- Summary

- Table Of Content

- Methodology

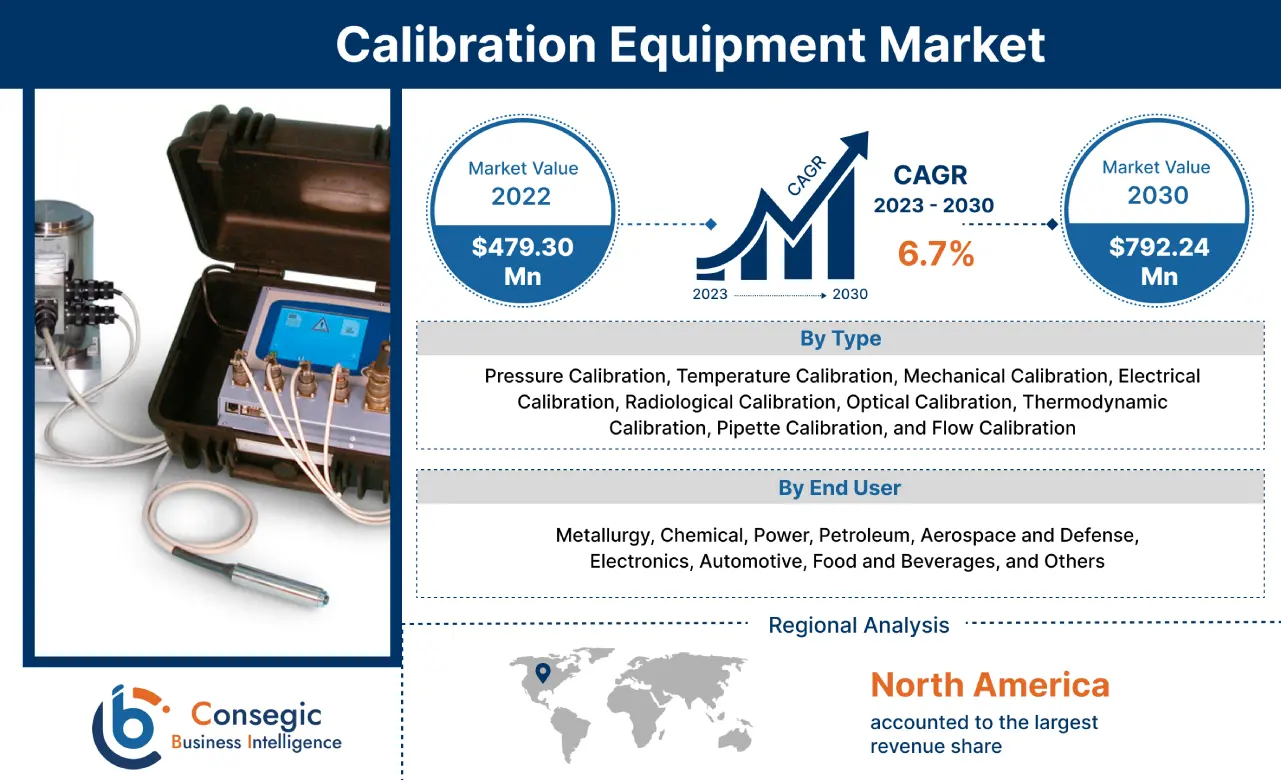

Calibration Equipment Market Size :

Calibration Equipment Market is estimated to reach over USD 792.24 Million by 2030 from a value of USD 479.30 Million in 2022, growing at a CAGR of 6.7% from 2023 to 2030.

Calibration Equipment Market Scope & Overview:

Calibration equipment refers to a set of tools, instruments, or devices used to measure, adjust, and validate the accuracy, precision, and reliability of other measuring instruments. The equipment ensures that the measurements obtained from various devices or systems are reliable, consistent, and traceable to established standards. Additionally, the equipment includes instruments namely reference standards, calibration sources, simulators, meters, gauges, sensors, and software among others. The tools are utilized to compare the measurements obtained from the Device Under Test (DUT) with known or certified values to determine any deviations or errors.

