- Summary

- Table Of Content

- Methodology

Carbide Insert Market Introduction :

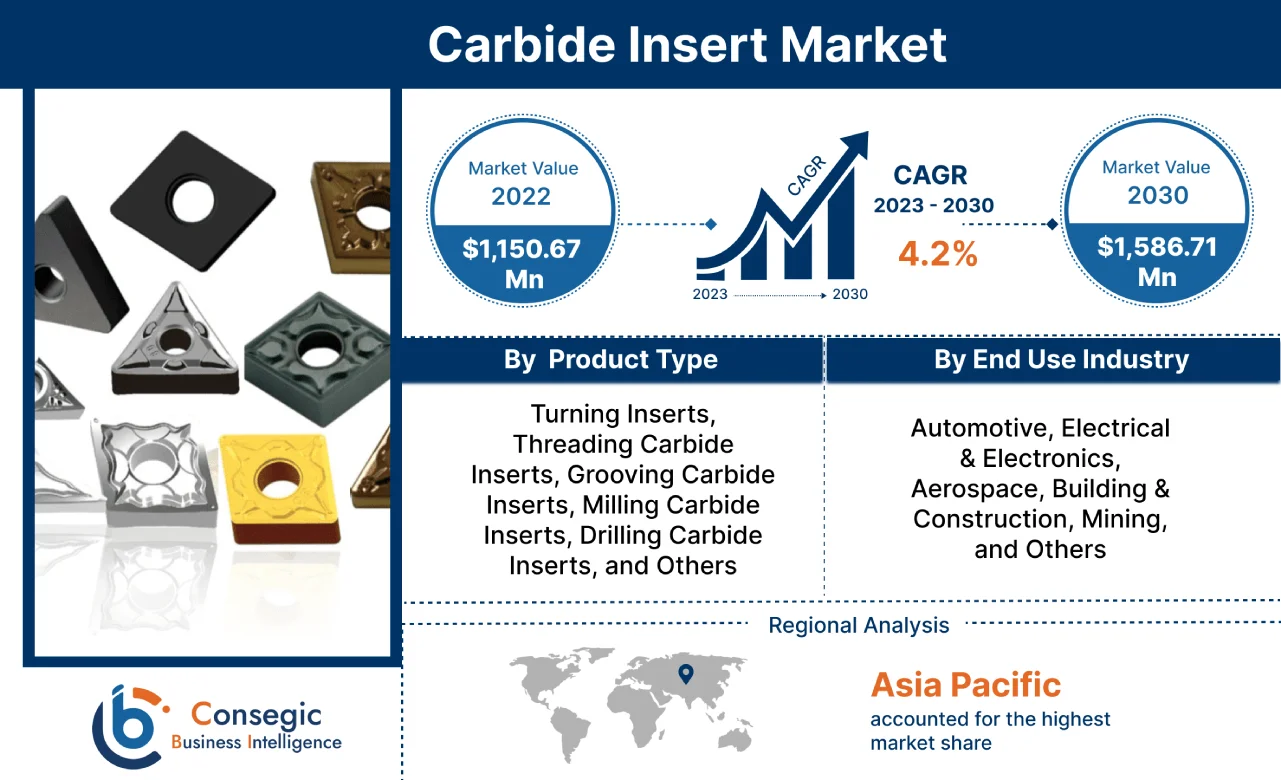

Consegic Business Intelligence analyzes that the carbide insert market is growing with a healthy CAGR of 4.2% during the forecast period (2023-2030), and the market is projected to be valued at USD 1,586.71 Million by 2030 from USD 1,150.67 Million in 2022.

Carbide Insert Market Definition & Overview:

The carbide insert is a type of cutting tool that is used in machining. It is a small, replaceable cutting tool made of cemented carbide, which is a very hard and wear-resistant material. The major types of carbide inserts include threading carbide inserts, turning inserts, milling carbide inserts, grooving carbide inserts, drilling carbide inserts, and others. These carbide inserts are highly efficient and cost-effective compared to similar tools. Thus, due to the above-listed benefits, carbide inserts are an ideal solution for various end-use industries such as automotive, electrical & electronics, aerospace, building & construction, mining, and others.

