- Summary

- Table Of Content

- Methodology

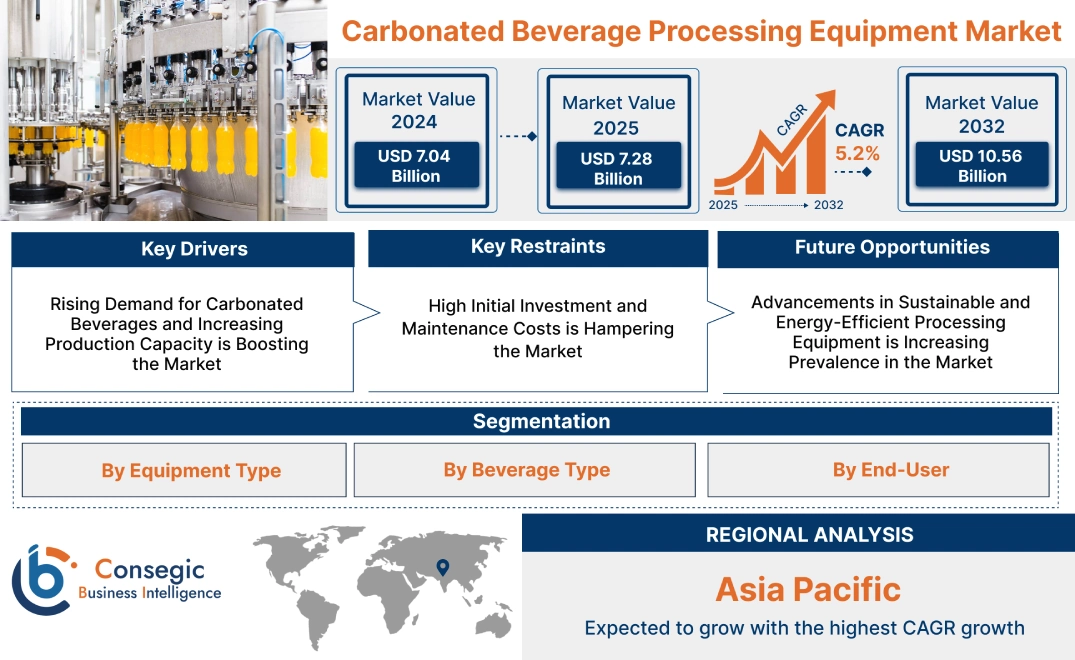

Carbonated Beverage Processing Equipment Market Size:

Carbonated Beverage Processing Equipment Market size is estimated to reach over USD 10.56 Billion by 2032 from a value of USD 7.04 Billion in 2024 and is projected to grow by USD 7.28 Billion in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

Carbonated Beverage Processing Equipment Market Scope & Overview:

The carbonated beverage processing equipment industry focuses on machinery and systems used in the production, bottling, and packaging of carbonated drinks such as soft drinks, sparkling water, and energy drinks. This includes equipment for mixing, carbonating, filling, sealing, and labeling, ensuring consistency, efficiency, and high production standards. Advanced processing solutions integrate automation and IoT-enabled monitoring to enhance operational precision.

Key characteristics of carbonated beverage processing equipment include high-speed production capabilities, precision carbonation control, sanitation compliance, and energy efficiency. The benefits include improved beverage quality, extended shelf life, reduced production costs, and enhanced process automation.

Applications span soft drink manufacturing, craft soda production, and flavored sparkling water processing in both large-scale production facilities and small to mid-sized beverage plants. End-users include beverage manufacturers, bottling companies, and contract packaging firms, driven by increasing consumer demand for carbonated beverages, advancements in processing technologies, and rising investments in sustainable and energy-efficient beverage production solutions.