Calibration Equipment Market Insights :

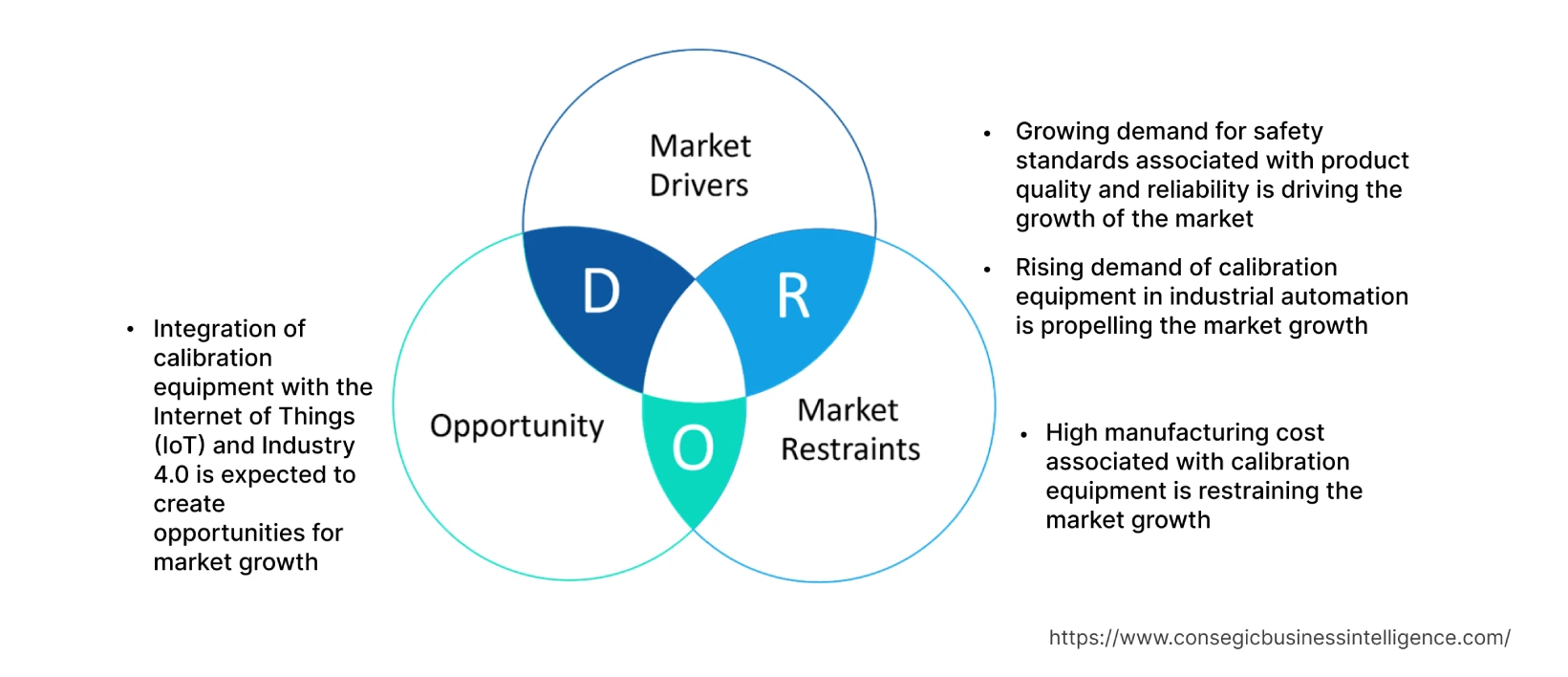

Key Drivers :

Growing demand for safety standards associated with product quality and reliability is driving the market.

