- Summary

- Table Of Content

- Methodology

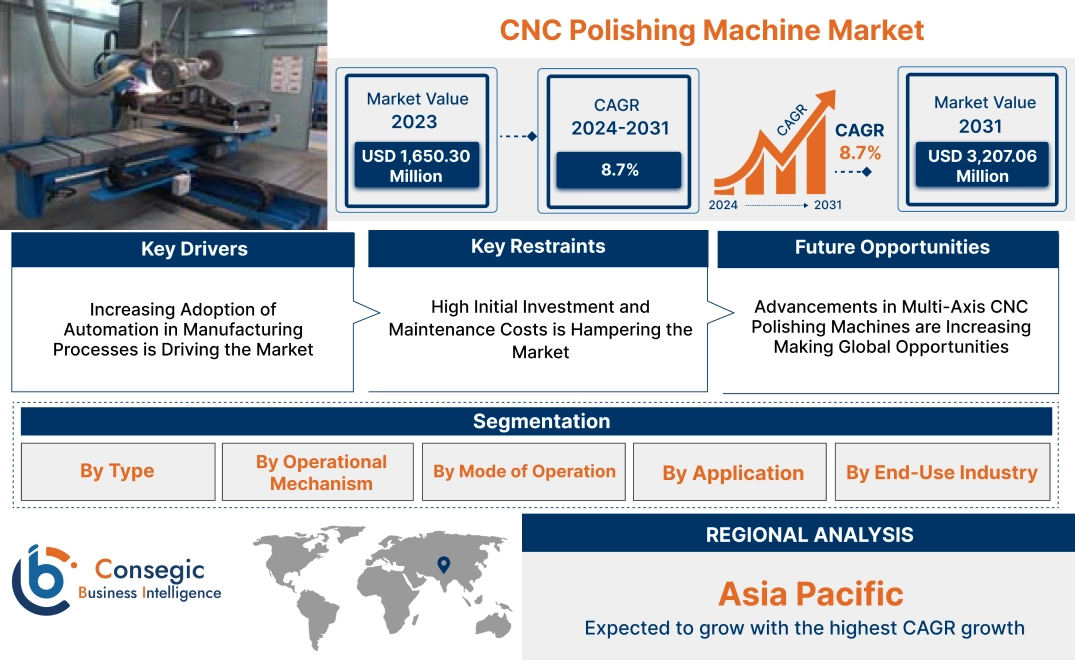

CNC Polishing Machine Market Size:

CNC Polishing Machine Market size is estimated to reach over USD 3,207.06 Million by 2031 from a value of USD 1,650.30 Million in 2023 and is projected to grow by USD 1,763.81 Million in 2024, growing at a CAGR of 8.7% from 2024 to 2031.

CNC Polishing Machine Market Scope & Overview:

The CNC polishing machine technologies are computer-controlled polishing systems designed to deliver high-precision surface finishes across a wide range of materials, including metals, plastics, and ceramics. These machines are widely used in industries where accuracy, consistency, and efficiency in surface treatment are critical. Key characteristics of polishing machines include programmable control, automation, and compatibility with complex geometries, ensuring uniform and superior polishing results. The benefits include enhanced surface quality, reduced manual labor, and increased productivity in manufacturing processes. Applications span automotive components, aerospace parts, medical devices, and electronic products, where precise finishing is essential for performance and aesthetics. End-users include automotive manufacturers, aerospace companies, electronics producers, and industrial machinery developers, driven by advancements in automation technologies, growing CNC polishing machine market trends for high-quality finished products, and the increasing adoption of smart manufacturing practices.