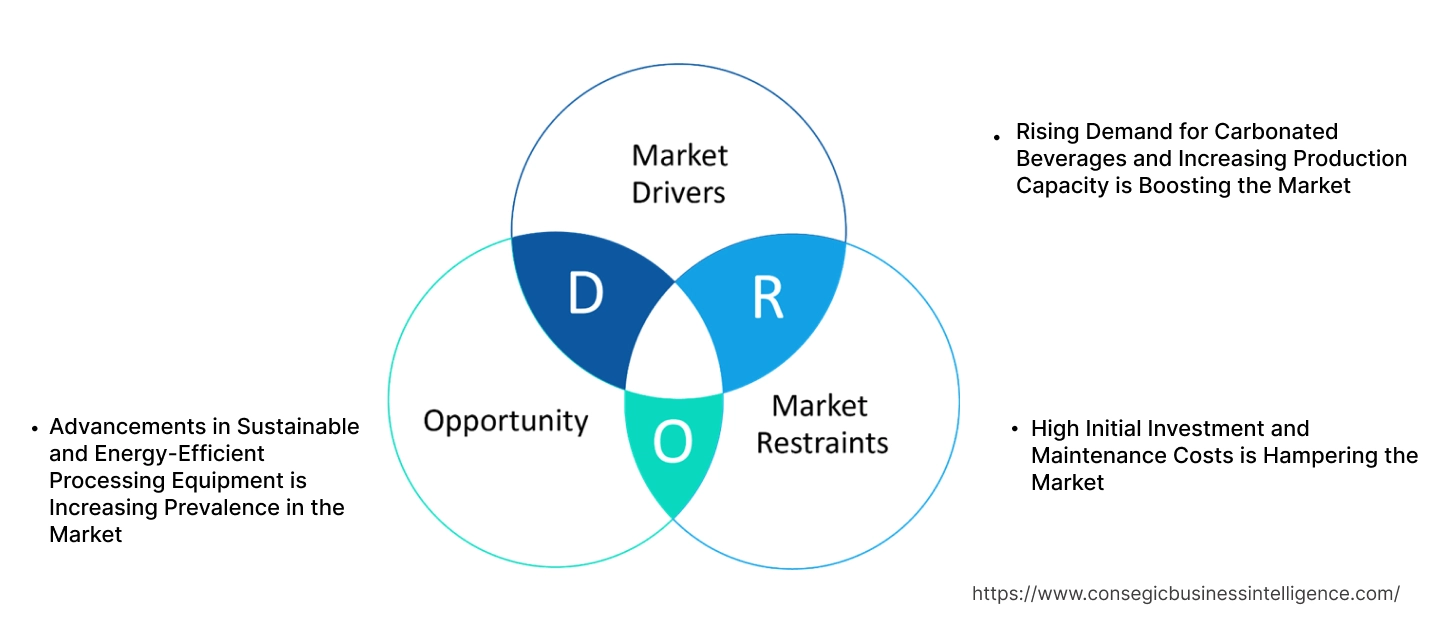

Key Drivers:

Rising Demand for Carbonated Beverages and Increasing Production Capacity is Boosting the Market

The growing carbonated beverage processing equipment market demand, including soft drinks, energy drinks, and sparkling water, is a major driver for the market. Changing consumer preferences, urbanization, and expanding beverage portfolios by key manufacturers have led to increased production capacity across the industry. With companies focusing on product innovation, including sugar-free and functional carbonated drinks, there is a heightened need for advanced processing equipment such as carbonation systems, filling machines, and filtration units. Additionally, trends in automation and precision engineering have enhanced production efficiency, allowing manufacturers to meet evolving consumer preferences while ensuring consistency in beverage quality.

Key Restraints:

High Initial Investment and Maintenance Costs is Hampering the Market.

A significant challenge for the market is the high initial cost of acquiring and installing advanced machinery. Equipment such as high-speed bottling lines, automated carbonators, and precision mixing systems require substantial capital investment, making it difficult for small and mid-sized beverage producers to adopt cutting-edge solutions. Additionally, maintenance costs for these systems can be considerable, particularly for equipment operating at high production speeds. Frequent servicing and the need for skilled personnel to manage automated processes further add to operational expenses, creating barriers to market entry for smaller players.

Future Opportunities :

Advancements in Sustainable and Energy-Efficient Processing Equipment is Increasing Prevalence in the Market

The increasing focus on sustainability and energy efficiency presents significant rise for the carbonated beverage processing equipment market opportunities. Manufacturers are investing in energy-efficient carbonation technologies, reduced water usage systems, and advanced recycling mechanisms to align with environmental regulations and corporate sustainability goals. The growth for eco-friendly processing solutions is also growing among beverage producers aiming to reduce carbon footprints and optimize resource utilization. Additionally, trends such as modular processing units and smart monitoring systems are improving production flexibility and enabling real-time quality control, further enhancing the appeal of next-generation processing equipment.

