- Summary

- Table Of Content

- Methodology

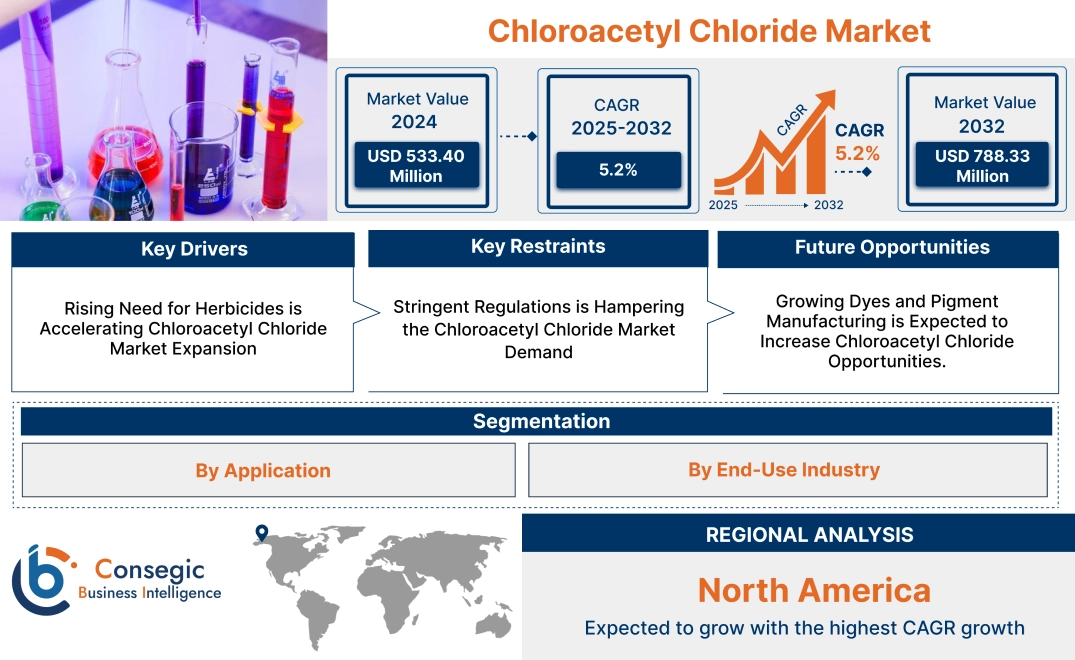

Chloroacetyl Chloride Market Size:

Chloroacetyl Chloride Market size is growing with a CAGR of 5.2% during the forecast period (2025-2032), and the market is projected to be valued at USD 788.33 Million by 2032 from USD 533.40 Million in 2024.

Chloroacetyl Chloride Market Scope & Overview:

Chloroacetyl chloride (CAC) is a chemical compound with the formula ClCH2COCl. It is a colorless light-yellow liquid with a pungent odor. It has a molecular weight of 112.9, a boiling point of 223°F, a freezing point of -7°F, a vapor pressure of 19 mmHg, and a specific gravity of 1.42. The compound is soluble in organic solvents such as benzene and ether but reacts violently with water, releasing hydrogen chloride gas. The primary advantages of this chemical compound include its high reactivity and versatility. Its ability to participate in diverse chemical reactions such as acylation and halogenation properties makes it valuable in synthesizing complex organic compounds. Its versatility in forming intermediates, such as chloroacetamide and chloroacetates, is a significant advantage for manufacturers. It is primarily used in producing herbicides, pesticides, and pharmaceuticals such as sedatives and antihistamines. It also finds applications in dye and pigment synthesis and water treatment chemicals.

