- Summary

- Table Of Content

- Methodology

CNC Fiber Laser Market Introduction :

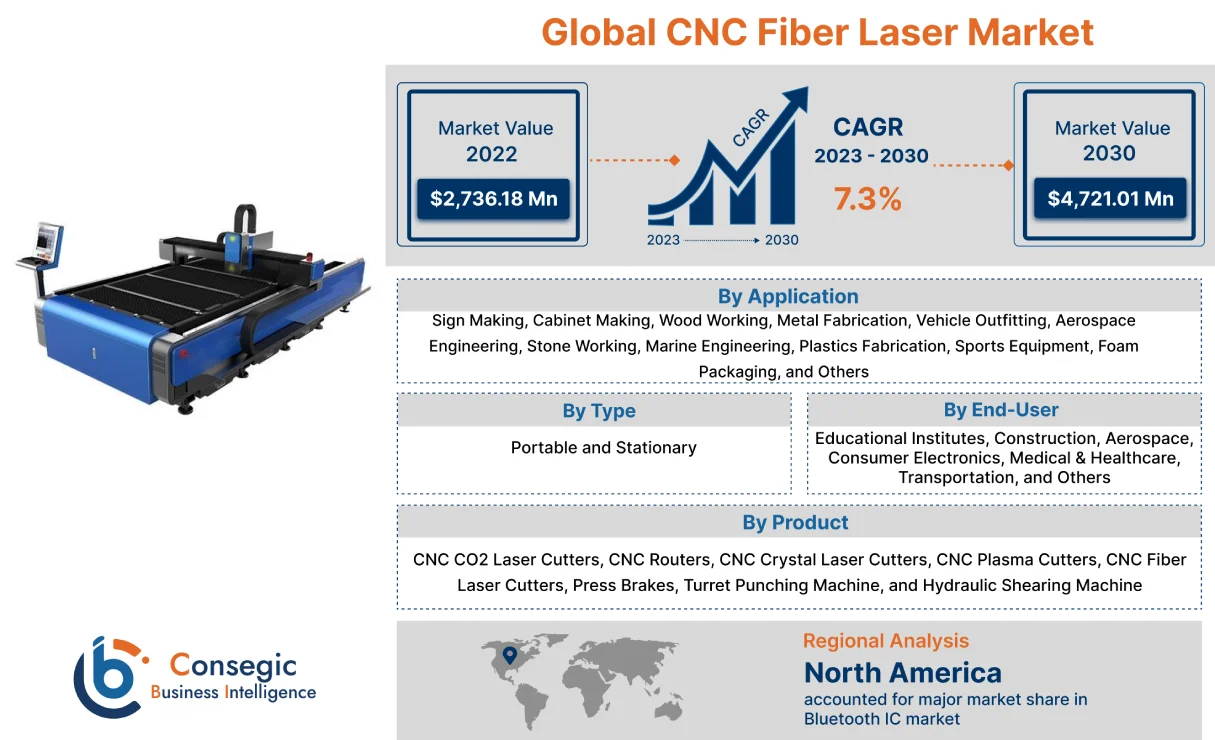

CNC Fiber Laser Market is estimated to reach over USD 4,721.01 Million by 2030 from a value of USD 2,736.18 Million in 2022, growing at a CAGR of 7.3% from 2023 to 2030.

CNC Fiber Laser Market Definition & Overview:

A CNC fiber laser is a computer-controlled machining system that utilizes a high-powered fiber laser source to cut, engrave, and mark various materials with precision. The technology combines Computer Numerical Control (CNC) capabilities, allowing for automated and intricate designs to be executed accurately on materials including metal, plastic, and wood. The fiber laser's concentrated and intense beam rapidly heats and vaporizes the material, resulting in precise cuts with minimal heat-affected zones. Additionally, CNC fiber laser machines are adopted in various end-use industries including manufacturing, automotive, aerospace, and among others.

