- Summary

- Table Of Content

- Methodology

Ceramic Filters Market Size:

Ceramic Filters Market size is estimated to reach over USD 2.56 Billion by 2032 from a value of USD 1.56 Billion in 2024 and is projected to grow by USD 1.63 Billion in 2025, growing at a CAGR of 6.4% from 2025 to 2032.

Ceramic Filters Market Scope & Overview:

Ceramic filters are porous structures designed from inorganic materials, mainly alumina, silica, or silicon carbide, to filter particulates from liquids or gases. They are extensively applied in water purification, air filtration, metal casting, and automotive emissions control, providing a long-lasting and heat-resistant solution.

Its distinctive characteristics include even pore distribution, chemical stability, mechanical durability, and regenerative ability. These attributes make them capable of providing reliable performance under high thermal and chemical stress, maintaining long service life, and requiring minimal maintenance.

Their capacity to capture fine impurities while permitting effective fluid or air flow enables accurate filtration in industrial and environmental processes. Moreover, their reusability and thermal shock resistance increase operational cost-effectiveness. Ceramic filters satisfy the requirements of critical filtration environments where reliability, structural integrity, and purity are crucial, rendering them a choice of high-performance filtration applications in various industries.

Key Drivers:

Rising Application in Diesel Particulate Filters (DPFs) for Emission Compliance Bolsters Market Growth

Cordierite and silicon carbide-based ceramic filters are the backbone of diesel particulate filters (DPFs), efficiently trapping soot and fine particulate matter from the exhaust of diesel engines. As international emission norms like Euro VI, EPA Tier 4, and Bharat Stage VI enforce near-zero particulate emissions for both light-duty and heavy-duty vehicles, the uptake of next-generation after-treatment systems is accelerating. Automotive Original Equipment Manufacturers are increasingly using DPFs with ceramic substrates to meet regulatory requirements without affecting engine performance. These filters provide high thermal stability, chemical stability, and porosity designed for steady-state regeneration cycles. The global production of commercial vehicles coupled with the demand for clean vehicle technologies is directly elevating the need for effective exhaust filtration materials. This is propelling steady ceramic filters market expansion.

Key Restraints:

Brittleness and Mechanical Fragility during Handling and Installation Limits Market Expansion

Even with their superior chemical and thermal performance, ceramic filters have intrinsic brittleness owing to their hard microstructure. They can chip, crack, or break during logistics, installation, or maintenance under mechanical stress, vibration, or impact. Their fragility requires special handling precautions, support housings, and protective packaging, all of which increase the system cost and complexity. Mobile or vibration-intensive industries require strict measures to avoid filter damage, adding more labor and lowering operational flexibility. Such physical restrictions are especially taxing in applications demanding frequent filter change or remote operation, where the risk of failure is equivalent to downtime and safety risks. With rising demand for heavy-duty and low-maintenance filtration systems across industries, mechanical brittleness poses a significant hurdle to ceramic filters market growth.

Future Opportunities:

Integration in Advanced Water Treatment Systems for PFAS and Heavy Metal Removal Presents Promising Market Opportunity

Ceramic filters are being designed with innovative functionalized surfaces to specifically remove emerging contaminants like PFAS, arsenic, and lead from drinking water and industrial effluents. Their chemical inertness, long life, and backwashable properties render them desirable for continuous-use municipal and industrial water treatment facilities. With tightening regulatory oversight on micro-contaminants and increasing public anxiety regarding water quality, utilities are moving toward membrane technologies with long-term cost-effectiveness and stable performance. Such filters are also being used in hybrid treatment systems, where they function as a pretreatment layer to shield downstream reverse osmosis or ion exchange units. The need for chemical-resistant, high-efficiency filtration in sustainable water infrastructure is on the rise in developed and developing countries alike.

- For instance, in July 2024, researchers from the University of Bath and the University of Auckland published their study investigating the effectiveness of 3D printed ceramic-infused lattices, referred to as monoliths, in removing PFOA and PFAS from water. The monoliths were found to successfully remove 75% of the targeted substances from the treated water.

As water treatment techniques improve to handle multifaceted contaminants, these abilities are building robust ceramic filters market opportunities, led by necessity and growth.

Ceramic Filters Market Segmental Analysis :

By Product Type:

Based on product type, the market is segmented into ceramic water filters and ceramic air filters.

The ceramic water filters segment accounted for the largest ceramic filters market share in 2024.

