- Summary

- Table Of Content

- Methodology

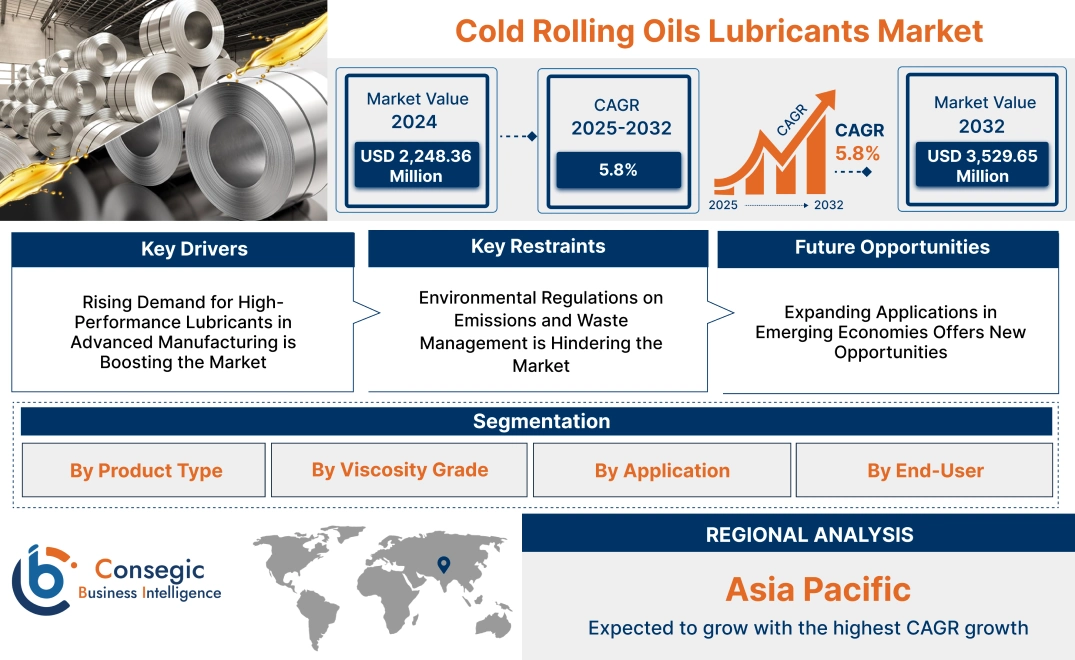

Cold Rolling Oils Lubricants Market Size:

Cold Rolling Oils Lubricants Market size is estimated to reach over USD 3,529.65 Million by 2032 from a value of USD 2,248.36 Million in 2024 and is projected to grow by USD 2,338.70 Million in 2025, growing at a CAGR of 5.8% from 2025 to 2032.

Cold Rolling Oils Lubricants Market Scope & Overview:

The cold rolling oils and lubricants are specialized fluids and solutions used in the cold rolling process to enhance the performance and quality of rolled metal products. These oils and lubricants minimize friction, reduce heat generation, and protect metal surfaces during rolling, ensuring precision and efficiency in metal forming. Key characteristics of cold rolling oils and lubricants include excellent lubricating properties, thermal stability, and compatibility with various metals such as steel, aluminum, and copper. The benefits include improved surface finish, extended equipment life, and enhanced process efficiency. Applications span industries such as automotive, construction, electrical appliances, and aerospace, where high-quality rolled metals are essential. End-users include steel manufacturers, metalworking companies, and rolling mill operators, driven by increasing trends for lightweight and high-strength materials, advancements in rolling technologies, and the growing emphasis on sustainable and efficient manufacturing practices.

Key Drivers:

Rising Demand for High-Performance Lubricants in Advanced Manufacturing is Boosting the Market

High-performance lubricants, such as cold rolling oils, have become indispensable in advanced manufacturing processes due to their ability to enhance efficiency, reduce tool wear, and ensure precise product quality. Industries like automotive, aerospace, and electronics rely on these lubricants to achieve superior surface finishes, maintain dimensional accuracy, and optimize equipment performance during high-precision operations.