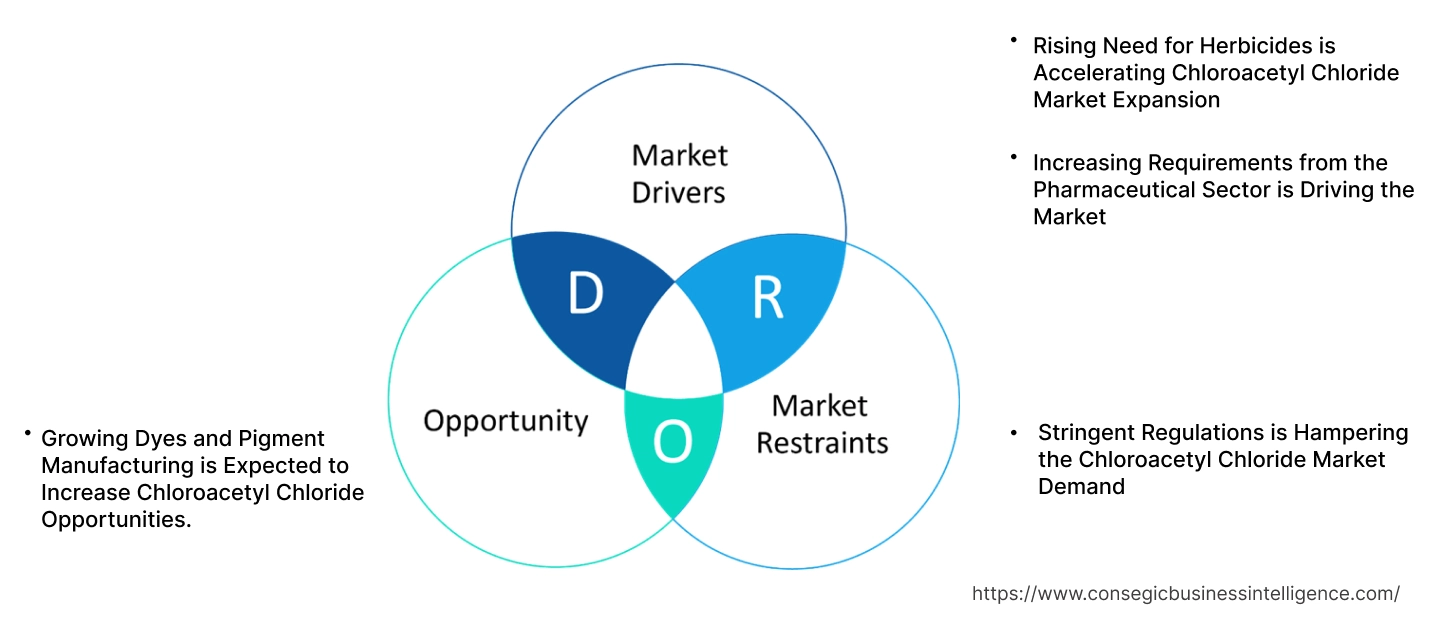

Key Drivers:

Rising Need for Herbicides is Accelerating Chloroacetyl Chloride Market Expansion

An herbicide is a chemical substance designed to kill or inhibit the growth of unwanted plants, commonly referred to as weeds. Chloroacetyl chloride is used to produce herbicides in the chloroacetanilide family, including alachlor, butachlor, acetochlor, and metolachlor which are commonly applied pre-emergence to control annual grasses and broadleaf weeds.

Its high reactivity allows for efficient synthesis of herbicide molecules by facilitating acylation reactions with other chemical compounds. Its reactive nature enables its use in various synthetic pathways to produce different classes of herbicides. High yields and efficient reactions contribute to reduced production costs for these herbicides, positively impacting the trends.

The requirement to increase crop yields to feed a growing global population, the emergence of herbicide-resistant weeds, and the shift towards labor-saving technologies in agriculture have led to the growing need for herbicides.

- According to the USDA National Agricultural Statistics Service, the application of pesticides is widespread across the United States, playing a crucial role in sustaining agricultural productivity, as herbicides were utilized on 96% of the 93.4 million acres of corn cultivated in 2021 alone. This has positively influenced the chloroacetic chloride market trends as it serves as a crucial intermediate in the synthesis of several widely used herbicides.

