- Summary

- Table Of Content

- Methodology

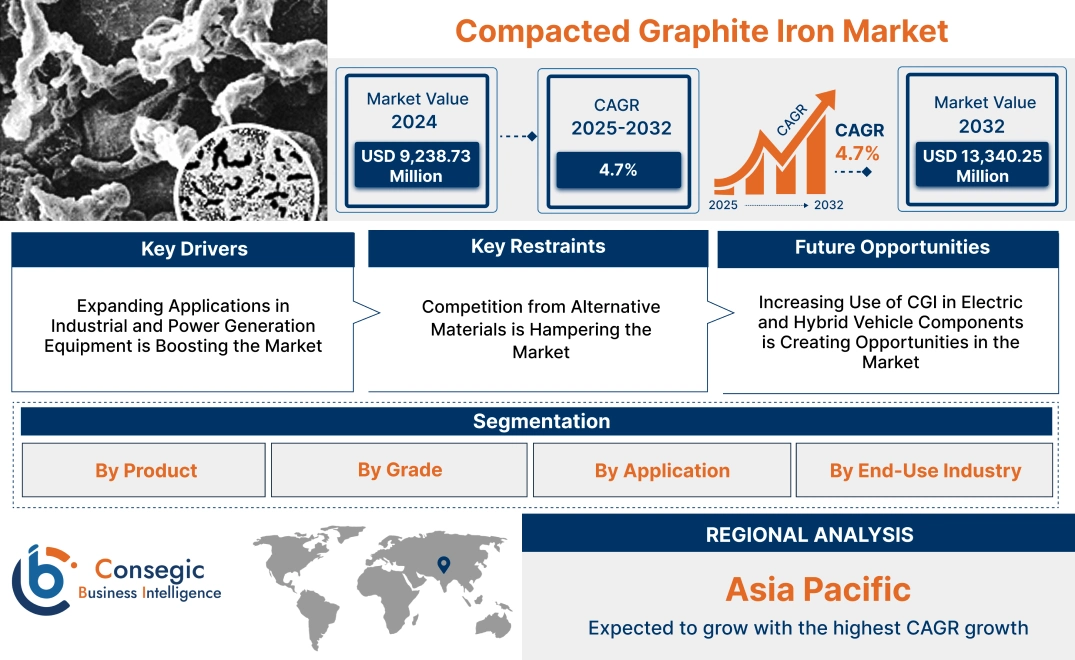

Compacted Graphite Iron Market Size:

Compacted Graphite Iron Market size is estimated to reach over USD 13,340.25 Million by 2032 from a value of USD 9,238.73 Million in 2024 and is projected to grow by USD 9,508.33 Million in 2025, growing at a CAGR of 4.7% from 2025 to 2032.

Compacted Graphite Iron Market Scope & Overview:

The compacted graphite iron (CGI) is a high-strength, lightweight material offering superior mechanical and thermal properties compared to traditional cast irons. CGI is widely used in industries such as automotive, construction, and energy for components requiring durability, wear resistance, and thermal efficiency. Key characteristics of compacted graphite iron include its enhanced strength-to-weight ratio, excellent fatigue resistance, and improved thermal conductivity. These properties make it an ideal choice for demanding applications such as engine blocks, cylinder heads, and brake discs. The benefits include reduced component weight, increased performance efficiency, and extended product lifespan. Applications span automotive engines, industrial machinery, power generation equipment, and construction machinery. End-users include automotive manufacturers, industrial equipment producers, and energy companies, driven by the increasing trends for lightweight materials, advancements in metal casting technologies, and the growing emphasis on fuel efficiency and emission reduction.

Key Drivers:

Expanding Applications in Industrial and Power Generation Equipment is Boosting the Market

Compacted Graphite Iron (CGI) is gaining traction in industrial and power generation applications due to its ability to endure extreme thermal and mechanical stresses. Its superior mechanical properties, including high strength, thermal conductivity, and fatigue resistance, make it an ideal material for critical components such as turbine housings, compressors, and exhaust manifolds. These components often operate in high-pressure and high-temperature environments, where CGI provides enhanced durability and reliability.