- Ceramic water filters are widely utilized for removing pathogens and suspended solids from drinking water in both residential and rural water purification systems.

- The growth in global awareness toward potable water and the increasing installation of household filtration units is a key driver for this segment.

- These filters are particularly favored in low-income regions due to their cost-effectiveness and reliable microbial filtration without electricity.

- As per the ceramic filters market trends, continuous advancements in filter pore design and impregnation with silver or activated carbon to enhance their performance and shelf life are driving the segment’s growth.

The ceramic air filters segment is projected to experience the fastest CAGR during the forecast period.

- Ceramic air filters offer superior thermal and chemical resistance, making them ideal for applications in high-temperature gas filtration and industrial air purification.

- These filters are seeing rising demand from the metal processing, power generation, and manufacturing industries due to stringent air quality regulations.

- The expansion of industrial zones across Asia-Pacific and rising investments in emission control are major contributing factors.

- According to the ceramic filters market analysis, growing focus on environmental sustainability and pollution control boosts its adoption across emerging economies.

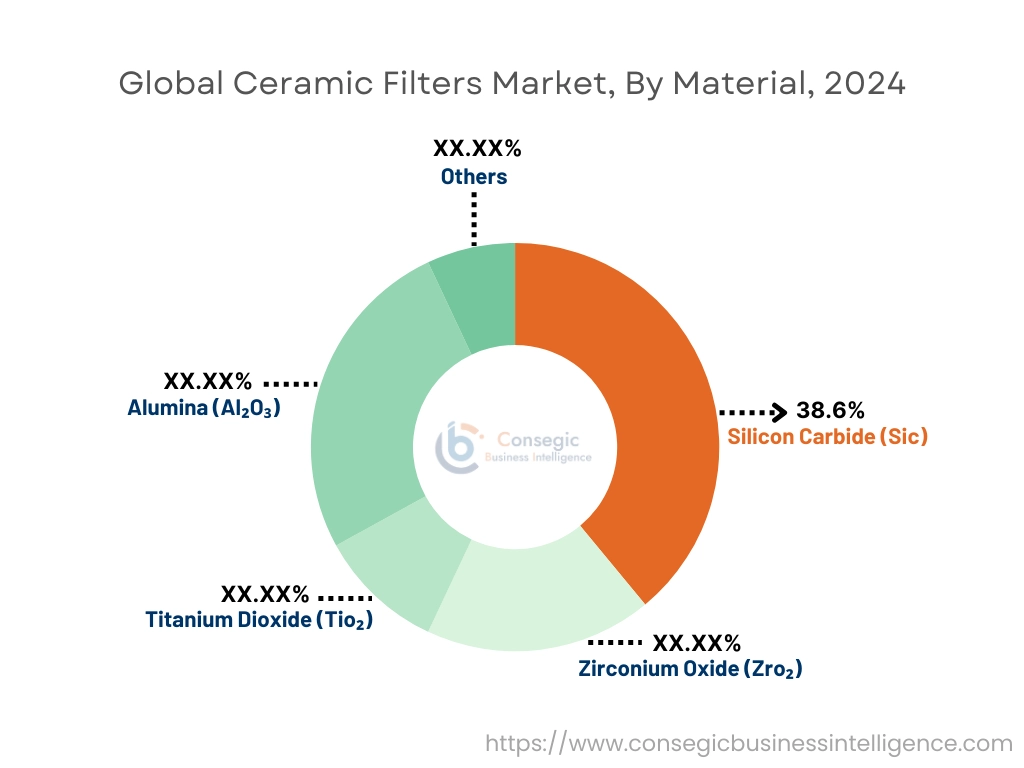

By Material:

Based on material, the ceramic filters market is segmented into alumina (Al₂O₃), silicon carbide (SiC), zirconium oxide (ZrO₂), titanium dioxide (TiO₂), and others.

The silicon carbide (SiC) segment dominated the market with a share of 38.6% in 2024.

- Silicon carbide filters are highly durable and exhibit superior thermal shock resistance, ideal for aggressive chemical environments.

- They are increasingly used in hot gas filtration, diesel particulate filters, and biomass energy plants due to their corrosion and oxidation resistance.

- As per the ceramic filters market analysis, rapid industrialization and rising necessity for high-efficiency filtration solutions drive this segment.

- Ongoing innovations in lightweight SiC filter designs improve filtration efficiency, aligning with global sustainability trends.

The alumina (Al₂O₃) segment is expected to register robust CAGR.