These market dynamics highlight the increasing trends for technologically advanced and sustainable beverage processing solutions. While cost remains a challenge, the growth for automation, precision, and energy-efficient equipment is creating new growth opportunities for manufacturers. As trends in consumer preferences continue to evolve, beverage companies are expected to invest in innovative processing technologies to meet demand while enhancing operational efficiency.

Carbonated Beverage Processing Equipment Market Segmental Analysis :

By Equipment Type:

Based on equipment type, the market is segmented into mixing equipment, filling equipment, packaging equipment, heat exchangers, filtration equipment, and others.

The filling equipment segment accounted for the largest revenue of carbonated beverage processing equipment market share in 2024.

- Filling equipment plays a crucial role in ensuring accurate and high-speed bottling of carbonated beverages, maintaining carbonation levels and product consistency.

- Increasing investments in automated and high-capacity filling machines by beverage manufacturers enhance operational efficiency.

- Technological advancements, such as inline carbonation systems and pressure-sensitive filling, improve product quality.

- Rising production volumes of carbonated drinks, including soft drinks and energy drinks, drive trends for advanced filling solutions.

The packaging equipment segment is anticipated to register the fastest CAGR during the forecast period.

- Growing consumer preference for convenient and sustainable packaging formats, such as PET bottles and aluminum cans, fuels trends for advanced packaging equipment.

- Expanding the use of smart packaging technologies, including tamper-proof seals and extended shelf-life solutions, supports the segment in carbonated beverage processing equipment market growth.

- Rising automation in beverage packaging, coupled with carbonated beverage processing equipment market demand for efficient labeling and sealing systems, enhances adoption.

- Increasing regulatory focus on eco-friendly and recyclable packaging materials encourages innovations in sustainable packaging equipment.

By Beverage Type:

Based on beverage type, the market is segmented into soft drinks, carbonated water, energy drinks, alcoholic carbonated beverages, and others.

The soft drinks segment accounted for the largest revenue share in 2024.

- Soft drinks, including colas and flavored carbonated beverages, continue to dominate global consumption, driving trends for large-scale production equipment.

- Increasing consumer preference for low-sugar and functional carbonated drinks expands product diversity within this segment.

- Advancements in beverage processing technology, such as precision carbonation and ingredient mixing, enhance product taste and quality.

- Expanding distribution networks and brand investments in new flavor innovations contribute to the market's strength.

The energy drinks segment is anticipated to register the fastest CAGR during the forecast period.

- Rising global demand for functional beverages, including caffeinated and vitamin-enriched energy drinks, drives rapid production inflation.

- Increasing preference for on-the-go energy beverages boosts investments in high-speed and efficient carbonated beverage processing equipment.

- Technological advancements in carbonation and ingredient infusion enable manufacturers to develop healthier and more innovative formulations.

- Growing penetration of energy drinks in developing markets accelerates carbonated beverage processing equipment market trends for processing equipment tailored to specialized formulations.