Overall, the rising need for herbicides is significantly boosting the chloroacetyl chloride market expansion.

Increasing Requirements from the Pharmaceutical Sector is Driving the Market

Chloroacetyl chloride is a critical intermediate in the pharmaceutical sector, playing a pivotal role in the synthesis of various active pharmaceutical ingredients (APIs). It is widely used in the production of sedatives, antihistamines, and analgesics, where it serves as a precursor to chloroacetamides and chloroacetates. These derivatives are essential components in developing drugs for treating allergies, pain, and anxiety disorders.

Additionally, they are utilized in the synthesis of intermediates for antibiotics and other therapeutic agents. The primary advantage of this chemical compound lies in its high reactivity, which facilitates the efficient synthesis of complex molecules. Its ability to participate in versatile reactions, such as acylation and halogenation, allows pharmaceutical manufacturers to create a wide range of compounds. An aging population with increased chronic health conditions, rising prevalence of mental health disorders, and increased awareness and diagnosis of various ailments have led to increased need for sedatives, antihistamines, and analgesics.

- According to an article published by the National Center for Biotechnology Information, in 2024, between 2012 and 2022, the consumption of analgesics in Portugal significantly increased by around 32%, rising from 53 to 70 DDD/1000 inhab/day. This has influenced the need for this chemical compound as it is used in the production of various pharma APIs.

Overall, the growing need for sedatives, antihistamines, and analgesics is accelerating the global chloroacetyl chloride market growth.

Key Restraints:

Stringent Regulations is Hampering the Chloroacetyl Chloride Market Demand

Stringent regulations surrounding this chemical compound significantly impact its market. This compound is highly reactive, corrosive, and toxic, necessitating strict guidelines for its production, handling, storage, and transportation. Regulatory bodies such as OSHA, REACH, and EPA enforce stringent measures to ensure safety and minimize environmental and health risks. Compliance with these regulations requires manufacturers to invest in advanced safety equipment, employee training programs, and environmentally sound disposal practices, which increase operational costs.

Moreover, government-imposed restrictions on emissions and waste management during production add additional compliance burdens. In some regions, licensing, and permits for handling hazardous chemicals such as CAC are difficult to obtain, limiting market expansion. Violations of these regulations lead to substantial fines, legal actions, or even facility shutdowns, creating uncertainty for manufacturers. These regulatory pressures not only raise production costs but also discourage smaller players from entering the market, further hindering the market.

Overall, market analysis shows that the stringent regulations, encompassing safety, environmental, and operational aspects significantly hamper the chloroacetyl chloride market demand by increasing production costs, and limiting market entry.

Future Opportunities :

Growing Dyes and Pigment Manufacturing is Expected to Increase Chloroacetyl Chloride Opportunities.

Dyes and pigments are substances used to impart color to materials. Dyes are soluble in water or solvents and bond chemically with substrates, while pigments are insoluble particles that provide color through dispersion. Both are essential in sectors such as textiles, paints, plastics, and printing.

CAC is primarily used as a starting material to introduce a chloroacetyl group into a molecule, which is then further reacted with other chemicals to create the desired dye or pigment structure. It is used to create reactive dyes, which bond chemically with fibers, ensuring vibrant and durable colors in textiles. In pigment production, CAC contributes to creating complex organic structures, enhancing color stability and performance. Consumer preferences are changing and increasingly they require products with vibrant colors and diverse finishes, which has led to an increase in dyes and pigments production, positively impacting chloroacetyl chloride market trends.

- According to SME communities, the India dyes and pigments market is projected to grow at a compound annual growth rate (CAGR) of 5.5% between 2024 and 2032. This creates potential for the market as CAC serves as a key intermediate in the synthesis of multiple dyes and pigments.

Overall, the increasing need for dyes and pigments is expected to increase chloroacetyl chloride market opportunities.

