- Summary

- Table Of Content

- Methodology

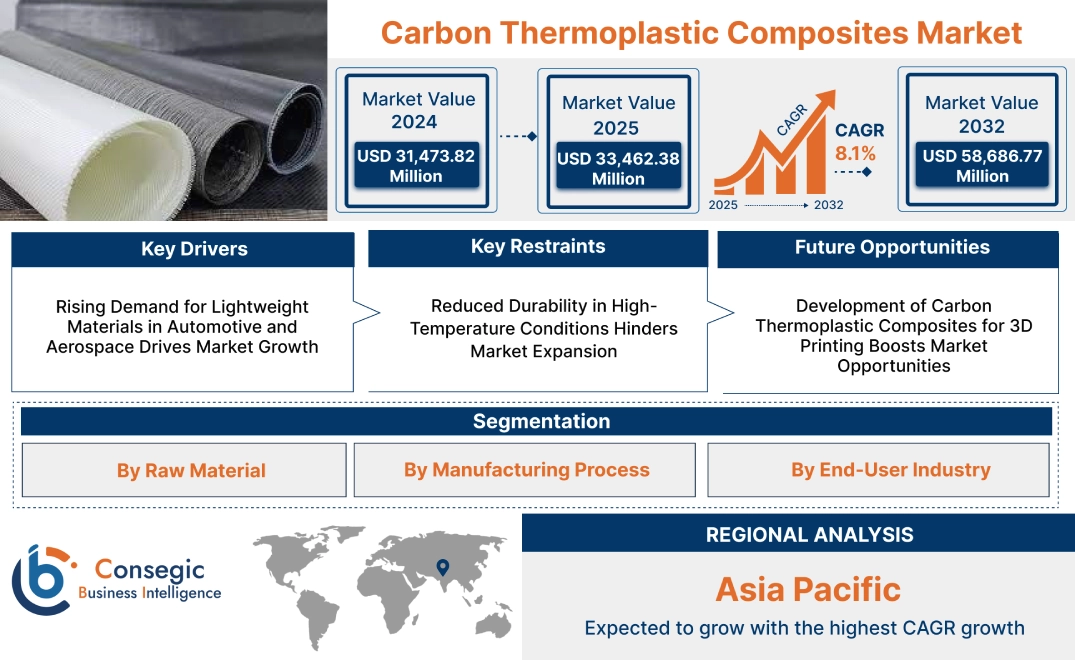

Carbon Thermoplastic Composites Market Size:

Carbon thermoplastic composites market size is estimated to reach over USD 58,686.77 Million by 2032 from a value of USD 31,473.82 Million in 2024 and is projected to grow by USD 33,462.38 Million in 2025, growing at a CAGR of 8.1% from 2025 to 2032.

Carbon Thermoplastic Composites Market Scope & Overview:

Carbon thermoplastic composites are high-performance materials composed of carbon fibers within a thermoplastic matrix, known for their strength, durability, and impact resistance. These materials offer lightweight construction, corrosion resistance, and recyclability, making them a preferred choice in industries requiring structural efficiency. Their adaptability allows for efficient processing and reshaping, enhancing design flexibility across various applications.

Widely used in aerospace, automotive, and industrial sectors, these materials contribute to better fuel efficiency, structural integrity, and performance optimization. The aerospace field benefits from their strength-to-weight ratio, while the automotive sector utilizes them to enhance safety and energy efficiency. Additionally, applications in defense, consumer goods, and construction continue to expand due to their durability and continued innovation.

Industries such as transportation and energy are driving adoption, leveraging these materials for weight reduction and enhanced mechanical properties. Ongoing advancements in manufacturing processes are further improving production efficiency, ensuring broader integration across multiple sectors.

Key Drivers:

Rising Demand for Lightweight Materials in Automotive and Aerospace Drives Market Growth

The need for fuel efficiency, performance optimization, and regulatory compliance accelerates the need for such materials in the aerospace and automotive industry. Carbon thermoplastics composites offer an ideal balance of strength, durability, and reduced weight, making them essential for aircraft structures, vehicle body panels, and electric vehicle battery enclosures. In aerospace, manufacturers integrate these composites to enhance fuel economy, extend operational lifespan, and meet stringent safety standards. In the automotive sector, particularly in electric vehicles, reducing vehicle weight directly improves battery efficiency and driving range. Additionally, they enable faster production cycles and recyclability, aligning with sustainability goals. Their superior impact resistance and thermal stability further contribute to vehicle safety and structural integrity.