CNC Fiber Laser Market Insights :

CNC Fiber Laser Market Dynamics - (DRO) :

Key Drivers :

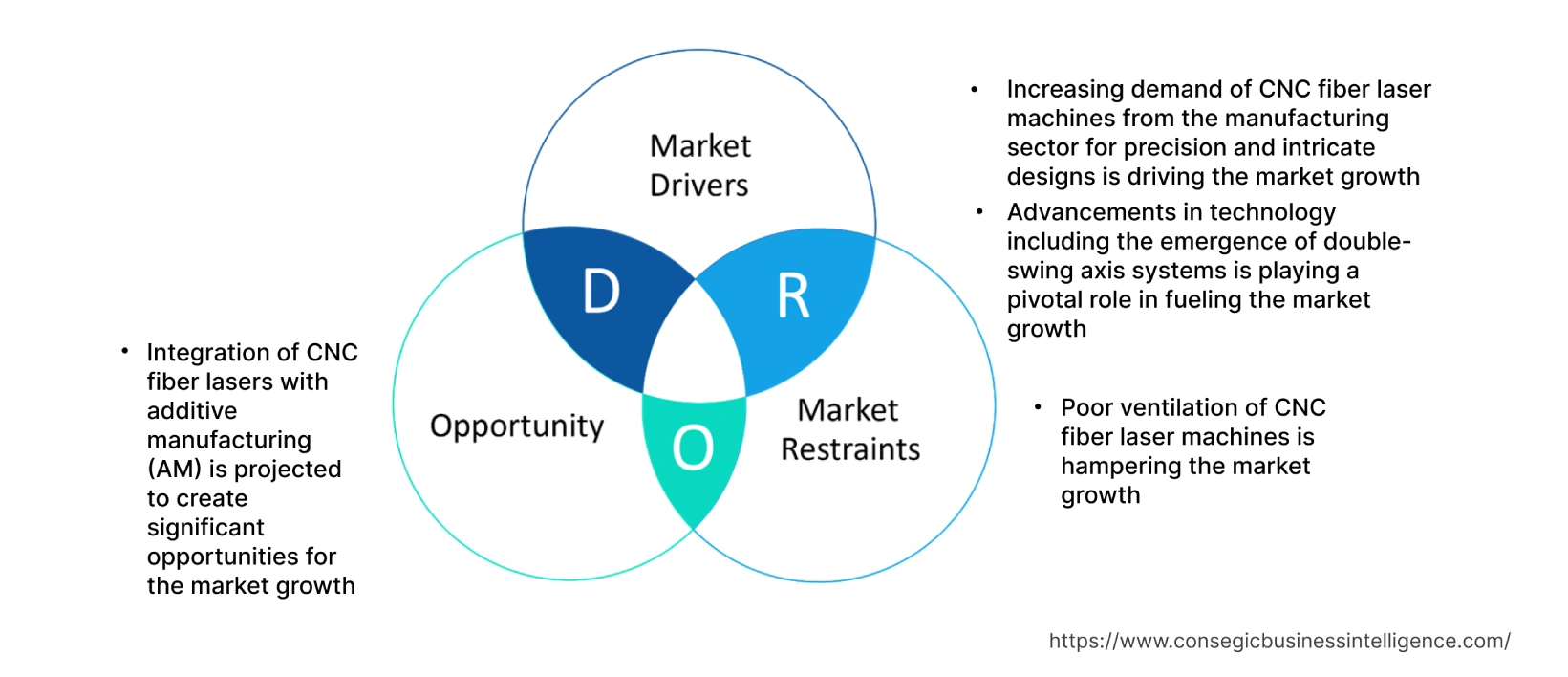

Increasing demand of CNC fiber laser machines from the manufacturing sector for precision and intricate designs is driving the market growth

CNC fiber lasers utilize a highly focused laser beam that is precisely controlled through a computer numerical control (CNC) system. Precise control allows for intrinsic cuts and markings that were previously challenging to achieve with conventional methods. Additionally, CNC fiber lasers also enable delicate patterns engravings on jewelry and fine details on electronic devices, further driving the adoption of fiber lasers. Moreover, the consistency and repeatability offered by CNC fiber lasers ensure that each manufactured piece meets the same high standard of precision. Consequently, CNC fiber lasers offer a solution by providing unparalleled precision, enabling manufacturers to create intricate designs and fine features on a variety of materials. For instance, in June 2020, Yamazaki Mazak UK Ltd. launched FT-150 FIBER a compact fiber laser processing machine to cut a wide variety of materials including stainless steel, copper, mild steel, brass, and aluminum. The advanced FT-150 FIBER machine is designed to deliver accurate and high-quality cutting and facilitates ultra-high-speed cutting to avoid internal surface burning, thus contributing significantly in accelerating the market growth.