Trends in industrial automation and energy-efficient systems are driving the need for advanced materials like CGI. As industries prioritize operational efficiency and the longevity of equipment, CGI's unique properties are increasingly being recognized as essential for ensuring consistent performance. Analysis indicates that its expanding use in heavy-duty machinery and power generation systems highlights its critical role in supporting modern industrial requirements.

Key Restraints:

Competition from Alternative Materials is Hampering the Market

CGI faces significant competition from alternative materials, such as aluminum alloys and advanced composites, particularly in applications where weight reduction is a priority. For instance, in the automotive and aerospace industries, lightweight materials are often favored to improve fuel efficiency and meet environmental regulations. While CGI offers excellent mechanical strength and thermal performance, its relatively higher weight compared to these alternatives can limit its adoption in applications focused on lightweight design.

Additionally, the cost-effectiveness and established supply chains of competing materials pose challenges to CGI's market penetration. Trends in material innovation and cost optimization emphasize the need for CGI manufacturers to differentiate their products by highlighting their unique advantages, such as superior fatigue resistance and thermal stability in high-stress environments.

Future Opportunities :

Increasing Use of CGI in Electric and Hybrid Vehicle Components is Creating Opportunities in the Market

The shift toward electric and hybrid vehicles presents a significant opportunity for CGI due to its excellent thermal management properties and ability to withstand mechanical stresses. As EV and hybrid platforms require lightweight yet robust materials for critical components like battery casings, motor housings, and thermal management systems, CGI is emerging as a valuable solution. Its thermal conductivity ensures efficient heat dissipation, which is essential for maintaining the performance and safety of electric powertrains.

Dominance in electrification and green mobility are driving innovation in material applications, with manufacturers exploring CGI's potential to meet the unique compacted graphite iron market trends of electric vehicle components. Analysis highlights that its application in this growing sector offers a pathway for expanding its market presence while supporting the automotive sector's transition to sustainable and efficient transportation solutions.

Compacted Graphite Iron Market Segmental Analysis :

By Product:

Based on product, the (CGI) market is segmented into spheroid and nodules.

The spheroid segment accounted for the largest revenue compacted graphite iron market share in 2024.

- Spheroid-shaped CGI is extensively used in manufacturing engine blocks, cylinder heads, and brake discs due to its superior strength, wear resistance, and thermal conductivity.

- The compact microstructure of spheroidal CGI provides enhanced durability, making it a preferred choice for automotive and industrial machinery applications.

- The increasing trends for high-performance materials in the automotive sector, coupled with advancements in CGI processing technologies, have significantly driven the adoption of spheroidal CGI products.

The nodules segment is anticipated to register the fastest CAGR during the forecast period.

- Nodular CGI is gaining traction due to its improved machinability and superior mechanical properties, making it suitable for applications such as turbocharger housings and brake discs.

- This product type offers a balance between strength and lightweight characteristics, catering to the growing analysis for efficient and lightweight materials in the automotive and aerospace industries.

- Advancements in casting technologies and the rising focus on reducing emissions and improving fuel efficiency in vehicles are expected to propel the compacted graphite iron market growth of the nodules segment.

