- Summary

- Table Of Content

- Methodology

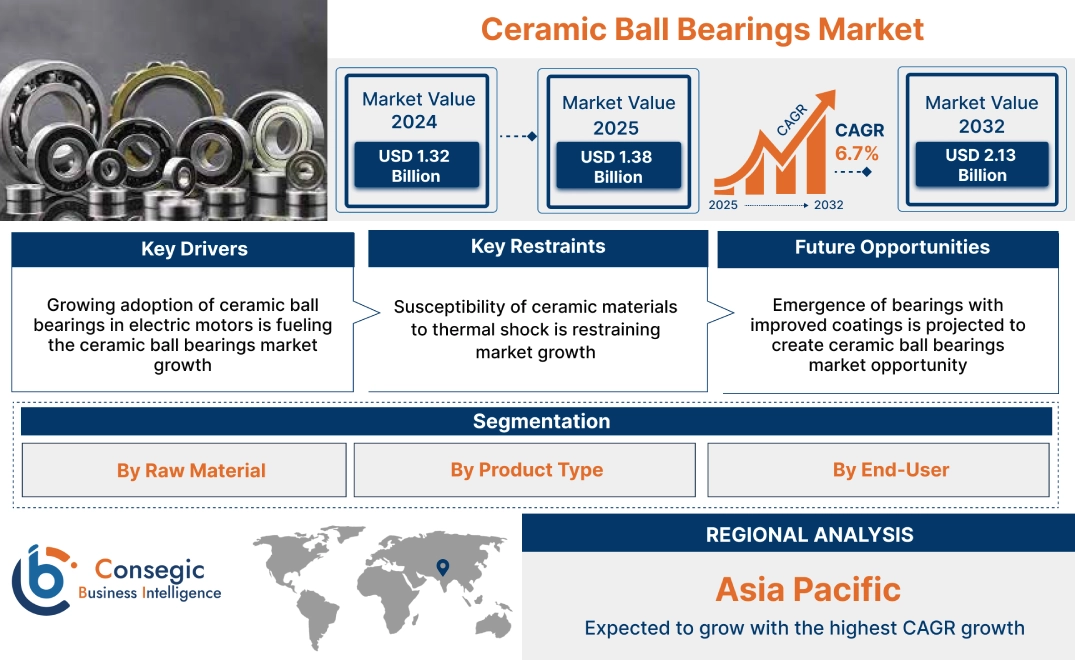

Ceramic Ball Bearings Market Size:

Ceramic Ball Bearings Market Size is estimated to reach over USD 2.13 Billion by 2032 from a value of USD 1.32 Billion in 2024 and is projected to grow by USD 1.38 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

Ceramic Ball Bearings Market Scope & Overview:

Ceramic ball bearings are a type of rolling-element bearing that utilizes balls made from ceramic materials, such as silicon nitride or zirconia, instead of traditional steel. These bearings often feature steel inner and outer races and are valued for their exceptional hardness, low friction, corrosion resistance, and high-temperature tolerance, making them suitable for demanding applications where standard steel bearings may fall short.

