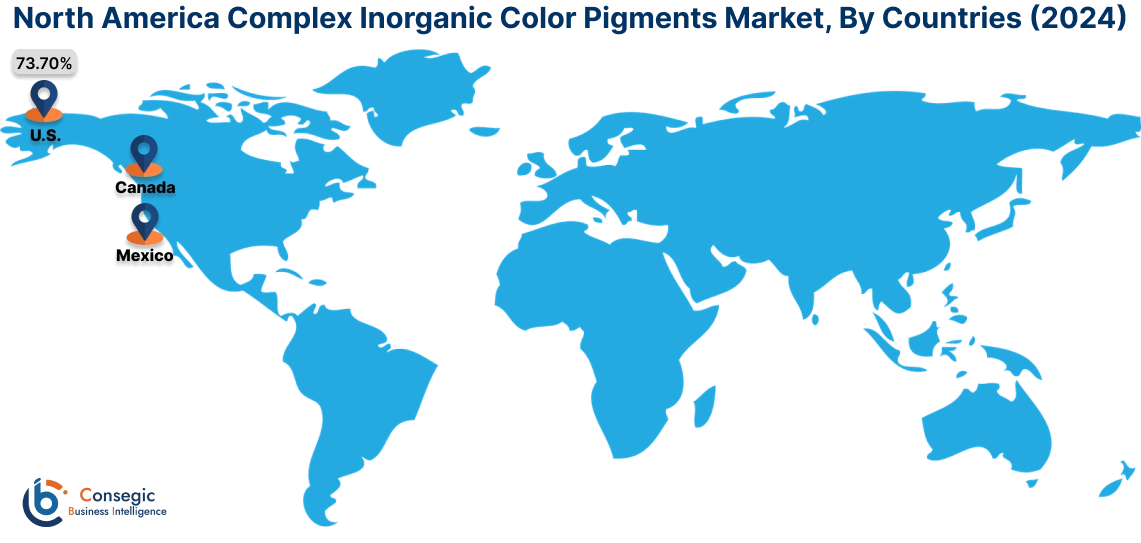

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,308.66 Million and is expected to reach USD 1,776.92 Million in 2032. In North America, the U.S. accounted for the highest share of 73.70% during the base year of 2024. North America holds a significant share in the complex inorganic color pigments market analysis, driven by growing demand from the construction, automotive, and industrial sectors. The U.S. dominates the region due to the extensive use of CICP in architectural coatings, automotive finishes, and plastics. These pigments are highly sought after for their durability, heat stability, and UV resistance, especially in outdoor applications. Canada contributes to the market with the rising adoption of CICPs in eco-friendly coatings and sustainable infrastructure projects. However, environmental regulations surrounding the use of heavy metals in pigments may pose challenges for manufacturers.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.6% over the forecast period. In the complex inorganic color pigments market analysis, fueled by rapid industrialization, urbanization, and growing trends from construction, automotive, and plastics industries in China, India, and Japan. China dominates the market with large-scale use of CICPs in architectural coatings and industrial applications, driven by its booming construction and manufacturing sectors. India’s expanding infrastructure projects and increasing adoption of decorative coatings further support market growth. Japan focuses on high-performance CICPs for advanced applications in automotive coatings and electronics. However, cost sensitivity and competition from organic pigments may challenge the growth of CICPs in certain areas.

Europe is a prominent global complex inorganic color pigments market, supported by the region's well-established construction and automotive industries, along with stringent environmental regulations. Countries like Germany, France, and the UK are key contributors. As per the analysis, Germany leads with high complex inorganic color pigments market demand in automotive coatings and industrial applications requiring heat and weather resistance. France emphasizes their use in decorative paints and coatings for heritage restoration projects, while the UK focuses on innovative uses of CICPs in sustainable construction materials. However, compliance with strict EU regulations on chemical usage and sustainability may increase production costs for manufacturers.

The Middle East & Africa region is witnessing steady growth in the global complex inorganic color pigments market, driven by increasing investments in construction and infrastructure projects. In the Middle East, countries like Saudi Arabia and the UAE utilize CICPs in architectural coatings and industrial applications for their durability in extreme weather conditions. In Africa, South Africa is an emerging market, leveraging CICPs in building materials and decorative coatings for urban development. However, limited local production and reliance on imports for advanced pigments may restrict market growth in the region.

Latin America is an emerging market, with Brazil and Mexico leading the region. Brazil’s expanding construction and automotive sectors drive demand for CICPs in architectural coatings, industrial applications, and vehicle finishes. As per the analysis, Mexico focuses on the use of CICPs in plastics and decorative paints for residential and commercial projects. The region’s emphasis on improving infrastructure and urban development further supports market growth. However, economic instability and inconsistent regulatory frameworks may pose challenges to complex inorganic color pigments market expansion in some countries.

Top Key Players and Market Share Insights:

The complex inorganic color pigments market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the complex inorganic color pigments market. Key players in the complex inorganic color pigments industry include -

- Asahi Kasei Kogyo Co., Ltd. (Japan)

- Clariant AG (Switzerland)

- Sun Chemical Limited (USA)

- Tata Pigments Limited (India)

- The Shepherd Color Company (USA)

- Ferro Corporation (USA)

- Heubach GmbH (Germany)

- LANXESS AG (Germany)

- Venator Materials PLC (UK)

- DCL Corporation (Canada)

Recent Industry Developments :

Business Expansions:

- In April 2024, Oxerra Europe, formerly known as Cathay Industries, announced plans to construct a new facility in China dedicated to the production of complex inorganic color pigments (CICPs). This strategic expansion aims to enhance their manufacturing capabilities and support their existing plant in Kidsgrove, UK.

Complex Inorganic Color Pigments Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 5,482.63 Million |

| CAGR (2025-2032) | 4.2% |

| By Type |

|

| By Grade |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Complex Inorganic Color Pigments Market by 2032? +

Complex Inorganic Color Pigments Market size is estimated to reach over USD 5,482.63 Million by 2032 from a value of USD 3,945.21 Million in 2024 and is projected to grow by USD 4,040.61 Million in 2025, growing at a CAGR of 4.2% from 2025 to 2032.

What factors are driving the growth of the CICP market? +

Growth is driven by increasing demand for high-performance coatings, advancements in pigment technology, and expanding applications in the industrial and architectural sectors.

What are the emerging opportunities in the CICP market? +

Expanding applications in infrared reflective coatings and energy-efficient materials for sustainable construction present significant growth opportunities.

Which type of pigment dominates the market? +

The mixed metal oxide pigments segment holds the largest market share, with cobalt-based, chromium-based, and iron-based pigments widely used for their durability and heat resistance.