Calcined Bauxite Market Size:

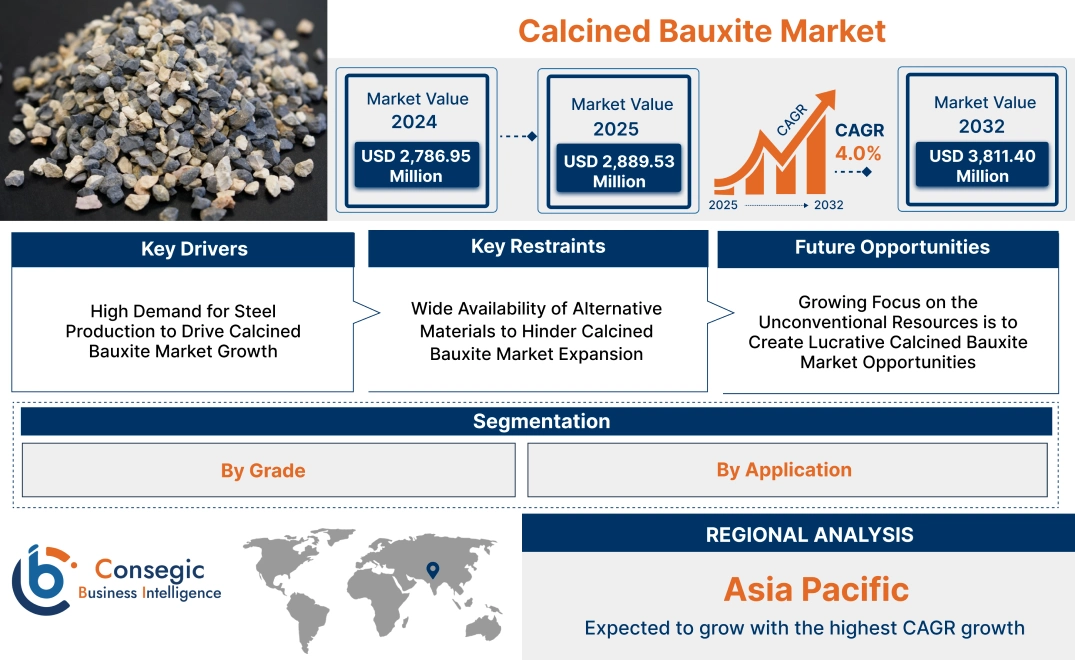

The Calcined Bauxite Market size is growing with a CAGR of 4.0% during the forecast period (2025-2032), and the market is projected to be valued at USD 3,811.40 Million by 2032 from USD 2,786.95 Million in 2024. Additionally, the market value for 2025 attributed to USD 2,889.53 Million.

Calcined Bauxite Market Scope & Overview:

Calcined bauxite is a form of aluminum oxide that is produced by heating bauxite at high temperatures. This process, known as calcination, takes place in kilns and removes moisture, resulting in dry, powdery material. The process of heating bauxite in kilns removes moisture, increases the alumina content and refractoriness of the calcined form bauxite. It also reduces iron content and enhances grain hardness and toughness. These properties, including thermal stability, high mechanical strength, and resistance to molten slags, make calcined bauxite a suitable raw material. It is primarily used in manufacturing refractory materials. It is also used to make abrasives, proppants, anti-skid agents, and other products.

How is AI Transforming the Calcined Bauxite Market?

AI is playing a crucial role in transforming the calcined bauxite market, particularly for optimizing various stages of the value chain, ranging from resource exploration to end-product delivery. AI and automation solutions can be used to optimize bauxite mining operations, predict equipment failures, improve quality control in processing, and enhance supply chain management.

Moreover, AI-powered vision systems and sensors can monitor calcination temperatures and material properties in real-time, which ensures consistent product quality. AI solutions are also used to optimize calcination processes, in turn improving efficiency and reducing energy consumption. The use of AI-powered solutions can contribute to increased efficiency, reduced costs, and improved sustainability. Therefore, the aforementioned factors are expected to positively impact the market growth in the upcoming years.