- Alumina-based filters are highly effective in removing fine particulates and possess exceptional mechanical strength and wear resistance.

- Their widespread application across the chemical, metallurgical, and power sectors positions them as a leading material in high-demand use cases.

- Increasing use of alumina ceramic membranes in high-temperature flue gas filtration highlights its industrial relevance.

- Favorable pricing and availability of alumina also enhance its competitiveness among other advanced ceramics, propelling the ceramic filters market expansion.

By Application:

Based on application, the market is segmented into commercial, residential, and industrial (including oil/water filtration, bio-filtration, and hot gas filtration).

The industrial segment accounted for the largest ceramic filters market share in 2024.

- They are integral in industrial filtration for separating particles in extreme temperatures, chemical exposure, or high-pressure environments.

- Applications like oil/water separation in offshore rigs, flue gas treatment in power plants, and catalyst recovery in chemical plants dominate requirement.

- Rapid growth in sectors such as oil & gas, energy, and chemicals continues to boost the ceramic filters market demand.

- Enhanced R&D investment in advanced filtration systems tailored for industrial processes supports market expansion.

The residential segment is anticipated to grow significantly in the coming years.

- Rising concerns over water quality and growing adoption of eco-friendly, reusable filtration systems support the need in households.

- Their reusability and chemical-free operation appeals to environmentally conscious consumers, particularly in urban settings.

- Increasing affordability of compact filtration units contributes to market penetration across emerging markets.

- As per ceramic filters market trends, innovations in aesthetic design and multi-stage filtration are boosting adoption in premium residential segments.

By End-Use Industry:

Based on end-use industry, the ceramic filters market is segmented into automotive, water & wastewater, oil & gas, chemicals & petrochemicals, pharmaceuticals & biotechnology, food & beverage, power generation, metallurgy, electronics & semiconductors, and others.

The water & wastewater segment held the largest revenue share in 2024.

- They are widely used in municipal water treatment plants, decentralized sanitation systems, and wastewater recycling facilities.

- Their longevity, low maintenance, and ability to operate without chemical additives make them highly suitable for sustainable water purification.

- Urbanization and tightening global water quality regulations are key factors driving ceramic filters market growth in this segment.

- Segmental analysis indicates increasing integration of membrane bioreactor (MBR) systems for advanced wastewater treatment.

The pharmaceuticals & biotechnology segment is projected to witness rapid growth.

- This sector requires ultra-clean environments and precise separation capabilities, where ceramic membranes excel due to high purity and biocompatibility.

- The surge in biopharmaceutical production, vaccine manufacturing, and laboratory R&D boosts market trends in this end-use.

- As per segmental analysis, the need for contamination-free and reusable filtration units aligns with operational efficiency goals.

- Rising investments in pharmaceutical infrastructure across emerging markets fuels the ceramic filters market demand.

