- Summary

- Table Of Content

- Methodology

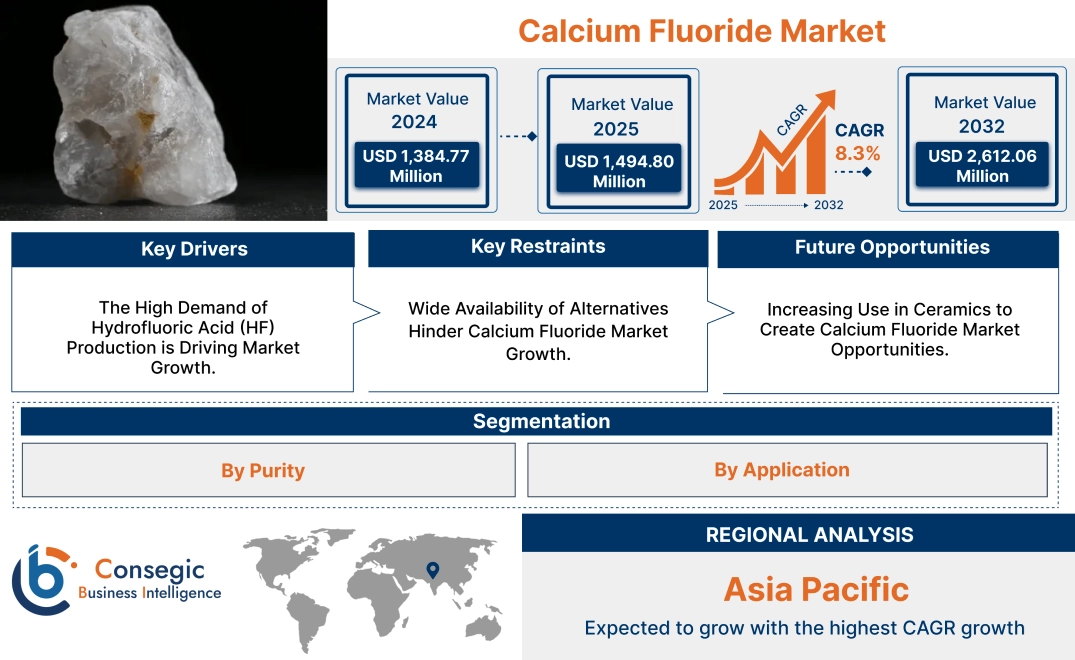

Calcium Fluoride Market Size:

The Calcium Fluoride Market size is growing with a CAGR of 8.3% during the forecast period (2025-2032), and the market is projected to be valued at USD 2,612.06 Million by 2032 from USD 1,384.77 Million in 2024. Additionally, the market value for 2025 is attributed to USD 1,494.80 Million.

Calcium Fluoride Market Scope & Overview:

Calcium fluoride (CaF2), a naturally occurring mineral known as fluorite or fluorspar. It is an inorganic compound composed of calcium and fluorine. This white, often crystalline solid is characterized by its insolubility in water and its distinctive cubic crystal structure. One of its properties is its transparency, making it valuable in the production of optical components like lenses and windows. However, the primary industrial significance of this compound lies in its role as the primary compound in production of hydrofluoric acid (HF). It is a highly reactive and crucial chemical, is itself a building block for numerous other compounds used in diverse industries. It is also used as a fluxing agent in the manufacturing of steel, aluminum, and cement, contributing to the efficiency and quality of these essential materials.