Advancements in technology including the emergence of double-swing axis systems is playing a pivotal role in fueling the market growth

Double-axis swing technology allows the laser cutting head to move along two separate axes while performing rotational movement. The multi-dimensional movement capability enables the laser to approach the material from various angles, facilitating the cutting of complex shapes, bevels, chamfers, and contours with precision. In addition, double axis swing also provides a high degree of reproducibility, finer adjustments, and minimizes workpiece interference that occurs during the processing of complex shapes. Subsequently, the ability of double-swing axis systems to offer improved productivity with shorter processing time is contributing notably in boosting the growth of the CNC fiber laser market. For instance, in March 2023, Amada Press System Co., Ltd. launched LM-16A, a 15-axis CNC machine with a wire-rotating mechanism and double-swing axis. The machine enables a high degree of reproducibility, fine movement, and high-precision processing, hence contributing significantly in propelling the growth of the market.

Key Restraints :

Poor ventilation of CNC fiber laser machines is hampering the market growth

CNC fiber laser machines generate high-energy laser beams that interact with materials through cutting, engraving, and marking processes. Additionally, laser cutting also produces fumes, smoke, and particles as materials are vaporized. Inefficient ventilation leads to the accumulation of byproducts in the working area, posing health risks to machine operators due to potential exposure to harmful substances and poor air quality. Moreover, the production of flammable gases, fumes, and particles in an improperly ventilated environment is susceptible to fire accidents, particularly while working with materials including plastic and wood. In conclusion, the poor ventilation associated with CNC fiber laser machines is impeding the growth of the global market.

Future Opportunities :

Integration of CNC fiber lasers with additive manufacturing (AM) is projected to create significant opportunities for the market growth

CNC fiber lasers in combination with additive manufacturing precisely melt and fuse metal powders layer by layer, enabling the creation of intricate and complex geometries that were challenging to achieve with traditional subtractive manufacturing methods. Additionally, the integrated approach also allows to selectively melt and fuse multiple materials within the same part, paving the way for creating functional gradients, composite structures, and components with varying material properties. Moreover, integration is also utilized for post-processing steps including surface finishing, polishing, and marking, streamlining the production process and reducing the need for additional equipment. In conclusion, the combination of CNC fiber lasers with additive manufacturing is anticipated to create potential opportunities for market growth.

CNC Fiber Laser Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 4,721.01 Million |

| CAGR (2023-2030) | 7.3% |

| By Type | Portable and Stationary |

| By Product | CNC CO2 Laser Cutters, CNC Routers, CNC Crystal Laser Cutters, CNC Plasma Cutters, CNC Fiber Laser Cutters, Press Brakes, Turret Punching Machine, and Hydraulic Shearing Machine |

| By Application | Sign Making, Cabinet Making, Wood Working, Metal Fabrication, Vehicle Outfitting, Aerospace Engineering, Stone Working, Marine Engineering, Plastics Fabrication, Sports Equipment, Foam Packaging, and Others |

| By End-User | Educational Institutes, Construction, Aerospace, Consumer Electronics, Medical & Healthcare, Transportation, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | MCMILLANCO, LLC, Mantech (UK) Ltd, ZINSER GmbH, Accurl, Yamazaki Mazak Corporation, GMT Engineers Private Limited, Messer Cutting Systems GmbH, HPC Laser LTD., BODOR, TRUMPF Group |

CNC Fiber Laser Market Segmental Analysis :

Based on the Type :

The type segment is bifurcated into stationary and portable. Stationary CNC fiber laser machines accounted for the largest market share in 2022 owing to the high stability, precision, and versatility. Additionally, stationary CNC fiber lasers are designed for heavy-duty industrial applications, offering a solid and rigid structure that minimizes vibrations and ensures consistent cutting or engraving quality. Moreover, the stationary nature of the machines enhances accuracy by reducing the chances of movement-related errors during operation. Furthermore, machines are also preferred for high-volume production and complex designs, leading to increased adoption in various end-use industries including manufacturing, automotive, aerospace, and electronics. Consequently, the aforementioned factors are collectively responsible in propelling the growth of the stationary CNC fiber laser segment.