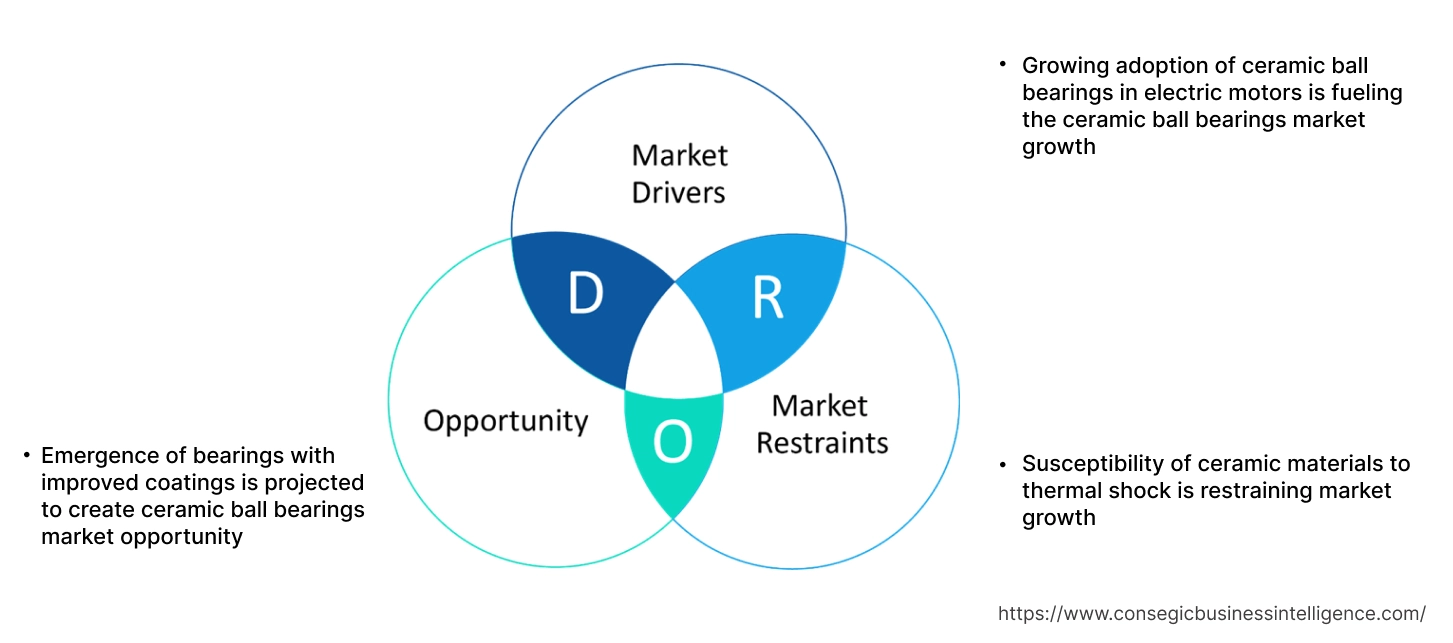

Key Drivers:

Growing adoption of ceramic ball bearings in electric motors is fueling the ceramic ball bearings market growth

Electric motors operate at higher rotational speeds than internal combustion engines. The lower density of ceramic balls results in less centrifugal force at high speeds, allowing the motor to spin faster without increased wear or heat generation. Additionally, higher speed capability is crucial for achieving the desired power output and performance characteristics of electric drivetrains. Hybrid ceramic bearings reportedly operate at speeds up to 50% higher than steel ball bearings, thereby driving the ceramic ball bearings market size.

- For instance, in Nov 2021, NTN Bearing Corporation of America announced to expand its product line to include ceramic ball bearings tailored for electric motor applications. This new series from NTN is engineered specifically to eliminate electrical arcing across a range of uses.

Consequently, growing adoption of ceramic ball bearings in electric motors is driving the ceramic ball bearings market expansion.

Key Restraints:

Susceptibility of ceramic materials to thermal shock is restraining market growth

Ceramics are brittle materials and have limited ability to deform under stress before fracturing. Unlike metals, which bend or yield, ceramics tend to crack when subjected to high stress, including those induced by thermal gradients. Additionally, many ceramics have relatively low thermal conductivity compared to metals, resulting in a larger temperature difference between the surface and the interior, leading to higher internal stresses. Moreover, rapid changes can induce significant stress, especially if the temperature difference is large. The mismatch in thermal expansion between different components in a hybrid bearing (ceramic balls and steel races) can also contribute to stress under rapid temperature fluctuations.

Therefore, as per the analysis, these combined factors are significantly hindering ceramic ball bearings market share.

Future Opportunities :

Emergence of bearings with improved coatings is projected to create ceramic ball bearings market opportunity

Advanced coatings, such as Diamond-Like Carbon (DLC), titanium nitride, or specialized ceramic coatings, significantly enhance the surface hardness and resistance to wear and corrosion. This extends the lifespan of the bearings, especially in harsh operating environments like chemical processing, marine applications, and humid conditions. In addition, coatings made of ceramic materials like alumina oxide provide excellent electrical insulation, crucial in applications such as electric motors, generators, and wind turbines. Ceramic-coated ball bearings offer high insulation resistance, preventing electrical corrosion and increasing cost efficiency due to extended bearing life, hence boosting ceramic ball bearings market demand.

- For instance, in Jan 2025, Schaeffler released its J20G series of ceramic ball bearings featuring a specialized coating, Insutect A, designed to provide exceptional protection against electrical current passage. This innovation directly addresses the problem of current leakage in machinery, which can severely degrade lubricants and damage components like balls and raceways, ultimately causing premature failure.

