- Summary

- Table Of Content

- Methodology

Carbon Fiber Composite Heating Element Market Introduction :

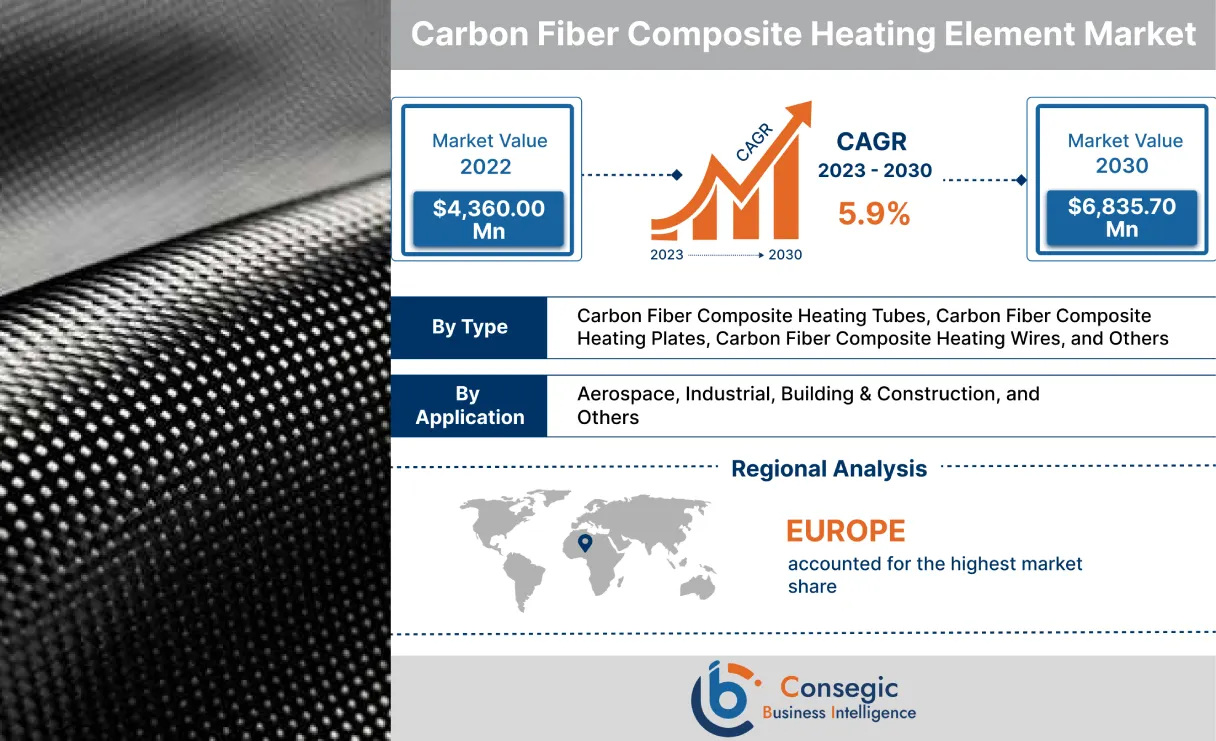

Consegic Business Intelligence analyzes that the carbon fiber composite heating element market size is growing with a healthy CAGR of 5.9% during the forecast period (2023-2030), and the market is projected to be valued at USD 6,835.70 Million by 2030 from USD 4,360.00 Million in 2022.

Carbon Fiber Composite Heating Element Market Definition & Overview :

A carbon fiber composite heating element is a type of heating element that is made from carbon fibers and a polymer matrix. The carbon fibers provide the strength and stiffness of the heating element, while the polymer matrix provides electrical conductivity. The carbon composite heating element has superior flexibility in comparison with metal alloys such as steel. Thus, carbon composite heating elements have the advantage of bending into a diverse range of shapes and maintaining superior mechanical strength. As per the analysis, the major product types of this heating elements include carbon fiber composite heating tubes, carbon fiber composite heating plates, and carbon fiber composite heating wires, among others. These products exhibit superior performance features such as high-temperature endurance, lightweight, and excellent tensile strength. As a result, carbon composite heating element is an ideal product for various applications, including aerospace, industrial, building & construction, and others.