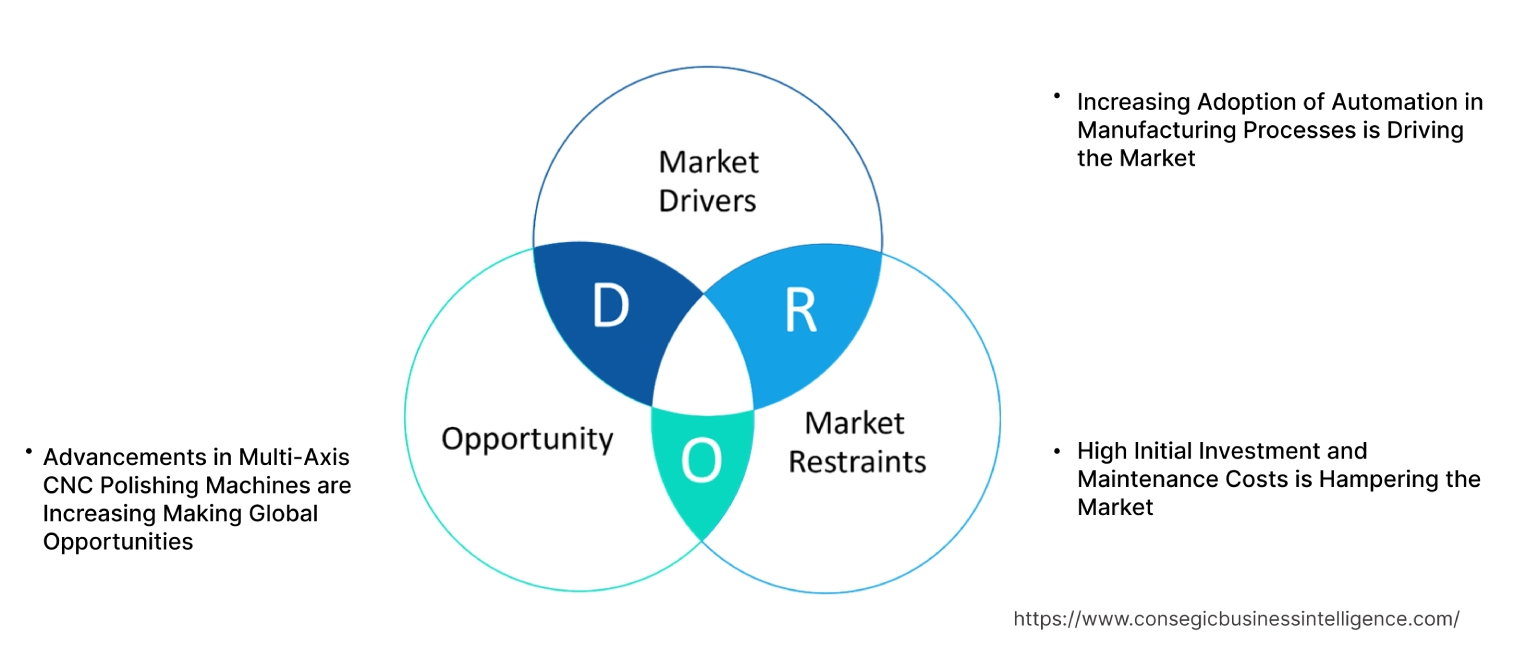

Key Drivers:

Increasing Adoption of Automation in Manufacturing Processes is Driving the Market

The growing shift toward automation in manufacturing has significantly impacted the adoption of CNC polishing machines. These machines provide unparalleled precision, consistency, and efficiency in polishing applications across industries such as automotive, aerospace, and electronics. By automating the polishing process, manufacturers can achieve high-quality surface finishes while reducing human error and operational inefficiencies.

Trends in industrial automation emphasize the importance of minimizing production downtime and enhancing scalability. The polishing machines, equipped with advanced control systems, allow for seamless integration into smart manufacturing workflows. The analysis highlights that as industries focus on optimizing production processes and adhering to stringent quality standards, automated CNC solutions are becoming an integral part of modern manufacturing strategies.

Key Restraints:

High Initial Investment and Maintenance Costs is Hampering the Market

One of the primary challenges associated with CNC polishing machines is their high upfront cost. These machines are equipped with advanced technology and precision components, which significantly increase their price. Additionally, maintaining CNC machines involves regular calibration, replacement of wear-and-tear parts, and software updates, all of which contribute to ongoing operational expenses.

For small and medium-sized enterprises (SMEs), these financial barriers can deter adoption, especially in cost-sensitive markets. Furthermore, the need for skilled technicians to operate and maintain these machines adds to the overall costs, creating additional hurdles for manufacturers with limited resources. Addressing these concerns through cost-efficient designs and financing options could help expand the accessibility of CNC polishing technology.

Future Opportunities :

Advancements in Multi-Axis CNC Polishing Machines are Increasing Making Global Opportunities

Technological advancements in multi-axis CNC polishing machines have opened new possibilities for achieving complex and precise surface finishes. Multi-axis machines allow for the polishing of intricate geometries and high-value components used in industries like aerospace, medical devices, and high-end consumer goods. Their ability to perform multiple operations in a single setup enhances productivity and reduces production time.

