- Summary

- Table Of Content

- Methodology

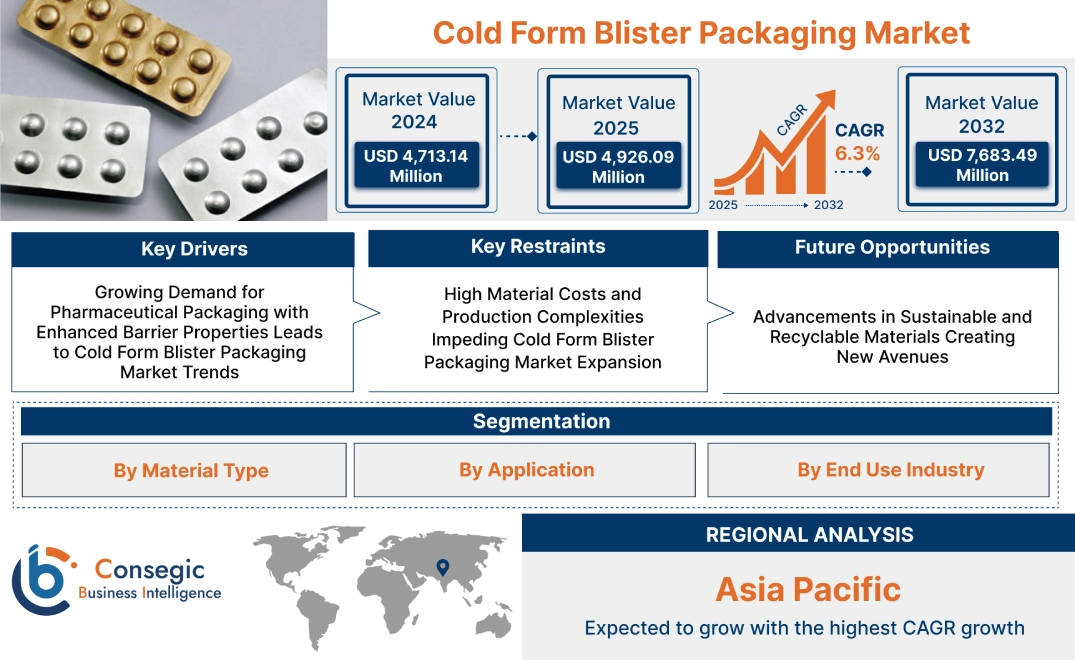

Cold Form Blister Packaging Market Size:

Cold Form Blister Packaging Market size is estimated to reach over USD 7,683.49 Million by 2032 from a value of USD 4,713.14 Million in 2024 and is projected to grow by USD 4,926.09 Million in 2025, growing at a CAGR of 6.3% from 2025 to 2032.

Cold Form Blister Packaging Market Scope & Overview:

Cold form blister packaging is a durable and moisture-resistant solution widely used for securing pharmaceutical and healthcare products. It involves forming aluminum-based laminates into pockets to house products, providing exceptional protection against external factors like light, moisture, and oxygen. This packaging is commonly used for sensitive products requiring high barrier protection. The key properties of cold form blister packaging include its impermeability, strength, and ability to create an airtight seal. The aluminum laminate used offers robust structural integrity, ensuring long-term product preservation. Its tamper-evident design enhances product safety, making it suitable for critical applications. The benefits of this packaging type include extended product shelf life, reduced risk of contamination, and improved compliance with regulatory standards. It also supports product traceability through customizable labeling and design options, contributing to effective branding and consumer trust.

Applications of cold form blister packaging span pharmaceuticals, nutritional supplements, medical devices, and diagnostic kits. It is commonly used to package tablets, capsules, syringes, and vials, ensuring product stability and safety. End-use industries such as healthcare, biotechnology, and life sciences rely on cold form blister packaging for its reliable performance, regulatory compliance, and ability to meet diverse product requirements. Its utility in maintaining product integrity makes it a preferred choice across these sectors.

