- Summary

- Table Of Content

- Methodology

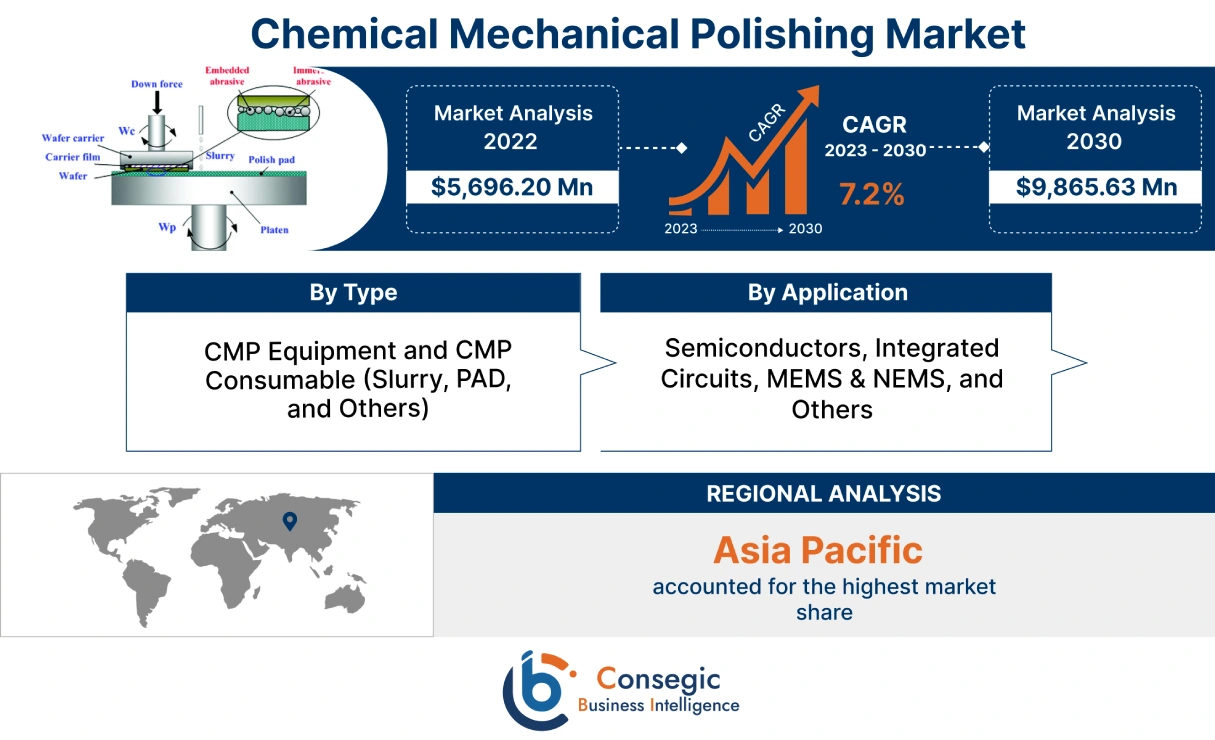

Chemical Mechanical Polishing Market Size :

Consegic Business Intelligence analyzes that the chemical mechanical polishing market size is growing with a healthy CAGR of 7.2% during the forecast period (2023-2030), and the market is projected to be valued at USD 9,865.63 Million by 2030 from USD 5,696.20 Million in 2022.

Chemical Mechanical Polishing Market Scope & Overview:

Chemical mechanical polishing (CMP) is a procedure that levels surfaces using both chemical and mechanical forces. The two main types of CMP include polishing equipment and consumables. The reducing characteristics of this process help minimize surface defects. Additionally, CMP is relatively environmentally friendly as it eliminates the presence of hazardous gases. These beneficial properties make it an ideal solution for various applications, including semiconductors, integrated circuits, MEMS & NEMS, and others.