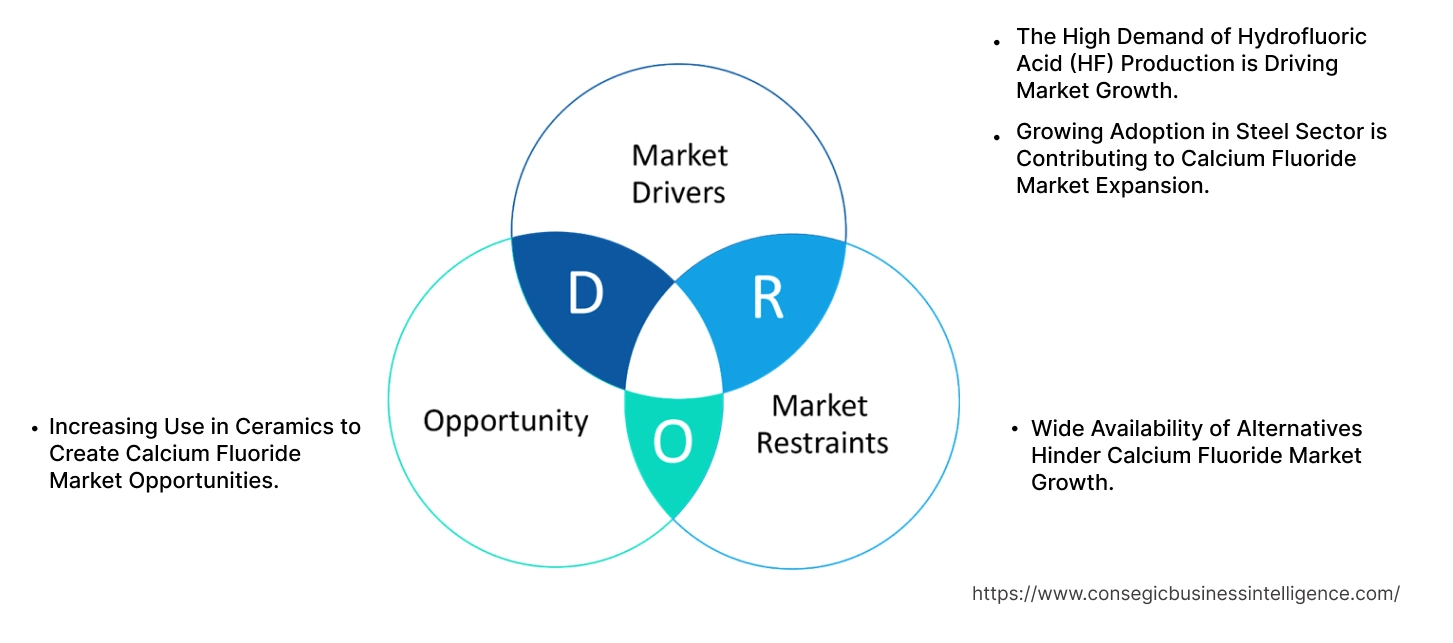

Key Drivers:

The High Demand of Hydrofluoric Acid (HF) Production is Driving Market Growth.

Calcium fluoride is used as the principal raw material in HF production. The calcium fluoride market growth is directly linked to the increasing need for HF across a diverse range of industrial applications. HF's critical role in the manufacturing of refrigerants contributes significantly to this dynamic. Furthermore, the aluminum sector is another major consumer of HF in its smelting processes and contributes to the substantial need.

- For instance, according to OEC World, the growth rate in export of hydrofluoric acid in Spain increased by 16.2% in 2023 compared to previous year, showcasing an increasing need in European countries.

Therefore, the growing reliance on HF across these various sectors indirectly has a positive impact on the substantial calcium fluoride market demand.

Growing Adoption in Steel Sector is Contributing to Calcium Fluoride Market Expansion.

In steelmaking, calcium fluoride acts as a crucial fluxing agent. Fluxing agents are substances added to molten metal to reduce its viscosity and surface tension. This makes it easier to pour and refine. It helps to lower the melting point of impurities in the molten steel. This purification process results in higher quality steel with improved mechanical properties. As the global need for steel continues to rise, due to the rise in infrastructure development, construction, automotive production, and other industrial activities, the need for effective fluxing agents is also increased.

