- Summary

- Table Of Content

- Methodology

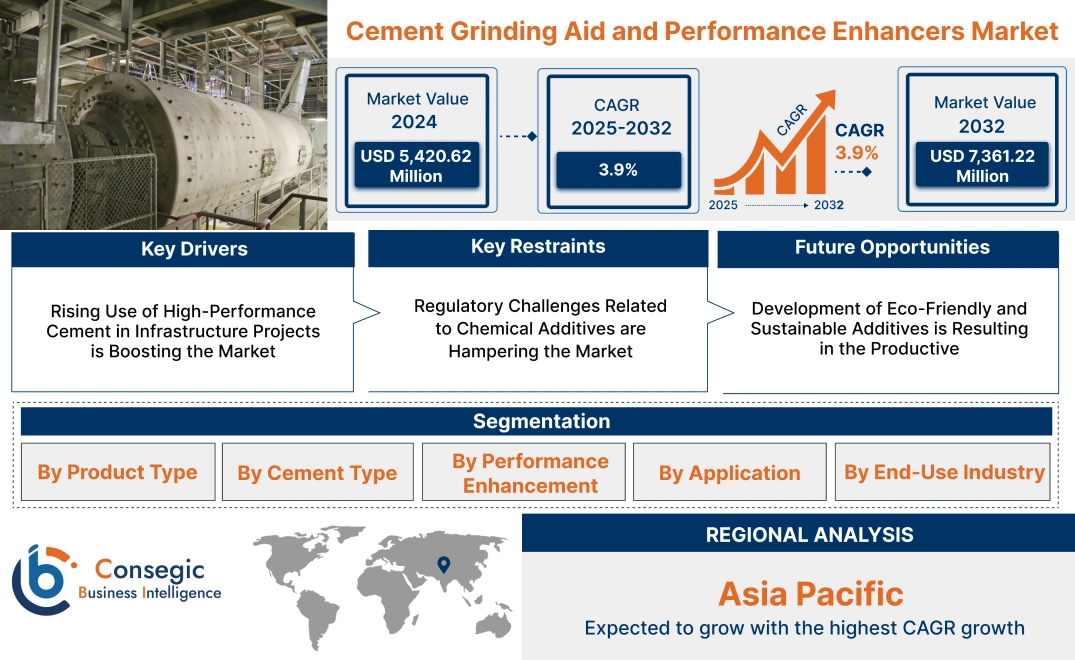

Cement Grinding Aid and Performance Enhancers Market Size:

Cement Grinding Aid and Performance Enhancers Market size is estimated to reach over USD 7,361.22 Million by 2032 from a value of USD 5,420.62 Million in 2024 and is projected to grow by USD 5,535.44 Million in 2025, growing at a CAGR of 3.9% from 2025 to 2032.

Cement Grinding Aid and Performance Enhancers Market Scope & Overview:

The cement grinding aid and performance enhancers are chemical additives used in the cement manufacturing process to improve grinding efficiency and enhance the performance of cement in construction applications. Grinding aids reduce energy consumption, improve particle size distribution, and increase mill productivity, while performance enhancers optimize cement properties such as strength, durability, and setting time. Key characteristics include their compatibility with various cement formulations, ease of integration into the production process, and ability to meet specific construction requirements. The benefits include reduced production costs, enhanced product quality, and improved operational efficiency. Applications span residential, commercial, and infrastructure construction, where high-performance cement is essential. End-users include cement manufacturers, construction companies, and infrastructure developers, driven by rising demand for sustainable construction materials, advancements in cement additive technologies, and increasing urbanization and infrastructure investments globally.