Key Drivers:

Growing Demand for Pharmaceutical Packaging with Enhanced Barrier Properties Leads to Cold Form Blister Packaging Market Trends

The pharmaceutical industry increasingly relies on cold-form blister packaging due to its superior barrier properties, which provide exceptional protection against moisture, light, and oxygen. This ensures the stability and shelf life of sensitive medications, including tablets, capsules, and powders. For example, aluminum-based cold-form blister packs are extensively used to store high-value drugs that degrade quickly when exposed to external elements. By offering a reliable solution for preserving drug efficacy and meeting stringent regulatory standards, cold-form blister packaging has become indispensable in pharmaceutical applications. Consequently, the rising focus on quality and safety in the healthcare sector significantly boosts the trend for this packaging solution.

Key Restraints:

High Material Costs and Production Complexities Impeding Cold Form Blister Packaging Market Expansion

The manufacturing of cold-form blister packaging involves the use of premium materials, such as aluminum foils and multilayer films, which contribute to higher costs compared to other packaging solutions. Additionally, the cold-forming process is more complex and time-intensive, requiring specialized equipment and skilled operators to ensure precise molding and sealing. These factors lead to increased production expenses, which may deter smaller manufacturers from adopting cold-form blister packaging. For instance, the cost of producing aluminum-based blisters often surpasses that of thermoformed alternatives, making it less economically viable for budget-conscious enterprises. These challenges pose significant barriers to the widespread adoption of cold-form blister packaging, particularly in cost-sensitive markets.

Future Opportunities :

Advancements in Sustainable and Recyclable Materials Creating New Avenues

The development of sustainable and recyclable materials for cold-form blister packaging is expected to create substantial cold form blister packaging market growth opportunities. Manufacturers are investing in innovative solutions, such as bio-based multilayer films and aluminum-free barrier materials, to reduce the environmental impact of traditional packaging. These advancements aim to balance the high barrier performance of conventional cold-form packs with eco-friendly characteristics. For example, research into recyclable polymer composites is paving the way for greener alternatives without compromising product protection. As sustainability becomes a key focus across industries, the integration of environmentally responsible materials is anticipated to drive the market forward in the coming years.

Cold Form Blister Packaging Market Segmental Analysis :

By Material Type:

Based on material type, the market is segmented into aluminum, PVC (Polyvinyl Chloride), PET (Polyethylene Terephthalate), PP (Polypropylene), and others.

The aluminum segment accounted for the largest revenue in cold form blister packaging market share in 2024.

- Aluminum is the most commonly used material for cold form blister packaging due to its excellent barrier properties, which help protect sensitive products from external factors such as light, moisture, and oxygen.

- Aluminum also offers superior strength and is widely used for pharmaceutical applications, ensuring the integrity and safety of the products inside the packaging.

- The benefits of aluminum packaging include its ability to be easily molded into complex shapes, improving product presentation and user experience.

- Furthermore, it is highly recyclable, contributing to the growing trend for sustainable packaging solutions.

- As a result, the aluminum segment continues to lead in revenue generation for the market.

- Therefore, according to cold form blister packaging market analysis, the aluminum segment is expected to maintain its dominant position due to its versatility, superior protective properties, and growing sustainability trends.

The PVC segment is anticipated to register the fastest CAGR during the forecast period.

- PVC offers a lower-cost alternative to aluminum while still providing reliable product protection, particularly for non-sensitive items like food and cosmetics.

- This material is known for its durability and formability, allowing manufacturers to produce packaging with intricate designs.

- The increasing trend for cost-effective and versatile packaging solutions is expected to drive the growth of the PVC segment in the coming years.

- Furthermore, advancements in PVC production technology are enhancing its properties, making it an attractive option for a wide range of applications.

- Thus, PVC is expected to experience significant growth, both in terms of revenue and market share.

- Thus, according to cold form blister packaging market analysis, PVC's rapid adoption across various industries, due to its cost-effectiveness and versatility, makes it the fastest-growing segment in the market.

By Application:

Based on application, the market is segmented into pharmaceuticals, food & beverages, cosmetics & personal care, electronics, and others.

The pharmaceuticals segment accounted for the largest revenue in cold form blister packaging market share in 2024.

- Cold form blister packaging is predominantly used in the pharmaceutical industry to ensure the safe and tamper-evident packaging of medicines, particularly tablets, capsules, and other dosage forms.