- For instance, according to World Steel Association, the steel demand increased by 1.9% in 2024, attributing to a consumption of 1,8491 million metric tons across the globe.

Therefore, the continued operation of the steel sector is driving the Calcium Fluoride market expansion.

Key Restraints:

Wide Availability of Alternatives Hinder Calcium Fluoride Market Growth.

Several substances are used as substitutes for fluorspar in various applications, creating competition and limiting the requirement for calcium fluoride. For example, in steelmaking, other fluxing agents like lime calcium oxide and dolomite are used depending on the desired output and availability. Similarly, in the production of hydrofluoric acid, while fluorspar is the primary source, research is ongoing into alternative production methods using other fluorine-containing compounds. The glass and ceramics industries also explore different materials to achieve desired properties, in turn reducing their reliance on this compound. This substitute's availability creates price pressure and limits the market share that the compound generates. Hence, the aforementioned factors are restraining market development.

Future Opportunities :

Increasing Use in Ceramics to Create Calcium Fluoride Market Opportunities.

Calcium fluoride is also used in applications such as in the production of various ceramic materials. It acts as a fluxing agent in ceramic formulations, influencing the melting point and flow properties of the ceramic mixture during firing. This is crucial for achieving desired textures, densities, and overall quality in the final ceramic product. As the ceramics sector continues to evolve, with increasing need for specialized ceramics in applications ranging from construction and tableware to advanced technical ceramics, the need of this compound is likely to become more prominent.

- For instance, according to Vibrant Gujrat, the ceramics industry is expected to grow by 5.2% over the forecast period with Asia Pacific being a lucrative region.

In addition to this, the focus on research and development to optimize the compound's use in various ceramic formulations is expected to create calcium fluoride market opportunities.

Calcium Fluoride Market Segmental Analysis :

By Purity:

Based on Purity, the market is categorized into high purity (>= 97%) and standard purity (< 97%).

Trends in Purity:

- The inclusion of high purity calcium fluoride in production of high-quality glass is gaining popularity.

- The preference for standard purity due to its cost-effective as well as its usage as a fluxing agent in steel and aluminum production is growing.

The standard purity (< 97%) segment accounted for the largest market share in 2024.

- Calcium fluoride with standard purity (< 97%) is prominent due to the established and substantial need from traditional end-use industries such as steelmaking, cement production, and certain glass manufacturing processes. They all typically utilize this more cost-effective grade.

- In addition to this, the volume of this compound required by these long-standing industries has led to an assurance related to the continuance of the standard purity and segment's market dominance.

- For instance, according to ITC Trademap, the import value for calcium fluoride with standard purity under the HS Code: 252921 increased by more than 35% in 2023 compared to its previous year. This showcases a high requirement for standard purity with United States being one of the key importers

- Thus, as per the analysis, the standard purity (< 97%) segment dominates the Calcium Fluoride market demand and trends.

The high purity (>= 97%) segment is expected to be the fastest growing segment over the forecast period.

- The high-purity (>=97%) calcium fluoride segment is projected to experience the most rapid development in the coming years.

- The market is driven by factors such as the increasing need of advanced technologies for semiconductor manufacturing, specialized glass production, and advanced optics.

- The rise of new innovative applications and growing investments in high-purity production capabilities further contribute to this development.

- The premium pricing commanded by this grade of this compound also incentivizes producers to prioritize its development and supply.

- Moreover, the high-purity segment's development is fueled by its role in diverse industries and its expanding range of applications, making it a lucrative option for key players to focus on.