Industries have to follow strict quality standards and regulatory requirements to ensure the safety, reliability, and performance of their products and services. Calibration equipment is essential for fulfilling the standards by verifying the accuracy and reliability of measuring instruments used in manufacturing, testing, and quality control processes. Moreover, the equipment helps to improve product quality and reliability by ensuring that measurements and test results are accurate and consistent. Furthermore, the calibration of instruments including temperature sensors, pressure gauges, and flow meters, enables the manufacturers to minimize errors, leading to better product quality and reduced waste.

- For instance, in March 2023, according to the U.S. Food & Drug Administration (FDA), the manufacturers must ensure the inspection and testing of each piece of equipment and also routinely calibrate, inspect, and check the equipment.

The market trends analysis shows that regulatory standards are implemented to ensure that the measurements obtained from various devices are reliable and consistent, thus contributing significantly to driving the calibration equipment market growth.

The rising demand for calibration equipment in industrial automation is propelling the market.

Industrial automation involves the application of advanced control systems, robotics, and sensors to automate manufacturing and industrial processes. Automated systems rely on accurate and reliable measurements to function properly. Calibration equipment is crucial for calibrating and validating the accuracy of sensors, controllers, and other automated components, ensuring the proper operation within predefined parameters. Additionally, precision control is essential in industrial automation to achieve optimal performance and productivity. The equipment is utilized to calibrate control instruments including pressure transmitters, temperature sensors, and flow meters, to ensure accurate measurements and precise control of industrial processes.

- For instance, according to the International Federation of Robotics (IFR), industrial robot installation accounted for 517,385 units in the second pandemic year, 2021. Industrial robots represent a growth rate of 31% in 2021 in comparison to 2020.

Thus, the analysis of market trends depicts that industrial automation is bolstering the calibration equipment market demand.

Key Restraints :

High manufacturing costs associated with calibration equipment are restraining the market.

The high cost of production of calibration equipment is the major factor responsible for hampering the market. The initial investment required to purchase equipment is high and limits the adoption of the equipment by small and medium-sized enterprises (SMEs) with limited budgets. Additionally, the reference standards utilized in equipment namely voltage references, resistance standards, and pressure references are prepared using specialized expensive materials including platinum, thus hindering the market. Moreover, the equipment also comprises advanced sensors, detectors, and Digital Signal Processing (DSP) units that further contribute to additional upfront costs. Consequently, as per the market trends show that the aforementioned factors including the high production cost and integration of advanced sensors and detectors are impeding the calibration equipment market growth.

Future Opportunities :

Integration of calibration equipment with the Internet of Things (IoT) and Industry 4.0 is expected to create opportunities.

The advent of the Internet of Things (IoT) enables the connectivity of devices and sensors, allowing real-time data collection and analysis. Calibration equipment integrates with IoT platforms to provide remote monitoring, data logging, and automated calibration processes. Connectivity improves efficiency, reduces human error, and enables predictive maintenance, creating calibration equipment market opportunities to offer advanced and connected solutions. Additionally, Industry 4.0 emphasizes the application of automation and robotics to enhance productivity and efficiency. The equipment is ideal for Industry 4.0 applications by incorporating automation features including robotic arms, automated probe placement, and automated calibration sequences. Automation streamlines the calibration process, increases throughput, and reduces manual intervention, enabling organizations to calibrate a higher volume of equipment with improved accuracy. In conclusion, market trends analysis portrays that the integration of the equipment with the Internet of Things and Industry 4.0 is anticipated to create potential opportunities for market growth.

Calibration Equipment Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2030 |

| Market Size in 2030 | USD 792.24 Million |

| CAGR (2023-2030) | 6.7% |

| By Type | Pressure Calibration, Temperature Calibration, Mechanical Calibration, Electrical Calibration, Radiological Calibration, Optical Calibration, Thermodynamic Calibration, Pipette Calibration, and Flow Calibration |

| By End User | Metallurgy, Chemical, Power, Petroleum, Aerospace and Defense, Electronics, Automotive, Food and Beverages, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Additel Corporation, Ametek Inc., Bronkhorst High-Tech B.V., Chino Corporation, Endress+Hauser AG, ESSCO Calibration Laboratory, Extech Instruments, Fluke Corporation, Godrej & Boyce Mfg. Co. Ltd., Launch Tech Co. Ltd., Meriam Process Technologies |

Calibration Equipment Market Segmental Analysis :

By Type :

The type segment is classified into pressure calibration, temperature calibration, mechanical calibration, electrical calibration, radiological calibration, optical calibration, thermodynamic calibration, pipette calibration, and flow calibration.