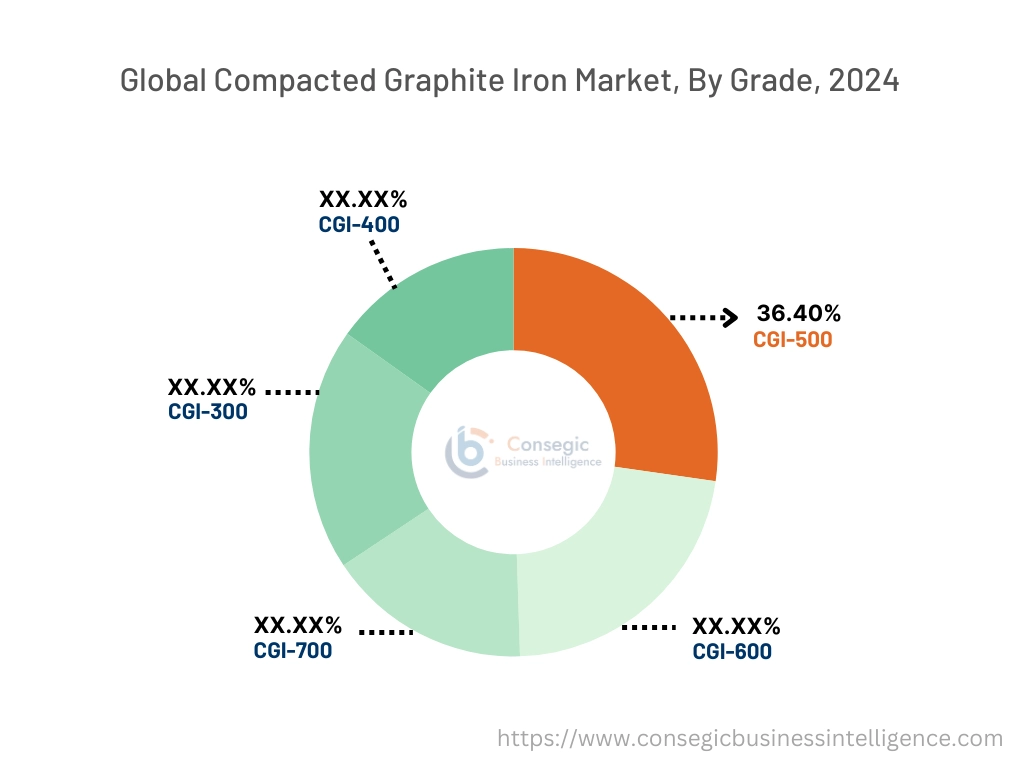

By Grade:

Based on grade, the (CGI) market is segmented into CGI-300, CGI-400, CGI-500, CGI-600, and CGI-700.

The CGI-500 segment accounted for the largest revenue of compacted graphite iron market share of 27.40% in 2024.

- CGI-500 is widely used across various industries due to its excellent balance of strength, thermal conductivity, and machinability.

- This grade is particularly favored in manufacturing engine blocks, cylinder heads, and turbocharger housings, where performance under high temperatures and pressures is critical.

- The increasing compacted graphite iron market opportunities in the production of high-performance vehicles and the growing trends for durable industrial components have driven the dominance of the CGI-500 segment.

The CGI-700 segment is anticipated to register the fastest CAGR during the forecast period.

- CGI-700 offers exceptional tensile strength and thermal resistance, making it ideal for heavy-duty applications such as industrial machinery and construction equipment.

- The growing adoption of this grade in advanced engineering solutions for marine and aerospace industries is contributing to its rapid growth.

- Additionally, the trends for materials that can withstand extreme conditions and provide extended service life are further fueling the adoption of CGI-700.

By Application:

Based on application, the (CGI) market is segmented into engine blocks, cylinder heads, brake discs, turbocharger housings, and others.

The engine blocks segment accounted for the largest revenue share in 2024.

- Engine blocks are a major application of CGI, particularly in the automotive and industrial machinery sectors.

- CGI's superior strength-to-weight ratio and thermal conductivity make it an ideal material for engine block manufacturing, enabling enhanced engine performance and fuel efficiency.

- The increasing production of lightweight and high-performance engines for passenger and commercial vehicles has driven the adoption of CGI in this segment.

The turbocharger housings segment is anticipated to register the fastest CAGR during the forecast period.

- Turbocharger housings require materials with excellent thermal resistance and mechanical strength, making CGI a preferred choice.

- The rising trend analysis for turbocharged engines in vehicles to improve fuel efficiency and reduce emissions is driving the adoption of CGI in this application.

- Additionally, advancements in turbocharger technology and the growing emphasis on lightweight materials in the automotive and aerospace sectors are expected to propel the segment's growth.

By End-User Industry:

Based on end-use, the (CGI) market is segmented into automotive, construction equipment, marine, industrial machinery, aerospace, and others.

The automotive segment accounted for the largest revenue share in 2024.