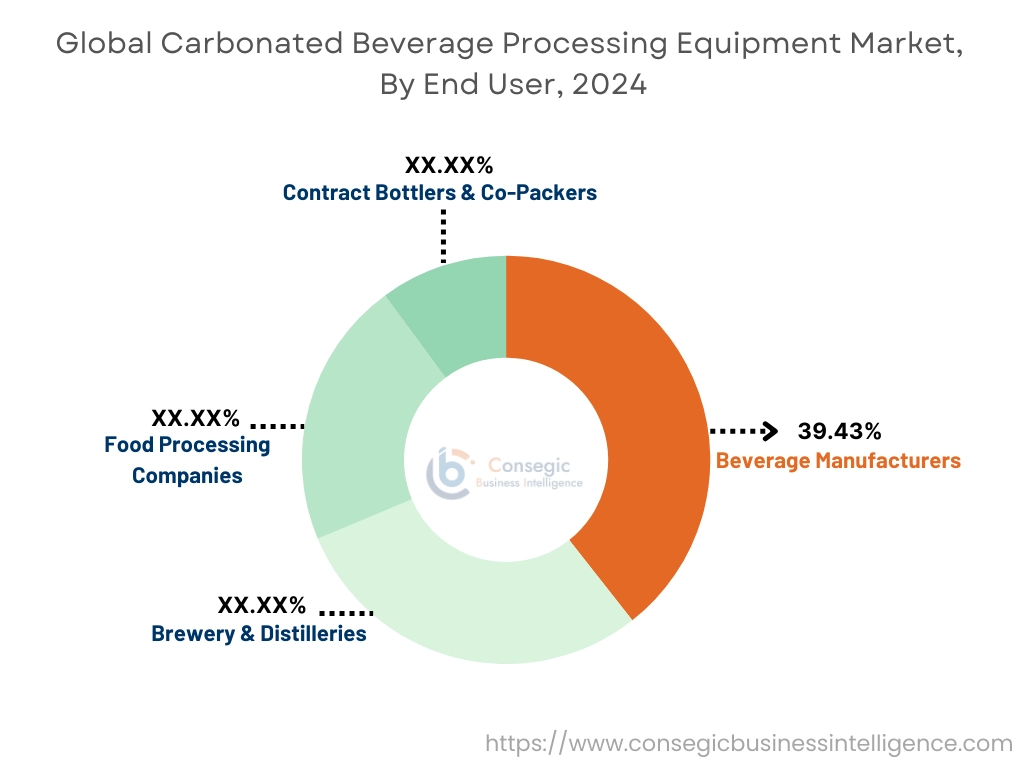

By End-User:

Based on end-user, the market is segmented into beverage manufacturers, brewery & distilleries, food processing companies, and contract bottlers & co-packers.

The beverage manufacturers segment accounted for the largest revenue of carbonated beverage processing equipment market share of 39.43% in 2024.

- Leading beverage companies continuously invest in state-of-the-art processing equipment to enhance efficiency, maintain quality, and expand production capacity.

- Increasing consumer demand for diverse and innovative carbonated beverages supports large-scale production investments.

- Rising adoption of automated processing lines, including digital monitoring and predictive maintenance, enhances production output.

- Extension strategies of multinational beverage brands into emerging markets contribute to sustained growth for advanced processing equipment.

The contract bottlers & co-packers segment is anticipated to register the fastest CAGR during the forecast period.

- Increasing outsourcing of beverage production by brands looking to optimize costs and focus on marketing drives trends for co-packing services.

- Contract bottlers invest in versatile processing equipment to accommodate various formulations and packaging formats.

- Growing market entry of niche and craft carbonated beverages encourages flexible production capabilities in contract manufacturing facilities.

- The rising adoption of eco-friendly and sustainable processing solutions in co-packing operations supports this segmental analysis.

Regional Analysis:

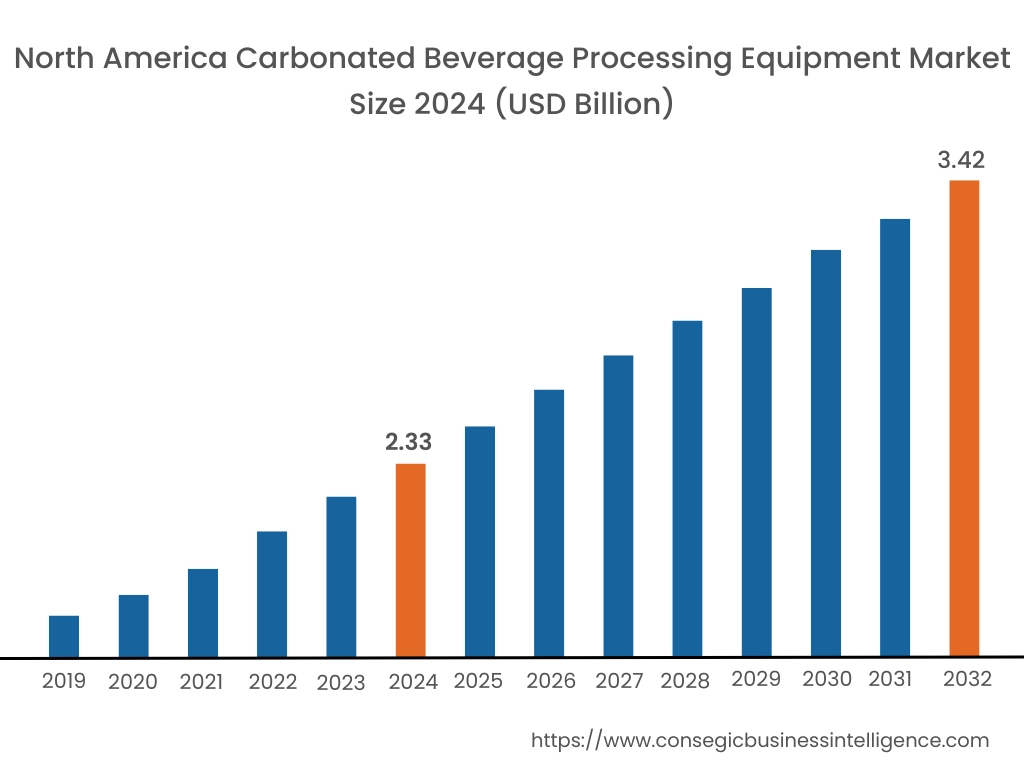

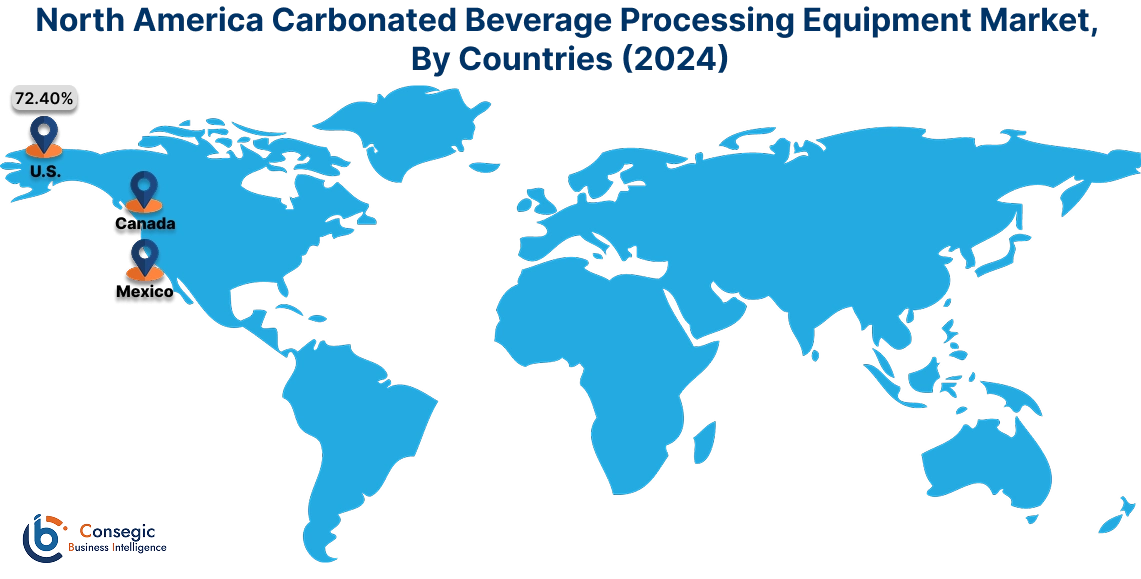

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 2.33 Billion and is expected to reach USD 3.42 Billion in 2032. In North America, the U.S. accounted for the highest share of 72.40% during the base year of 2024. North America holds a significant share of the market, driven by the high consumption of soft drinks, flavored sparkling water, and energy drinks. The U.S. leads the region with continuous investments in automated beverage processing technologies and advanced filling and packaging solutions. Canada supports carbonated beverage processing equipment market expansion with an increasing surge for healthier carbonated beverages, such as low-sugar and functional sparkling drinks. Analysis highlights that the growing focus on sustainable processing and packaging is shaping equipment innovations in this region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. Asia-Pacific is the fastest-growing region in the carbonated beverage processing equipment market, fueled by rising urbanization, growing disposable incomes, and increasing opportunities for soft drinks and functional beverages in China, India, and Japan. China dominates the region with large-scale investments in high-speed carbonation and bottling equipment to meet the growing beverage industry needs. India’s expanding middle class and increasing preference for carbonated juices and flavored sodas are driving the adoption of cost-effective processing equipment. Japan focuses on precision beverage processing technologies, integrating automation and smart monitoring systems. Analysis highlights that government initiatives supporting food and beverage manufacturing are accelerating equipment adoption in the region.