Carbide Insert Market Insights :

Key Drivers :

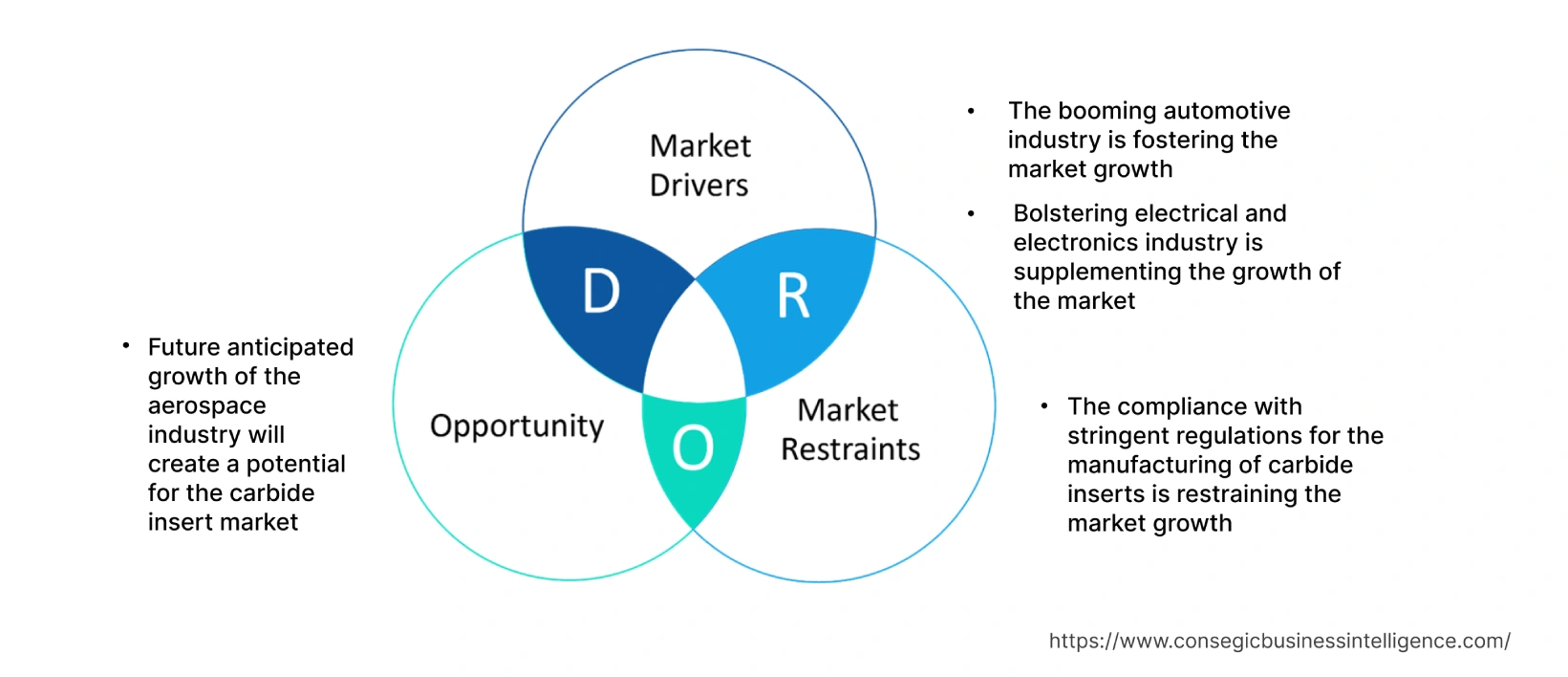

The booming automotive industry is fostering the market growth

Carbide inserts are utilized in the automotive industry to ensure superior thermal stability and good chip control. The carbide inserts are deployed in automotive products such as passenger cars, light commercial vehicles, and heavy commercial vehicles. The increasing purchasing power of people, the rising adoption of electric vehicles, and others are some of the prominent factors accelerating the growth of the automotive industry. For illustration, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2021, the production of automotive vehicles at the global level was 80,205,102 units, and in 2022, it was 85,016,728 units, an increase of 6%. Thus, the booming automotive industry is a prime factor boosting the demand for carbide inserts at the global level to ensure excellent wear resistance. This factor is driving the carbide insert market growth at the global level.