Portable CNC fiber laser machines are projected to witness the fastest CAGR in the market owing to the space-saving characteristic of portable machines, suitable for workshops and facilities with limited space. Additionally, for businesses focusing on prototyping or producing small batches, portable CNC fiber laser machines offer an efficient solution by quickly creating precise cuts, contributing to faster iteration and production cycles. Moreover, portable CNC fiber lasers also offer less power consumption capabilities to achieve the highest production efficiency and require less maintenance. For instance, GuSheng Technology introduced an advanced portable CNC fiber laser cutting machine with conversion efficiency of more than 30%. Furthermore, the portable machine provides high stability, reduces the cost of accessories and maintenance time, and has excellent cutting and welding ability, hence contributing notably in boosting the market growth.

Based on the Product :

The product segment is classified into CNC CO2 laser cutters, CNC routers, CNC crystal laser cutters, CNC plasma cutters, CNC fiber laser cutters, press brakes, turret punching machine, and hydraulic shearing machine. CNC fiber laser cutters accounted for the largest market share in 2022 owing to the high speed, precision, and accuracy. Additionally, CNC fiber laser cutters offer high-quality cuts on various materials, energy efficiency, and minimal maintenance. Moreover, the growing adoption of fiber laser cutters in industrial applications due to the ability to handle intricate designs and fast cutting speeds is also spurring the market growth. In conclusion, the above-mentioned factors are contributing remarkably in driving the growth of CNC fiber laser market.

CNC CO2 laser cutters are predicted to register the fastest CAGR during the forecast period as CO2 laser cutters have the capability to cut a wide variety of materials including metals, plastics, wood, and organic material. Additionally, CO2 laser cutters excel in cutting thicker materials compared to other laser types, particularly advantageous in industries namely metal fabrication, automotive, and aerospace. Moreover, the advancements in technology including the emergence of 3-axis orthogonal type CO2 laser to provide enhanced CFRP processing speeds is further contributing to the market growth. For instance, Mitsubishi Electric Corporation launched two models of 3D CO2 laser processing systems for cutting carbon fiber reinforced plastics (CFRP) utilized in automobiles. The machine is designed to offer high productivity and processing quality and has unique 3-axis orthogonal type oscillator for cutting CFRP, thus contributing notably in bolstering the growth of the market.

Based on the Application :

The application segment is classified into sign making, cabinet making, wood working, metal fabrication, vehicle outfitting, aerospace engineering, stone working, marine engineering, plastics fabrication, sports equipment, foam packaging, and others. Metal fabrication accounted for the largest market share in 2022 and is also predicted to witness the fastest CAGR during the forecast period owing to the high precision and efficiency of fiber lasers. CNC fiber lasers are employed for various tasks including cutting, engraving, and welding metals. Additionally, lasers also offer high accuracy, speed, and versatility, becoming ideal for intricate designs, complex shapes, and even mass production. Moreover, the CNC fiber lasers allow cutting of metals of varying thickness, further driving the growth of metal fabrication segment. In addition, the emergence of advanced technologies including BrightLine Weld to distribute the laser power between the core and the surrounding ring in a two-in-one laser light cable to process thin sheets of steel and aluminum is also contributing to the market growth. For instance, in April 2022, TRUMPF Group launched next generation TruFiber S lasers for industrial welding and cutting applications. The product utilizes advanced BrightLine Weld technology to enhance the quality and productivity of welding applications, hence contributing notably in boosting the growth of metal fabrication segment.