- This packaging type is ideal for pharmaceutical products that require protection from moisture, light, and oxygen, thus extending shelf life and maintaining product efficacy.

- The increasing focus on patient safety, convenience, and the demand for high-quality packaging solutions in the pharmaceutical sector is driving the market for cold form blister packaging.

- Additionally, regulatory requirements for packaging safety are reinforcing the adoption of cold form blister packaging in the pharmaceutical industry.

- Therefore, the pharmaceuticals segment remains the largest contributor to the market’s revenue.

- Therefore, according to market analysis, the pharmaceutical industry's growing trend for safe, secure, and efficient packaging solutions ensures that the pharmaceuticals segment remains the dominant revenue generator.

The food & beverages segment is expected to register the fastest CAGR during the forecast period.

- The food and beverage industry is increasingly adopting cold form blister packaging to provide enhanced protection, convenience, and portion control for products like snacks, dairy, and frozen items.

- Blister packs are becoming popular for single-serving packaging, catering to the growing trend for convenience and on-the-go consumption.

- The desire for longer shelf life, combined with the ability to customize packaging for branding and consumer appeal, is propelling the adoption of cold form blister packaging in this sector.

- Additionally, the increasing trend of sustainability in the food industry is promoting the use of recyclable and eco-friendly blister packaging solutions.

- As a result, the food & beverages application segment is poised for rapid growth in the coming years.

- Therefore, according to market analysis, the food & beverages segment's increasing demand for convenient, sustainable, and well-protected packaging is driving its rapid cold form blister packaging market growth in the market.

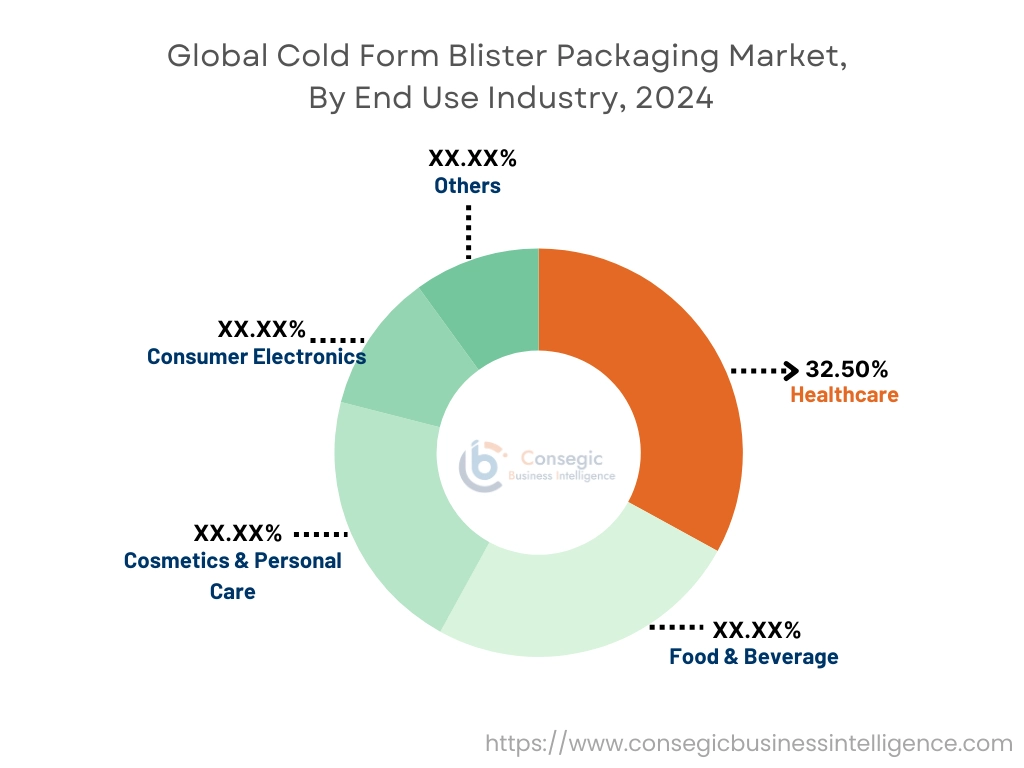

By End-Use Industry:

Based on end-use industry, the market is segmented into healthcare, food & beverage, cosmetics & personal care, consumer electronics, and others.