Bolstering electrical and electronics industry is supplementing the growth of the market

Carbide inserts are an essential tool for the electrical and electronics industry. They are used to machine a variety of components that are used in a wide range of products. Carbide inserts are hard, wear-resistant, and can be used at high speeds. Carbide inserts are used in a variety of applications in the electrical and electronics industry. Prominent factors such as the development of new electronic manufacturing facilities, technological advancements, and others are amplifying the electrical and electronics market growth at the global level. For instance, according to the recent statistics published by the German Electrical and Electronic Manufacturers' Association (ZVEI), in 2020, the German electronics market, which consists of products such as television, smartphones, and others was valued at EURO 128 billion (USD 146.2 billion), and in 2021, it was EUR0 140.8 billion (USD 166.5 billion). The German electrical & electronics industry registered a year-on-year growth rate of 11% in 2021. Hence, the bolstering electrical and electronics industry is fostering the demand for carbide inserts to ensure superior versatility properties, which, in turn, is driving the market growth.

Key Restraints :

The compliance with stringent regulations for the manufacturing of carbide inserts is restraining the market growth

Carbide inserts are utilized in various end-use industries such as building & construction, electrical & electronics, and others to ensure superior accuracy in machine metals. As a result, the carbide insert manufacturers have to comply with stringent manufacturing quality regulations to ensure superior product performance. For instance, the Internation Standard organization regulation named ISO 3364:2017(en) specifies the dimensions of carbide inserts with cylindrical, rounded corners, fixing holes, and with 0° normal clearance. Hence, compliance with stringent regulations for the manufacturing of carbide inserts is posing a major bottleneck for the market growth during the projected forecast period.

Future Opportunities :

Future anticipated growth of the aerospace industry will create a potential for the carbide insert market

Carbide inserts are an ideal product for aerospace machines to ensure superior hardness. The favorable government policies for the aerospace industry, expansion of aerospace manufacturing facilities, and others are supplementing the aerospace industry's growth at the global level. For instance, according to the Airbus 2023-2042 forecast, the demand for new passengers and freighter aircraft will be 40,850 in the upcoming 20 years. Thus, it is evident from the above data that the aerospace industry will register growth in the long run. Henceforth, the growth of the aerospace industry will boost the demand for carbide inserts as these materials are utilized in the manufacturing process of aircraft. This, in turn, will create a potential growth opportunity for chrome metal powder in the upcoming years.

Carbide Insert Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 1,586.71 Million |

| CAGR (2023-2030) | 4.2% |

| By Product Type | Turning Inserts, Threading Carbide Inserts, Grooving Carbide Inserts, Milling Carbide Inserts, Drilling Carbide Inserts, and Others |

| By End-use Industry | Automotive, Electrical & Electronics, Aerospace, Building & Construction, Mining, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Iscar, Mitsubishi, Tungaloy, Walter-Valenite, Kyocera, Tool-Flo, Sumitomo, Carmet Tools & Inserts Ltd., Winstar Cutting Technologies Corp., and Knight Carbide, Inc. |

Carbide Insert Market Segmental Analysis :

Based on the Product Type :