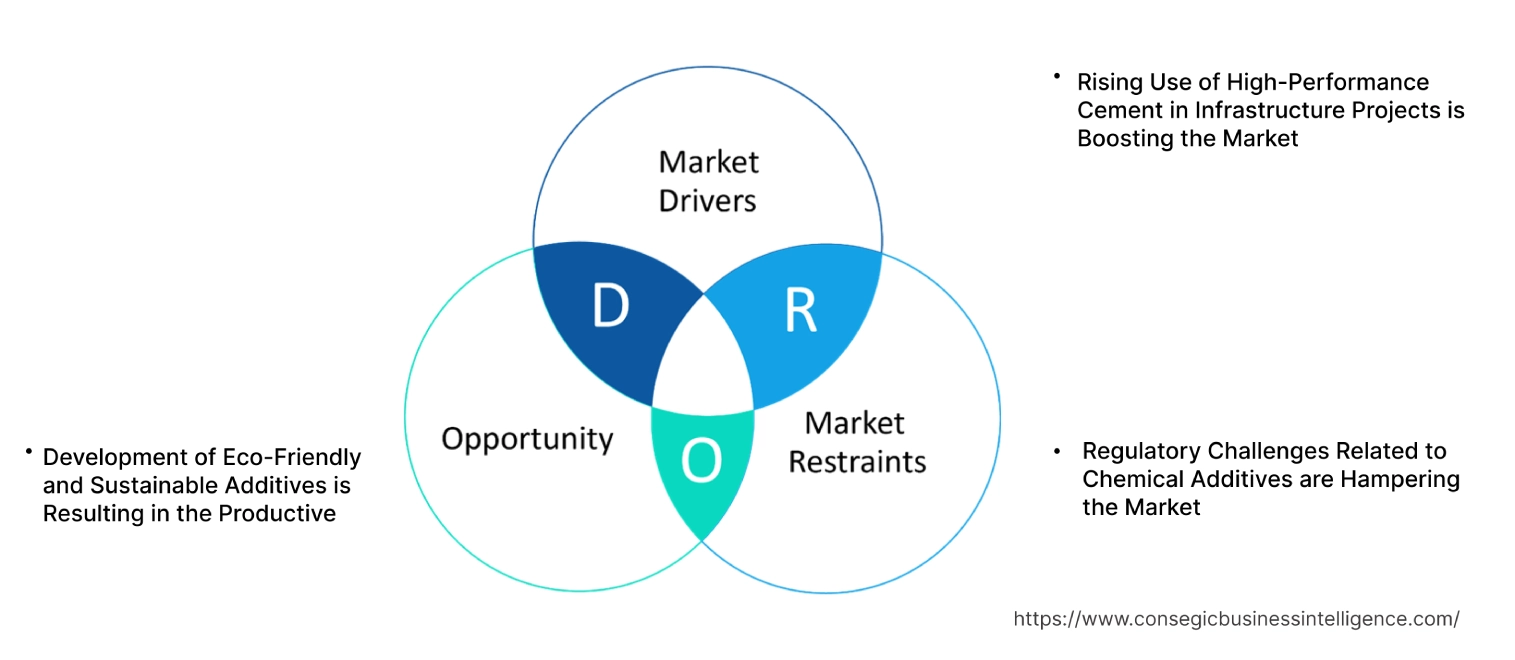

Key Drivers:

Rising Use of High-Performance Cement in Infrastructure Projects is Boosting the Market

The construction sector is increasingly turning to high-performance cement for infrastructure projects that require enhanced durability, strength, and workability. Cement grinding aids and performance enhancers play a critical role in achieving these properties by improving the efficiency of the grinding process, enhancing particle dispersion, and optimizing the chemical composition of cement. These additives are particularly essential in large-scale projects like bridges, high-rise buildings, and transportation infrastructure, where consistent quality and superior performance are paramount.

Dominance in urbanization and the growing focus on constructing resilient infrastructure have highlighted the importance of advanced construction materials. Analysis underscores that grinding aids and performance enhancers contribute to meeting these requirements while ensuring cost-effective and energy-efficient cement production, making them a valuable tool for modern construction needs.

Key Restraints:

Regulatory Challenges Related to Chemical Additives are Hampering the Market

The use of chemical additives in cement production is heavily regulated due to environmental and health concerns. Additives such as grinding aids and performance enhancers must comply with stringent standards to minimize emissions, reduce toxicity, and ensure workplace safety. Navigating these regulations often requires significant investment in research, testing, and product reformulation, which can be a barrier for manufacturers, especially in regions with strict compliance requirements.

Additionally, concerns regarding the potential environmental impact of chemical residues during the lifecycle of cement products add complexity to the regulatory landscape. Trends in sustainable manufacturing practices and increasing scrutiny over construction materials highlight the need for innovative solutions that meet regulatory requirements while maintaining high performance.