Electrical calibration accounted for the largest market share of the total calibration equipment market share in 2022 owing to the strict regulatory standards and quality requirements to ensure the safety, accuracy, and reliability of electrical instruments in industries. The calibration of electrical equipment plays a crucial role in meeting compliance requirements, thus contributing notably to boosting the market. Additionally, electrical instruments including oscilloscopes, power analyzers, signal generators, and electronic loads require accurate calibration to ensure correct measurements and maintain traceability. Consequently, the growing need for specialized calibration equipment to efficiently calibrate electrical instruments is contributing remarkably to spurring the market.

- For instance, in July 2022, Fluke Corporation launched the Fluke Calibration 5560A multi-product electrical calibrator with improved performance to provide accurate electrical workload coverage. The calibrator encompasses 30 A continuous current output that prevents the equipment from overheating and also reduces the wait time, thus contributing considerably to propelling the calibration equipment market demand.

Temperature calibration is anticipated to witness the fastest CAGR in the calibration equipment market during the forecast period. The growth is credited to the advancements in technology that have led to the development of sophisticated temperature control systems, including precision ovens, environmental chambers, and thermal chambers. The systems require accurate calibration to ensure uniform and stable temperature profiles that raise the demand for equipment, which in turn, promotes the market. Additionally, thermal imaging cameras and infrared thermometers are widely utilized for non-contact temperature measurements in various applications, including building diagnostics, industrial maintenance, and electrical inspections. The devices require periodic calibration to maintain accuracy, further driving the calibration equipment market trends during the forecast period.