Chemical Mechanical Polishing Market Insights :

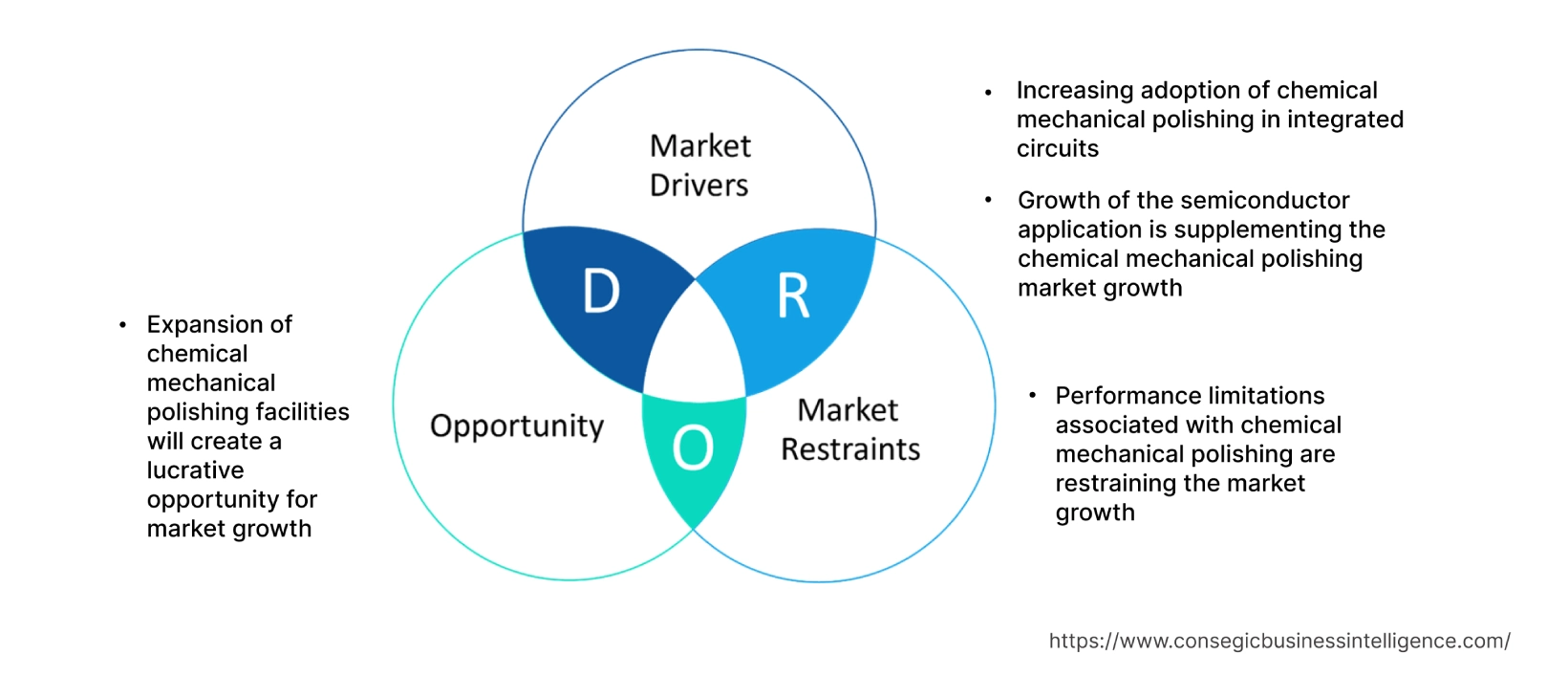

Key Drivers :

Increasing adoption of chemical mechanical polishing in integrated circuits

Chemical mechanical polishing is frequently utilized in the manufacturing of integrated circuits to ensure efficient fabrication of integrated circuits. The technological advancements associated with electronics & assembly, the development of new manufacturing facilities, and others are the key factors driving integrated circuits production.

- For instance, according to the recent data published by the Japan Electronics and Information Technology Industries Association (JEITA), in 2020, global electronics production, including integrated circuits, integrated circuits, and others was USD 30,337 hundred million, and in 2021, it was USD 33,602 hundred million, an increase of 10.8%.

Hence, market analysis portrays that the rise in the production of integrated circuits is driving the adoption of this mechanical polishing to remove surface materials. This prime factor is amplifying the chemical mechanical polishing market growth.

Surge of the semiconductor applications is supplementing the chemical mechanical polishing market growth.

Chemical mechanical polishing is employed in the semiconductors' final stage production to improve the workflows. The factors including incentive plans, public-private partnerships, attracting foreign players to set up manufacturing plants in their countries, tax rebates, and more are fueling the production rise of semiconductors.