Hence, based on the analysis, emergence of bearings with improved coatings is expected to create ceramic ball bearings market opportunities.

Ceramic Ball Bearings Market Segmental Analysis :

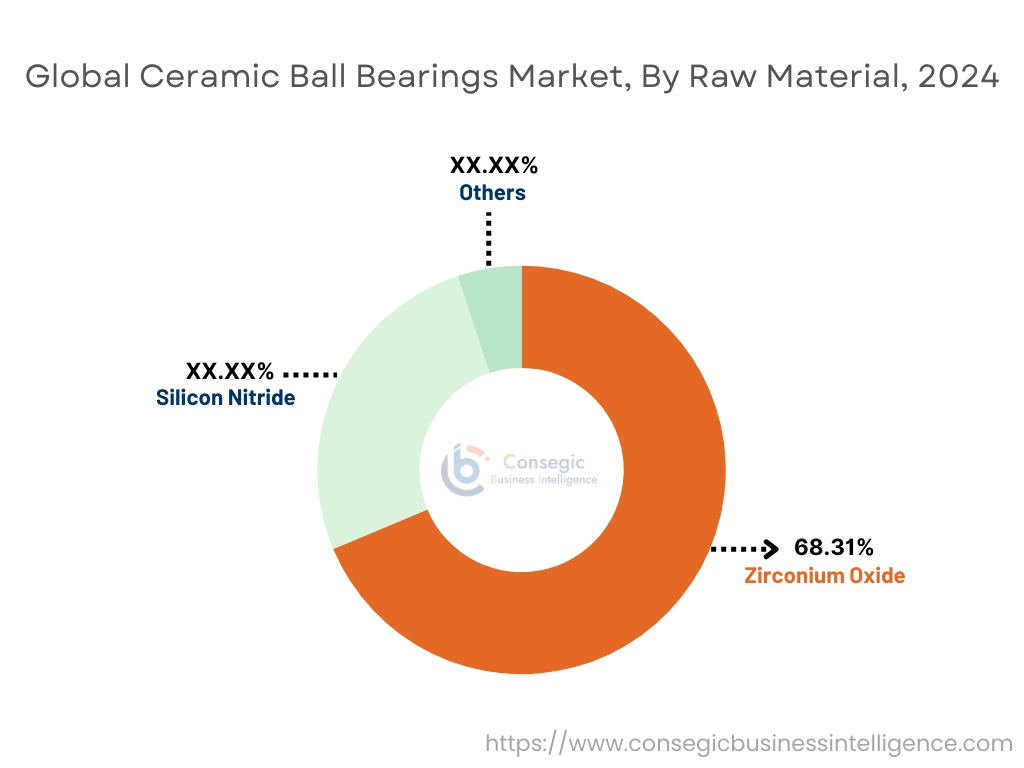

By Raw Material:

Based on the raw material, the market is categorized into zirconium oxide, silicon nitride, and others.

Trends in the Raw Material:

- Growing trend towards the integration of silicon nitride to offer advantages like low density, high strength and toughness, excellent wear resistance, superior thermal shock resistance, and good high-temperature performance.

- Increasing trend of zirconium oxide in manufacturing high-performance ceramics due to its high fracture toughness and mechanical strength.

Zirconium Oxide accounted for the largest revenue share of 68.31% in 2024 and is also predicted to register the fastest CAGR.

- High melting point and thermal stability of zirconium oxide make it ideal for use in industrial furnaces and kilns, thereby driving ceramic ball bearings market expansion.

- Additionally, growing use in dental applications (crowns, bridges, implants) due to biocompatibility, strength, and aesthetics is also boosting the market share.

- Increasing usage in electronic components like capacitors, resistors, and transistors due to its excellent electrical properties and high-temperature stability is further boosting the ceramic ball bearings market size.

- For instance, SMB Bearings introduced a new line of full ceramic ball bearings made from zirconia, available for shaft diameters ranging from 0.125" to 1.0". These zirconium dioxide bearings are characterized by their high hardness, exceptionally smooth wear surfaces, and ability to operate without lubrication.

- Thus, as per the ceramic ball bearings market analysis, the aforementioned factors are driving the zirconium oxide segment size.