Carbon Fiber Composite Heating Element Market Insights :

Key Drivers :

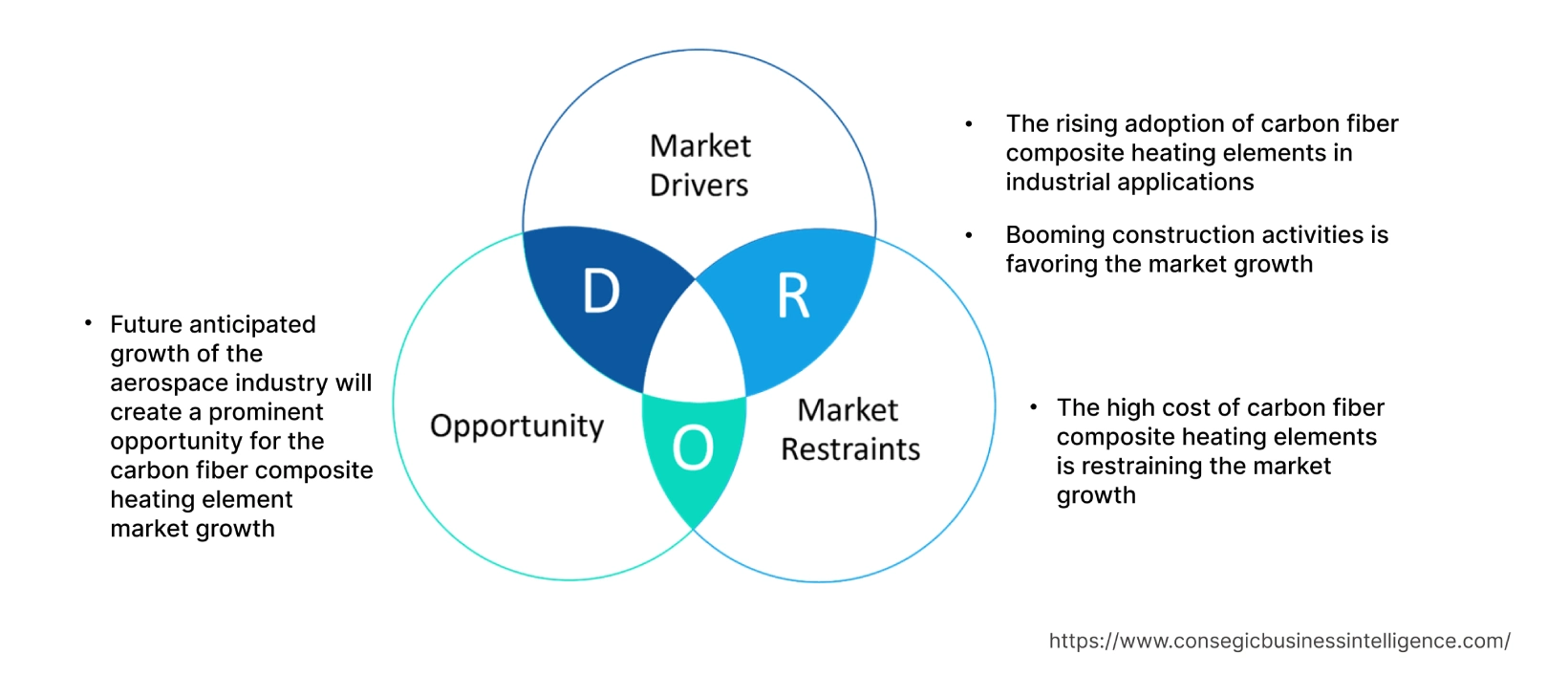

The rising adoption of carbon fiber composite heating element in industrial applications

The utilization of carbon fiber composite heating element is essential in industrial settings to ensure excellent stiffness and strength. Based on the analysis, the heating elements are deployed in industrial manufacturing such as heavy machinery, agriculture equipment, automotive, and others. For instance, according to the Association of Equipment Manufacturers (AEM), in 2021, the agriculture equipment and machinery industry in crucial countries such as the U.S., Japan, the UK, Eastern Europe, and Eurozone reported a growth of 27%, 5%, 3%, 8%, and 1% respectively. Thus, the development in industrial manufacturing activities is boosting the demand for these heating elements to ensure excellent durability. This, in turn, is accelerating the trend of the market.