As original equipment manufacturers (OEMs) increasingly prioritize lightweight solutions, advancements in material technology and increased adoption in next-generation transportation systems results in carbon thermoplastic composites market growth.

Key Restraints:

Reduced Durability in High-Temperature Conditions Hinders Market Expansion

Unlike thermoset composites, which maintain structural integrity under sustained thermal exposure, carbon thermoplastic composites experience softening, warping, or degradation when subjected to elevated temperatures. This characteristic restricts their usage in industries such as aerospace, automotive, and energy, where materials must endure extreme heat without compromising performance. In applications like aircraft engine components, high-performance automotive parts, and industrial machinery, maintaining mechanical stability under thermal stress is essential. The demand for materials that withstand prolonged heat exposure remains high, but thermoplastic composites face challenges in meeting these requirements. Ultimately, the loss of desired properties at elevated temperatures restraints the carbon thermoplastic composites market expansion.

Future Opportunities :

Development of Carbon Thermoplastic Composites for 3D Printing Boosts Market Opportunities

As industries seek efficient and customizable manufacturing solutions, the demand for advanced materials compatible with additive manufacturing is increasing. 3D printing is able to manufacture carbon thermoplastic composites at a faster, cheaper rate with complex geometries. Additionally, the opportunity to recycle plastic and reduce waste through 3D printing, makes it a sustainable alternative manufacturing process, inviting substantial research and investment. In aerospace, 3D-printed composite components contribute to weight reduction and improved fuel efficiency, while in automotive, they support the development of next-generation vehicle structures. The growth of 3D printing technologies, coupled with advancements in composite formulations, is expanding possibilities for high-performance, customized manufacturing solutions, boosting carbon thermoplastic composites market opportunities.

Carbon Thermoplastic Composites Market Segmental Analysis :

By Raw Material:

Based on raw material, the market is segmented into polyether ether ketone (PEEK), polyamide (PA), polypropylene (PP), polycarbonate (PC), and others.

The PEEK segment formed the largest carbon thermoplastic composites market share in 2024.

- PEEK is widely used in aerospace & defense and automotive industries.

- This material is a preferred choice for structural components in aircraft and high-performance vehicles due to its high fatigue resistance, lightweight properties, exceptional mechanical strength, thermal stability, and chemical resistance.

- The demand for fuel-efficient and lightweight materials in commercial aviation and next-generation automobiles is driving PEEK adoption.

- Continuous advancements in high-performance composites manufacturing are further improving the cost-effectiveness and structural integrity of PEEK-based components.

- In October 2023, Evonik introduced the world’s first carbon-fiber reinforced PEEK filament for long-term 3D printed medical implants. Its properties include high strength and ductility, the ability to define the alignment of the carbon fibers during the 3D printing process, and high biocompatibility for metal allergy patients.

- Therefore, these factors contribute to PEEK accounting for the largest revenue segment.

The polyamide (PA) market share is projected to experience the fastest CAGR during the forecast period.

- Polyamide-based composites offer an optimal balance of mechanical strength, flexibility, and ease of processing, making them highly suitable for automotive and consumer goods applications.

- The increasing adoption of lightweight materials in electric vehicles (EVs) to enhance energy efficiency and extend battery range is accelerating demand for PA composites.

- It is an ideal material for the manufacture of large volume of regular items like gears and bearings.

- Ongoing innovations in reinforced PA composites are expanding their application potential across industries, improving material performance and longevity.

- Therefore, as per carbon thermoplastic composites market analysis, polyamide is anticipated to have the fastest CAGR.

By Manufacturing Process:

Based on the manufacturing process, the carbon thermoplastic composites market is segmented into injection molding, compression molding, pultrusion, automated fiber placement (AFP), and others.

The injection molding segment accounted for the largest revenue share in 2024.

- Injection molding is the most widely used process due to its high scalability, precision, and cost-effectiveness in mass production.

- This process is extensively utilized in automotive and consumer goods industries for the manufacturing of complex, lightweight components.