- For instance, in 2022, the European Commission implemented the European Chips Act as part of the EU's effective set of measures to enable the security of supply, resilience, and Europe's technological leadership in the semiconductor sector.

- The European Chips Act is expected to bring EURO 43 billion (USS 49.2 billion) of public and private funding for the European semiconductor industry till 2030. As a result of new government initiatives, the production activities associated with semiconductors are increasing.

Thus, analysis of the market depicts that the increasing application of semiconductors is boosting the demand for this mechanical polishing to efficiently fabricate memory disks. This, in turn, is driving the chemical mechanical polishing market trends.

Key Restraints :

Performance limitations associated with chemical mechanical polishing are restraining the market.

Chemical mechanical polishing is equipped with various beneficial features such as superior durability, efficient elimination of surface materials, and others. As a result, this polishing is an ideal choice for various applications such as integrated circuits, semiconductors, and others. Nevertheless, the performance limitations associated with chemical mechanical polishing are restraining the market.

- For instance, the CMP process has several potential defects such as delaminating at weak interfaces, stress cracking, and corrosive attacks from slurry chemicals, among others. These limitations may impact the overall performance of the final product.

Thus, market trends analysis shows that the above performance limitations associated with CMP are posing a bottleneck for chemical mechanical polishing market demand during the forecast years.

Future Opportunities :

The expansion of chemical mechanical polishing facilities will create a lucrative opportunity.

Government initiatives for semiconductor production growth, coupled with advancements in MEMS & NEMS technologies, are significantly driving production in these sectors. As the demand for smaller, more efficient, and high-performance electronic devices increases, industries such as semiconductors, integrated circuits, and sensors require precise surface polishing, which boosts the need for chemical mechanical polishing (CMP). Additionally, the growing trend of miniaturization and the need for defect-free surfaces in advanced technologies are driving innovation in CMP solutions. With the increasing adoption of CMP in the production of microchips, sensors, and other critical components, market players are focused on enhancing the effectiveness of polishing processes to meet the high-quality standards required by these industries. The integration of automation and eco-friendly practices in CMP production is also expected to play a key role in addressing the growing market demand.

- For instance, in March 2022, FUJIFILM Electronic Materials, U.S.A., Inc., completed a USD 88 million expansion for the production growth of chemical mechanical polishing.

Hence, analysis of market trends depicts that the production expansion of this polishing is creating a prominent chemical mechanical polishing market opportunity.

Chemical Mechanical Polishing Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 9,865.63 Million |

| CAGR (2023-2030) | 7.2% |

| By Type | CMP Equipment and CMP Consumable (Slurry, PAD, and Others) |

| By Application | Semiconductors, Integrated Circuits, MEMS & NEMS, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Ebara Corporation, Applied Materials, Inc., Cabot Microelectronics Corporation, Lapmaster Wolters GmbH, DuPont Electronic Solutions, Fujimi Incorporated, Okamoto Corporation, Strasbaugh Inc., Accretech Create Corp., and Revasum Inc. |

Chemical Mechanical Polishing Market Segmental Analysis :

By Type :

The type segment is categorized into CMP equipment and CMP consumables.

In 2022, the CMP consumables segment accounted for the highest market in the chemical mechanical polishing market share. These consumables help the end product manufacturer to produce faster, smaller, and more highly sophisticated products. These consumables such as slurry, pads, and other products are vital in the manufacturing of integrated circuits, advanced semiconductor devices, and others.

- For instance, in February 2022, Merck Korea, a semiconductor material manufacturer launched a semiconductor chemical mechanical polishing (CMP) slurry production plant in South Korea. The company will develop semiconductor materials in the South Korean plant.

Thus, the development of new CMP consumable plants to ensure efficient semiconductor material production will accelerate the chemical mechanical polishing market trends.

However, the CMP equipment segment is expected to be the fastest-growing segment during the forecast period. CMP equipment has various beneficial characteristics such as removing unevenness, ensuring superior durability in the end product, and others. These properties ensure the superior shelf life of the product. As per the market trends analysis, CMP equipment is deployed in various applications such as semiconductors, integrated circuits, and others.