Booming construction activities is favoring the market

These heating elements have high stiffness and superior resistivity for meander or plate-shaped heating elements. As a result, these heating element is deployed in building and construction projects to ensure superior durability of outer structures. As per the analysis, the rising investment in the new healthcare infrastructure, expansion of leisure construction projects, and others are bolstering the expansion of new construction projects at the global level. For instance, as of July 2023, various construction projects are in the near completion phase, including USD 476 million for The Eight Office Tower project in the United States (completion year 2024), USD 1,760 million Lok Ma Chau Emergency Hospital Development project in China (project completion year Q4 2023), and others. Hence, the development in the near completion of construction projects at the global level is boosting the demand for these heating elements to protect the outer structure from corrosion. Henceforth, the development of building & construction projects is supplementing the carbon fiber composite element market growth and trend.

Key Restraints :

The high cost of carbon fiber composite heating element is restraining the market

The overall cost of carbon fiber composite heating element is dependent on the cost of production, followed by the cost of raw materials. Furthermore, as per the analysis, the increasing transportation cost, increasing oil prices, electricity cost, labor cost, and others impact the overall pricing of vinyl ester resins resins products. For instance, in 2022, the surge in the price of oil to a record high level of USD 139 per barrel. The highest level recorded in the past 16 years has resulted in higher transportation costs of raw materials, logistics, and more, which is causing significant disruption in the supply chain associated with multiple industries at the global level. Hence, the factors such as higher transportation costs, supply constraints, and others are some of the prominent determinants fostering the prices of these elements, which, in, turn, is posing a bottleneck for the expansion of the market.

Future Opportunities :

Future anticipated growth of the aerospace industry will create a prominent opportunity for the carbon fiber composite heating element market

The prime benefits of carbon fiber composite heating element include superior durability, higher strength, and others. These benefits make these heating elements an ideal solution for the aircraft furnace. For instance, according to the Airbus 2023-2042 forecast, the demand for new passengers and freighter aircraft will be 40,850 in the upcoming 20 years. Thus, based on the analysis, it is evident from the above data that the aerospace industry will register development in the long run. As a result, the expansion of the aerospace sector will boost the demand for these heating elements for the aircraft furnace. This, in turn, will create a potential carbon fiber composite heating element market opportunities and trends during the projected forecast period.

Carbon Fiber Composite Heating Element Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 6,835.70 Million |

| CAGR (2023-2030) | 5.9% |

| By Product Type | Carbon Fiber Composite Heating Tubes, Carbon Fiber Composite Heating Plates, Carbon Fiber Composite Heating Wires, and Others |

| By Application | Aerospace, Industrial, Building & Construction, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Solvay S.A., SGL Group, CFC Carbon Co., Ltd, Tokai Carbon, Schunk Group, Premium Graphite Pvt. Ltd., Reliance Industries Ltd., Toyo Tanso Co.,Ltd., Hexcel Corporation, and ADENTE Advanced Engineering Technologies |

Carbon Fiber Composite Heating Element Market Segmental Analysis :

Based on the Product Type :

The product type segment is categorized into carbon fiber composite heating tubes, carbon fiber composite heating plates, carbon fiber composite heating wires, and others. In 2022, the carbon fiber composite heating tubes segment accounted for the highest market share in the carbon fiber composite heating element market. Carbon fiber composite heating tubes have various prominent properties such as bulk density of 1.4~1.5 g/cm3, tensile strength of 40~60 MPa, tensile modulus of 25~30 GPa, bending strength of 80~110 MPa, compressive strength at 90~120 MPa, and others. These features ensure superior thermal conductivity of 30~50 W/mk, excellent processing temperature of 2200℃, and others. Thus, based on the analysis, carbon fiber composite heating tubes are ideal for the production of aerospace vacuum heat treating furnaces in aircraft. For instance, according to Airbus, a leading aircraft manufacturer, the monthly production of A330 aircraft increased by 3 in 2022. Furthermore, Airbus is targeting to increase the monthly production of A330 aircraft by 4 in the year 2024. Thus, the rise in the production of aircraft is accelerating the demand for carbon fiber composite heating tubes to ensure superior thermal performance. This, in turn, is driving the trend and segmental development of the market.