Chloroacetyl Chloride Market Segmental Analysis :

By Application:

Based on application, the market is categorized into drug formulations, pesticides, chemical intermediates, dyes and pigments, and others.

Trends in Application:

- The emergence of novel drug formulations is creating new applications for CAC.

- Growing requirements for high-performance pigments are driving the need for CAC.

The chemical intermediates segment accounted for the largest market share in 2024.

- A chemical intermediate is a substance formed during a chemical reaction that is neither the starting reactant nor the final product but is produced in one step of the reaction and then consumed in a subsequent step to ultimately form the desired product.

- CAC is a key intermediate in the production of numerous industrial chemicals and materials, owing to its ability to introduce acyl groups into organic molecules. This reactivity makes it crucial in synthesizing specialty chemicals and advanced materials.

- Increasing global population, rising need for consumer goods, and advancements in technology have led to an increase in the chemical sector.

- For instance, according to data from the American Chemistry Council, US chemical exports significantly increased in 2021, with the value of exports reaching USD 151 billion, marking a rebound from the previous year. The increased chemical manufacturing has led to the need for CAC for various production stages, positively influencing market trends.

- Thus, according to the market analysis, increasing chemical manufacturing is driving the segment in the chloroacetyl chloride market growth.

The pesticides segment is expected to grow at the fastest CAGR over the forecast period.

- Pesticides are further categorized into insecticides, herbicides, and fungicides. They are substances used to control, prevent, or destroy pests such as insects, weeds, fungi, and other organisms that harm crops, livestock, or human health. They are classified into various types based on their target pests and mode of action, including insecticides, herbicides, fungicides, and rodenticides.

- CAC is a critical component in the synthesis of various pesticides, including herbicides, insecticides, and fungicides. Its ability to introduce acetyl and chloro groups into organic compounds makes it an essential building block for formulating active ingredients.

- It also enhances the bioactivity and stability of pesticide compounds, ensuring long-lasting crop protection. Moreover, its use in scalable production processes reduces overall manufacturing costs for pesticides. Additionally, it helps mitigate crop losses due to pests and diseases, contributing to food security.

- As per the market analysis, the growing global population, which necessitates increased food production, leading to more reliance on intensive farming practices that heavily utilize pesticides to maximize crop yields, will drive the segment in the market for the forecasted years.