- The automotive sector is the largest consumer of CGI, driven by the compacted graphite iron market demand for lightweight, high-performance materials in engine components, brake discs, and turbocharger housings.

- CGI helps improve vehicle fuel efficiency and reduce emissions, aligning with stringent environmental regulations.

- The increasing opportunities in the production of electric vehicles (EVs) and hybrid vehicles, coupled with the adoption of advanced engine technologies, have further boosted the trends for CGI in the automotive sector.

The aerospace segment is anticipated to register the fastest CAGR during the forecast period.

- The aerospace sector is increasingly adopting CGI for manufacturing components that require high strength, thermal resistance, and lightweight characteristics.

- CGI is used in applications such as turbine housings and structural components, where performance under extreme conditions is critical.

- The growing investments in aerospace manufacturing and the rising compacted graphite iron market trends for fuel-efficient and durable materials in aircraft production are expected to propel significant compacted graphite iron market growth in this segment.

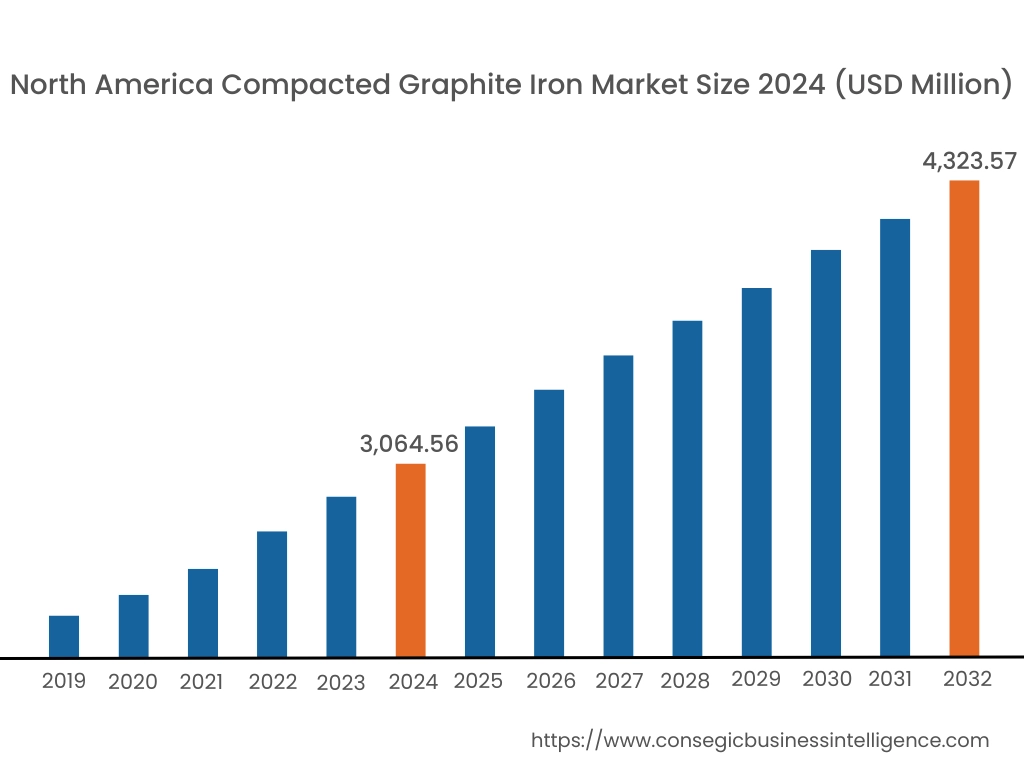

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 3,064.56 Million and is expected to reach USD 4,323.57 Million in 2032. In North America, the U.S. accounted for the highest share of 71.80% during the base year of 2024. North America holds a significant share in the compacted graphite iron market analysis, driven by the strong presence of automotive and heavy-duty machinery industries. The U.S. leads the region, with increasing adoption of CGI in the production of engine blocks and cylinder heads for light and heavy-duty vehicles. The demand is fueled by the growing emphasis on improving fuel efficiency and reducing emissions through lightweight materials. Canada contributes with its use of CGI in industrial and agricultural machinery. However, high production costs and the complexity of manufacturing CGI may limit broader adoption in cost-sensitive applications.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.1% over the forecast period. In the compacted graphite iron market analysis, fueled by rapid industrialization, increasing vehicle production, and growing infrastructure projects in China, India, and Japan. China dominates the market with extensive use of CGI in heavy-duty truck engines and industrial equipment, driven by the country’s expanding manufacturing base. India’s growing automotive and agricultural sectors support the adoption of CGI in tractor engines and other high-performance machinery. Japan emphasizes precision manufacturing and advanced CGI applications in automotive and industrial equipment. However, limited technical expertise in some emerging markets may hinder CGI adoption.

Europe is a prominent global compacted graphite iron market, supported by its advanced automotive and industrial sectors. Countries like Germany, France, and the UK are key contributors. Germany drives demand with its focus on high-performance automotive engines, particularly in premium vehicles, where CGI is used for its strength and thermal conductivity. France emphasizes its use of energy-efficient industrial machinery, while the UK focuses on CGI applications in marine and defense industries. However, the region faces challenges such as stringent environmental regulations and the need for advanced manufacturing technologies to meet CGI production requirements.