Based on the End-User :

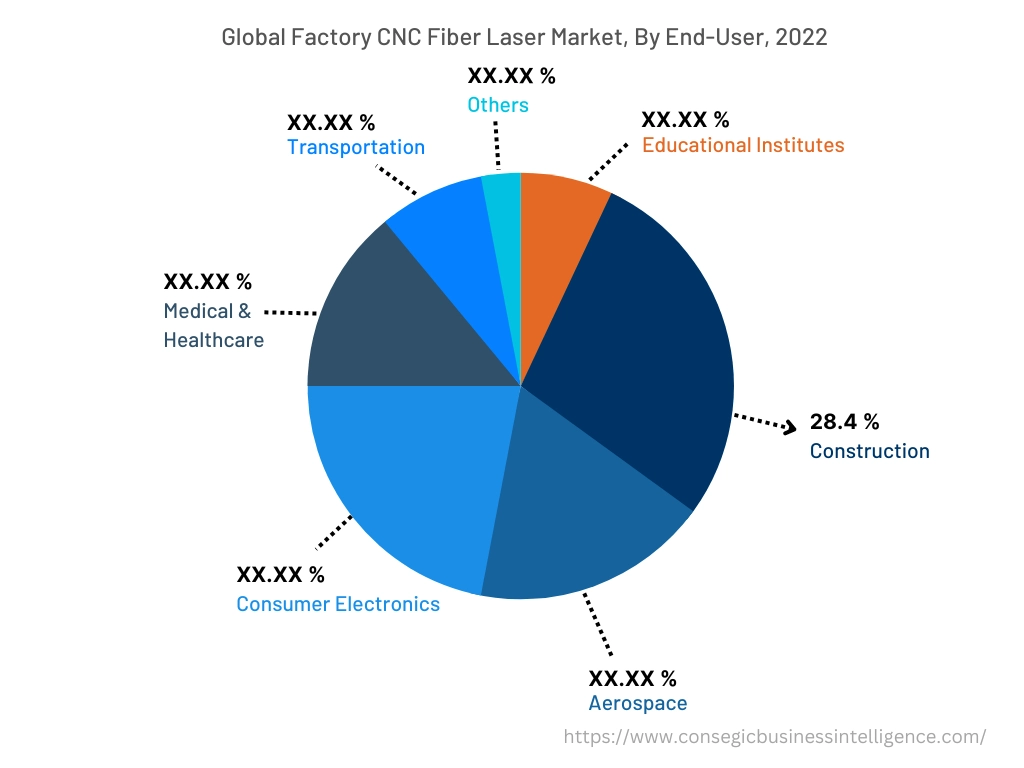

The end-user segment is classified into educational institutes, construction, aerospace, consumer electronics, medical & healthcare, transportation, and others. Construction industry accounted for the largest market share of 28.4% in 2022 as CNC fiber laser are utilized to precisely cut metal sheets and plates for various construction components including beams, columns, trusses, and connectors. The high-speed cutting and ability to handle various metal thicknesses enable accurate fabrication of parts that are crucial for structural integrity. Additionally, CNC fiber lasers are employed to cut and shape structural steel elements used in buildings and bridges. The lasers create intricate cuts and notches required for joints, connections, and custom designs, resulting in accurate fits and smooth assembly, reducing on-site adjustments and labor costs. Moreover, CNC fiber lasers cut metals into intricate patterns, decorative screens, and façade elements, enhancing the aesthetics of buildings and thus, contributing to unique architectural designs.

Consumer electronics is anticipated to witness the fastest CAGR in the CNC fiber laser market during the forecast period. The growth is attributed to the increasing adoption of CNC fiber lasers to cut, engrave, and mark intricate patterns and designs on smartphone components including metal frames, back covers, buttons, and speaker grills. Fiber lasers ensure high precision and consistency in producing visually appealing and functional parts. Additionally, fiber lasers are also employed in the manufacturing of PCBs for consumer electronics and are used to create fine traces, drill holes, and selectively remove material for circuitry and connectors. Moreover, fiber lasers are also employed to cut and mark keypad buttons, ensuring clear and durable markings on devices namely remote controls, game controllers, and other handheld electronics. In conclusion, the above mentioned reasons are expected to drive the adoption of CNC fiber lasers in consumer electronics during the forecast period.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