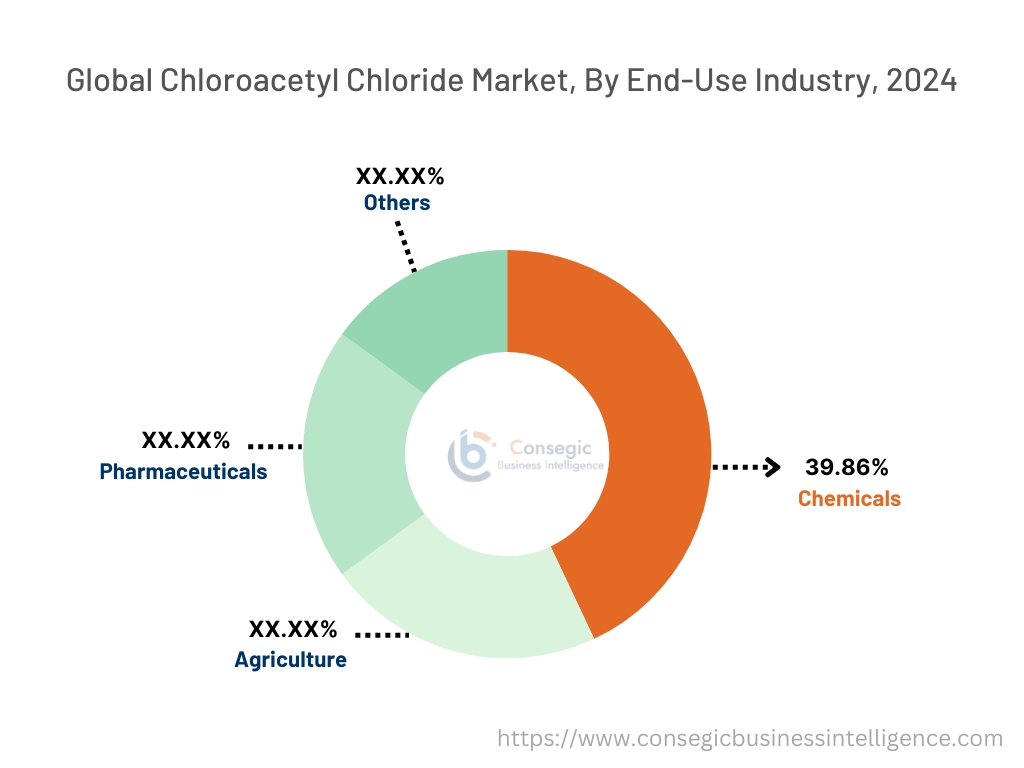

By End-Use Industry:

The end-use industry segment is categorized into pharmaceuticals, agriculture, chemicals, and others.

Trends in the End-Use Industry

- Advancements in chemical synthesis and the development of new materials are creating new potential for CAC applications.

- Focus on personalized medicine and targeted therapies are driving the need for more complex and specialized pharmaceutical intermediates such as CAC.

The chemical segment accounted for the largest market share of 39.86% in 2024.

- CAC plays a pivotal role in the chemical sector as a key intermediate in producing specialty and industrial chemicals. Its high reactivity and ability to introduce acetyl and chloro groups make it valuable for synthesizing advanced materials and additives.

- In polymer manufacturing, this chemical compound is used to create high-performance resins with enhanced durability, heat resistance, and chemical stability. These polymers find applications in electronics and industrial machinery. It is also employed in producing chemical catalysts and stabilizers that improve process efficiency in various industrial reactions.

- Moreover, CAC is integral in manufacturing flame retardants and corrosion inhibitors, which enhance the safety and longevity of materials in the automotive, aerospace, and construction sectors.

- Overall, as per the market analysis, technological advancements are driving this segmental growth in the chloroacetyl chloride industry.

The agriculture segment is expected to grow at the fastest CAGR over the forecast period.

- CAC plays a vital role in the agriculture sector in synthesizing various compounds that enhance crop protection and productivity. Its reactivity and ability to introduce chloroacetyl groups into organic molecules make it essential for producing advanced agricultural products.

- In particular, this compound is used to manufacture plant growth regulators, which help improve crop yield, quality, and resistance to environmental stress. These regulators optimize plant metabolism, enhance nutrient uptake, and promote efficient water use. Additionally, it contributes to producing soil conditioners and additives that improve soil structure and fertility, creating a conducive environment for healthy plant growth.

- The compound is also involved in formulating anti-microbial agents for agricultural applications, protecting crops from bacterial and fungal infections. By ensuring better crop health and higher productivity, CAC indirectly supports sustainable farming practices and food security. Furthermore, it is involved in the production of herbicides, insecticides, and fungicides. Consumers are increasingly becoming aware of food safety.

- For instance, the S. Department of Agriculture released data showing that food insecurity in the United States increased by 6% in 2023. This creates demand for high-quality and safe food products necessitating pesticides, creating potential for the segment in the upcoming years.