Trends in precision engineering and the use of high-strength materials emphasize the role of advanced lubricants in supporting consistent and efficient production workflows. Cold rolling oils are specifically designed to manage extreme conditions such as high temperatures, intense pressure, and extended operating cycles. The analysis highlights that their contribution to improving productivity and reducing operational costs makes them essential for industries prioritizing material optimization and sustainability in manufacturing.

Key Restraints:

Environmental Regulations on Emissions and Waste Management is Hindering the Market

Environmental regulations targeting emissions, waste disposal, and resource efficiency pose significant challenges for the cold rolling oils lubricants market. Used lubricants often contain contaminants that can harm the environment if not managed properly, leading to strict regulatory requirements for recycling, disposal, and emissions control. Compliance with these standards necessitates investment in eco-friendly formulations, advanced waste management systems, and sustainable production practices.

Industries are increasingly adopting greener alternatives, but transitioning to these solutions often involves additional costs and operational adjustments. Trends in regulatory compliance and environmental awareness are reshaping the market, requiring manufacturers to innovate and align their products with evolving standards. Addressing these challenges is critical to maintaining market competitiveness while adhering to stringent sustainability guidelines.

Future Opportunities :

Expanding Applications in Emerging Economies Offers New Opportunities

Emerging economies are witnessing significant industrialization, creating opportunities for cold rolling oils and lubricants in applications such as automotive production, construction, and metal fabrication. Investments in infrastructure development and manufacturing capabilities in regions like Asia-Pacific, Latin America, and Africa are driving the adoption of advanced rolling processes to meet growing material and production standards.

Trends in localized manufacturing and regional customization are opening new avenues for lubricant manufacturers to provide tailored solutions that cater to the specific needs of these markets. Analysis suggests that offering technical support, cost-effective products, and eco-friendly alternatives can help companies establish a strong presence in these expanding industrial hubs, ensuring sustained cold rolling oils lubricants market growth and innovation.

Cold Rolling Oils Lubricants Market Segmental Analysis :

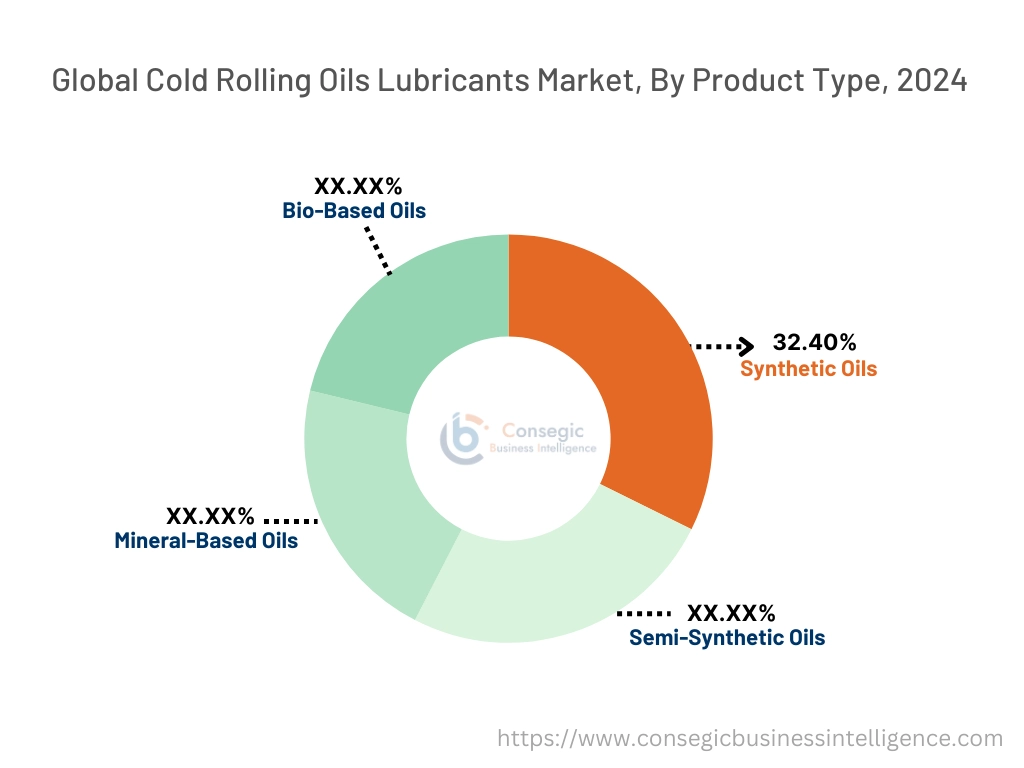

By Product Type:

Based on product type, the market is segmented into synthetic oils, semi-synthetic oils, mineral-based oils, and bio-based oils.