However, the carbon fiber composite heating tubes segment is projected to be the fastest-growing segment during the forecast period. This is due to the increasing industrial production activities, which are fostering segmental development and trend in the upcoming years.

Based on the Application :

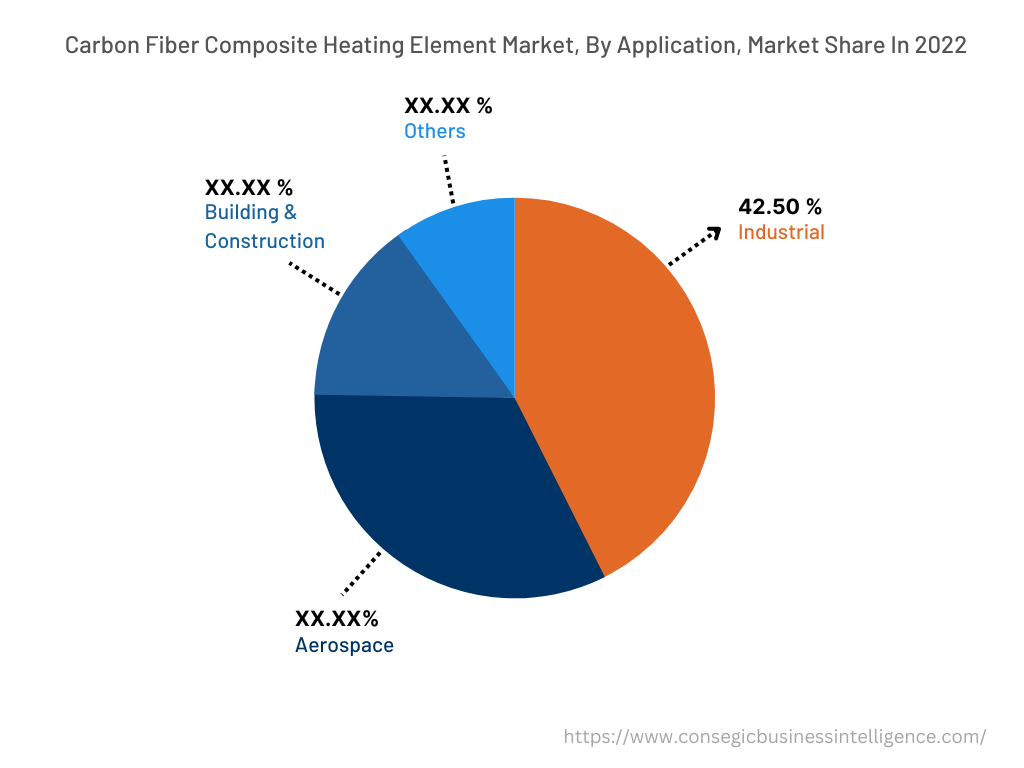

The application segment is categorized into aerospace, industrial, building & construction, and others. In 2022, the industrial segment accounted for the highest carbon fiber composite heating element market share of 42.50% in the overall carbon fiber composite heating element market. The vital properties associated with these elements include superior corrosion resistance, extreme temperature resistance, and lightweight. As a result, these heating element is an ideal solution in industries such as heavy trucks, heavy equipment, and others. For instance, according to the recent statistics published by the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2020, the production of heavy load trucks in the North American region was 388,244 units and in 2021, it was 463,591 units, an increase of 19%. Furthermore, in 2020, the production of heavy-load trucks in Japan was 405,451 units and in 2021, it was 516,988 units, an increase of 28%. Therefore, the development in the industrial activities associated with heavy trucks, heavy equipment, and others are fostering the carbon fiber composite heating element market demand to ensure superior tensile strength, which, in turn, is driving the market trend.