- The growth of high-volume, repeatable, and precise production in structural and interior applications is fueling adoption.

- Innovations in automated injection molding techniques and advanced thermoplastic formulations are enhancing material properties and processing efficiency.

- In June 2023, Tool Gauge And Victrex collaborated to produce composite parts for commercial aircraft using hybrid over-molding combined with injection molding and thermoforming to manufacture a finished part that is lighter, cheaper, produces less waste, can be produced faster, and has superior fatigue performance.

- This results in injection molding driving carbon thermoplastic composites market trends.

The automated fiber placement (AFP) segment is anticipated to have the fastest CAGR during the forecast period.

- AFP is increasingly adopted in aerospace & defense for the production of lightweight and high-strength structural components.

- This high-precision process allows for optimized fiber alignment, improving the mechanical performance and durability of final product.

- The rise of next-generation aircraft and space exploration programs is propelling increased adoption of AFP technology.

- Advancements in robotic automation and real-time fiber placement monitoring are further improving its efficiency and cost-effectiveness.

- As per segmental trend analysis, the carbon thermoplastic composites market demand is bolstered by these factors.

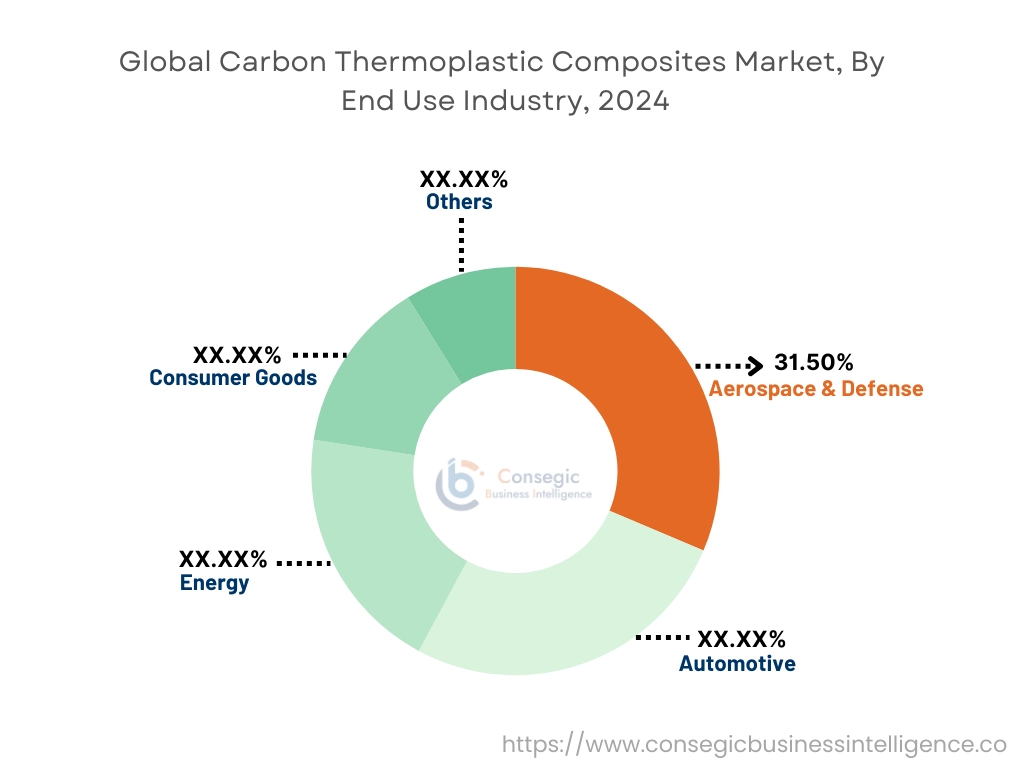

By End Use Industry:

Based on end-use industry, the market is categorized into aerospace & defense, automotive, energy, consumer goods, and others.

The aerospace & defense segment accounted for the largest carbon thermoplastic composites market share of 31.50% in 2024.

- The push for lighter and more fuel-efficient aircraft is driving the trend of utilizing high-strength, lightweight composite materials in the aerospace & defense sector.

- Leading manufacturers such as Boeing and Airbus are incorporating thermoplastic composites into next-generation aircraft to improve structural integrity while reducing weight.