Future Opportunities :

Development of Eco-Friendly and Sustainable Additives is Resulting in the Productive

The increasing emphasis on sustainability in the construction sector is driving innovation in eco-friendly grinding aids and performance enhancers. These formulations focus on reducing environmental impact through the use of bio-based or non-toxic ingredients while maintaining or improving the performance of traditional additives. Such developments align with cement grinding aid and performance enhancers market trends in green building certifications and global initiatives to lower carbon emissions in construction materials.

Analysis suggests that the adoption of sustainable additives offers manufacturers a competitive edge, particularly in markets where environmental compliance and sustainability goals are prioritized. By focusing on the development of eco-friendly solutions, companies can cater to the growing demand for environmentally responsible construction practices, positioning themselves as leaders in the transition toward sustainable cement production.

Cement Grinding Aid and Performance Enhancers Market Segmental Analysis :

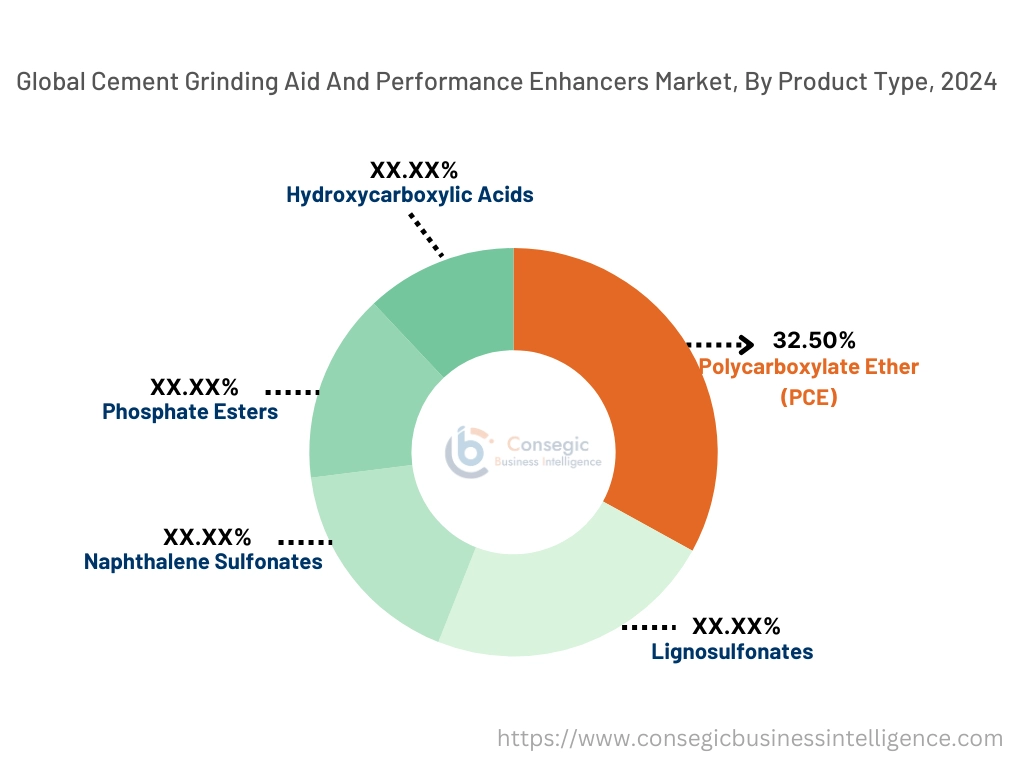

By Product Type:

Based on product type, the concrete admixtures market is segmented into polycarboxylate ether (PCE), lignosulfonates, naphthalene sulfonates, phosphate esters, and hydroxycarboxylic acids.

The polycarboxylate ether (PCE) segment accounted for the largest revenue of 32.50% in the cement grinding aid and performance enhancers market share in 2024.

- Polycarboxylate ether (PCE) admixtures are widely used due to their superior performance in improving concrete workability, strength, and durability.

- These admixtures are particularly valued in high-performance and self-compacting concrete applications, where precision and quality are critical.

- PCE admixtures are also more efficient at reducing water content compared to traditional admixtures, contributing to their widespread adoption in the construction of residential, commercial, and industrial buildings.

- The rising demand for sustainable and high-strength concrete in urban infrastructure projects has further driven the dominance of PCE admixtures in the market.

The lignosulfonates segment is anticipated to register the fastest CAGR during the forecast period.