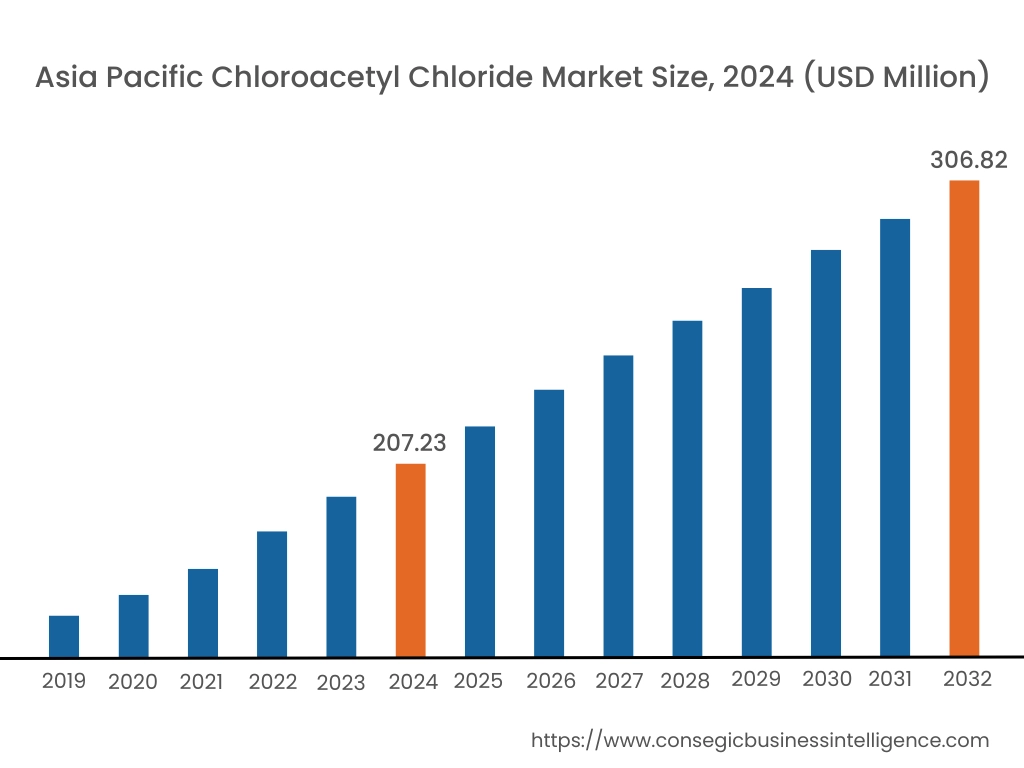

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest chloroacetyl chloride market share at 38.85% and was valued at USD 207.23 Million and is expected to reach USD 306.82 Million in 2032. In Asia Pacific, China accounted for the highest chloroacetyl chloride market share of 22.86% during the base year of 2024. The region is experiencing rapid industrialization, particularly in countries such as China and India. This has led to a surge in the need for chloroacetyl chloride, a key intermediate in various sectors. Moreover, the Asia Pacific region boasts a strong chemical sector, with numerous manufacturers producing a wide range of chemicals, including CAC. This strong manufacturing base has contributed significantly to the region's dominance in the market.

Additionally, the region is witnessing a growing population and increasing healthcare expenditure, leading to a rising need for pharmaceuticals. CAC is an essential ingredient in the synthesis of several pharmaceutical drugs, further fueling the market. Furthermore, the increasing need for agrochemicals to boost agricultural productivity is driving up the consumption of CAC.

- According to AgroPages, the export value of India's agrochemicals saw a rapid increase, expanding at a CAGR of 14%, and reaching a total of USD 5.4 billion in exports during the financial year 2023.

Also, the availability of low-cost labor and raw materials in the Asia Pacific region provides manufacturers with a cost advantage, making the region an attractive destination for CAC production. This cost competitiveness further enhances the region's dominance in the global market. Overall, rapid industrialization, a growing pharmaceutical sector, and a robust chemical sector, coupled with the availability of low-cost labor and raw materials, have driven the strong need for CAC in the Asia Pacific region, solidifying its position as the market leader.