The synthetic oils segment accounted for the largest revenue share of 32.40% in 2024.

- Synthetic oils dominate the market due to their superior lubrication properties, thermal stability, and resistance to oxidation.

- These oils are extensively used in high-performance applications such as steel and aluminum rolling, where extreme pressures and high temperatures are involved.

- Their ability to enhance operational efficiency and reduce wear and tear on machinery makes them a preferred choice across various industries.

- The growing cold rolling oils lubricants market trends analysis for high-performance lubricants in industrial and automotive sectors has significantly contributed to the dominance of synthetic oils in the market.

The bio-based oils segment is anticipated to register the fastest CAGR during the forecast period.

- Bio-based oils are gaining traction due to their eco-friendly and biodegradable properties, making them an attractive alternative to conventional oils.

- These oils are extensively used in applications where environmental compliance and sustainability are critical, such as food-grade aluminum rolling and electronics manufacturing.

- The increasing cold rolling oils lubricants market opportunities to reduce carbon footprints and comply with stringent environmental regulations are driving the adoption of bio-based oils in the market.

By Viscosity Grade:

Based on viscosity grade, the market is segmented into low viscosity, medium viscosity, and high viscosity.

The medium viscosity segment accounted for the largest revenue share in 2024.

- Medium viscosity oils are widely used in rolling applications due to their balanced performance in providing lubrication, cooling, and surface finish.

- These oils are suitable for a broad range of applications, including steel, aluminum, and copper rolling, making them highly versatile.

- The growing adoption of medium viscosity oils in automotive and industrial machinery industries, where precision and efficiency are crucial, has driven their dominance in the market.

The low-viscosity segment is anticipated to register the fastest CAGR during the forecast period.

- Low-viscosity oils are increasingly preferred for high-speed and precision rolling applications, where minimal friction and optimal cooling are required.

- These oils are widely used in industries such as electronics and packaging, where surface finish and accuracy are critical.

- The rising cold rolling oils lubricants market demand for lightweight materials and thinner metal sheets in the automotive and electronics sectors is expected to propel the growth of low-viscosity oils during the forecast period.

By Application:

Based on application, the market is segmented into steel rolling, aluminum rolling, copper rolling, and others.

The steel rolling segment accounted for the largest revenue of cold rolling oils lubricants market share in 2024.

- Steel rolling is a major application for rolling oils, driven by the high trends for steel in construction, automotive, and industrial manufacturing.

- Rolling oils enhance the process by reducing friction, improving surface finish, and preventing oxidation during high-temperature operations.

- The growing focus on producing high-strength and corrosion-resistant steel for infrastructure and automotive applications has significantly boosted the adoption of rolling oils in this segment.

The aluminum rolling segment is anticipated to register the fastest CAGR during the forecast period.

- Aluminum rolling is gaining prominence due to the rising cold rolling oils lubricants market demand for lightweight and durable materials in aerospace, automotive, and packaging industries.

- Rolling oils play a critical role in achieving the desired surface finish and precision during aluminum sheet production.

- The increasing adoption of aluminum in electric vehicles (EVs) and sustainable packaging solutions is driving the growth of rolling oils in this segment.

- Additionally, advancements in rolling technologies are expected to enhance the efficiency and quality of aluminum rolling processes.

By End-User:

Based on end-use, the market is segmented into automotive, industrial machinery, construction, electronics, packaging, and others.

The automotive segment accounted for the largest revenue of cold rolling oils lubricants market share in 2024.

- The automotive sector is a key consumer of rolling oils, driven by the need for high-quality metal sheets and components.