Calcined Bauxite Market Dynamics - (DRO) :

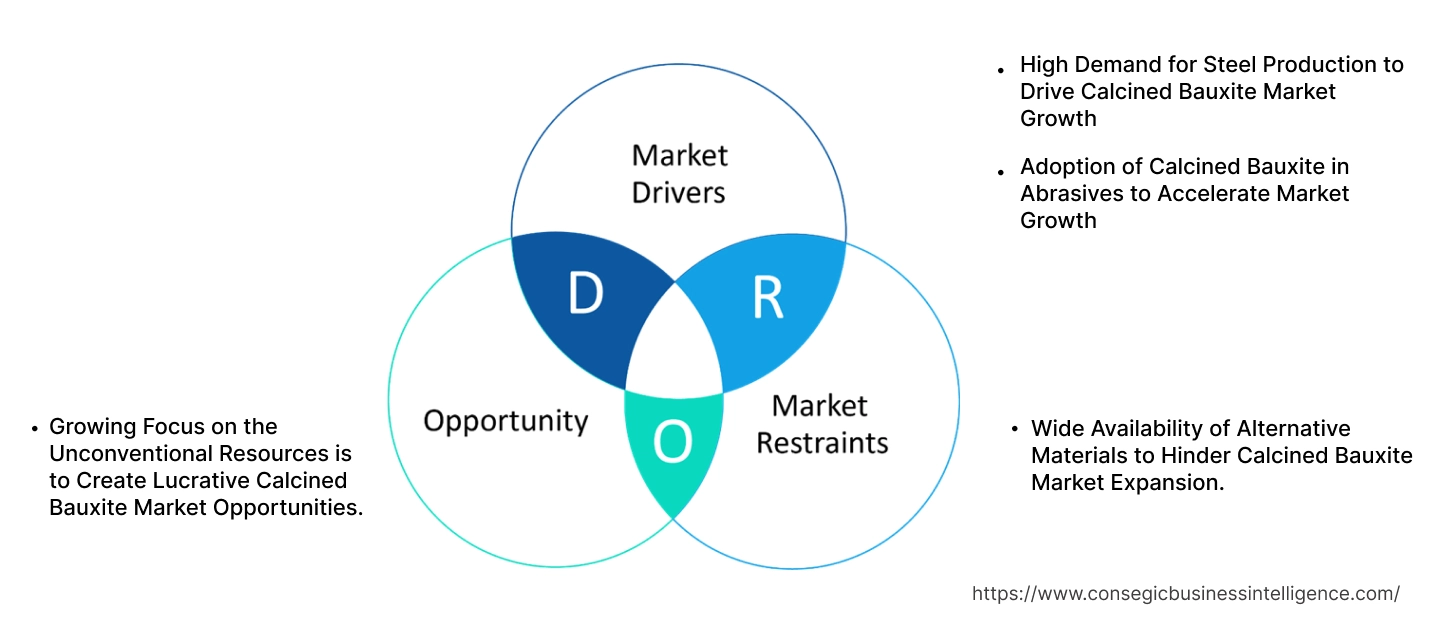

Key Drivers:

High Demand for Steel Production to Drive Calcined Bauxite Market Growth.

Steel production is high-temperature process. This process relies heavily on specialized linings within furnaces, ladles, and other equipment to withstand the intense heat and corrosive environment. These essential linings are made from refractory materials. Calcined bauxite serves as a crucial ingredient in refractory materials. Its high alumina content and ability to withstand extreme temperatures make it suitable for refractory production, contributing to the strength, durability, and heat resistance of these linings. The significant growth in production of steel is driving the requirement for calcined bauxite.

- For instance, according to the data published by World Steel Association AISBL, crude steel production for the 71 countries reporting to the World Steel Association increased by 5.6% in December 2024 compared to December 2023.

This high production directly impacts the adoption of calcined bauxite further propelling the market growth.

Adoption of Calcined Bauxite in Abrasives to Accelerate Market Growth

Calcined bauxite is exceptionally hard, making it suitable material for abrasive applications. Its hardness allows it to effectively grind, cut, polish, and finish various materials. This inherent hardness and durability results in longer lasting and more efficient abrasive products including grinding wheels, cutting discs, sandpaper, polishing compounds, and blasting media. Its versatility allows it to be used in a wide range of abrasive products including grinding wheels, cutting discs, sandpaper, polishing compounds, and blasting media. These abrasive products find application in diverse sectors such as manufacturing, metalworking, construction, automotive, aerospace, and woodworking, further contributing to the demand for this type of bauxite. As a result, manufacturers are increasingly developing alumina-based abrasives which are made from calcined bauxite.