- Lignosulfonates are cost-effective admixtures commonly used as plasticizers and water reducers in concrete production.

- Their ability to enhance workability and reduce cement usage makes them a preferred choice for mass construction projects, such as dams, bridges, and highways.

- The increasing demand for affordable construction materials in emerging economies, coupled with the growing adoption of lignosulfonates in blended and hydraulic cement applications, is expected to propel significant growth in this segment.

By Cement Type:

Based on cement type, the concrete admixtures market is segmented into Portland cement, blended cement, hydraulic cement, and others.

The Portland cement segment accounted for the largest revenue of cement grinding aid and performance enhancers market share in 2024.

- Portland cement remains the most widely used cement type in the construction sectors due to its versatility, durability, and compatibility with various admixtures.

- It is extensively applied in ready-mix concrete, precast concrete, and concrete products for residential, commercial, and infrastructure projects.

- The increasing focus on enhancing the strength and performance of Portland cement-based concrete using advanced admixtures has driven its dominance in the market.

- Additionally, the continued reliance on Portland cement for large-scale infrastructure projects has further supported its market expansion.

The blended cement segment is anticipated to register the fastest CAGR during the forecast period.

- Blended cement, which incorporates supplementary cementitious materials such as fly ash, slag, and silica fume, is gaining popularity due to its environmental benefits and enhanced durability.

- Admixtures used with blended cement improve workability, reduce cracking, and enhance resistance to chemical attacks.

- The growing trends for sustainable construction materials and the increasing adoption of blended cement in eco-friendly building projects are expected to drive significant growth in this segment.

By Performance Enhancement:

Based on performance enhancement, the concrete admixtures market is segmented into strength improvement, durability enhancement, workability enhancement, and cost reduction.

The strength improvement segment accounted for the largest revenue share in 2024.

- Admixtures designed for strength improvement are widely used to produce high-performance concrete with enhanced compressive, flexural, and tensile strength.

- These admixtures are critical for applications in high-rise buildings, bridges, and other structures requiring superior load-bearing capacity.

- The rising cement grinding aid and performance enhancers market trends for advanced concrete formulations to support the construction of resilient and long-lasting infrastructure have driven the adoption of strength-enhancing admixtures.

The workability enhancement segment is anticipated to register the fastest CAGR during the forecast period.

- Workability-enhancing admixtures improve the flow and placement of concrete without compromising its strength or stability.

- These admixtures are particularly useful in projects involving complex designs and challenging environments, such as precast concrete and self-leveling concrete applications.

- The increasing focus on improving construction efficiency and minimizing labor costs is expected to drive significant growth in this segment.

By Application:

Based on application, the concrete admixtures market is segmented into ready-mix concrete, concrete products, precast concrete, and grinding cement.

The ready-mix concrete segment accounted for the largest revenue share in 2024.

- Ready-mix concrete is the most commonly used concrete type in modern construction projects, offering convenience, consistency, and efficiency.

- Admixtures are widely used in ready-mix concrete to enhance workability, strength, and durability.

- The growing urbanization and infrastructure development, particularly in emerging economies, have significantly driven the cement grinding aid and performance enhancers market demand for ready-mix concrete.

- Additionally, the increasing adoption of advanced admixtures to improve the performance and sustainability of ready-mix concrete has further strengthened its market expansion.

The precast concrete segment is anticipated to register the fastest CAGR during the forecast period.

- Precast concrete applications rely heavily on admixtures to achieve the desired performance characteristics, such as strength, finish, and durability.

- These admixtures are critical for producing precast components, including panels, beams, and columns, used in residential, commercial, and industrial construction.

- The growing adoption of modular construction techniques and the rising cement grinding aid and performance enhancers market demand for prefabricated building solutions are expected to drive significant growth in the precast concrete segment.

By End-Use Industry:

Based on the end-use industry, the concrete admixtures market is segmented into residential, commercial, industrial, and government.

The residential segment accounted for the largest revenue share in 2024.

- The residential construction sector is a major consumer of concrete admixtures, driven by the increasing cement grinding aid and performance enhancers market opportunities for durable and sustainable building materials.

- Admixtures play a critical role in improving the quality and longevity of concrete used in residential projects such as homes, apartments, and community buildings.

- The growing urbanization and population trends, particularly in Asia-Pacific and Latin America, have fueled the adoption of concrete admixtures in residential construction.