The healthcare segment accounted for the largest revenue share by 32.50% in 2024.

- The healthcare industry’s need for secure and effective packaging solutions for medicines, medical devices, and other health-related products is a key driver of cold form blister packaging market

- This sector requires packaging that ensures product safety, maintains efficacy, and complies with strict regulatory standards.

- The healthcare industry also values blister packaging’s ability to provide tamper-proof seals, which enhances consumer trust and ensures the integrity of the product.

- Moreover, the growing demand for over-the-counter pharmaceuticals and supplements is expected to further boost the demand for cold form blister packaging in the healthcare industry.

- As a result, healthcare remains the dominant end-use industry for cold form blister packaging.

- Therefore, according to market analysis, the healthcare sector's stringent regulations and emphasis on safety and integrity make it the largest end-use industry for cold form blister packaging.

The food & beverage segment is expected to register the fastest CAGR during the forecast period.

- The food and beverage sector is increasingly turning to cold form blister packaging to offer portion-controlled, easy-to-carry, and long-lasting packaging solutions for a variety of products.

- Blister packs are highly valued in the food industry due to their ability to preserve the quality and freshness of the product while ensuring convenience for consumers.

- The growing demand for on-the-go and single-serve food products, coupled with innovations in food packaging technologies, is expected to drive rapid growth in the food & beverage segment.

- Additionally, the rise of consumer preference for sustainable and recyclable packaging is pushing for more environmentally friendly cold form blister packaging solutions in the food industry.

- Hence, this segment is forecasted to grow at the fastest pace in the market.

- Therefore, according to market analysis, the food & beverage segment's rapid adoption of innovative, sustainable, and consumer-friendly packaging solutions positions it as the fastest-growing sector in the cold form blister packaging market.