By Product Type:

Based on the product type, the market is classified into hybrid and full.

Trends in the Product Type:

- Increased trend towards the adoption of full ceramic bearings due to their exceptional resistance to corrosion, chemicals, and high temperatures, as well as being non-magnetic and electrically insulating.

- Ongoing research is focused on developing advanced ceramic materials with improved fracture toughness and load-bearing capabilities to broaden the application scope of full ceramic bearings.

Hybrid accounted for the largest revenue share in 2024 and is also projected to register fastest CAGR.

- The ceramic balls in hybrid bearings provide several advantages including reduced friction and heat, lower weight, and increased rigidity and precision is driving the ceramic ball bearings market demand.

- Hybrid ceramic bearings are increasingly adopted in high-growth sectors including Electric Vehicles (EVs), aerospace, and industrial automation and machine tools, driving the market trend.

- In many applications, hybrid bearings can be retrofitted into existing machinery designed for steel bearings due to their similar dimensional characteristics.

- For instance, in June 2023, SKF and Sinoma Nitride formed a Joint Venture to strengthen their collaboration in the hybrid ceramic ball bearings sector. This partnership underscores the strategic importance of ceramic bearing technology for SKF as a key area of future growth.

- Thus, as per the ceramic ball bearings market analysis, the aforementioned factors are driving hybrid segment.

By End User:

Based on the end user, the market is categorized into automotive, oil & gas, chemical, aerospace, medical, and others.

Trends in the End User:

- Full ceramic bearings, in particular, offer excellent resistance to a wide range of chemicals, making them ideal for use in pumps, mixers, and other equipment handling aggressive fluids.

- In medical imaging equipment like MRI machines, non-magnetic components are essential. Full ceramic bearings are non-magnetic and are preferred in such applications.

Automotive accounted for the largest revenue share in the market in 2024.

- Ceramic bearings enhance EV efficiency by reducing friction, extending range, and improving high-speed performance of electric motors. Their electrical insulation properties also prevent damage from current leakage.

- The automotive industry's push for lighter vehicles to improve fuel efficiency and reduce emissions is favoring the use of lighter ceramic bearings, driving the market trend.

- Ceramic bearings are increasingly used in high-performance and racing cars to reduce friction and enhance speed and durability.

- For instance, in Apr 2024, SKF introduced a new Conductive brush ring designed to improve the lifespan of electric vehicle eAxles by ensuring a reliable electrical connection between the rotor shaft and housing. This solution is particularly effective when paired with SKF Hybrid ceramic ball bearings, as the combination further minimizes damaging parasitic currents that can cause premature failure in bearings and other powertrain components.

- In conclusion, the aforementioned factors are contributing to the growth of global ceramic ball bearings market expansion.

Oil & Gas is predicted to register the fastest CAGR during the forecast period.

- The oil and gas industry deals with challenging environments involving heavy loads, high temperatures, and potential for corrosion. Ceramic bearings offer superior resistance to these conditions, extending equipment life and reducing downtime.

- Ceramic ball bearings are used in pumps, compressors, drilling equipment, and other critical machinery.

- Further, the longevity and low maintenance requirements of ceramic bearings are highly valued in this sector, especially in remote or offshore operations.

- Subsequently, as per the market analysis, the aforementioned factors are collectively responsible in accelerating the market during the forecast period.