Trends in advanced manufacturing emphasize the need for versatile and adaptive solutions, making multi-axis CNC systems a critical innovation in the market. These machines also integrate features such as real-time monitoring and AI-driven optimization, further enhancing their efficiency and reliability. As industries increasingly adopt sophisticated manufacturing techniques, multi-axis are positioned to address complex challenges and drive innovation across diverse applications.

CNC Polishing Machine Market Segmental Analysis :

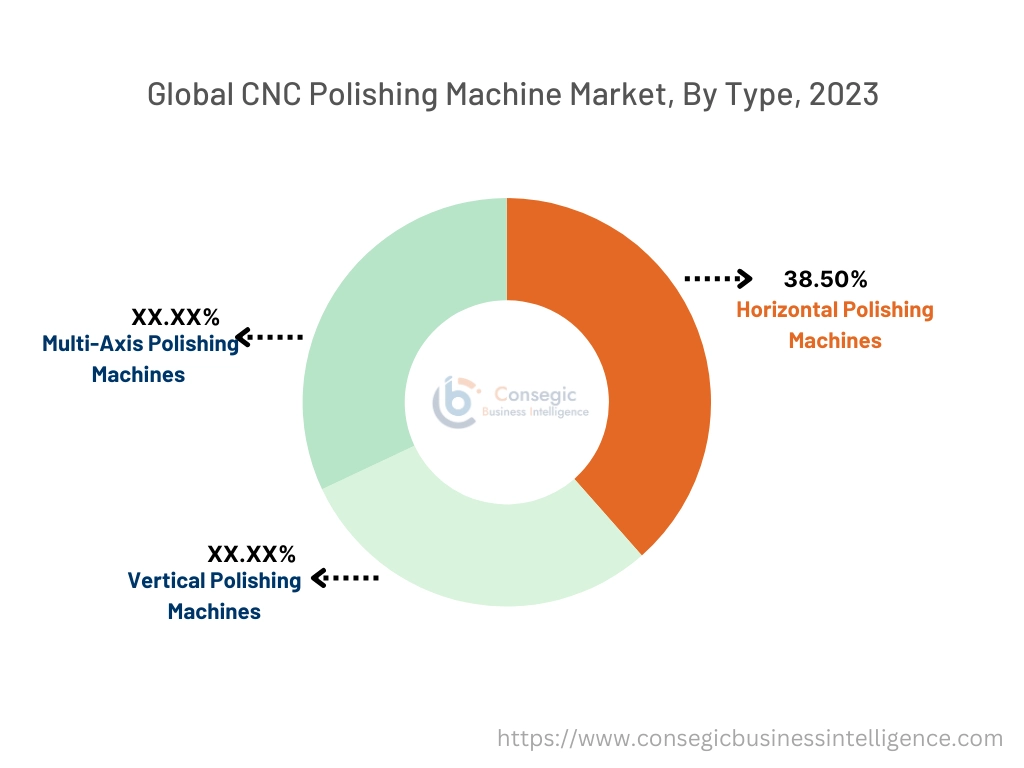

By Type:

Based on type, the market is segmented into horizontal polishing machines, vertical polishing machines, and multi-axis polishing machines.

The horizontal polishing machines segment accounted for the largest revenue of 38.50% in the CNC polishing machine market share in 2023.

- Horizontal polishing machines are widely utilized for polishing flat or slightly curved surfaces in a variety of industries, including automotive, electronics, and aerospace.

- These machines offer high precision and uniform polishing, making them ideal for applications requiring consistent surface finishes.

- Horizontal machines are particularly valued for their versatility, as they can handle a wide range of materials such as metals, plastics, and ceramics.

- Additionally, their efficient design and ease of operation make them a preferred choice in large-scale industrial settings.

- The trends for horizontal polishing machines are primarily driven by the increasing need for surface quality enhancement and finishing in manufacturing processes.

The multi-axis polishing machines segment is anticipated to register the fastest CAGR during the forecast period.

- Multi-axis polishing machines are gaining popularity due to their ability to handle complex shapes and intricate surfaces.

- These machines are extensively used in industries such as aerospace, jewelry, and pharmaceuticals, where precision and detailed finishing are critical.

- Equipped with advanced control systems and automation capabilities, multi-axis machines provide flexibility and superior performance for high-value applications.