However, the aerospace segment is expected to be the fastest-growing segment during the forecast period. This development is attributed to factors such as increasing investment in new aerospace manufacturing facilities, government initiatives for new aircraft model development, and others.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

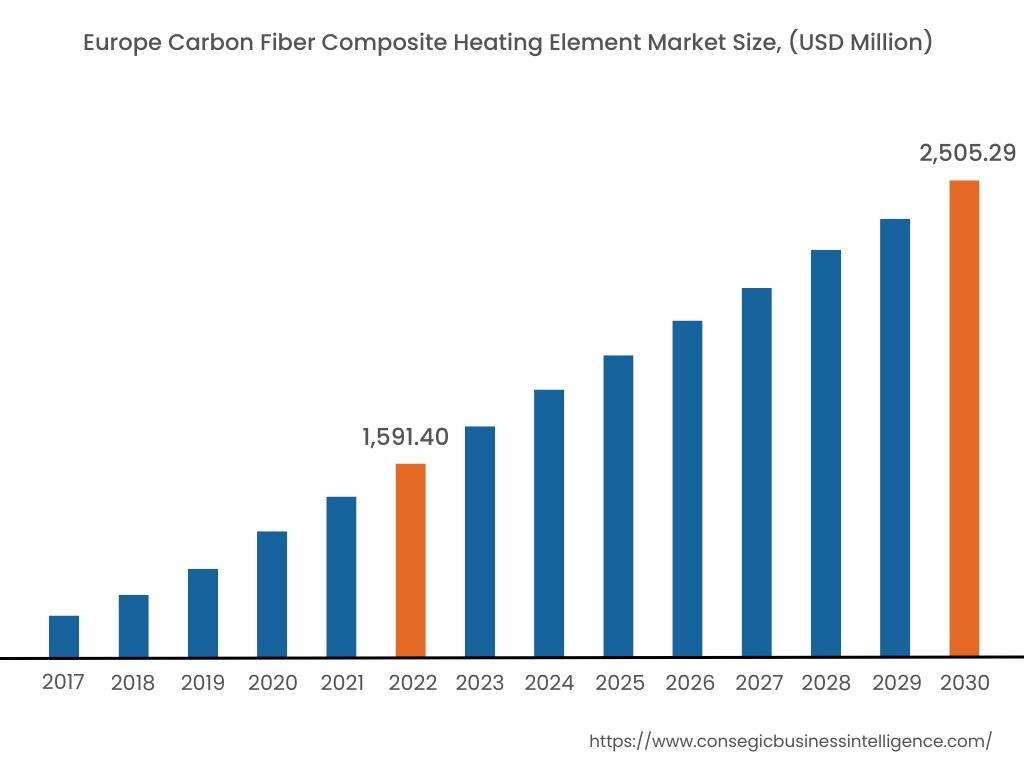

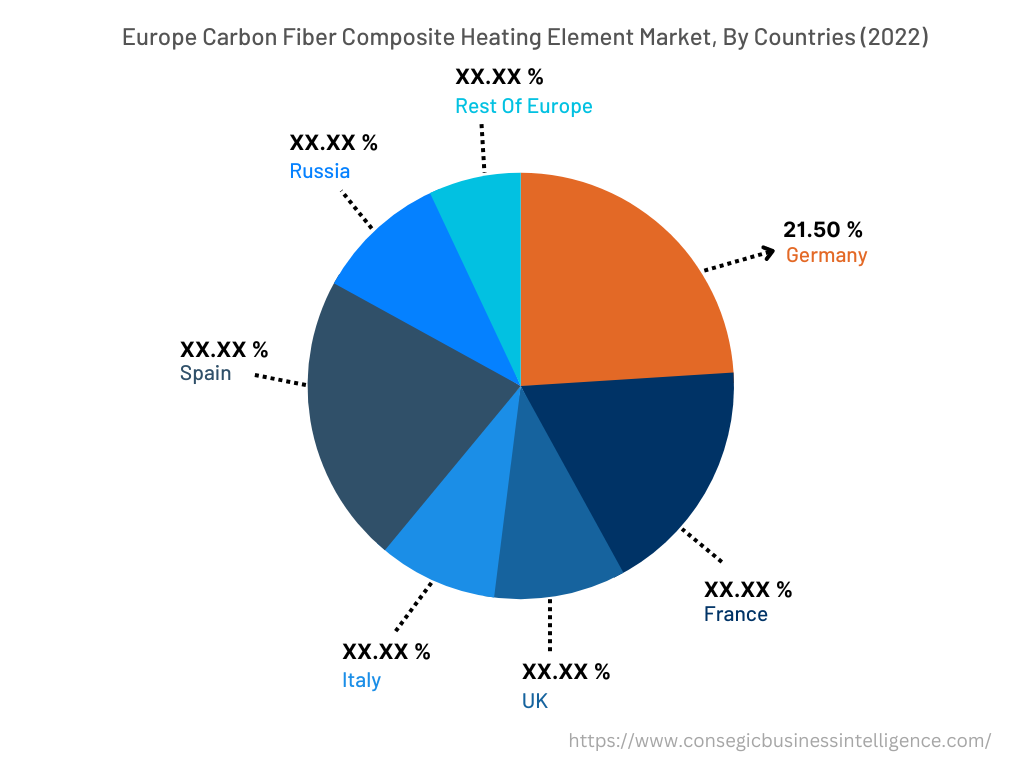

In 2022, Europe accounted for the highest market share at 36.50% and was valued at USD 1,591.40 million, and is expected to reach USD 2,505.29 million in 2030. In Europe, Germany accounted for the highest market share of 21.50% during the base year of 2022. Based on the carbon fiber composite heating element market analysis, this is due to the development in the production of heavy construction equipment, the development of new automotive plants, and others. For instance, according to Agoriya Belgium, a member of the Committee for European Construction Equipment (CECE), in 2021, the sales of less than 10 tons and more than 10 tons of earthmoving and construction equipment increased by 27% and 23%, respectively over 2020. Also, it further states that sales have gone up when compared with the Covid-19 time. Hence, the growth in the production of heavy construction equipment is accelerating the advancement of the industrial sector in Europe. This, in turn, is propelling the carbon fiber composite heating element market growth and trends.

Furthermore, Asia Pacific is expected to witness significant growth over the forecast period, growing at a CAGR of 6.6% during 2023-20230. This is due to the presence of various carbon fiber composite heating element industry players, the development of new industrial manufacturing facilities, and others. Thus, the aforementioned factors are propelling the carbon fiber composite heating element market trend in the upcoming years.

Top Key Players & Market Share Insights :

The carbon fiber composite heating element market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their carbon fiber composite heating element market revenue through mergers, acquisitions, and partnerships. The key players in global carbon fiber composite heating element market include-

- Solvay S.A.

- SGL Group

- Toyo Tanso Co.,Ltd.

- Hexcel Corporation

- ADENTE Advanced Engineering Technologies