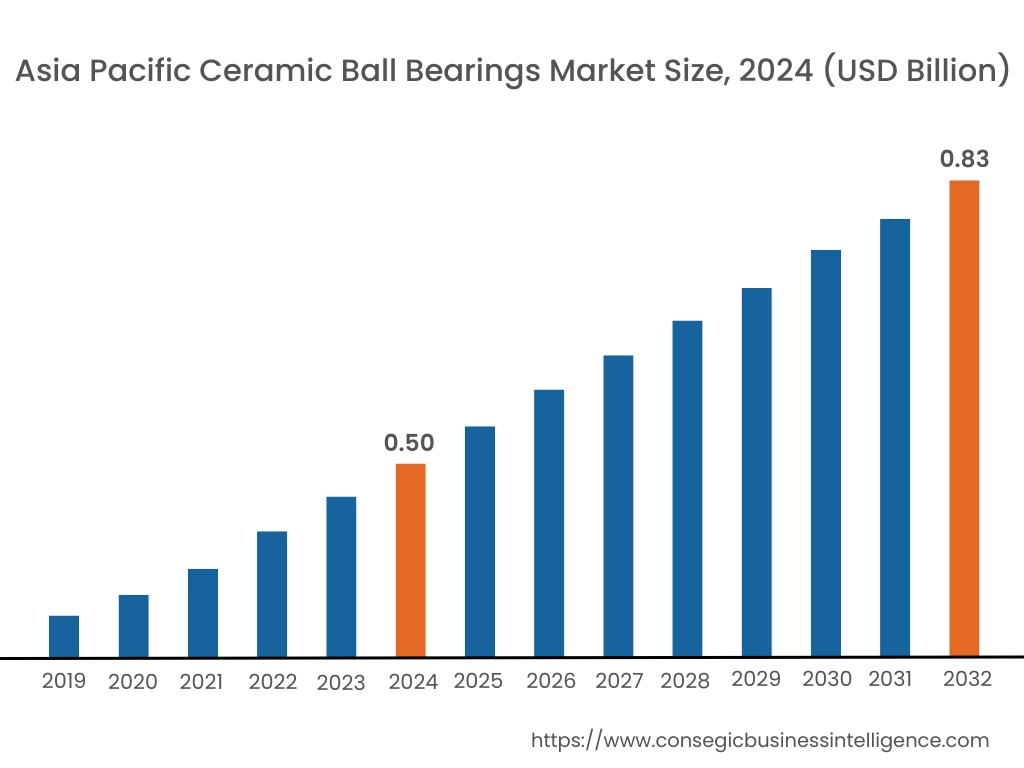

Regional Analysis:

The global ceramic ball bearings market has been classified by region into North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

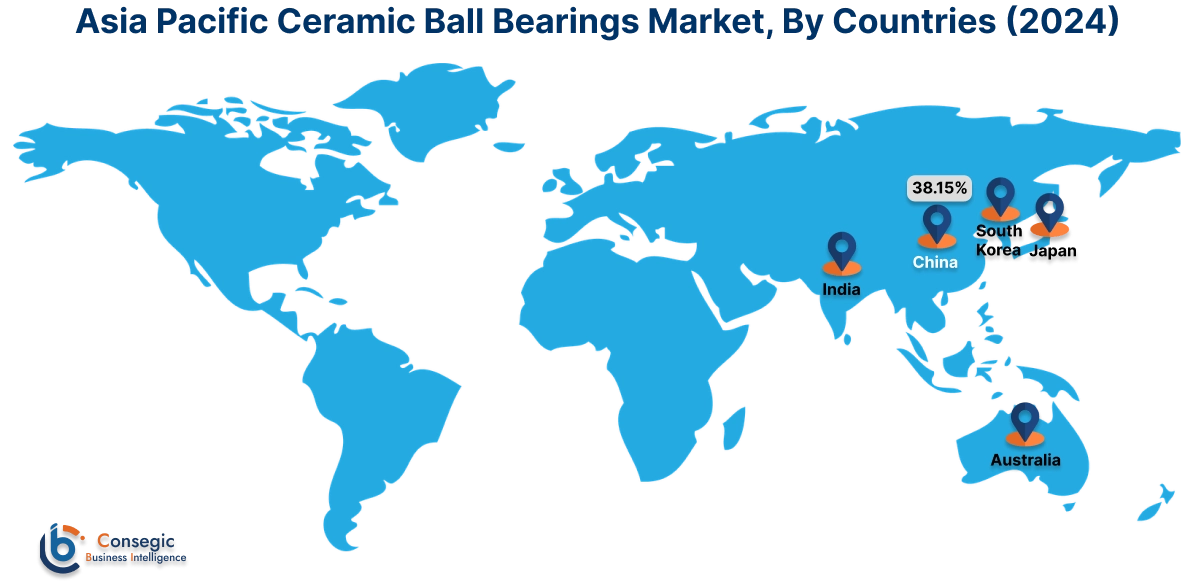

Asia Pacific was valued at USD 0.50 Billion in 2024. Moreover, it is projected to grow by USD 0.52 Billion in 2025 and reach over USD 0.83 Billion by 2032. Out of these, China accounted for the largest revenue share of 38.15% in 2024. Asia Pacific is witnessing significant growth in the adoption and production of electric vehicles, particularly in China and India, which is the world's largest EV market. Ceramic ball bearings, especially hybrid types, are increasingly being used in EV powertrains to enhance efficiency, extend range, and provide electrical insulation, driving substantial demand. Government initiatives and environmental regulations promoting EV adoption further fuel this growth.