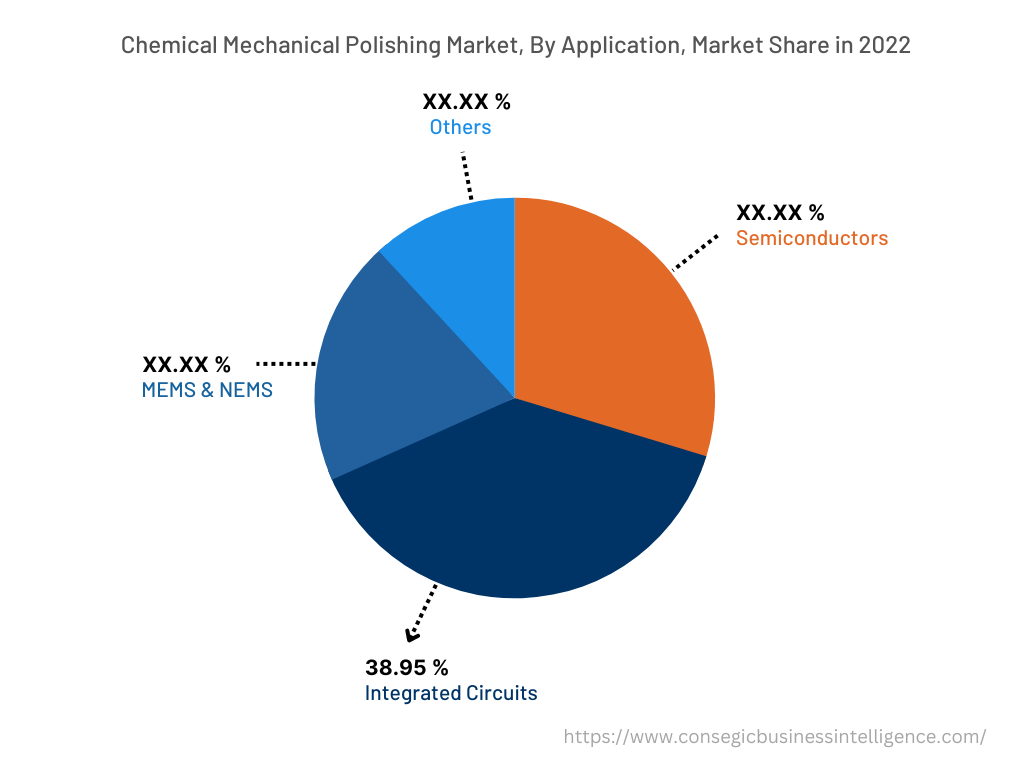

By Application :

The application segment is categorized into semiconductors, integrated circuits, MEMS & NEMS, and others.

In 2022, the integrated circuits segment accounted for the highest market share of 38.95% in the overall chemical mechanical polishing market share. Chemical mechanical polishing is primarily employed in the manufacturing of integrated circuits to smoothen the surfaces and design inlaid metal structures for the circuits. In addition, this polishing works equally efficiently for the manufacturing of single circuits and multiple circuits on a single chip. This polishing eradicates the rough edges of integrated circuits. This ensures more components are placed in less space, thereby leading to a more compact and higher-performing integrated circuit.

- For instance, according to the recent report published by the Electronic System Design Alliance (ESD Alliance), in Q2 of 2022, the Americas, was the leading revenue region for the electronics system design sector, which included integrated circuits, electronics physical devices, and more, with a revenue of USD 1,643.4 million, a 20.2% increase over the Q1 of 2022.

Hence, the increasing production activities associated with the integrated circuit are driving the demand for this polishing to ensure a superior compact design of the product. Thus, the segmental trends analysis shows that this prominent factor is proliferating the chemical mechanical polishing market demand.

However, the semiconductors segment is expected to be the fastest-growing segment during the forecast period. This growth is driven by the increasing adoption of advanced semiconductor devices and integrated circuits, which require precise surface finishing for optimal performance. CMP plays a crucial role in the manufacturing process of semiconductors by ensuring smooth, defect-free surfaces, making it essential for producing smaller, more powerful, and efficient electronic components. As per the chemical mechanical polishing market analysis, as the semiconductor sector continues to evolve, the adoption of CMP technology is anticipated to grow rapidly to meet these advanced requirements.