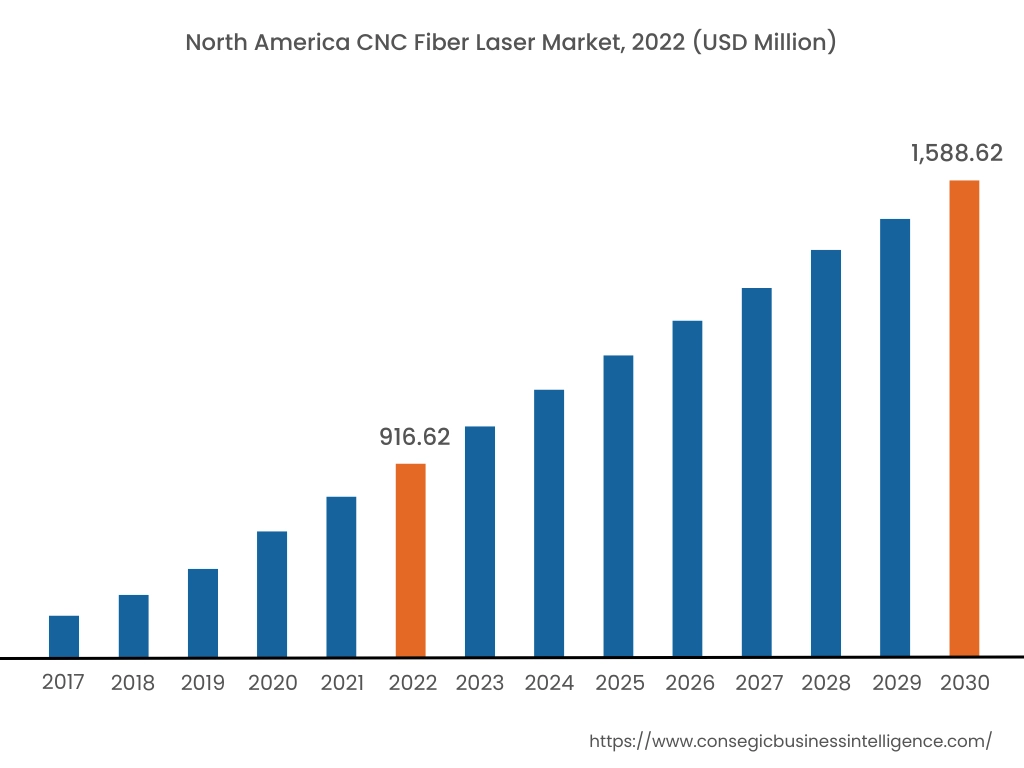

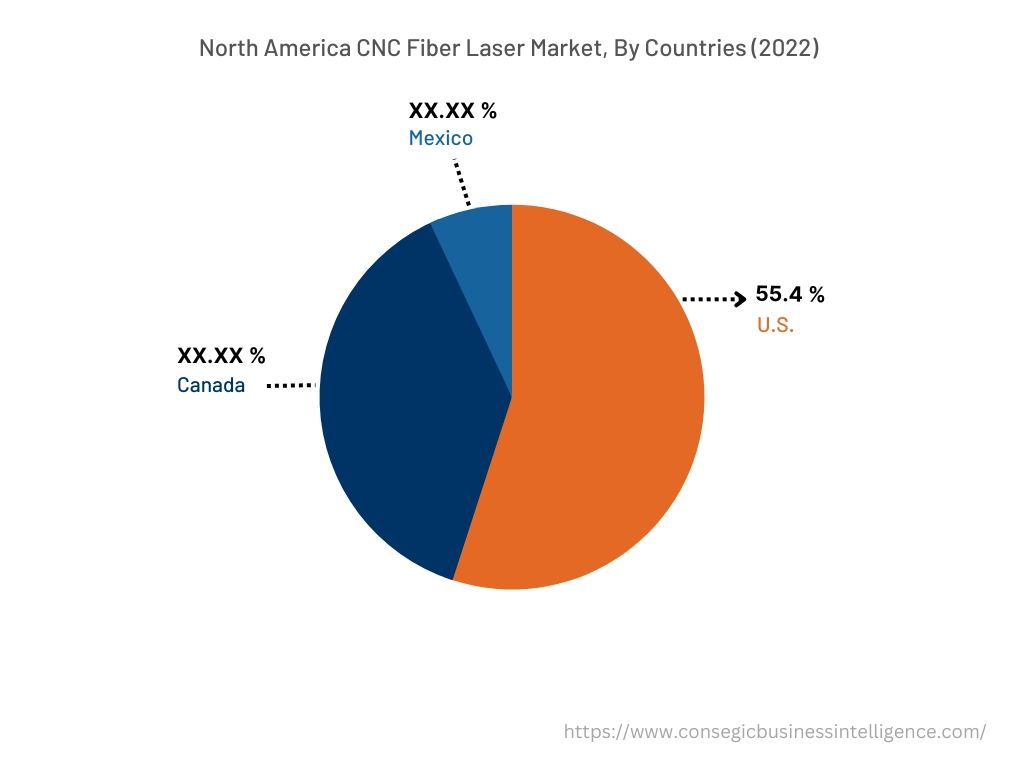

North America accounted for the largest market share of USD 916.62 million in 2022 and is expected to reach USD 1,588.62 million in 2030 in the CNC fiber laser market. In addition, in the region, U.S. accounted for the maximum revenue share of 55.4% in the year 2022. The growth is attributed to the region's strong emphasis in research and development and the presence of large number of research institutions that drive the innovation in laser technology. Additionally, the increasing investment by the government in improving the infrastructure, particularly in United States and Canada is also contributing significantly in boosting the market growth. For instance, in May 2023, the United States government invested USD 220 billion in approximately 32,000 specific projects to improve the infrastructure in all 50 states, D.C., and territories. Consequently, the increasing government investment and presence of research institutions are the major factors responsible for propelling the growth of CNC fiber laser market in the region.

Asia Pacific is predicted to witness the fastest CAGR of 7.6% in the CNC fiber laser market in the upcoming years. The growth is attributed to the presence of several manufacturing powerhouses in countries including China, Japan, South Korea, and India that heavily relies on precise manufacturing techniques including CNC fiber lasers. Additionally, the expanding consumer electronics industry in Asia Pacific countries is also contributing in propelling the growth of the market. CNC fiber lasers are utilized in the manufacturing of PCBs for consumer electronics and are also used to create fine traces, drill holes, and selectively remove material for circuitry and connectors. In conclusion, the expanding manufacturing and consumer electronics segment is projected to drive the growth of CNC fiber laser market in Asia Pacific countries.

Top Key Players & Market Share Insights:

The landscape of the CNC fiber laser market is highly competitive and has been examined in the report, along with complete profiles of the key players operating in the industry. In addition, the surge in innovations, acquisitions, mergers, and partnerships has further accelerated the growth of the CNC fiber laser market. Major players in the market include-

- MCMILLANCO, LLC

- Mantech (UK) Ltd

- HPC Laser LTD.

- BODOR

- TRUMPF Group

- ZINSER GmbH

- Accurl

- Yamazaki Mazak Corporation

- GMT Engineers Private Limited

- Messer Cutting Systems GmbH

Recent Industry Developments :

- In February 2022, TRUMPF acquired 80% stake in Active Fiber Systems GmbH (AFS), a German Company that that specializes in CNC fiber lasers.

Key Questions Answered in the Report

What is a CNC fiber laser? +

A CNC fiber laser is a computer-controlled machining system that utilizes a high-powered fiber laser source to cut, engrave, and mark various materials with precision.

What specific segmentation details are covered in the CNC fiber laser market report, and how is the dominating segment impacting the market growth? +

Stationary CNC fiber laser machines dominate the market owing to the high stability, precision, and versatility. Additionally, stationary CNC fiber lasers are designed for heavy-duty industrial applications, offering a solid and rigid structure that minimizes vibrations and ensures consistent cutting or engraving quality.

What specific segmentation details are covered in the CNC fiber laser market report, and how is the fastest segment anticipated to impact the market growth? +

Portable CNC fiber laser machines will emerge as the fastest growing segment owing to the space-saving characteristic of portable machines, suitable for workshops and facilities with limited space. Additionally, for businesses focusing on prototyping or producing small batches, portable CNC fiber laser machines offer an efficient solution by quickly creating precise cuts, contributing to faster iteration and production cycles.

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period due to the expanding manufacturing and consumer electronics segment.