- For instance, in 2024, Saint Gobain introduced AZ25L, an innovative abrasive grain. AZ25L is made up of 25% Alumina Zirconia, calcium bauxite amongst others. It is abrasive grain presents the microstructure features delivering extreme wear resistance and highly controlled friability.

Thus, due to the above-mentioned factors, the adoption of calcined bauxite in abrasives is contributing to calcined bauxite market expansion.

Key Restraints:

Wide Availability of Alternative Materials to Hinder Calcined Bauxite Market Expansion.

The wide availability of alternative materials presents a significant constraint to the adoption of calcined bauxite in several applications. In the proppants, frac sand is widely used. It serves as cost-effective solution and therefore preferred option for oil and gas companies. This competition significantly limits the demand for calcined bauxite proppants. In addition to this, within the refractories sector materials including fused alumina, silicon carbide, magnesia, and various clays offer viable alternatives. The abrasives applications also present substitutes, including silicon carbide, fused alumina, ceramics, and garnet, each with its own properties and cost advantages. This further limits the calcined bauxite market share. These alternative materials compete with this bauxite in various applications, particularly refractories and abrasives. Their availability puts pressure on its pricing and limits its calcined bauxite market demand.

Future Opportunities :

Growing Focus on the Unconventional Resources is to Create Lucrative Calcined Bauxite Market Opportunities.

The increased focus on unconventional resources, such as shale gas and tight oil is creating market growth over the forecast period. As conventional oil and gas reserves decline, the need to explore and exploit alternative sources of hydrocarbons becomes increasingly critical. Unconventional resource extraction often involves complex wellbores, including horizontal drilling and multi-stage fracturing. This increased fracturing activity directly drives demand for proppants, and calcined bauxite is a suitable material for this application. Furthermore, the growing investment in shale facilities is creating the requirement for this type of bauxite.

- For instance, in March 2024, Argentina's national oil company YPF announced that it will invest USD 3 billion of a USD 5 billion capital spending plan in 2024 in shale, as it looks to generate more cash by exiting some major conventional fields.

Thus, growing focus on unconventional resources creates upward market trajectory over the upcoming period.

Calcined Bauxite Market Segmental Analysis :

By Grade:

Based on grade, the market is categorized into refractory grade, abrasive grade, proppant grade, and others.

Trends in the Grade:

- Trend toward finer and more precisely controlled particle size distributions in abrasive grade to meet the needs of advanced manufacturing processes.

- Use of more energy-efficient refractory materials to reduce operating costs and environmental impact.

The refractory grade segment accounted for the largest market share in 2024.

- Refractory grade calcined bauxite is characterized by its high alumina content of typically 85% and low impurity levels.

- These properties make it suitable for use in high-temperature applications, such as in the production of refractory materials.

- This material is essential for lining furnaces, kilns, and other high-heat equipment in sectors such as steelmaking, cement production, glass manufacturing, and foundries.

- The growing cement production creates high adoption of refractory grade bauxite further driving the upward trajectory of segment.

- For instance, as per the analysis published by India Brand Equity Foundation, In financial year 2023, India's cement production increased 6.83% year-on-year compared to 2022.

- Collectively, aforementioned factors support segment in the overall market.

The proppant grade segment is expected to grow at the fastest CAGR in the forecast period.

- Proppant grade calcined bauxite is specifically processed for use as a propping agent in hydraulic fracturing operations in the oil and gas sector.

- Proppants are used to keep fractures open in the rock formation, allowing for the flow of oil and gas to the wellbore.

- This grade needs to meet specific crush strength requirements to perform effectively in this demanding application.

- Moreover, growing oil and gas production creates the requirement for cost-effective proppants such as calcined form of bauxite.

- As a result, considering this analysis, the proppant grade segment is expected to experience greater CAGR in the forecast years.