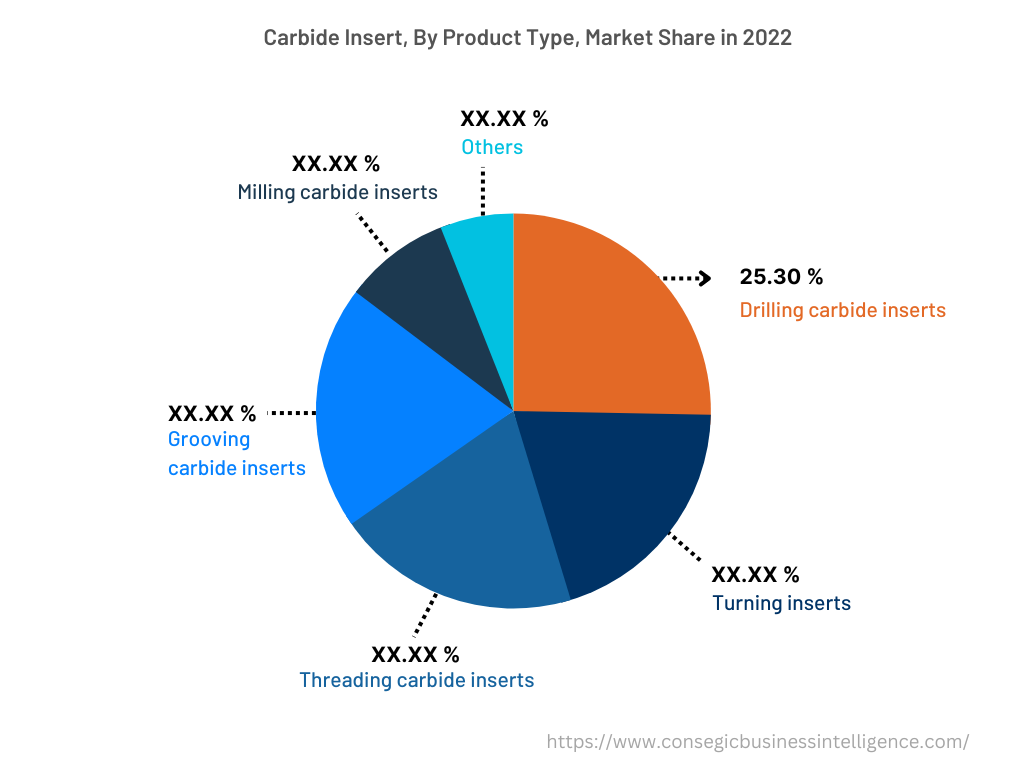

The product type segment is categorized into turning inserts, threading carbide inserts, grooving carbide inserts, drilling carbide inserts, and others. In 2022, the drilling carbide inserts segment accounted for the highest market share of 25.30% in the overall carbide insert market. The crucial properties associated with dilling carbide inserts include superior wear resistance, excellent surface hardness, resistance against heat & oxidation, steady chemical performance, low thermal conductivity, and a small friction coefficient, among others. These properties ensure quicker machining and leave significant finishes on metal parts. The development of a new range of dilling carbide inserts is a key trend driving the growth of the segment.

However, the turning inserts segment is projected to be the fastest-growing segment during the forecast period. This is due to the vital features of turning inserts such as stronger cutting edge, excellent feed rates, excellent cutting force, higher vibration, and others.

Based on the End-Use-Industry :

The end-use industry segment is categorized into automotive, electrical & electronics, aerospace, building & construction, mining, and others. In 2022, the automotive segment accounted for the highest market share in the carbide insert market. The key technical properties of carbide inserts include high flexural strength (MPa5100), superior hardness (86 ~ 93HRA, equivalent to 69 ~ 81HRC), excellent thermal hardness (up to 900 ~ 1000 ° C maintain 60HRC), and others. As a result, carbide inserts are widely utilized in the automotive industry for cylinder heads, machining engine blocks, pipes, fittings, brake components, and other cast iron components. The development of infrastructure projects, growth of public transportation, and others are vital determinants accelerating the demand for commercial vehicles. These factors are contributing to the growth of automotive production. For illustration, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2020, the production of commercial vehicles at the global level was 21,787,126 units, and in 2021, it was 23,091,693 units. In 2021, the year-on-year growth rate for commercial vehicle production was 5.9%. Henceforth, the growth of the automotive industry is favoring the demand for carbide inserts to ensure a lightweight structure. This, in turn, is fostering market growth.