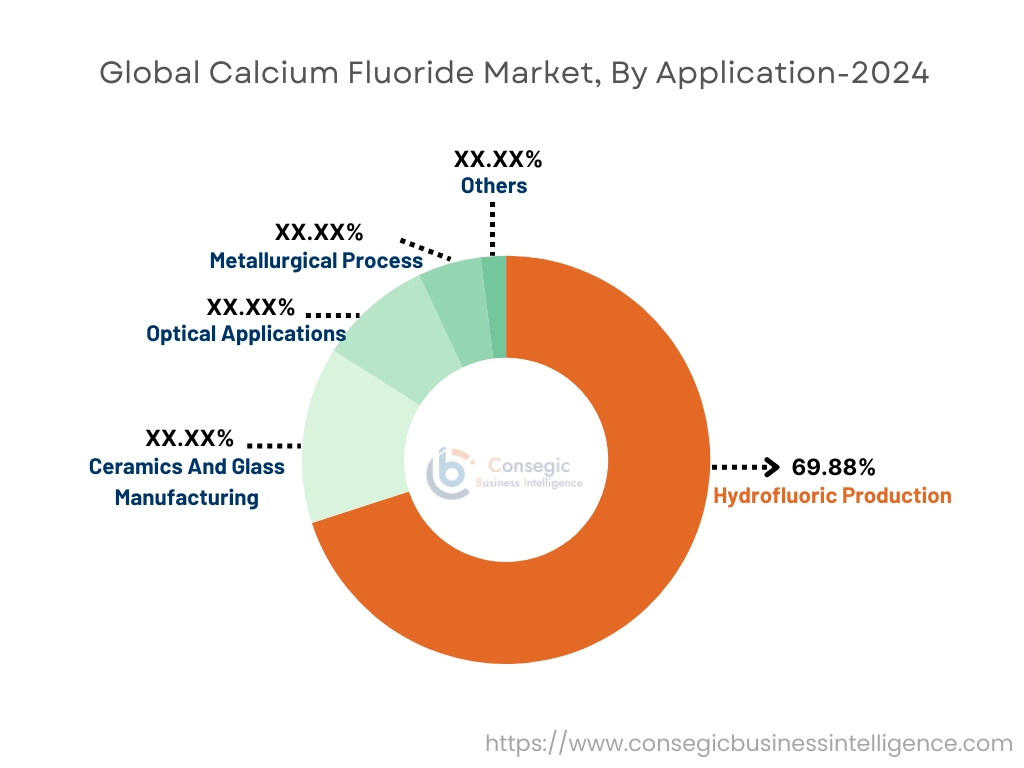

By Application:

The Application segment is categorized into hydrofluoric production, ceramics and glass manufacturing, optical applications, metallurgical process, others.

Trends in the Application:

- The increase in focus for calcium fluoride as a fluxing agent in aluminum production is leading to an improvement in the efficiency of the smelting process.

- The growing trend of optical components in electronics, lasers, and scientific instruments.

The hydrofluoric production segment accounted for the largest calcium fluoride share of 69.88% in 2024.

- The hydrofluoric acid (HF) production application is dominating since calcium fluoride, in its mineral form fluorspar, acts as the primary and most commercially viable source of HF.

- Hydrofluoric acid, in turn, is a chemical employed across a vast range of industrial processes and product manufacturing.

- Its crucial role in the production of refrigerants, a sector with consistently high need, contributes significantly to the requirement of this compound.

- The chemical processing sector, particularly in the synthesis of fluoropolymers like Teflon, also relies on HF. This has led to an increase in the importance of calcium fluoride as its source material.

- Thus, due to the above-mentioned factors the market revenue for this segment is expected to be the largest.

The optical applications segment is expected to be the fastest growing segment over the forecast period.

- The optical applications segment is driven by the increasing requirement for high-quality optical components across various sectors. A few of these sectors include electronics, healthcare, telecommunications, amongst others.

- The role of high-purity calcium fluoride in manufacturing lenses, prisms, and other optical elements for these advanced technologies, along with ongoing R&D in optics and photonics, are contributing to the new potential for the market.

