- Summary

- Table Of Content

- Methodology

Cobalt Alloy Powder Market Introduction :

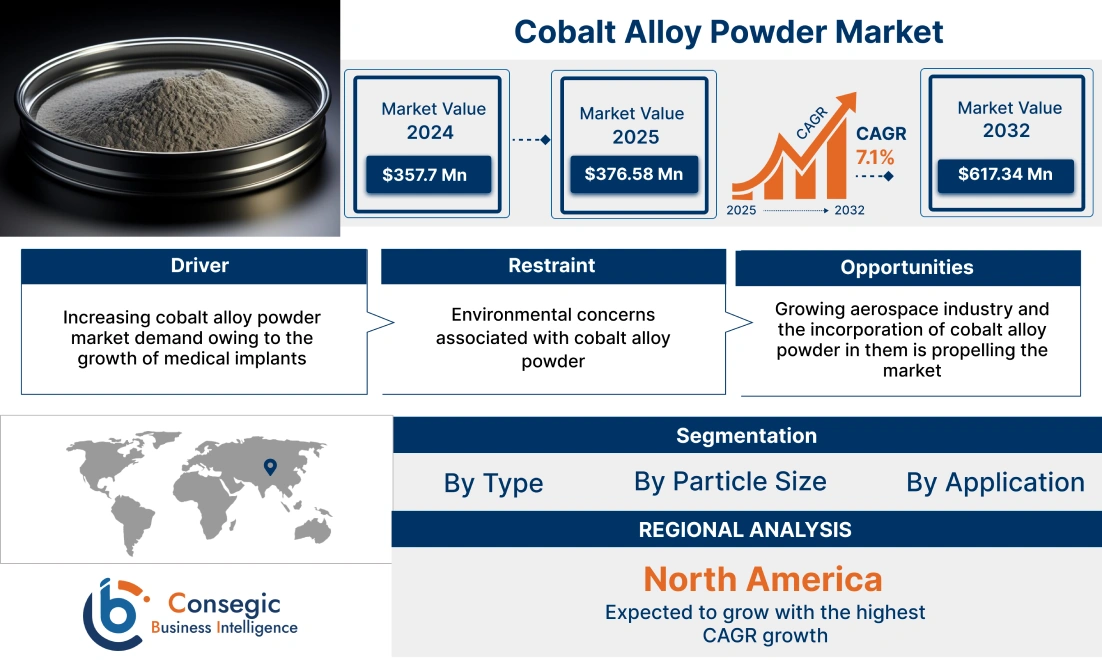

Consegic Business Intelligence analyzes that the Cobalt Alloy Powder Market size is estimated to reach over USD 617.34 Million by 2032 from a value of USD 357.7 Million in 2024 and is projected to grow by USD 376.58 Million in 2025, growing at a CAGR of 7.10% from 2025 to 2032.

Cobalt Alloy Powder Market Definition & Overview:

Cobalt alloy powder is defined as a finely divided form of material that combines cobalt with other elements to improve its properties for a range of industrial uses. These alloys usually comprise elements like molybdenum, nickel, tungsten, and chromium, which combine to form a strong, resilient substance with distinct properties. Chromium improves corrosion resistance, which makes cobalt alloys appropriate for high-temperature and chemically hazardous environments. Since tungsten adds to the alloy's hardness, it is particularly beneficial in applications where durability is essential. Molybdenum helps to improve the alloy's performance at high temperatures, while nickel improves the alloy's overall stability.

Chromium increases the corrosion resistance of cobalt alloy, which makes it appropriate for high-temperature and chemically aggressive environments. The hardness of the alloy is enhanced by tungsten, which makes it useful in situations where resistance is required. On the other hand, molybdenum helps to improve the alloy's performance at high temperatures, while nickel improves overall strength and stability. Manufacturing of high-performance turbine blades for gas turbines and aircraft engines is one frequent use of cobalt powder. Strength, hardness, resistance to corrosion, and tolerance to high temperatures are the major properties of cobalt powder. Based on the analysis, due to their biocompatibility and wear resistance, cobalt alloys are utilized in the medical sector for the production of orthopedic implants. The powder is made by incorporating raw materials and following that through several metallurgical procedures like casting, melting, and powder metallurgy. These techniques ensure an even dispersion of alloying elements, producing a fine powder with the required characteristics.