- Additionally, the focus on energy-efficient and eco-friendly housing solutions is further driving the opportunities for advanced admixtures in this segment.

The industrial segment is anticipated to register the fastest CAGR during the forecast period.

- The industrial sector requires high-performance concrete for constructing factories, warehouses, and heavy-duty infrastructure.

- Admixtures used in industrial construction ensure superior strength, durability, and resistance to harsh environments.

- The increasing investments in industrial facilities, coupled with the analysis for durable and low-maintenance materials, are driving significant growth in this segment.

- Furthermore, advancements in admixture formulations tailored for industrial applications are expected to boost adoption during the forecast period.

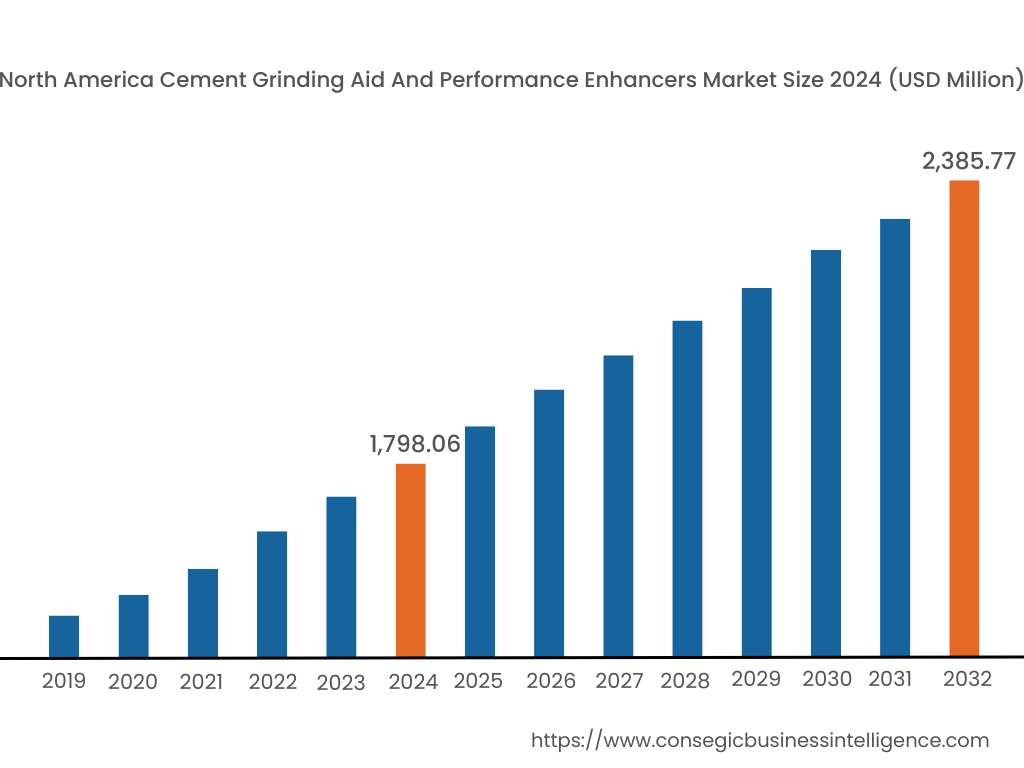

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,798.06 Million and is expected to reach USD 2,385.77 Million in 2032. In North America, the U.S. accounted for the highest share of 71.40% during the base year of 2024. North America holds a significant stake in the cement grinding aid and performance enhancers market analysis, driven by growing investments in infrastructure development and sustainable construction practices. The U.S. leads the region with high trends for these additives in improving cement quality and enhancing productivity in large-scale construction projects, including roads, bridges, and commercial buildings. The focus on green building initiatives also supports the adoption of performance enhancers to reduce energy consumption during cement grinding. Canada contributes with its increasing use of these additives in residential and commercial construction. However, stringent environmental regulations on chemical additives may impact market growth.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.3% over the forecast period. In the cement grinding aid and performance enhancers market analysis, fueled by rapid urbanization, industrialization, and increasing infrastructure investments in China, India, and Southeast Asia. China dominates the market with extensive use of grinding aids to improve cement production efficiency and support its large-scale infrastructure projects. India’s growing construction sector, driven by urban housing developments and government initiatives like the "Smart Cities Mission," supports trends for performance enhancers. Southeast Asian countries leverage these additives to improve cement quality for large infrastructure and industrial projects. However, fluctuating raw material prices and environmental concerns may hinder cement grinding aid and performance enhancers market expansion in some areas.