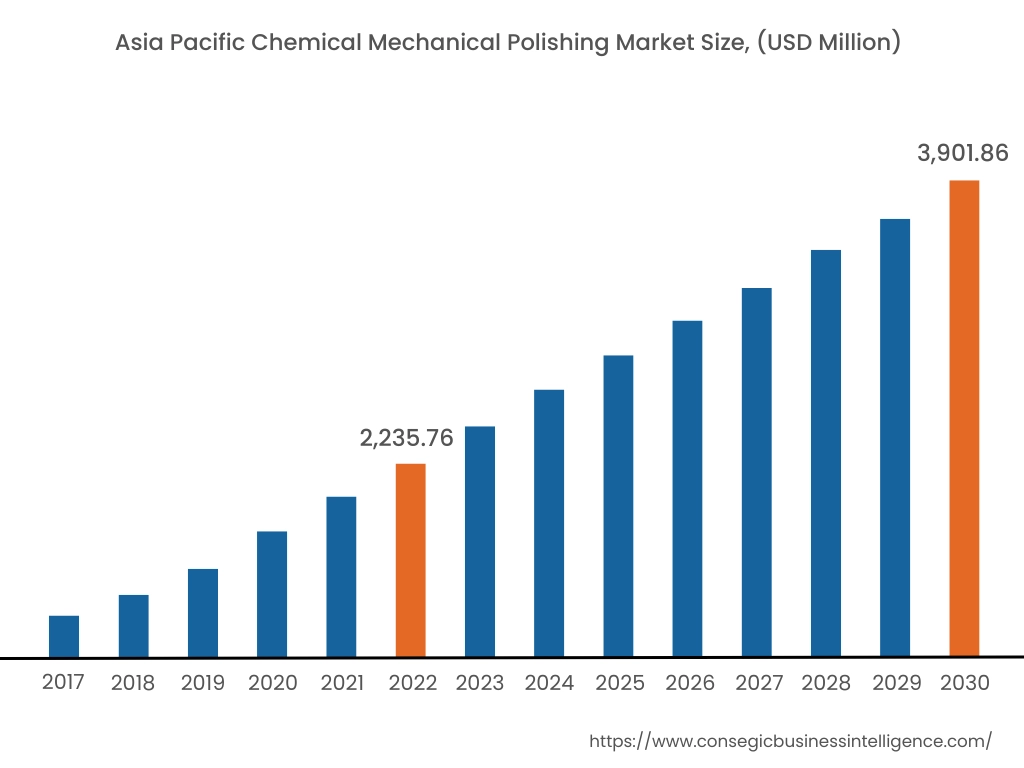

By Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

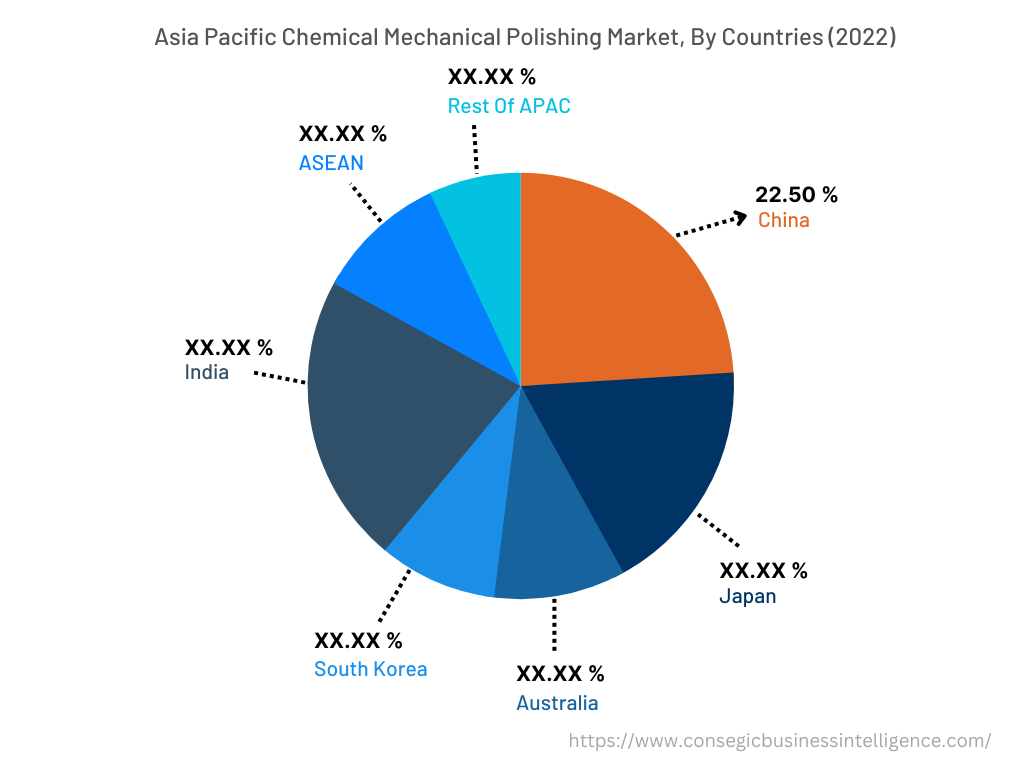

In 2022, Asia Pacific accounted for the highest market share at 39.25% valued at USD 2,235.76 million, and is expected to reach USD 3,901.86 million in 2030. In Asia Pacific, China accounted for the highest market share of 22.50% during the base year of 2022. Factors such as increasing investment in the development of new semiconductor plants, and surging demand from various end-use industries, including smartphones, computers, and others are the vital factors driving the rise of semiconductors, integrated circuits, and other electrical products growth.

- For instance, according to the Japan Electronics and Information Technology (JEITA), in 2020, the total production in the Japanese electronics industry consisting of semiconductors, printed circuit boards, and others was Japanese Yen 9,964,769 million (USD 93,389.8 million), and in 2021, it was Japanese Yen 10,954,346 million (USS 99,772.2 million).

- In 2021, the year-on-year growth rate of the Japanese electronics industry consisting of semiconductors, printed circuit boards, and others was 9.9%.

Hence, with the increase in the above-mentioned electrical products, the demand for mechanical polishing is increasing in the Asia Pacific region to ensure the superior durability of the product. This vital determinant is spurring the chemical mechanical polishing market expansion.

Furthermore, North America is expected to witness a significant rise over the forecast period, growing at a CAGR of 7.8% during 2023-2030. As per the chemical mechanical polishing market analysis, this is due to the increasing production activities associated with electrical products such as semiconductors, integrated circuits, MEMS & NEMS, and others in the North American region. As the demand for miniaturized and high-performance devices rises, the need for precise surface polishing becomes more critical, making CMP technology essential for achieving the required surface quality. Additionally, the presence of leading semiconductor manufacturers, technology companies, and research institutions in the region further supports the market. The adoption of CMP in the production of advanced electronic components, such as