- Military applications of high-performance composites in defense vehicles, drones, and ballistic protection systems further boost market expansion.

- Furthermore, the expanding aerospace & defense market is expected to boost the carbon thermoplastic composites market demand.

The automotive market share is expected to experience the fastest CAGR during the forecast period.

- These materials are widely used in structural, chassis, and powertrain components to reduce vehicle weight without compromising strength.

- The increasing shift toward electric vehicles (EVs) accelerates demand for lightweight materials to enhance battery efficiency and extend driving range.

- Innovations in sustainable materials are further expanding the use of carbon thermoplastics in next-generation vehicles.

- Advancements in manufacturing technologies, such as automated fiber placement and injection molding, are improving production scalability and cost-effectiveness.

- Thus, these factors bolster carbon thermoplastic composites market trends.

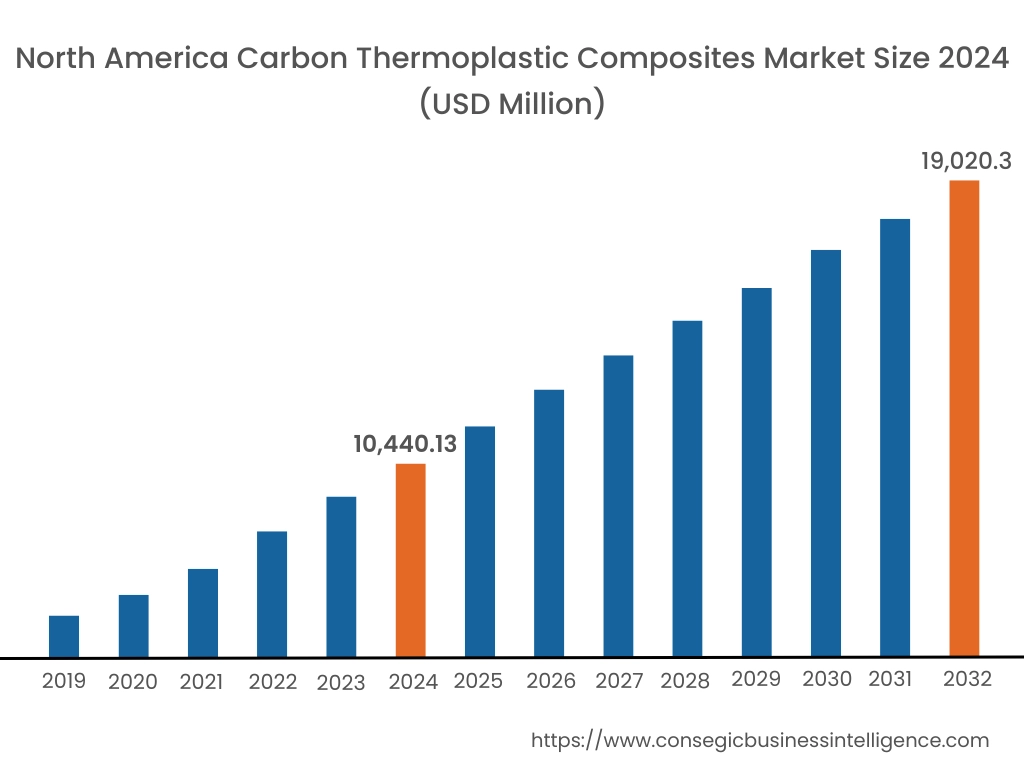

Regional Analysis:

The regional analysis of the carbon thermoplastic composites market includes North America, Europe, Asia Pacific, the Middle East & Africa, and Latin America.

North America is estimated to reach over USD 19,020.38 Million by 2032 from a value of USD 10,440.13 Million in 2024 and is projected to grow by USD 11,078.54 Million in 2025. In North America, the U.S. accounted for the highest share of 71.02% during the base year of 2024.

North America is a frontrunner in adopting these novel materials, particularly within the aerospace and defense sectors. The presence of major aircraft manufacturers, such as Boeing, underscores the region's commitment to integrating lightweight materials to enhance fuel efficiency and performance. Additionally, stringent environmental regulations are propelling the automotive sector to incorporate these materials, aiming to reduce vehicle emissions. Collaborations between research institutions and industry players further drive innovation, leading to the development of advanced composite solutions.