Europe is a key market that is supported by strong consumer carbonated beverage processing equipment market trends for premium and craft carbonated drinks, including sodas, flavored sparkling water, and kombucha. Countries like Germany, the UK, and France are major contributors. Germany drives market expansion through advanced processing technologies and efficiency-focused beverage manufacturing. The UK emphasizes automation in production lines to meet the increasing preference for sustainable and organic carbonated drinks, while France sees rising adoption of energy-efficient processing equipment. The carbonated beverage processing equipment market analysis suggests that the region’s stringent regulations on beverage production and packaging sustainability are influencing equipment upgrades.

The Middle East & Africa region is witnessing a steady rise in the carbonated beverage processing equipment market growth, which is driven by increasing beverage consumption, rising investments in manufacturing facilities, and growing trends for energy drinks and carbonated flavored water. Countries like Saudi Arabia and the UAE are expanding their beverage processing capacities, focusing on energy-efficient and sustainable equipment. In Africa, South Africa is emerging as a key market, with growing investments in local beverage production to meet domestic demand. Regional carbonated beverage processing equipment market analysis indicates that high import dependency for processing equipment poses cost challenges for manufacturers.

Latin America is an emerging market for carbonated beverage processing equipment, with Brazil and Mexico leading the region. Brazil’s increasing consumption of carbonated soft drinks and expansion of local beverage manufacturing facilities drive the rapid growth for high-speed filling and carbonation systems. Mexico focuses on modernizing its beverage processing sector, with a strong presence of international soft drink manufacturers investing in automated and efficient processing lines. Analysis reveals that the growing trend of functional and low-sugar carbonated beverages is encouraging equipment innovation, despite economic challenges in some smaller markets.

Top Key Players & Market Share Insights:

The carbonated beverage processing equipment market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global carbonated beverage processing equipment market. Key players in the carbonated beverage processing equipment industry include -

- Krones AG (Germany)

- GEA Group (Germany)

- Ziemann Holvrieka (Germany)

- BHS-Sonthofen (Germany)

- Cleveland Keg Works (USA)

- Tetra Pak International S.A. (Switzerland)

- SPX Flow, Inc. (USA)

- Alfa Laval (Sweden)

- Bucher Industries AG (Switzerland)

- FLSmidth (Denmark)

Carbonated Beverage Processing Equipment Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 10.56 Billion |

| CAGR (2025-2032) | 5.2% |

| By Equipment Type |

|

| By Beverage Type |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the current and projected size of the Carbonated Beverage Processing Equipment Market? +

Carbonated Beverage Processing Equipment Market size is estimated to reach over USD 10.56 Billion by 2032 from a value of USD 7.04 Billion in 2024 and is projected to grow by USD 7.28 Billion in 2025, growing at a CAGR of 5.2% from 2025 to 2032.

What are the key types of equipment used in carbonated beverage processing? +

The market is segmented into mixing equipment, filling equipment, packaging equipment, heat exchangers, and filtration equipment. Filling equipment held the largest market share in 2024 due to its essential role in maintaining carbonation levels and product consistency, while packaging equipment is expected to witness the fastest growth due to increasing demand for sustainable and smart packaging solutions.

Which beverage type dominates the Carbonated Beverage Processing Equipment Market? +

The soft drinks segment accounted for the largest revenue share in 2024, driven by the high consumption of carbonated beverages such as colas and flavored sodas. The energy drinks segment is projected to grow at the fastest CAGR due to increasing demand for functional beverages and caffeine-infused carbonated drinks.

What factors are driving the growth of the Carbonated Beverage Processing Equipment Market? +

Growth is driven by increasing consumer demand for carbonated beverages, technological advancements in automation and precision carbonation systems, and rising investments in sustainable and energy-efficient processing equipment.