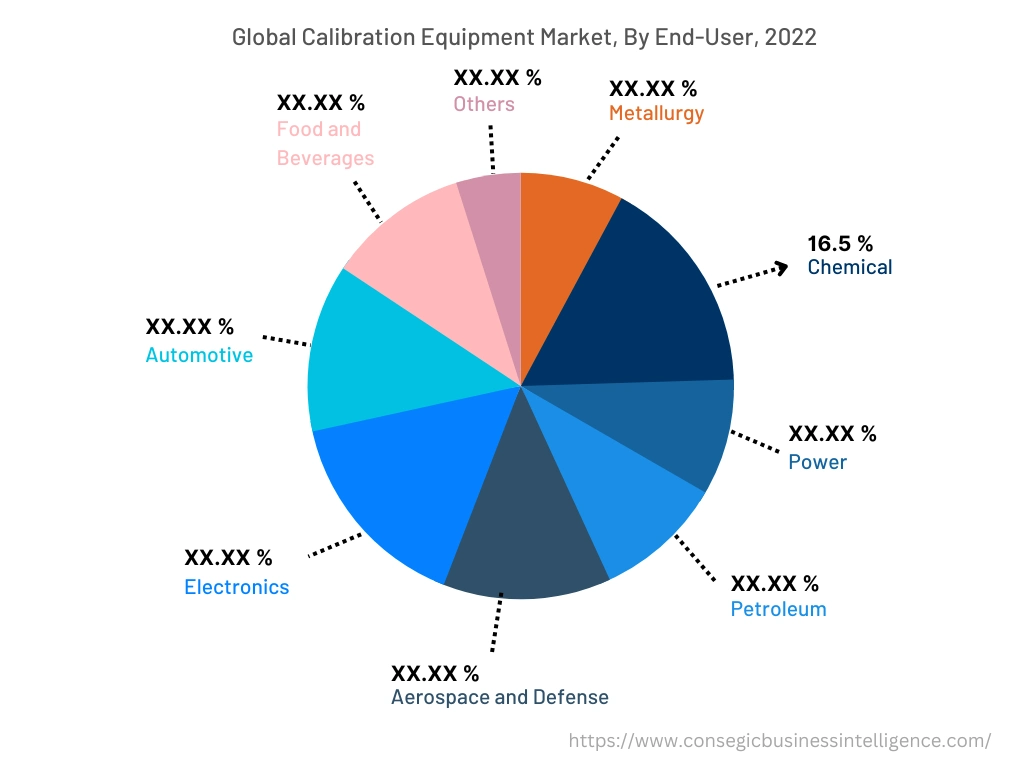

By End-User :

The end-user segment is classified into metallurgy, chemical, power, petroleum, aerospace and defense, electronics, automotive, food and beverages, and others.

The chemical sector accounted for the largest market share of 16.5% of the overall calibration equipment market share in 2022 as equipment is utilized to calibrate and verify the accuracy of process instruments namely pressure transmitters, temperature sensors, flow meters, level sensors, pH meters, conductivity meters, and analytical instruments. Accurate calibration of the aforementioned instruments is essential for precise control of chemical processes, ensuring product quality and safety. In addition, safety is paramount in the chemical sector, and safety instrumented systems play a vital role in preventing and mitigating accidents. The equipment is employed to calibrate safety devices including pressure gas detectors, flame detectors, unknown chemicals, and alarm systems. Proper calibration ensures that the safety systems operate reliably and respond appropriately to abnormal conditions, thus contributing significantly to bolstering the market growth.

- For instance, in March 2023, Eurofins Scientific SE launched Chem-ST, a smart chemical testing tool to detect the presence of unknown chemicals and quantify all notable chemicals. The chemical calibration equipment analyzes the sample with high accuracy and eliminates the need for costly traditional testing assessments, hence contributing remarkably to driving the calibration equipment market trends.

The power sector is predicted to witness the fastest CAGR in the calibration equipment market during the forecast period. The market is endorsed by the increasing adoption of equipment to validate the accuracy of instruments and devices used in power generation facilities. The instruments include sensors, transmitters, recorders, meters, and control systems that measure parameters including voltage, current, power, frequency, and energy. In addition, calibration is essential for the accurate measurement and monitoring of electrical parameters in transmission and distribution systems. The equipment is used to authenticate the accuracy of instruments including power transformers, current transformers, potential transformers, circuit breakers, protective relays, and power quality analyzers. Subsequently, the segmental trends analysis depicts that the aforementioned factors are collectively responsible for fueling the calibration equipment market opportunities during the forecast period.