The Middle East & Africa region is witnessing steady growth in the compacted graphite iron market, driven by increasing investments in industrial and construction equipment. Countries like Saudi Arabia and the UAE utilize CGI in energy and infrastructure projects, particularly in high-performance machinery requiring durability and thermal resistance. In Africa, South Africa is emerging as a market, leveraging CGI in mining equipment and industrial machinery. However, limited local production capabilities and reliance on imports for advanced materials may restrict broader market development in the region.

Latin America is an emerging market, with Brazil and Mexico leading the region. Brazil’s expanding automotive and industrial sectors drive compacted graphite iron market demand for CGI in engine blocks and heavy machinery components. Mexico, with its growing manufacturing base and automotive exports, supports the adoption of CGI in high-performance engine parts. The region is also exploring CGI applications in construction and agricultural equipment. However, economic instability and inconsistent infrastructure for advanced manufacturing may pose challenges to compacted graphite iron market expansion.

Top Key Players and Market Share Insights:

The compacted graphite iron market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the compacted graphite iron market. Key players in the compacted graphite iron industry include -

- Tupy SA (Brazil)

- SinterCast AB (Sweden)

- Eisengiesserei Baumgarte GmbH (Germany)

- ASI International, Ltd. (USA)

- Atlas Foundry Company (USA)

- Teksid S.p.A. (Italy)

- Waupaca Foundry, Inc. (USA)

- Durham Foundry (UK)

- Silbitz Group GmbH (Germany)

- Saguenay Foundry (Canada)

Recent Industry Developments :

Innovation:

- In June 2023, MAGMA's software models the complex solidification process of CGI, accounting for factors like graphite morphology and matrix structure, which are crucial for achieving desired mechanical properties.

Compacted Graphite Iron Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 13,340.25 Million/td> |

| CAGR (2025-2032) | 4.7% |

| By Product Type |

|

| By Viscosity Grade |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Compacted Graphite Iron (CGI) Market by 2032? +

Compacted Graphite Iron Market size is estimated to reach over USD 13,340.25 Million by 2032 from a value of USD 9,238.73 Million in 2024 and is projected to grow by USD 9,508.33 Million in 2025, growing at a CAGR of 4.7% from 2025 to 2032.

What factors are driving the growth of the CGI market? +

The rising adoption of CGI in industrial and power generation equipment, coupled with trends for lightweight materials and advancements in casting technologies, is boosting market growth.

What challenges does the CGI market face? +

CGI faces competition from alternative lightweight materials such as aluminum alloys and advanced composites, along with challenges in cost optimization and manufacturing complexity.

What opportunities exist in the CGI market? +

The growing use of CGI in electric and hybrid vehicle components, particularly for thermal management and structural applications, presents significant growth opportunities.

Which product type dominates the CGI market? +

The spheroid segment holds the largest market share due to its superior strength, wear resistance, and thermal conductivity, making it ideal for engine blocks and cylinder heads.