However, the electrical & electronics segment is expected to be the fastest-growing segment during the forecast period because of the development of new electrical and electronics manufacturing facilities, increasing research & development, and others.

Based on the Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

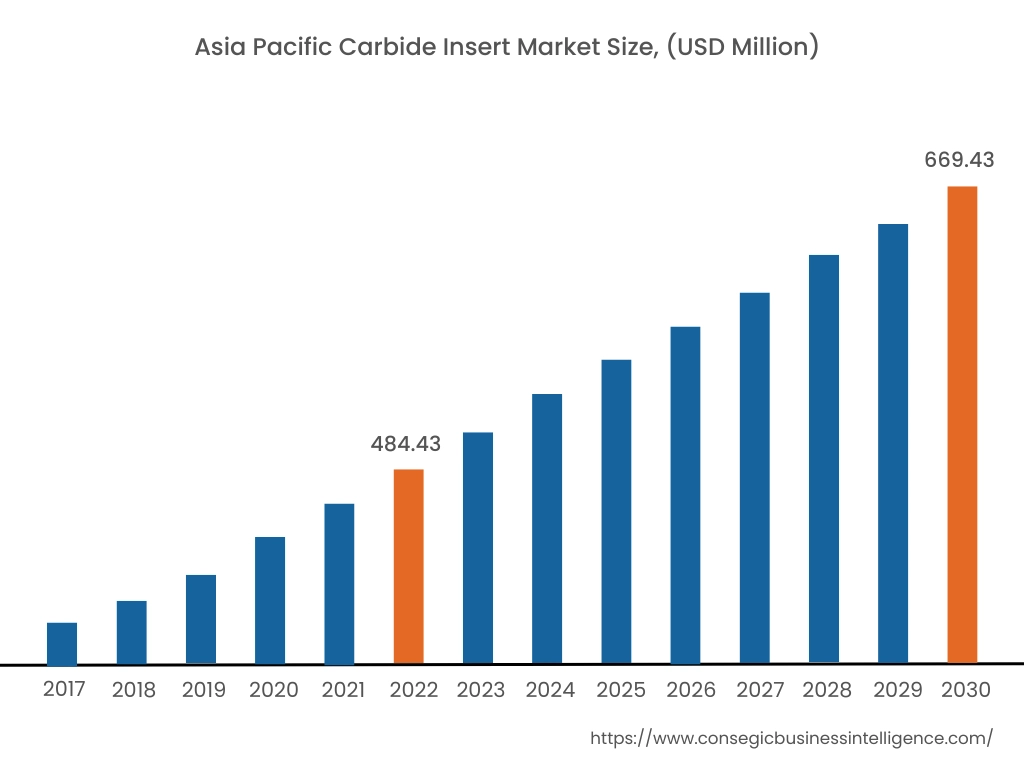

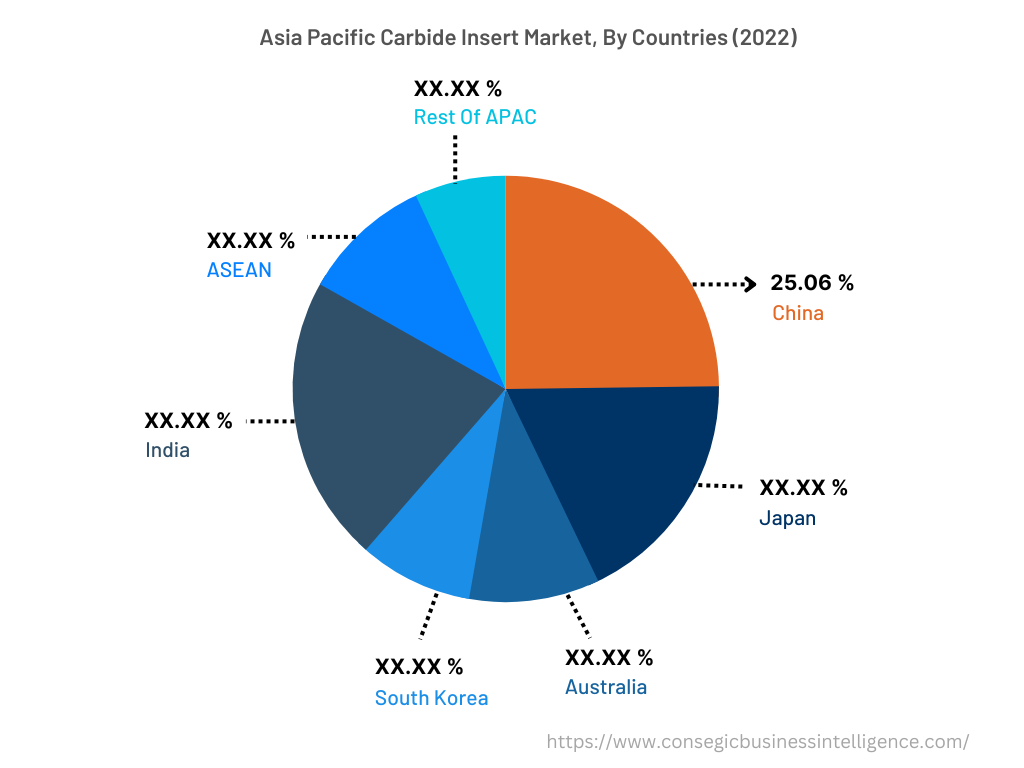

In 2022, Asia Pacific accounted for the highest market share at 42.10% and was valued at USD 484.43 million, and is expected to reach USD 669.43 million in 2030. In Asia Pacific, China accounted for the highest market share of 25.06% during the base year of 2022. This is due to the growth of various end-use industries such as automotive, aerospace, and others. For illustration, according to the recent statistics published by the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2022, the Asia Pacific region produced a significant number of automotive products at the global level, retaining a total share of 58.84% in the global automotive industry. Henceforth, the growth of the aforementioned industries in the region is accelerating the demand for carbide inserts, thereby spurring market growth.

Furthermore, North America is expected to witness significant growth over the forecast period, growing at a CAGR of 5.1% during 2023-20230. This is due to the increasing adoption of carbide inserts in various end-use industries such as automotive, aerospace, building & construction, mining, and others.

Top Key Players & Market Share Insights:

The carbide insert market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market share through mergers, acquisitions, and partnerships. The key players in the market include-

- Iscar

- Mitsubishi

- Carmet Tools & Inserts Ltd.

- Winstar Cutting Technologies Corp.

- Knight Carbide, Inc.

- Tungaloy

- Walter-Valenite

- Kyocera

- Tool-Flo

- Sumitomo

Recent Industry Developments :

- In May 2023, Kyocera, a global manufacturer that is dealing in the carbide inserts introduced a new range of CVD Coated Carbide Grades CA115P and CA125P for steel turning applications. Hence, the development of a new range of products is fostering market growth.

Key Questions Answered in the Report

What was the market size of the carbide insert industry in 2022? +

In 2022, the market size of carbide insert was USD 1,150.67 million.

What will be the potential market valuation for the carbide insert industry by 2030? +

In 2030, the market size of carbide insert will be expected to reach USD 1,586.71 million.

What are the key factors driving the growth of the carbide insert market? +

The booming automotive industry is fostering the carbide insert market growth at the global level.

What is the dominating segment in the carbide insert market by product type? +

In 2022, the milling carbide inserts segment accounted for the highest market share of 25.30% in the overall carbide insert market.

Based on current market trends and future predictions, which geographical region is the dominating region in the carbide insert market? +

Asia Pacific accounted for the highest market share in the overall carbide insert market.