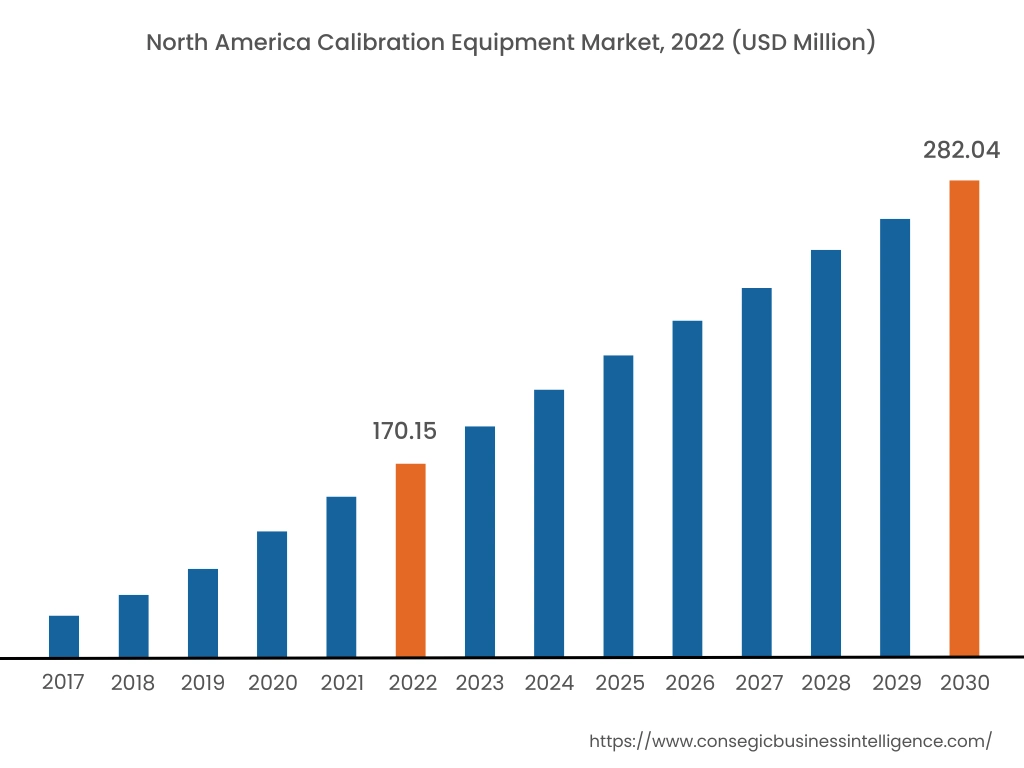

By Region :

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

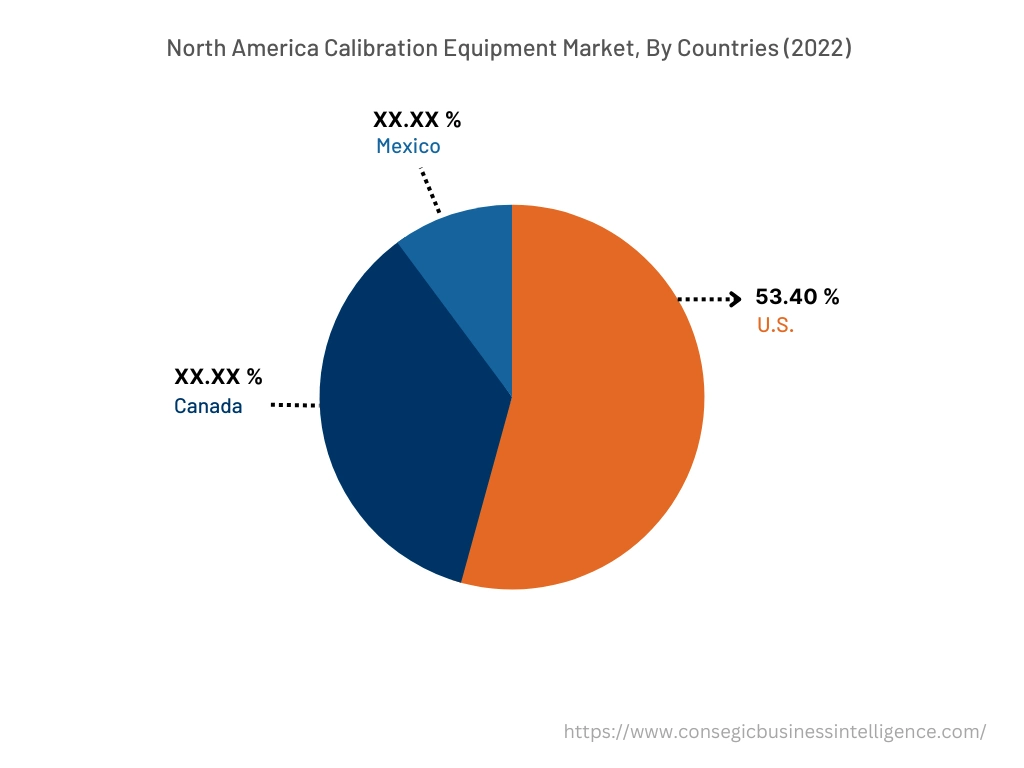

North America accounted for the largest revenue share of USD 170.15 Million in 2022 and is expected to reach USD 282.04 Million in 2030 in the market. In addition, in the region, the United States accounted for the maximum revenue share of 53.40% in the year 2022 as the region has stringent regulatory standards and quality requirements in industries namely healthcare, pharmaceuticals, and aerospace. Compliance with the regulatory standards necessitates regular calibration of instruments, increasing the demand for accurate equipment to meet regulatory standards.