Asia Pacific region was valued at USD 9,269.30 Million in 2024. Moreover, it is projected to grow by USD 9,882.81 Million in 2025 and reach over USD 17,870.12 Million by 2032. The Asia-Pacific region is witnessing rapid adoption of carbon thermoplastic composites, driven by industrialization and infrastructural developments. Countries such as China, Japan, and India are investing heavily in research and development to enhance production processes and material properties. The automotive sector's shift towards lightweight vehicles to improve efficiency is a significant trend, with manufacturers increasingly incorporating these materials. Additionally, the aerospace industry's growth in this region contributes to the carbon thermoplastic composites market expansion.

Europe stands as a significant player in the carbon thermoplastic composites industry, with countries like Germany, the UK, and France at the forefront. The region's strong automotive sector, featuring manufacturers such as BMW and Volkswagen, is increasingly utilizing these composites to achieve weight reduction and improve fuel efficiency. Moreover, Europe's emphasis on sustainability aligns with the recyclability of thermoplastic composites, making them a preferred choice in various applications. Research initiatives and government support further bolster the market, fostering advancements in composite technologies.

As per the carbon thermoplastic composites market analysis, the Middle East and African region is gradually gaining traction. The region's focus on diversifying economies and developing advanced manufacturing capabilities is leading to increased interest in high-performance materials. Sectors such as construction and automotive are exploring the benefits of these composites for their strength-to-weight ratio and durability. However, market growth is moderated by factors such as limited awareness and the need for technological expertise.

Lastly, Latin America is emerging as a potential market for carbon thermoplastic composites, with countries like Brazil and Mexico showing interest. The region's automotive sector is recognizing the advantages of weight reduction and fuel efficiency offered by these materials. Additionally, the wind energy sector's expansion presents opportunities for composite applications in turbine components. Collaborations with global players and investments in manufacturing capabilities is anticipated to drive carbon thermoplastic composites market growth.

Top Key Players & Market Share Insights:

The market is highly competitive with major players providing products and solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the carbon thermoplastic composites industry include-

- Toray Industries, Inc. (Japan)

- Teijin Limited (Japan)

- Celanese Corporation (USA)

- SABIC (Saudi Arabia)

- DowAksa (Turkey)

- Hexcel Corporation (USA)

- Solvay S.A. (Belgium)

- SGL Carbon SE (Germany)

- BASF SE (Germany)

- LANXESS AG (Germany)

Recent Industry Developments :

Business Expansion:

- In April 2024, Solvay inaugurated a new blowing agent production unit in Italy. This chemical, Alve-One, is an essential ingredient in thermoplastic production. It is a hazardous-free and eco-friendly chemical foaming agent that meets the latest and strictest regulatory standards.

Acquisition & Mergers:

- In November 2024, Toray Advanced Composites announced its expansion of its continuous fiber reinforced thermoplastic composite materials portfolio through the acquisition of Gordon Plastics. The new facility will serve as a satellite R&D and production center by integrating experienced Gordon Plastics personnel.

Carbon Thermoplastic Composites Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 58,686.77 Million |

| CAGR (2025-2032) | 8.1% |

| By Raw Material |

|

| By Manufacturing Process |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Carbon Thermoplastic Composites Market? +

Carbon thermoplastic composites market size is estimated to reach over USD 58,686.77 Million by 2032 from a value of USD 31,473.82 Million in 2024 and is projected to grow by USD 33,462.38 Million in 2025, growing at a CAGR of 8.1% from 2025 to 2032.

What specific segmentation details are covered in the Carbon Thermoplastic Composites Market report? +

The carbon thermoplastic composites market report includes specific segmentation details for raw material, manufacturing process and end-user industry.

Which is the fastest-growing region in the Carbon Thermoplastic Composites Market? +

Asia Pacific is the fastest-growing region in the carbon thermoplastic composites market.

Who are the major players in the Carbon Thermoplastic Composites Market? +

The key participants in the carbon thermoplastic composites market are Toray Industries, Inc. (Japan), Teijin Limited (Japan), Hexcel Corporation (USA), Solvay S.A. (Belgium), SGL Carbon SE (Germany), BASF SE (Germany), LANXESS AG (Germany), Celanese Corporation (USA), SABIC (Saudi Arabia) and DowAksa (Turkey).