Global Cobalt Alloy Powder Market Insights :

Key Drivers :

Increasing cobalt alloy powder market demand owing to the growth of medical implants

The use of this powder is encouraged by the rising demand for long-lasting and biocompatible medical implants, such as dental implants, spinal fusion devices, and hip and knee replacements. Because of the exceptional properties of cobalt alloy power such as resistance to corrosion, durability, strength, and stability, it is used in the medical industry, especially in the manufacturing of medical implants. Medical implants are defined as the devices or tissues that are used inside or outside the body to support, improve, or replace biological functions. These devices can range in complexity from basic devices to complex artificial organs, and they are generally used for therapeutic or diagnostic purposes. Modern medicine relies on medical implants to treat a variety of ailments.

Orthopedic implants consist of implants for the hips and knees as well as other joints, as well as implants for the bones and joints to treat degenerative diseases of fractures. Dental implants are surgically inserted into the jawbone to replace mossing teeth. They also act as anchors for dental prosthetics, or artificial teeth.

For instance,

- A study published in Frontiers in Surgery in December 2020 revealed that 457 dental implants with rough surfaces were used to support 71 complete dental prostheses fixed to implants in 52 patients. The implants were made using cobalt alloy powder and had a survival rate of 98.7% after 5.2 years.

Thus, the rise in medical implants is boosting the cobalt alloy powder market growth.

The incorporation of high-efficiency turbines drives cobalt alloy powder demand

The need for cobalt alloy powder has significantly increased due to the growing demand for high-efficiency turbines, which represents a crucial connection between material research and advanced engineering. Because of their excellent mechanical qualities such as the ability to withstand heat, and corrosion resistance, cobalt alloy has become essential in the development of turbines used in aerospace and energy generation industries. Turbine technology has advanced as a result of efforts to discover greener and more efficient energy sources for power generation. These changes are generally dependent on high-efficiency turbines, and cobalt powder helps create components that are durable and efficient enough to survive the demand of power generation. Turbines are generally used in wind power, in heat engines and hydropower generation. Turbines play a crucial role in hydropower power generation, converting the kinetic energy of flowing water into mechanical energy and then into electrical energy.

For instance,

- In October 2022, the Ministry of Power issued an amendment to the Scheme for Flexibility in the Generation and Scheduling of Thermal/Hydro Power Stations by bundling with renewable energy and storage power.

Thus, the increase in the use of turbines is boosting the expansion of the cobalt alloy powder market trends.

Key Restraints :

Environmental concerns associated with cobalt alloy powder

Cobalt is an essential ingredient in the production of this alloy powders. The extraction and processing of cobalt is the main source of environmental concern regarding this powder. The majority of cobalt is produced by mining operations, which are particularly concentrated in some areas. Deforestation, habitat destruction, and soil erosion can result from cobalt mining. Open-pit mining has been linked to ecological disruption and landscape alterations. Moreover, cobalt is not as abundant as some other metals. Overexploitation of cobalt results in long-term environmental damage and potentially damaging the ecosystem. Thus, these factors are restraining the expansion of the market trends.

Future Opportunities :

Growing aerospace industry and the incorporation of cobalt alloy powder in them is propelling the market

The powder is used extensively in the aerospace sector to meet the requirements needed for components used in aircraft and spacecraft. It is used in spacecraft and satellite parts, highlighting its role in advancing aviation and space exploration technologies.

Alloys containing cobalt in powder form, have exceptional heat resistance. Because of this property, they can be used in aerospace applications where the parts may come into contact with high temperatures, such as the combustion chambers of jet engines. The powder is used in the production of strong, lightweight components that are essential for improving aircraft performance and fuel economy. An exponential expansion is observed in the aviation and aerospace sectors.