- Rolling oils are used in the production of steel and aluminum parts for vehicle frames, body panels, and structural components.

- The increasing trends for lightweight and fuel-efficient vehicles, coupled with the rising adoption of electric vehicles (EVs), have fueled the growth of rolling oils in the automotive sector.

The electronics segment is anticipated to register the fastest CAGR during the forecast period.

- The electronics sector is increasingly utilizing rolling oils for producing precision metal components used in circuit boards, connectors, and enclosures.

- These oils ensure smooth surface finish and accuracy in rolling processes, critical for the performance of electronic devices.

- The growing trends for miniaturized and high-performance electronics, coupled with advancements in manufacturing technologies, are driving the adoption of rolling oils in this segment.

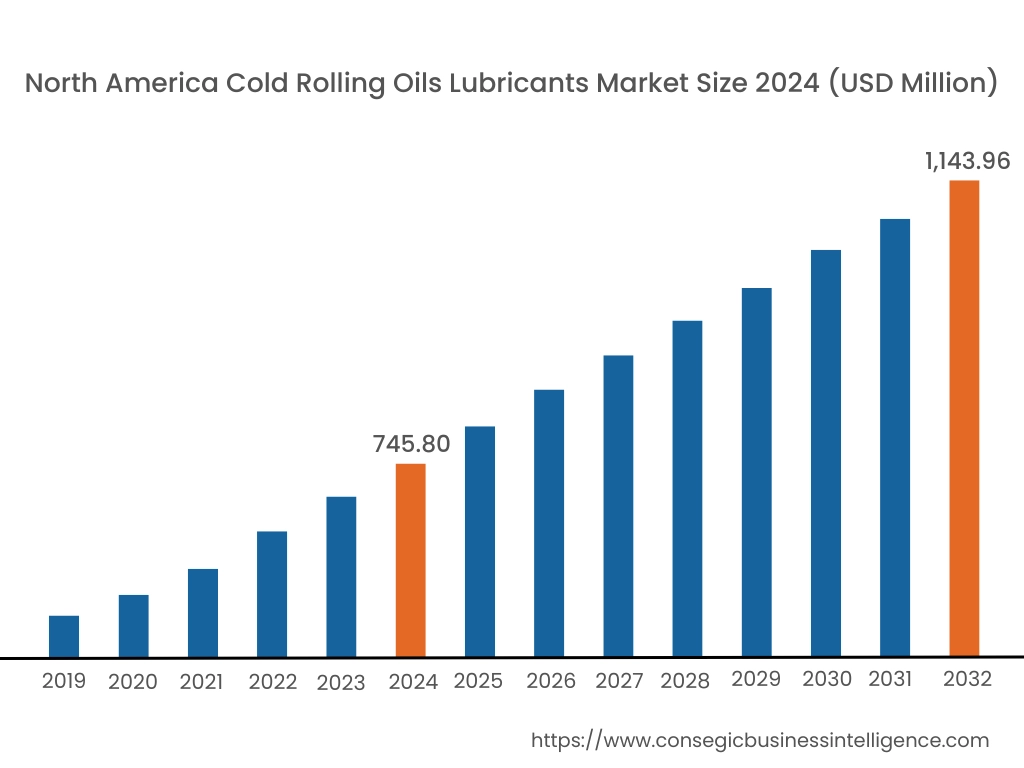

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 745.80 Million and is expected to reach USD 1,143.96 Million in 2032. In North America, the U.S. accounted for the highest share of 72.70% during the base year of 2024. North America holds a significant share in the cold rolling oils lubricants market, driven by the region's robust automotive, aerospace, and industrial sectors. The U.S. leads with high trends for cold rolling lubricants to enhance the efficiency and surface finish of rolled steel and aluminum used in automotive body panels, industrial machinery, and construction materials. Canada's growing metal fabrication and machinery industries also contribute to the market, particularly for applications in renewable energy and transportation. However, stringent environmental regulations on lubricant formulations and disposal may pose challenges for manufacturers.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 6.2% over the forecast period. In the cold rolling oils lubricants market analysis, fueled by rapid industrialization, urbanization, and expanding automotive and construction sectors in China, India, and Japan. China dominates the market with extensive use of cold rolling oils in steel and aluminum processing to meet the demands of its booming construction and automotive industries. India’s growing infrastructure projects and expanding manufacturing base also drive the adoption of rolling lubricants for producing high-quality metal sheets. Japan focuses on advanced rolling lubricants to support its precision engineering and electronics industries. However, fluctuating raw material costs and regulatory challenges in emerging markets may hinder growth in certain areas.