- For instance, in 2025, a study was conducted by Photons Spectra which stated that, the incorporation of calcium fluoride is the widely considered material for ArF laser-based microchip fabrication. Additionally, the study also resulted in improving the resistance of this compound in fabrication of microchips showcasing lucrative opportunities in optical applications

- Thus, as per the market analysis, considering the aforementioned factors, the optical applications are expected to grow at the fastest CAGR over the forecast period.

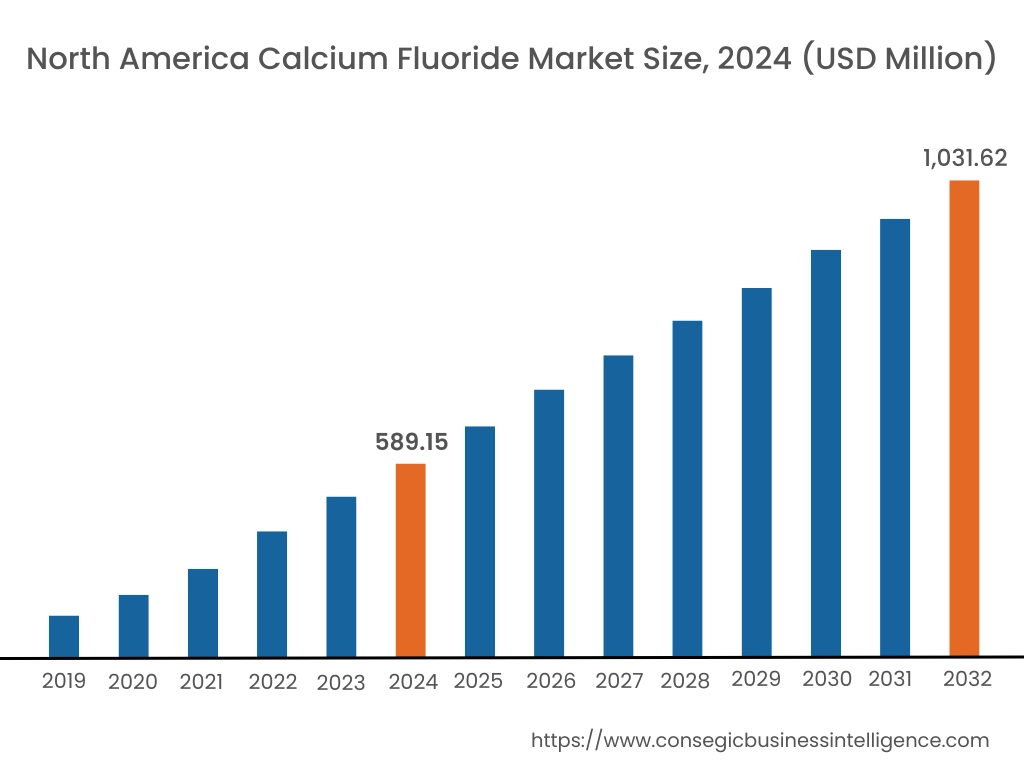

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest calcium fluoride market share at 42.55% and was valued at USD 589.15 Million and is expected to reach USD 1,031.62 Million in 2032. In North America, U.S. accounted for the calcium fluoride market share of 72.97% during the base year of 2024. The requirement for HF within North America is linked to the health and growth of key HF-consuming industries, most notably the aluminum sector, which relies heavily on HF for its smelting processes. Furthermore, the robust chemical manufacturing sector in North America, particularly the production of fluoropolymers and other specialized chemicals, contributes substantially to the overall HF requirement.

- For instance, according to USGS, the consumption of calcium fluoride attributed to roughly more than 350,000 tons for the FY 2023 in the U.S.

Thus, based on the Calcium Fluoride market analysis, due to the above-mentioned factors, North America is dominating the calcium fluoride market trends.