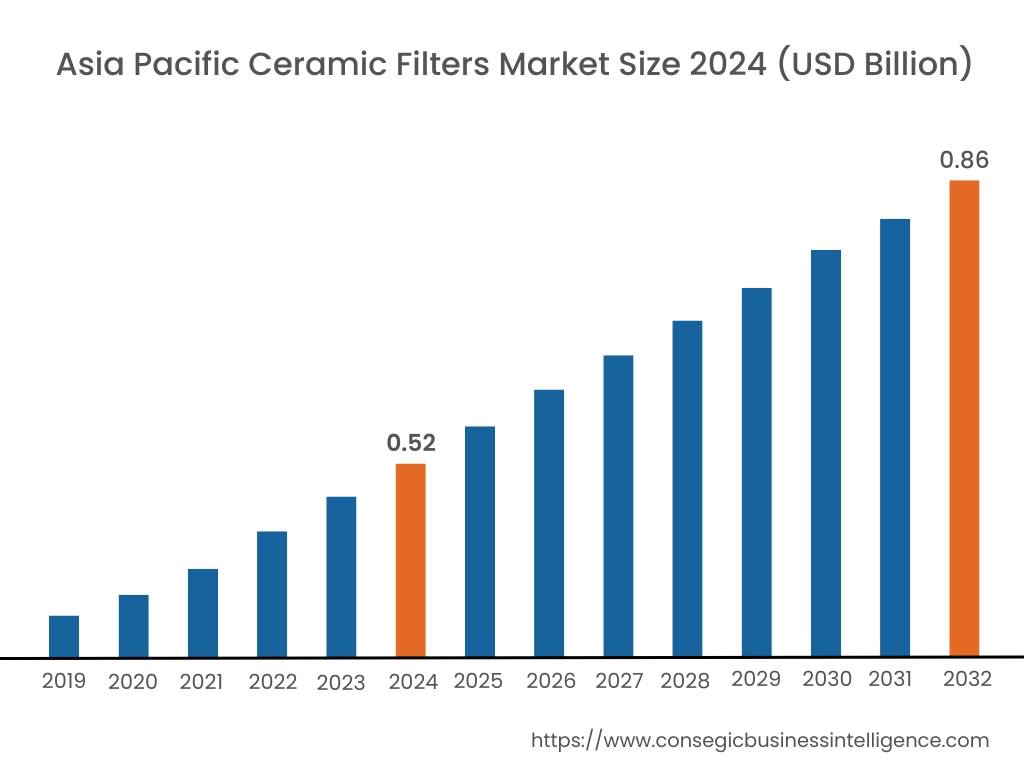

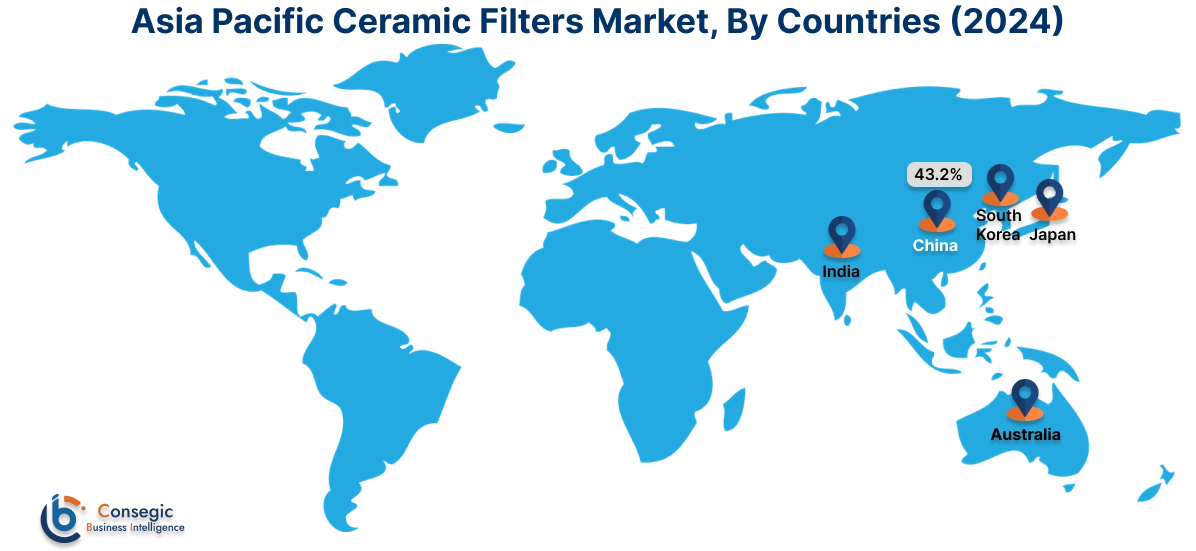

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 0.52 Billion in 2024. Moreover, it is projected to grow by USD 0.54 Billion in 2025 and reach over USD 0.86 Billion by 2032. Out of this, China accounted for the maximum revenue share of 43.2%. Asia-Pacific is witnessing rapid growth in the ceramic filters industry, driven by swift industrialization, environmental degradation issues, and regulatory tightening on emission standards and water quality. China, India, South Korea, and Japan are investing in water infrastructure upgrades, air filtration devices, and diesel exhaust controls, which greatly boosts ceramic filters market opportunity. Based on regional analysis, ceramic membrane technology is increasing its foothold in power generation, semiconductor production, and residential point-of-use filters. Urban population expansion and rising consumer awareness of waterborne diseases are driving adoption in domestic and commercial applications. Moreover, local manufacturing capabilities and export-oriented production are increasing regional competitiveness.

North America is estimated to reach over USD 0.75 Billion by 2032 from a value of USD 0.46 Billion in 2024 and is projected to grow by USD 0.48 Billion in 2025. North America dominates the market with widespread adoption of ceramic filtration technologies across water treatment, air purification, and diesel particulate filtration uses. The US and Canada have recorded constant utilization by municipal utilities and industrial water treatment plants for wastewater. Evaluation shows that tough EPA regulations and investment in decentralized water purification units have fortified local requirements. Further, expansion in pharmaceuticals and food processing industries is driving demand for high-purity filtration, in which ceramic media are used due to thermal resistance and reusability. Growth in home-based water filtration systems and off-grid applications also boosts market acceptance on a larger scale.