For instance,

- According to IBEF, India is expected to become the world's third-largest air passenger market by 2030, surpassing both China and the US. Furthermore, the number of airplanes in India is projected to reach 1,100 by 2027.

Thus these advancements are creating lucrative cobalt alloy powder market opportunities and trends for the development of the market.

Cobalt Alloy Powder Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 (USD Million) | USD 617.34 Million |

| CAGR (2025-2032) | 7.1 % |

| By Type | Cobalt-Chromium (Co-Cr), Cobalt-Chromium-Molybdenum(Co-Cr-Mo), Cobalt-Nickle(Co-Ni), Cobalt-Iron(Fe-Co), and Others. |

| By Particle Size | Nano-sized powder, Fine powder, Coarse powder |

| By Application | Additive Manufacturing, Brazing, Metal Injection Molding, Plasma and thermal spray, and Others |

| By Region | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Players | Höganäs Sweden, Eramet, Sherritt International, Minara Resources Pty Ltd., Mitsui, Norilsk Nickel, Sandviken, Shepherd chemical company, Sumitomo Metal Mining, Umicore- Cobalt & Specialty Materials |

Cobalt Alloy Powder Market Segmental Analysis :

Based on the Type :

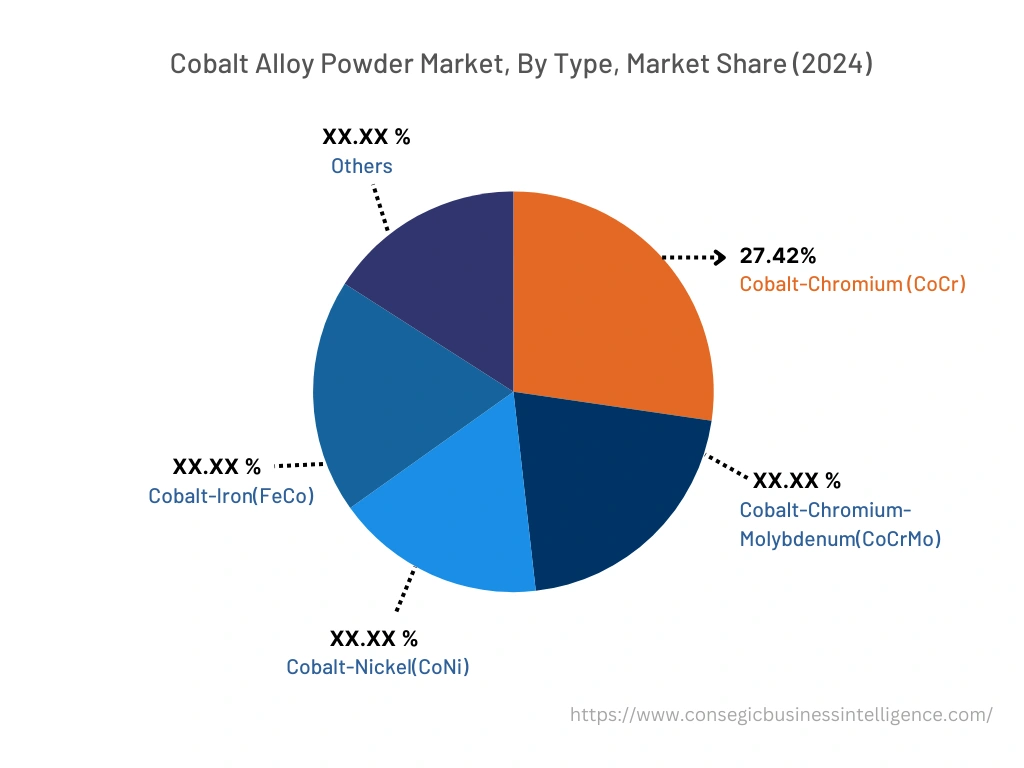

The type is categorized into Cobalt-Chromium (CoCr), Cobalt-Chromium-Molybdenum(CoCrMo), Cobalt-Nickle(CoNi), Cobalt-Iron(FeCo), and Others. In 2024, cobalt-chromium (CoCr) accounted for the highest cobalt alloy powder market share of 27.42% in the market. Cobalt chromium is formed by combining elements such as cobalt and chromium. Cobalt chromium is a metallic alloy that usually contains elements such as nickel, tungsten, and molybdenum. This alloy is widely used in industries, including dentistry, aerospace, and medical implants, because of its mechanical and thermal properties. CoCr is well known for its strength, resistance to corrosion, and biocompatibility, and is used in dental prosthetics, orthopedic implants, and aerospace parts like jet engine turbine blades. Based on the analysis, stability in extremely cold temperatures is supported by its heat resistance. CoCr is used in the dental sector, particularly in prosthodontics and restorative dentistry.

For instance,

- In May 2021, Wall Colmonoy Limited launched a new range of Wellex, cobalt chromium powders for the dental sector. It is ideal for dental implants, partial dentures, and prosthetics, due to its biocompatibility, strength, and wear resistance.

Thus, these advancements are boosting the growth and trends of the segment.

Moreover, the cobalt-chromium-molybdenum(CoCrMo) segment is expected to grow at the fastest CAGR in the overall cobalt alloy powder market. CoCrMo is a strong alloy used in orthopedic implants such as knee and hip replacements. It resists wear and corrosion in the human body and is well known for biocompatibility and durability. Longevity in implant application is ensured by the alloy's composition, which includes cobalt for corrosion resistance and molybdenum for added toughness. Its success in orthopedic surgeries can be attributed to its endurance to the harsh biomechanical conditions found in joints, which offer patients dependable and durable support.