Additionally, the calibration equipment market analysis shows that North American industries have a strong emphasis on quality control and product safety, further increasing the demand for equipment to ensure product quality. Moreover, the presence of key players in the region including Fluke Corporation, Meriam Process Technologies, and Additel Corporation is investing heavily in research and development to drive advancements in measurement technology. Consequently, the increasing investment by key players and the implementation of stringent regulatory standards are the major factors driving the calibration equipment market expansion in North America.

- For instance, in August 2021, Fluke Corporation launched a P5514B hydraulic pressure comparator for calibrating switches, gauges, and transducers with precise fine adjustment capabilities. The product is equipped with Vernier fine adjustment control to generate pressure up to 10,000 psi with improved reservoir valve sealing, thus contributing considerably to propelling the market growth.

Asia Pacific is expected to register the fastest CAGR of 7.0% in the market during the forecast period, 2023-30. The regional trends analysis show that the growth is attributed to a diverse manufacturing sector, including electronics, automotive, and consumer goods that heavily rely on the equipment to ensure the accuracy and reliability of the manufacturing processes and products. Additionally, the growing emphasis on maintaining high-quality standards also raises the demand for equipment to ensure the accuracy of measurements, meet quality requirements, and obtain necessary certifications. Furthermore, Asia Pacific is witnessing a significant rise in the healthcare and life sciences sectors. The equipment plays a vital role in the aforementioned industries for precise measurements in medical devices, laboratory equipment, pharmaceutical manufacturing, and research applications, further driving the market growth in the region.

Top Key Players & Market Share Insights:

The calibration equipment market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global calibration equipment market. Key players in the calibration equipment industry include -

- Additel Corporation

- Ametek Inc.

- Godrej & Boyce Mfg. Co. Ltd.

- Launch Tech Co. Ltd.

- Meriam Process Technologies

- Bronkhorst High-Tech B.V.

- Chino Corporation

- Endress+Hauser AG

- ESSCO Calibration Laboratory

- Extech Instruments

- Fluke Corporation

Recent Industry Developments :

- In June 2021, Godrej & Boyce Mfg. Co. Ltd. launched mobile calibration services to provide on-site calibration to customers in industries including aerospace, automobile, and manufacturing and also to meet the stringent environmental conditions for calibration.

- In January 2022, Launch Tech Co. Ltd. introduced advanced calibration equipment, X-431 ADAS PRO PLUS with real-time intelligence and laser range finders to accurately measure the distances during calibration.

Key Questions Answered in the Report

What is calibration equipment? +

Calibration equipment refers to a set of tools, instruments, or devices used to measure, adjust, and validate the accuracy, precision, and reliability of other measuring instruments.

What specific segmentation details are covered in the calibration equipment market report, and how is the dominating segment impacting the market growth? +

Electrical calibration equipment dominates the market in 2022 owing to the strict regulatory standards and quality requirements to ensure the safety, accuracy, and reliability of electrical instruments in industries.

What specific segmentation details are covered in the calibration equipment market report, and how is the fastest segment anticipated to impact the market growth? +

The power industry is anticipated to impact the growth of the market owing to the increasing adoption of calibration equipment to validate the accuracy of instruments and devices used in power generation facilities. The instruments include sensors, transmitters, recorders, meters, and control systems that measure parameters including voltage, current, power, frequency, and energy.

Which region is anticipated to witness the highest CAGR during the forecast period, 2023-2030? +

Asia Pacific is expected to witness the fastest CAGR during the forecast period due to a diverse manufacturing sector, including electronics, automotive, and consumer goods that heavily rely on calibration equipment to ensure the accuracy and reliability of the manufacturing processes and products.