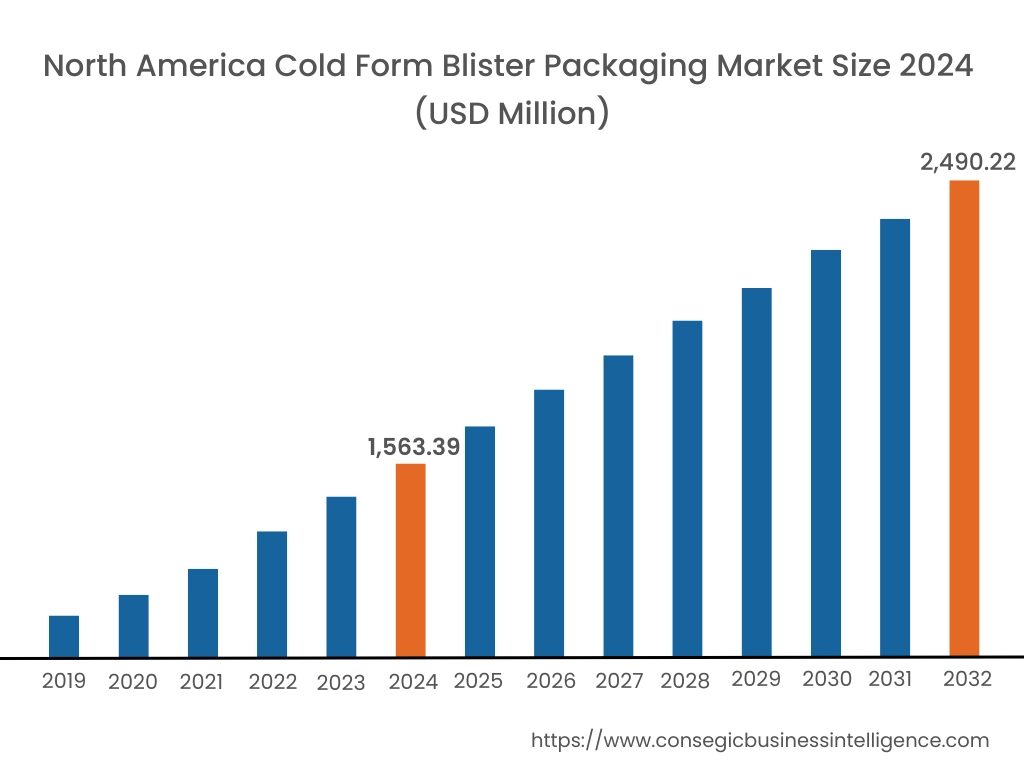

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,563.39 Million and is expected to reach USD 2,490.22 Million in 2032. In North America, the U.S. accounted for the highest share of 71.95% during the base year of 2024. North America holds a significant share of the cold form blister packaging market. The demand for this packaging is driven by the increasing need for pharmaceutical packaging due to the expanding healthcare sector. The U.S. dominates the market, with major pharmaceutical companies investing in packaging solutions that ensure product safety and compliance with regulatory standards. Factors such as stringent regulations and rising health awareness further support market development in this region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 6.7% over the forecast period. The Asia-Pacific region is witnessing rapid expansion in the cold form blister packaging market. The growing pharmaceutical industry in countries like China and India, coupled with increasing disposable incomes, is contributing to cold form blister packaging market demand. Additionally, the rise in healthcare infrastructure and the growing middle-class population are increasing the need for advanced packaging solutions in this region. Manufacturers in Asia-Pacific are investing heavily in modernizing packaging processes to meet international standards.

Europe is another dominant region in the cold form blister packaging market. Countries like Germany, France, and the U.K. are at the forefront due to their established pharmaceutical sectors. The increasing demand for protective and tamper-evident packaging solutions, along with rising regulatory requirements in the region, are influencing the market. Additionally, sustainability concerns are pushing manufacturers to adopt eco-friendly and recyclable packaging solutions in Europe.

In the Middle East and Africa, the cold form blister packaging market is experiencing steady growth. The expanding pharmaceutical sector, particularly in countries like Saudi Arabia and the UAE, is increasing the demand for advanced packaging solutions. The region is also seeing higher investments in healthcare infrastructure, which is positively influencing the market. However, the market faces challenges related to the economic stability and political conditions in certain countries, which can affect overall demand.

The cold form blister packaging market in Latin America is driven by growing healthcare needs and the increasing prevalence of chronic diseases. Countries like Brazil and Mexico are seeing a rise in pharmaceutical manufacturing and packaging solutions. The demand for child-resistant and secure packaging is on the rise due to increasing healthcare regulations in the region. Despite some economic challenges, the growing population and improvements in healthcare services continue to create cold form blister packaging market opportunities for expansion.

Top Key Players & Market Share Insights:

The Global Cold Form Blister Packaging Market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Global Cold Form Blister Packaging Market. Key players in the Cold Form Blister Packaging industry include-

- Amcor plc (Australia)

- Essentra plc (United Kingdom)

- Multivac Inc. (United States)

- SteriPack (Ireland)

- Rondo Packaging (Germany)

- Klockner Pentaplast (Germany)

- Uflex Limited (India)

- Sealed Air Corporation (United States)

- Bilcare Limited (India)

- Constantia Flexibles (Austria)

Cold Form Blister Packaging Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 7,683.49 Million |

| CAGR (2025-2032) | 6.3% |

| By Material Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Cold Form Blister Packaging Market? +

In 2024, the Cold Form Blister Packaging Market was USD 4,713.14 million.

What will be the potential market valuation for the Cold Form Blister Packaging Market by 2032? +

In 2032, the market size of Cold Form Blister Packaging Market is expected to reach USD 7,683.49 million.

What are the segments covered in the Cold Form Blister Packaging Market report? +

The material type, application, and end-use industry are the segments covered in this report.

Who are the major players in the Cold Form Blister Packaging Market? +

Amcor plc (Australia), Essentra plc (United Kingdom), Klockner Pentaplast (Germany), Uflex Limited (India), Sealed Air Corporation (United States), Bilcare Limited (India), Constantia Flexibles (Austria), Multivac Inc. (United States), SteriPack (Ireland), Rondo Packaging (Germany) are the major players in the Cold Form Blister Packaging market.