In North America, the chloroacetyl chloride market is experiencing the fastest growth with a CAGR of 5.5% over the forecast period. North America is emerging in the CAC market due to its well-established chemical sector, strong need from end-use sectors, and advanced manufacturing capabilities. The region's significant presence of large-scale chemical manufacturers ensures a consistent supply of CAC and related products. One of the primary drivers is the extensive use of CAC in specialty chemical production, including advanced polymers, coatings, and additives, which are critical for industrial and commercial applications. The robust demand from sectors such as automotive, construction, and electronics in the United States and Canada further propels the market. The combination of technological advancement and regulatory compliance further solidifies the North American region in this market.

Europe's chloroacetyl chloride market analysis states that several trends are responsible for the progress of the market in the region. It is driven by its established specialty chemicals sector and focuses on advanced manufacturing. Europe’s dominance stems from its strict environmental regulations, which promote the use of high-quality intermediates, driving the market. The region's chemical sector benefits from a robust export market, with Germany, France, and the Netherlands acting as key hubs for global trade. Europe’s strong presence in advanced material manufacturing, including adhesives, sealants, and performance coatings, heavily relies on CAC for synthesis. Additionally, the growing pharmaceutical sector contributes significantly to the need for high-purity chemical intermediates, driving the market.

The Middle East and Africa (MEA) chloroacetyl chloride market analysis states that the region is also witnessing a notable surge. Several trends are responsible for the progression. The region’s rising construction activities and infrastructural development are boosting the demand for advanced polymers and coatings, where CAC is a key intermediate. Additionally, the growing oil and gas sector in the Middle East is creating potential for the chemical sector, including corrosion inhibitors and performance materials derived from CAC. Furthermore, the region's agricultural sector is undergoing significant development. This necessitates the use of agrochemicals, thereby boosting the demand for CAC, a key ingredient in their production. However, challenges such as limited production capacities and dependency on imports hinder the chloroacetyl chloride market share.

Latin America's chloroacetyl chloride market size is also emerging. It is supported by its growing industrialization and expanding agriculture sector. Countries such as Brazil, Mexico, and Argentina are leading the need, primarily for advanced materials and agrochemicals. Moreover, the region’s increasing focus on infrastructure development drives the need for high-performance coatings and adhesives, boosting CAC usage. Additionally, the presence of a flourishing textile and polymer sector in Latin America further supports the market's increase. The region is witnessing a rise in healthcare expenditure and growing demand for pharmaceuticals, particularly in countries like Brazil and Mexico. This increased requirements for pharmaceuticals translate into higher consumption of CAC, a crucial intermediate in drug synthesis.

Top Key Players and Market Share Insights:

The Chloroacetyl Chloride market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Chloroacetyl Chloride market. Key players in the Chloroacetyl Chloride industry include-

- Merck KGaA (Germany)

- ALTIVIA (U.S.)

- Karan Intermediates Pvt. Ltd. (India)

- Anhui Royal Chemical Co., Ltd., (China)

- Shiva Pharmachem (India)

- Thermo Scientific Chemicals (U.S.)

- Loba Chemie (India)

- Tokyo Chemical (Japan)

- Shandong Xinhua Pharma Co., Ltd. (China)

- LGC Limited (UK)

Chloroacetyl Chloride Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 788.33 Million |

| CAGR (2025-2032) | 5.2% |

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Chloroacetyl Chloride market? +

In 2024, the Chloroacetyl Chloride market is USD 533.40 Million.

Which is the fastest-growing region in the Chloroacetyl Chloride market? +

North America is the fastest-growing region in the Chloroacetyl Chloride market.

What specific segmentation details are covered in the Chloroacetyl Chloride market? +

Application and End-Use Industry segmentation details are covered in the Chloroacetyl Chloride market

Who are the major players in the Chloroacetyl Chloride market? +

Merck KGaA (Germany), ALTIVIA (U.S.), Thermo Scientific Chemicals (U.S.), Loba Chemie (India), Tokyo Chemical (Japan), Shandong Xinhua Pharma Co., Ltd. (China), LGC Limited (UK), Karan Intermediates Pvt. Ltd. (India), Anhui Royal Chemical Co., Ltd., (China), and Shiva Pharmachem (India).