Europe is a prominent market for cold rolling oils lubricants, supported by its advanced automotive, construction, and industrial manufacturing sectors. Countries like Germany, France, and the UK are key contributors. As per the analysis, Germany’s strong automotive sectors drive the adoption of high-performance rolling lubricants to meet stringent quality standards for precision-engineered components. France emphasizes their use in aerospace and construction applications, while the UK focuses on cold-rolling lubricants for advanced industrial machinery. However, strict EU regulations on chemical safety and the push for eco-friendly alternatives may challenge traditional lubricant manufacturers.

The Middle East & Africa region is witnessing steady growth in the cold rolling oils lubricants market expansion, driven by increasing investments in industrial and infrastructure development. In the Middle East, countries like Saudi Arabia and the UAE utilize cold rolling lubricants in steel and aluminum processing for construction projects and energy infrastructure. In Africa, South Africa is emerging as a key market, leveraging cold rolling oils in mining and industrial equipment manufacturing. However, limited local production capabilities and dependence on imports may restrict cold rolling oils lubricants market growth in the region.

Latin America is an emerging market for cold rolling oil lubricants, with Brazil and Mexico leading the region. Brazil’s expanding automotive and construction sectors drive demand for rolling lubricants to produce high-quality rolled metal products for domestic and export markets. Mexico, with its growing manufacturing and industrial base, supports the use of lubricants in steel and aluminum rolling processes. The region is also exploring sustainable lubricant solutions to align with global environmental cold rolling oils lubricants market trends. However, economic instability and inconsistent regulatory frameworks may pose challenges for broader adoption in smaller markets.

Top Key Players and Market Share Insights:

The global cold rolling oils lubricants market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the cold rolling oils lubricants market. Key players in the cold rolling oils lubricants industry include -

- Exxon Mobil Corporation (USA)

- BP plc (UK)

- Houghton International Inc. (USA)

- Quaker Chemical Corporation (USA)

- ETNA Products Inc. (USA)

- TotalEnergies (France)

- Indian Oil Corporation Ltd. (India)

- Hindustan Petroleum Corporation Limited (India)

- Croda International PLC (UK)

- Eastern Petroleum Pvt. Ltd. (India)

Recent Industry Developments :

Collaborations:

- In January 2024, Q8Oils collaborates closely with customers to tailor oil compositions that align with specific rolling mill conditions, optimizing performance and productivity. This focus on viscosity underscores Q8Oils' commitment to advancing lubrication technology in the cold rolling sector, ensuring that their products meet the evolving demands of modern metal processing industries.

Cold Rolling Oils Lubricants Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,529.65 Million |

| CAGR (2025-2032) | 5.8% |

| By Product Type |

|

| By Viscosity Grade |

|

| By Application |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the Cold Rolling Oils Lubricants Market by 2032? +

Cold Rolling Oils Lubricants Market size is estimated to reach over USD 3,529.65 Million by 2032 from a value of USD 2,248.36 Million in 2024 and is projected to grow by USD 2,338.70 Million in 2025, growing at a CAGR of 5.8% from 2025 to 2032.

What industries utilize cold rolling oils and lubricants? +

Industries such as automotive, construction, aerospace, electronics, and packaging use these lubricants for metal rolling processes involving steel, aluminum, and copper.

What factors are driving the growth of the cold rolling oils lubricants market? +

Increasing demand for high-performance lubricants, advancements in manufacturing processes, and the rise in lightweight and high-strength material applications are key drivers.

What challenges are faced by the cold rolling oils lubricants market? +

Environmental regulations on emissions, waste management, and the need for sustainable solutions pose significant challenges for market players.