Europe is a mature and regulation-focused market for ceramic filtration solutions. Germany, the UK, and the Netherlands have incorporated ceramic filters in industrial emissions control and clean drinking water infrastructure. Market research shows that the European Union's emphasis on circular economy practices and reduction in single-use plastics is driving demand for long-life, regenerable filter media. Additionally, growing concern for indoor air quality and rising retrofitting of HVAC equipment with particulate filtration modules increases the uptake of ceramic components. Environmental restoration and pollution control public-private partnerships offer long-term growth opportunities for filter suppliers across various industries.

Latin America is witnessing expanding demand for ceramic filtration systems, especially in areas impacted by water scarcity and industrial pollution. Nations such as Chile, Mexico, and Brazil are integrating ceramic filters in mining activities, food processing facilities, and public health programs. Market research indicates that although penetration levels are lower in developing areas than in developed areas, rural adoption is being fueled by community-based water purification schemes and NGO-funded clean water initiatives. Emphasis on upgrading sanitation infrastructure and regulatory support for low-maintenance filtration systems presents long-term prospects for ceramic-based technology.

The Middle East and Africa are emerging but strategically significant markets for ceramic filters, especially due to water shortages, particulate air pollution, and infrastructure growth. Ceramic filtration units are being incorporated into desalination facilities, industrial water recycling, and domestic air cleaners in the Gulf and sections of North Africa. Market research points out that the pressure is increasing in sub-Saharan Africa through humanitarian efforts to improve access to clean water. Restricted access to electricity in some regions adds to the appeal of gravity-fed filters. Scaling up adoption, though, will require more robust distribution networks and end-user awareness of long-term cost savings.

Top Key Players & Market Share Insights:

The ceramic filters market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global ceramic filters market. Key players in the ceramic filters industry include -

- Murata Manufacturing Co., Ltd. (Japan)

- Pall Corporation (USA)

- 3M Company (USA)

- Aquacera (USA)

- Ceramicx Ltd. (Ireland)

- Corning Incorporated (USA)

- Doulton (Royal Doulton) (United Kingdom)

- Unifrax LLC (USA)

- Veolia Environnement S.A. (France)

- Haldor Topsøe A/S (Denmark)

Recent Industry Developments :

Product Launches:

- In November 2024, Evove unveiled a brand new ceramic filter, CeraFab S320, manufactured using Lithoz’s market-leading ceramic 3D printing machines for numerous applications, including lithium extraction. These membranes lower energy use by 80%, recycle 80% more water and increase the output fivefold.

Acquisitions:

- In December 2024, GBC Advanced Materials acquired an XJet Carmel 1400 Ceramic AM solution. This enabled GBC to cut down the production-to-delivery cycle from months to weeks. This move will also allow the company to benefit from greater geometric freedom, production efficiency, and superior performance and functionality as it enhances its service to the medical, aerospace, semiconductor and defence industries.

Ceramic Filters Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2.56 Billion |

| CAGR (2025-2032) | 6.4% |

| By Product Type |

|

| By Material |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Ceramic Filters Market? +

Ceramic Filters Market size is estimated to reach over USD 2.56 Billion by 2032 from a value of USD 1.56 Billion in 2024 and is projected to grow by USD 1.63 Billion in 2025, growing at a CAGR of 6.4% from 2025 to 2032.

What specific segmentation details are covered in the Ceramic Filters Market report? +

The Ceramic Filters market report includes specific segmentation details for product type, material, application and end-use industry.

What are the end-use industries of the Ceramic Filters Market? +

The end-use industries of the Ceramic Filters Market are automotive, water & wastewater, oil & gas, chemicals & petrochemicals, pharmaceuticals & biotechnology, food & beverage, power generation, metallurgy, electronics & semiconductors and others.

Who are the major players in the Ceramic Filters Market? +

The key participants in the Ceramic Filters market are Murata Manufacturing Co., Ltd. (Japan), Pall Corporation (USA), Corning Incorporated (USA), Doulton (Royal Doulton) (United Kingdom), Unifrax LLC (USA), Veolia Environnement S.A. (France), Haldor Topsøe A/S (Denmark), 3M Company (USA), Aquacera (USA) and Ceramicx Ltd. (Ireland).