- The growing adoption of additive manufacturing and 3D printing, which require advanced polishing solutions for intricate geometries, is a key factor driving the CNC polishing machine market growth of this segment.

By Operational Mechanism:

Based on the operational mechanism, the polishing machines market is segmented into pneumatic polishing machines and electric polishing machines.

The electric polishing machines segment accounted for the largest revenue share in 2023.

- Electric polishing machines are highly preferred across various industries due to their superior power output, reliability, and ease of use.

- These machines are extensively used for polishing metals, plastics, and ceramics in applications such as automotive, aerospace, and electronics manufacturing.

- Electric machines provide consistent performance and are compatible with automated systems, making them suitable for modern manufacturing processes.

- The increasing focus on energy efficiency and cost-effective operations has further bolstered the CNC polishing machine market trends as per the analysis for electric polishing machines in the global market.

The pneumatic polishing machines segment is anticipated to register the fastest CAGR during the forecast period.

- Pneumatic polishing machines operate using compressed air, offering several advantages such as lightweight design, enhanced safety, and lower operational costs.

- These machines are particularly favored in industries where explosive environments may be present, such as in pharmaceuticals and chemicals.

- Their ability to deliver precise and smooth finishes makes them suitable for polishing delicate materials like glass and ceramics.

- The growing adoption of pneumatic machines in specialized applications, combined with advancements in pneumatic technologies, is driving their rapid growth in the CNC polishing machine market expansion.

By Mode of Operation:

Based on the mode of operation, the polishing machines market is segmented into automatic polishing machines and semi-automatic polishing machines.

The automatic polishing machines segment accounted for the largest revenue share in 2023.

- Automatic polishing machines are widely used in industrial settings due to their ability to perform high-precision polishing tasks with minimal manual intervention.

- These machines are equipped with advanced control systems and sensors, enabling consistent quality and increased productivity.

- Automatic machines are extensively adopted in sectors such as automotive, aerospace, and electronics, where efficiency and precision are critical.

- The integration of robotic systems in automatic polishing machines has further enhanced their capabilities, making them the preferred choice for large-scale manufacturing operations.

The semi-automatic polishing machines segment is anticipated to register the fastest CAGR during the forecast period.

- Semi-automatic polishing machines combine manual and automated operations, offering a balance between precision and cost-effectiveness.

- These machines are particularly useful for small and medium-sized enterprises (SMEs) that require flexibility in production processes.

- Semi-automatic machines are widely used in the jewelry and pharmaceutical industries, where intricate detailing and customization are essential.

- The growing demand for cost-efficient solutions with customizable features is expected to drive the growth of this segment analysis.

By Application:

Based on application, the market is segmented into metal polishing, glass polishing, plastic polishing, ceramics polishing, and others.

The metal polishing segment accounted for the largest revenue of the CNC polishing machine market share in 2023.

- Metal polishing machines are extensively used in industries such as automotive, aerospace, and construction for improving the surface finish and enhancing the durability of metal components.

- These machines are crucial for applications like polishing engine parts, aerospace components, and industrial tools.

- The increasing opportunities in adoption for high-quality metal finishes in manufacturing processes, coupled with the trends of industries requiring polished metal surfaces, have driven the dominance of this segment.

- Additionally, advancements in polishing technologies that reduce processing times and improve precision have further propelled the expansion of metal polishing machines.

The glass polishing segment is anticipated to register the fastest CAGR during the forecast period.

- Glass polishing machines are gaining prominence due to their application in industries such as electronics, construction, and automotive.

- These machines are used to enhance the transparency, smoothness, and optical properties of glass products, including smartphone screens, automotive windshields, and architectural glass.

- The rising advancement for premium-quality glass in consumer electronics and automotive applications is a key factor driving the growth of this segment.

- Moreover, the adoption of smart glass technologies and increased investments in construction projects worldwide are expected to boost the CNC polishing machine market demand for glass polishing machines.

By End-Use Industry:

Based on end-use, the market is segmented into automotive, aerospace, electronics, pharmaceuticals, jewelry, and others.

The automotive segment accounted for the largest revenue share in 2023.

- Polishing machines are extensively used in the automotive sector for refining and finishing components such as body panels, wheels, and interior trims.

- The increasing production of vehicles, coupled with the growing demand for premium finishes, has propelled the adoption of polishing machines in this sector.