For instance,

- In August 2023, Smith+ Nephew launched OR30 a dual mobility system in India for hip arthroplasty.

Thus, these developments are creating opportunities and trends for the market.

Based on the Particle Size :

The particle size is categorized into nano-sized powder, fine powder, and coarse powder. In 2024, coarse powder accounted for the highest market share in the market and is expected to grow at the fastest CAGR in the overall cobalt alloy powder market. Larger particle sizes, usually greater than 100 microns, define coarse cobalt alloy powder. This alloy contains cobalt in addition to chromium and molybdenum, which makes it a desirable option for various applications. The alloy powder in coarse form is a basic material in powder metallurgy that is used to create components with improved mechanical properties and regulated porosity. Because of its strength, it can be incorporated into industrial machinery where toughness and wear resistance are crucial.

Based on the analysis, coarse alloy powder is used in the medical sector, especially in the orthopedic department for implants such as hip and knee replacements. Coarse cobalt alloy powder has the ability to withstand corrosion and wear reinforces which signifies the development of medicine.

For instance,

- Ametek Specialty Metal Products (SMP), in October 2020, observed an increasing demand for metal filter powders for ventilators.

Thus, the advancement is boosting the growth of the segment.

Based on the Application :

The application is categorized into additive manufacturing, brazing, metal injection molding, plasma and thermal spray, and others. In 2024, metal injection molding accounted for the highest market share in the cobalt alloy powder market. For this alloy powder, metal injection molding (MIM) offers, a promising path in advanced manufacturing. MIM is a powder metallurgy technique that combines a variety of metal powders as a material with the designed flexibility of plastic injection molding. With cobalt alloys such as CoCrMo, this technique enables complex geometries and accurate parts. This powder and a thermoplastic binder are combined in the MIM process to create feedstock that is subsequently injection molded into a predetermined shape. As per the analysis, the final metal part is obtained by sintering the part at a high temperature after it has undergone a debinding process to remove the binder.

For instance,

- In 2021, Metal Powder Products announced its acquisition of US-based Proform Powdered Metals. The company usually supplies high-quality sintered bronze bearings and spacers made from the MIM technique.