In Asia Pacific, the Calcium Fluoride industry is experiencing the fastest growth with a CAGR of 10.4% over the forecast period. Asia Pacific stands as a powerhouse in ceramic production, including a wide range of products from everyday tableware and tiles to highly specialized technical ceramics crucial for advanced industries. The high requirement for these ceramic goods across the region is creating a need for calcium fluoride in ceramics applications. The compound acts as a valuable fluxing agent that modifies the melting point and flow characteristics of ceramic mixtures during the firing process. This influence on the ceramic material's behavior allows manufacturers to fine-tune the texture, density, and overall quality of the final product. Furthermore, as per the market analysis, it also contributes to the aesthetic appeal of ceramics, enhancing the color and surface finish of glazes and ceramic bodies, driving the market trends.

European steel manufacturers rely on calcium fluoride as a vital fluxing agent, a substance essential for refining molten steel by lowering the melting point of impurities and facilitating their removal as slag. This process contributes significantly to the quality of the final steel product, improving its mechanical properties and making it suitable for a wide range of applications. The overall volume of steel production in Europe, including both crude steel and specialized alloys, directly impacts the quantity of this compound required by the sector. Furthermore, as per the market analysis, the focus on optimizing production processes and minimizing costs has led to the implementation of advanced fluxing techniques that further emphasize the use of this compound, thus driving the calcium fluoride market trends.

The potential for increased calcium fluoride recycling in the Latin American market is currently limited but with potential for growth driven by a factor such as environmental, economic, technological, and social factors. Growing environmental consciousness and the increasing stringency of regulations regarding mining practices and waste management are key drivers. The environmental footprint of fluorspar mining is contributing to development of new opportunities in the region. Furthermore, proper handling of fluorspar-containing waste from industrial processes and end-of-life products is becoming a critical concern, and recycling offers a more sustainable solution. For Latin American nations with limited domestic fluorspar reserves, recycling offers the potential to enhance resource security and reduce dependence on imports.

The MEA region's characteristically hot climate creates a substantial and increasing need for refrigeration and air conditioning systems, many of which utilize fluorochemicals as refrigerants. Furthermore, several MEA nations possess thriving aluminum production industries, where hydrofluoric acid (HF), derived from calcium fluoride. The region's developing chemical processing sector, including the production of fluoropolymers and other specialized chemicals, also contributes to the rising fluorochemicals demand. Even the vital oil and gas sector, a key industry of many MEA economies, utilizes fluorochemicals in various applications, such as drilling fluids and pipeline coatings. As per the calcium fluoride market analysis, since a large proportion of these fluorochemicals are synthesized from HF, and HF is primarily produced from this compound, the growing fluorochemicals requirement directly translates into increased demand, thus driving the market trends.

Top Key Players & Market Share Insights:

The Global Calcium Fluoride Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Calcium Fluoride market. Key players in the Calcium Fluoride industry include

- Solvay (Belgium)

- Reade International Corp. (U.S.)

- Super Conductor Materials Inc. (U.S.)

- Alufluor (India)

- Vizag Chemical (India)

- American Elements (U.S.)

- GFS Chemicals, Inc. (U.S.)

- Fluorchemie Group (U.S.)

- KPL International Limited (India)

- Mitsui Mining and Smelting Co. (Japan)

Calcium Fluoride Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,612.06 Million |

| CAGR (2025-2032) | 8.3% |

| By Purity |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Calcium Fluoride market? +

In 2024, the Calcium Fluoride market is USD 1,384.77 Million.

Which is the fastest-growing region in the Calcium Fluoride market? +

Asia Pacific is the fastest-growing region in the Calcium Fluoride market.

What specific segmentation details are covered in the Calcium Fluoride market? +

By Purity and Application segmentation details are covered in the Calcium Fluoride market.

Who are the major players in the Calcium Fluoride market? +

Solvay (Belgium), Reade International Corp. (U.S.), American Elements (U.S.), GFS Chemicals, Inc. (U.S.), Fluorchemie Group (U.S.), KPL International Limited (India) are some of the major players in the market