- Additionally, the rise of electric vehicles (EVs) and autonomous vehicles (AVs), which require advanced manufacturing processes, has further driven the demand for polishing machines.

- Automotive manufacturers are increasingly focusing on enhancing product aesthetics and durability, making polishing machines an essential tool in the sectors.

The jewelry segment is anticipated to register the fastest CAGR during the forecast period.

- The jewelry industry relies heavily on polishing machines to achieve precise and intricate finishes on precious metals and gemstones.

- These machines are essential for enhancing the shine, texture, and overall appearance of jewelry pieces.

- The growing advancement for customized and high-quality jewelry, coupled with advancements in polishing technologies, is driving the adoption of polishing machines in this segment.

- Additionally, the increasing trends of handcrafted and designer jewelry are expected to boost the CNC polishing machine market demand for polishing machines in the jewelry industry during the forecast period.

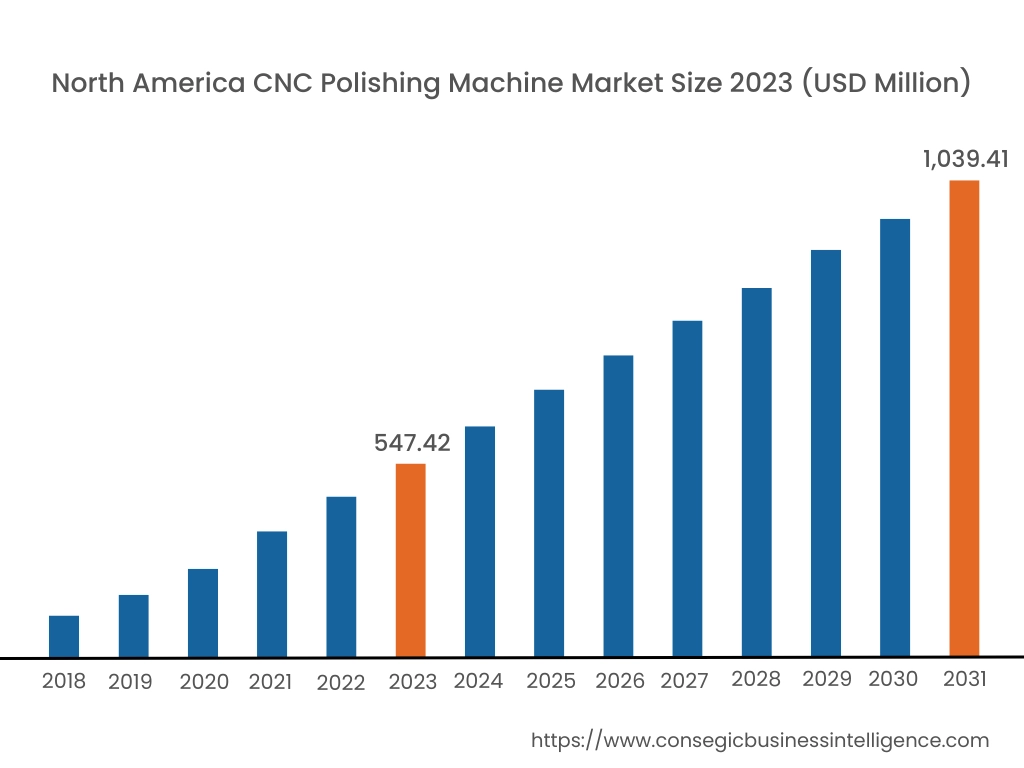

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 547.42 Million and is expected to reach USD 1,039.41 Million in 2031. In North America, the U.S. accounted for the highest share of 72.30% during the base year of 2023. North America holds a significant stake in the CNC polishing machine market analysis, driven by the strong presence of advanced manufacturing industries such as automotive, aerospace, and medical devices. The U.S. leads the region, with high demand for precision polishing solutions to enhance surface finishes and improve the durability of components. The growing adoption of automation and Industry 4.0 technologies further supports the integration of polishing machines in manufacturing processes. Canada contributes with increasing use of CNC machines in the production of high-precision components for aerospace and industrial applications. However, the high cost of advanced CNC machines may limit adoption among small and medium-sized enterprises.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 9.1% over the forecast period. The market is fueled by rapid industrialization, urbanization, and increasing trends from sectors such as consumer electronics, automotive, and machinery in China, Japan, and South Korea. China dominates the market with its expanding manufacturing sector, utilizing polishing machines to improve efficiency and product quality in electronics and automotive production. Japan focuses on high-precision CNC machines for advanced applications in electronics, optics, and medical devices. South Korea emphasizes its use in semiconductor and display manufacturing. India is also witnessing rising adoption, driven by CNC polishing machine market growth in industrial manufacturing. However, limited awareness of advanced polishing technologies in smaller markets may restrict growth in some areas.