Thus, these factors are boosting the trends of the segment.

Moreover, the additive manufacturing segment is expected to grow at the fastest CAGR in the overall cobalt alloy powder market. The market for cobalt alloy is changing as a result of additive manufacturing, or 3D printing. This process is advantageous for cobalt alloys, such as CoCrMo, because of their superior mechanical properties. Intricate designs and customizations are made possible by this technology, especially when it comes to patient-specific medical implants.

For instance,

- In August 2023, Kennametal launched KAR85-AM-K, a corrosion-resistant tungsten for metal additive manufacturing.

Thus these factors are boosting the growth and trends of the segment.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

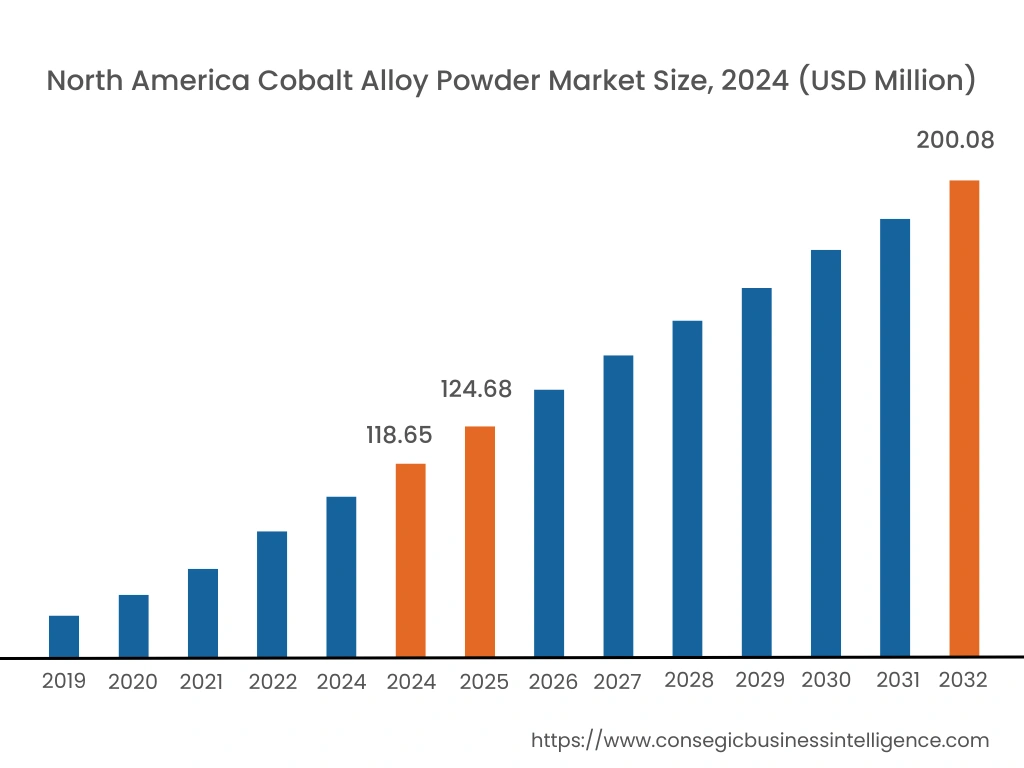

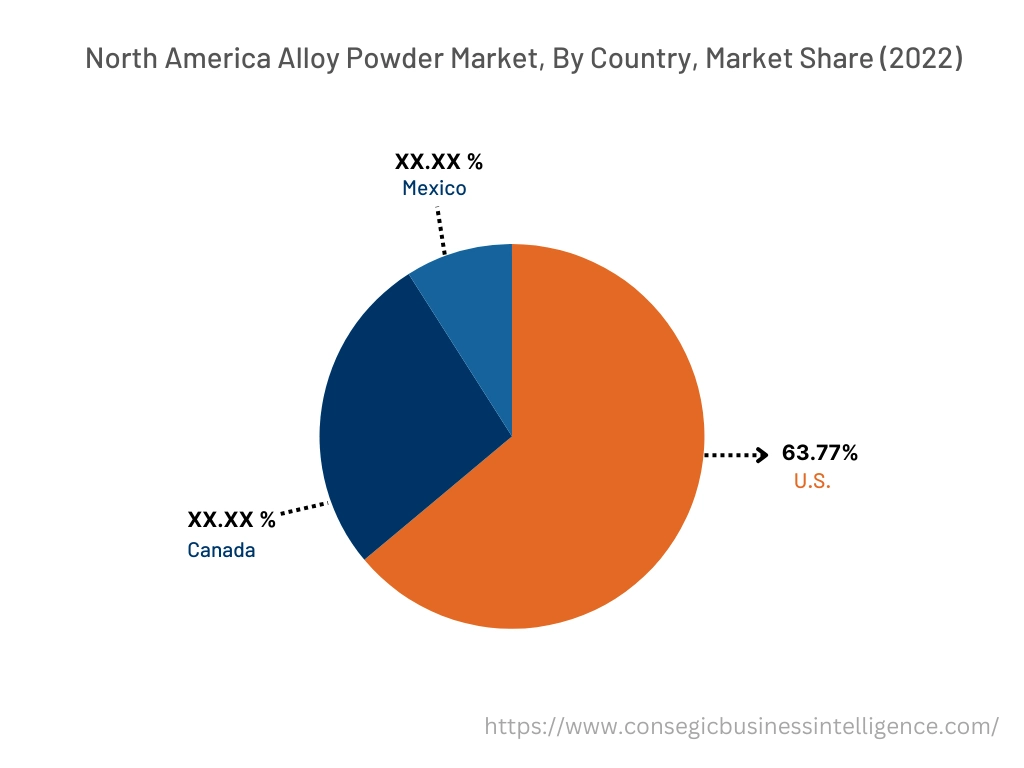

North America is estimated to reach over USD 200.08 Million by 2032 from a value of USD 118.65 Million in 2024 and is projected to grow by USD 124.68 Million in 2025. In North America, the US accounted for a major market share of 63.77% in the year 2024. Based on the cobalt alloy powder market analysis, technological advancements are observed in the aerospace and healthcare sectors. Moreover, as per the analysis, various research and developments are occurring in the North America region.

For instance,

- According to Science and Engineering Indicators, US research and experimental development (R&D) spending hit USD 581 billion in 2019 and is expected to reach USD 658 billion in 2020. Thus, the aforementioned factors are boosting the market in North America region.