Europe is a prominent market for cement grinding aids and performance enhancers, supported by advanced construction technologies and strict environmental regulations. Countries like Germany, France, and the UK are key contributors. Germany drives trends through its large-scale infrastructure and industrial construction projects, focusing on sustainable cement production. As per the analysis France emphasizes the use of performance enhancers to improve cement quality and meet high standards in commercial and residential construction. The UK focuses on reducing carbon emissions in cement production, further boosting the adoption of energy-efficient grinding aids. However, compliance with stringent EU regulations on chemical formulations may pose challenges for manufacturers.

The Middle East & Africa region is witnessing steady development in the cement grinding aid and performance enhancers market, driven by increasing investments in construction and infrastructure projects. In the Middle East, countries like Saudi Arabia and the UAE are adopting grinding aids to enhance cement quality and production efficiency in large-scale urban and industrial development projects. In Africa, South Africa and Nigeria are key markets, leveraging these additives to meet the growing trends for residential and commercial construction. However, limited manufacturing capabilities and reliance on imports for advanced additives may restrict market development in certain parts of the region.

Latin America is an emerging market for cement grinding aids and performance enhancers, with Brazil and Mexico leading the region. Brazil’s expanding construction sector, particularly in infrastructure and housing projects, drives trends for these additives to improve cement performance and reduce production costs. Mexico focuses on large-scale commercial and industrial construction, utilizing grinding aids to enhance cement quality and meet international standards. The region is also exploring sustainable additives to align with global cement grinding aids and performance enhancers in environmental advancement. However, economic instability and inconsistent regulatory frameworks may pose challenges to cement grinding aid and performance enhancers market expansion.

Top Key Players and Market Share Insights:

The cement grinding aid and performance enhancers market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the cement grinding aid and performance enhancers market. Key players in the cement grinding aid and performance enhancers industry include -

- BASF SE (Germany)

- The Dow Chemical Company (USA)

- CHRYSO SAS (France)

- GCP Applied Technologies Inc. (USA)

- Mapei S.p.A. (Italy)

- Fosroc International Ltd. (UK)

- Sika AG (Switzerland)

- Ashtech India Pvt. Ltd. (India)

- Thermax Limited (India)

- T. Penta-Chemicals Indonesia (Indonesia)

Recent Industry Developments :

Product Launches:

- In August 2024, Ambuja Cement launched Ambuja Kawach, which is a specially formulated water-repellent cement designed to prevent all forms of seepage, thereby enhancing the sustainability and durability of structures. The product boasts a carbon footprint that is nearly 33% lower than ordinary Portland cement (OPC), contributing significantly to lower CO2 emissions. The Ambuja Kawach has been recognized as an efficient Green Building Solution by the Solar Impulse Foundation and is listed in GRIHA’s Green Product Catalogue, a national green rating system developed by the Government of India.

Cement Grinding Aid and Performance Enhancers Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 7,361.22 Million |

| CAGR (2025-2032) | 3.9% |

| By Product Type |

|

| By Cement Type |

|

| By Performance Enhancement |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the estimated market size of the Cement Grinding Aid and Performance Enhancers Market by 2032? +

Cement Grinding Aid and Performance Enhancers Market size is estimated to reach over USD 7,361.22 Million by 2032 from a value of USD 5,420.62 Million in 2024 and is projected to grow by USD 5,535.44 Million in 2025, growing at a CAGR of 3.9% from 2025 to 2032.

What is cement grinding aids and performance enhancers? +

Cement grinding aids and performance enhancers are chemical additives used in the cement manufacturing process to improve grinding efficiency, reduce energy consumption, and enhance cement performance in construction applications.

What are the primary drivers for the Cement Grinding Aid and Performance Enhancers Market? +

The rising adoption of high-performance cement in infrastructure projects, driven by urbanization and the need for durable, high-strength construction materials, is a key market driver.

What challenges are impacting the market growth? +

Regulatory challenges related to chemical additives, such as stringent environmental and health compliance standards, hinder the market's growth by requiring significant investment in product reformulation and testing.