Europe is prominent for CNC polishing machines market opportunities, supported by its advanced automotive, aerospace, and industrial sectors. Countries like Germany, France, and Italy are key contributors. Germany leads with the extensive adoption of polishing machines in the automotive and machinery industries to achieve high-quality surface finishes and precision. France emphasizes their use in aerospace applications, particularly for polishing turbine blades and other critical components. Italy’s strong industrial manufacturing base supports the use of CNC machines for polishing decorative and functional parts. However, high labor and operational costs, along with stringent EU regulations on industrial machinery, may pose challenges.

The Middle East & Africa region is experiencing steady development in the CNC polishing machine market, driven by increasing investments in industrial development and infrastructure. Countries like Saudi Arabia and the UAE are adopting polishing machines for use in oil and gas equipment manufacturing, as well as in industrial machinery. In Africa, South Africa is emerging as a market with growing adoption in mining and heavy machinery applications, where precision and durability are essential. However, limited access to advanced machinery and reliance on imports for CNC polishing equipment may hinder market expansion in the region.

Latin America is an emerging global CNC polishing machines market, with Brazil and Mexico leading the region. Brazil’s expanding automotive and aerospace industries drive trends for CNC polishing machines to enhance component quality and meet international standards. As Mexico’s analysis the growing manufacturing sector, particularly in electronics and industrial machinery, supports the adoption of CNC polishing solutions. The region also benefits from increasing interest in automated and high-precision manufacturing processes. However, economic instability and limited infrastructure for advanced manufacturing may pose challenges to broader adoption.

Top Key Players and Market Share Insights:

The CNC Polishing Machine market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global CNC polishing machine market. Key players in the CNC polishing machine industry include -

- DMG Mori Seiki AG (Germany)

- Hwacheon Machinery (South Korea)

- Jieying Machinery (China)

- Supfina (Germany)

- Rollomatic AG (Switzerland)

- Matsuura Machinery Corporation (Japan)

- Yamazaki Mazak Corp. (Japan)

- Mitutoyo Corporation (Japan)

- Danobatgroup (Spain)

- CHIRON Group (Taiwan)

Recent Industry Developments :

Product Launches:

- In August 2024, Mazak showcased next-generation 5-axis machining center featuring a spacious machining area and a tilting/rotary table, ideal for large workpieces. Equipped with the advanced SmoothAi CNC, it offers high-accuracy machining over extended periods.

Innovations:

- In May 2024, Zeeko developed the SAG process, a novel method for polishing and finishing metal, ceramic, and carbide components. This technique employs a low-cost robotic platform and flexible, diamond-impregnated pads, enabling efficient finishing of complex geometries and hard materials.

CNC Polishing Machine Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 3,207.06 Million |

| CAGR (2024-2031) | 8.7% |

| By Type |

|

| By Operational Mechanism |

|

| By Mode of Operation |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the CNC Polishing Machine Market by 2031? +

CNC Polishing Machine Market size is estimated to reach over USD 3,207.06 Million by 2031 from a value of USD 1,650.30 Million in 2023 and is projected to grow by USD 1,763.81 Million in 2024, growing at a CAGR of 8.7% from 2024 to 2031.

What factors are driving the growth of the CNC Polishing Machine Market? +

Key drivers include the increasing adoption of automation in manufacturing processes, growing demand for high-precision surface finishes, and advancements in smart manufacturing practices. The rising use of CNC machines in industries like automotive, aerospace, and electronics further supports market growth.

What challenges does the market face? +

High initial investment and maintenance costs are significant challenges. Additionally, the requirement for skilled technicians and the financial constraints faced by small and medium-sized enterprises (SMEs) hinder market adoption.

What opportunities exist in the market? +

Advancements in multi-axis CNC polishing machines offer significant opportunities, particularly in handling complex geometries and intricate components. Integration with AI-driven optimization and real-time monitoring systems further expands potential applications.