Furthermore, the Asia Pacific region is expected to witness significant growth over the forecast period, growing at a CAGR of 7.9% during 2025-2032. The increase in the industrial and construction sector is observed in the Asia Pacific region because of the rise in population and developments in the region. Thus, these factors are boosting the growth and of the market in the Asia Pacific region.

Top Key Players & Market Share Insights :

The global cobalt alloy powder market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The cobalt alloy powder industry is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market size through mergers, acquisitions, and partnerships. The key players in the market include-

Recent Industry Developments :

- In February 2023, Wisconsin-based Winsert purchased Alloy Cast Products Inc., a manufacturer of exotic cobalt alloys specializing in investment casting and machining.

Key Questions Answered in the Report

What was the market size of the Cobalt alloy powder Market in 2024? +

In 2024, the market size of cobalt alloy powder was USD 357.7 million.

What will be the potential market valuation for the cobalt alloy powder industry by 2032? +

In 2032, the market size of cobalt alloy powder will be expected to reach USD 617.34 million.

What are the key factors driving the growth of the Cobalt alloy powder? +

Increasing demand of cobalt alloy powder owing to the growth of medical implants.

What is the dominant segment in the Cobalt alloy powder for the particle size? +

In 2024, the coarse powder segment accounted for the highest market share.

Based on current market trends and future predictions, which geographical region is the dominant in the Cobalt alloy powder Market? +

North America accounted for the highest market share in the overall market.