- CFC Carbon Co., Ltd

- Tokai Carbon

- Schunk Group

- Premium Graphite Pvt. Ltd.

- Reliance Industries Ltd.

Recent Industry Developments :

- In February 2023, Tex Tech Industries, a global supplier of materials acquired SGL Carbon operations in Gardena, California, United States. The Gardena site manufactures carbon fiber composite heating. The major aim of the acquisition was to increase the market share of Tex Tech Industries in the global market.

- In April 2022, SGL Carbon, a Germany-based manufacturer of carbon fiber composite heating developed a new range of carbon fiber materials and fiber composite solutions with heating properties. The products are ideal for application in automobiles and industries. Thus, the development of a new range of products will accelerate the market growth in the upcoming years.

- In May 2021, Toray Industries, Inc., headquartered in Japan which offers carbon fiber composite products developed a high thermal conductivity technology utilized for the production of carbon fiber composite heating. Hence, the introduction of new technologies will create a lucrative opportunity for market growth.

Key Questions Answered in the Report

What was the market size of the carbon fiber composite heating element industry in 2022? +

In 2022, the market size of carbon fiber composite heating element was USD 4,360.00 million.

What will be the potential market valuation for the carbon fiber composite heating element industry by 2030? +

In 2030, the market size of carbon fiber composite heating element will be expected to reach USD 6,835.70 million.

What are the key factors driving the growth of the carbon fiber composite heating element market? +

The rising adoption of carbon fiber composite heating elements in industrial applications is boosting market growth.

What is the dominating segment in the carbon fiber composite heating element market by application? +

In 2022, the industrial segment accounted for the highest market share of 42.50% in the overall carbon fiber composite heating element market.

Based on current market trends and future predictions, which geographical region is the dominating region in the carbon fiber composite heating element market? +

Europe accounted for the highest market share in the overall carbon fiber composite heating element market.