memory devices, logic chips, and sensors, is expanding, along with innovations in CMP equipment and consumables. Furthermore, the shift towards environmentally friendly and cost-effective production processes, coupled with the growing trend of automation in semiconductor manufacturing, is enhancing the chemical mechanical polishing market expansion in North America.

Top Key Players & Market Share Insights:

The global chemical mechanical polishing market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market stake through mergers, acquisitions, and partnerships. The key players in the chemical mechanical polishing industry include-

- Ebara Corporation

- Applied Materials, Inc.

- Strasbaugh Inc.

- Accretech Create Corp.

- Revasum Inc.

- Cabot Microelectronics Corporation

- Lapmaster Wolters GmbH

- DuPont Electronic Solutions

- Fujimi Incorporated

- Okamoto Corporation

Recent Industry Developments :

- In July 2022, Entegris a leading manufacturer in the United States acquired CMC Materials. CMC Materials is a chemical mechanical polishing manufacturer in the United States. The prime focus of the acquisition was to increase the market share of Entegris in the global market.

Key Questions Answered in the Report

What was the market size of the chemical mechanical polishing industry in 2022? +

In 2022, the market size of chemical mechanical polishing was USD 5,696.20 million.

What will be the potential market valuation for the chemical mechanical polishing industry by 2030? +

In 2030, the market size of chemical mechanical polishing will be expected to reach USD 9,865.63 million.

What are the key factors driving the growth of the chemical mechanical polishing market? +

Increasing adoption of chemical mechanical polishing in integrated circuits is favoring the growth of the market.

What is the dominating segment in the chemical mechanical polishing market by application? +

In 2022, the integrated circuits segment accounted for the highest market share of 38.95% in the overall chemical mechanical polishing market.

Based on current market trends and future predictions, which geographical region is the dominating region in the chemical mechanical polishing market? +

Asia Pacific accounted for the highest market share in the overall chemical mechanical polishing market.