- For instance, under Phase-II of India's FAME scheme, the Ministry of Heavy Industries has allocated a capital subsidy of USD 96.13 million for the establishment of 7,432 public electric vehicle charging stations. This initiative is part of the larger USD 1.43 billion FAME II policy aimed at boosting the adoption of electric vehicles and supporting their domestic manufacturing.

North America region was valued at USD 0.36 Billion in 2024. Moreover, it is projected to grow by USD 0.37 Billion in 2025 and reach over USD 0.57 Billion by 2032. North America is a global leader in aerospace manufacturing, and the need for lightweight, high-performance ceramic bearings in aircraft engines, auxiliary power units, and other critical systems remains robust. Additionally, the presence of a sophisticated medical device industry in North America creates a consistent need for ceramic bearings in surgical instruments, medical imaging equipment (non-magnetic full ceramic bearings), and dental applications due to their sterilization compatibility and non-magnetic properties.

As per the ceramic ball bearings market analysis, Europe has a robust industrial manufacturing base, encompassing sectors like machine tools, robotics, chemical processing, and renewable energy (wind turbines). Ceramic bearings are increasingly preferred for their performance advantages in these demanding applications. While still in its early stages, the electric vehicle market in Latin America is beginning to gain traction, which could lead to increased demand for ceramic bearings in EV powertrains in the future. Moreover, the dominant oil and gas sector in the Middle East demands durable and reliable equipment. Ceramic bearings' resistance to harsh chemicals and high temperatures makes them suitable for certain applications in this industry.

Top Key Players and Market Share Insights:

The market is highly competitive with major players providing ceramic ball bearings to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the ceramic ball bearings industry include-

- NSK Ltd. (Japan)

- JTEKT Corporation (Koyo Bearings) (Japan)

- MinebeaMitsumi Inc. (NMB Bearings) (Japan)

- Haining Tarso Bearing Technology Co., Ltd. (China)

- Luoyang Bearing Science & Technology Co., Ltd. (ZYS) (China)

- TQ Abrasive Machining (USA)

- CeramicSpeed (Denmark)

- NBK Bearing (USA)

- SKF (Sweden)

- Emerson Bearing (USA)

- Boca Bearing Company (USA)

- Ritbearing Corporation (USA)

- CoorsTek, Inc. (USA)

- Advanced Ceramic Technology (USA)

- Beijing Zhongxing Shiqiang Ceramic Bearing Co., Ltd. (China)

Ceramic Ball Bearings Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2.13 Billion |

| CAGR (2025-2032) | 6.7% |

| By Raw Material |

|

| By Product Type |

|

| By End User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the ceramic ball bearings market? +

The ceramic ball bearings market size is estimated to reach over USD 2.13 Billion by 2032 from a value of USD 1.32 Billion in 2024 and is projected to grow by USD 1.38 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

What specific segmentation details are covered in the ceramic ball bearings report? +

The ceramic ball bearings report includes specific segmentation details for raw material, product type, end user, and regions.

Which is the fastest segment anticipated to impact the market growth? +

In the ceramic ball bearings market, oil and gas is the fastest-growing segment during the forecast period.

Who are the major players in the ceramic ball bearings market? +

The key participants in the Ceramic Ball Bearings market are NSK Ltd. (Japan), JTEKT Corporation (Koyo Bearings) (Japan), MinebeaMitsumi Inc. (NMB Bearings) (Japan), SKF (Sweden), Emerson Bearing (USA), Boca Bearing Company (USA), Ritbearing Corporation (USA), CoorsTek, Inc. (USA), Advanced Ceramic Technology (USA), Beijing Zhongxing Shiqiang Ceramic Bearing Co., Ltd. (China), Haining Tarso Bearing Technology Co., Ltd. (China), Luoyang Bearing Science & Technology Co., Ltd. (ZYS) (China), TQ Abrasive Machining (USA), CeramicSpeed (Denmark), NBK Bearing (USA), and Others.