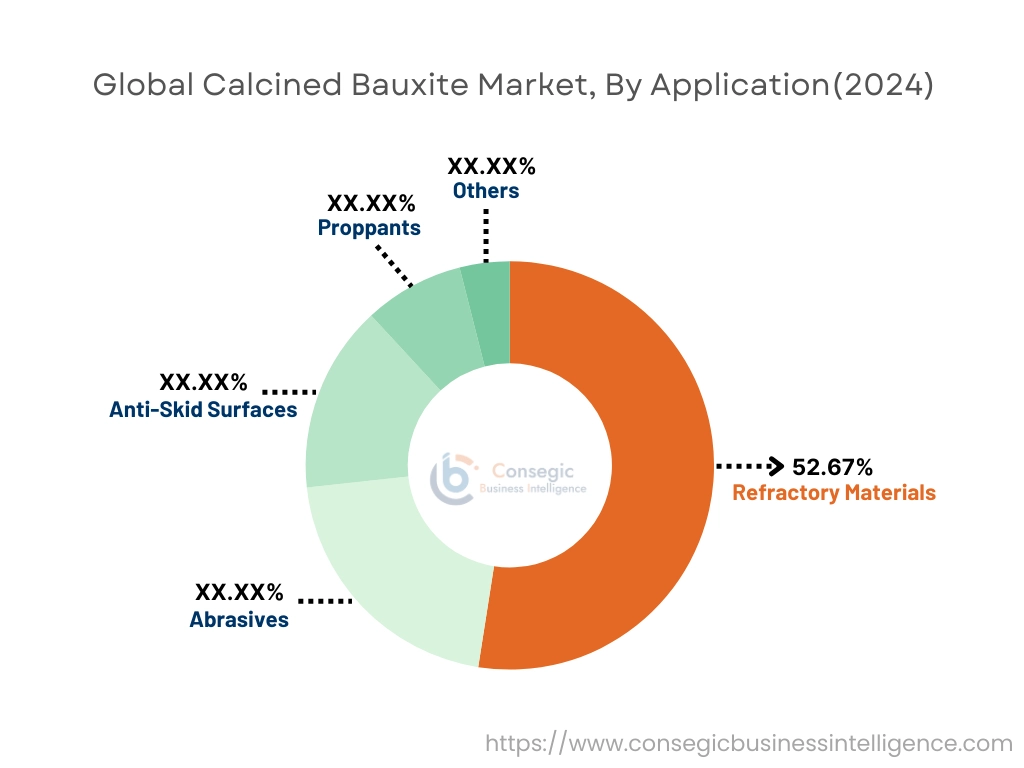

By Application:

The application segment is categorized into refractory materials, abrasives, anti-skid surfaces, proppants, and others.

Trends in the Application:

- There’s a growing emphasis on higher-quality refractories with improved thermal shock resistance, chemical inertness, and longer lifespans.

- Trend of developing more durable and efficient abrasives is rising.

The refractory materials segment accounted for the largest market share of 52.67% in 2024.

- Refractory materials are materials that present capability to withstand high temperatures, chemical attack, and decomposition. Calcined bauxite is used in the production of alumina based refractory materials.

- Refractory materials are essential for lining high-temperature equipment such as furnaces and kilns in areas such as steelmaking, cement production, glass manufacturing, and foundries.

- High alumina content of this bauxite and ability to withstand extreme temperatures make it a crucial component in these refractories.

- Ongoing industrial activity and infrastructure development worldwide are creating growing need for refractory materials. As a result, there is growing focus on the development of alumina refractories creating high requirement of this bauxite.

- Owing to the above-mentioned factors, the refractory materials segment occupies a dominant state in the overall calcined bauxite market analysis.

The proppants segment is expected to grow at the fastest CAGR over the forecast period.

- Proppants are granular materials pumped into hydraulically fractured wells to keep the fractures open, allowing oil and gas to flow to the wellbore.

- The primary driver of proppant adoption is the level of hydraulic fracturing activity. Increased drilling and well completion directly impacts higher proppant consumption. Thus, the adoption of proppants is heavily reliant on activity levels in the oil and gas sector.

- For instance, in March 2022, Shell Offshore Inc., the start of production at PowerNap, a subsea development in the U.S. Gulf of Mexico with an estimated peak production of 20,000 barrels of oil equivalent per day. The development of such oil production projects creates the requirement for proppants.

- Thus, due to the above-mentioned factors, the proppants segment is expected to register the fastest CAGR over the forecast period in the overall calcined bauxite market opportunities.

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

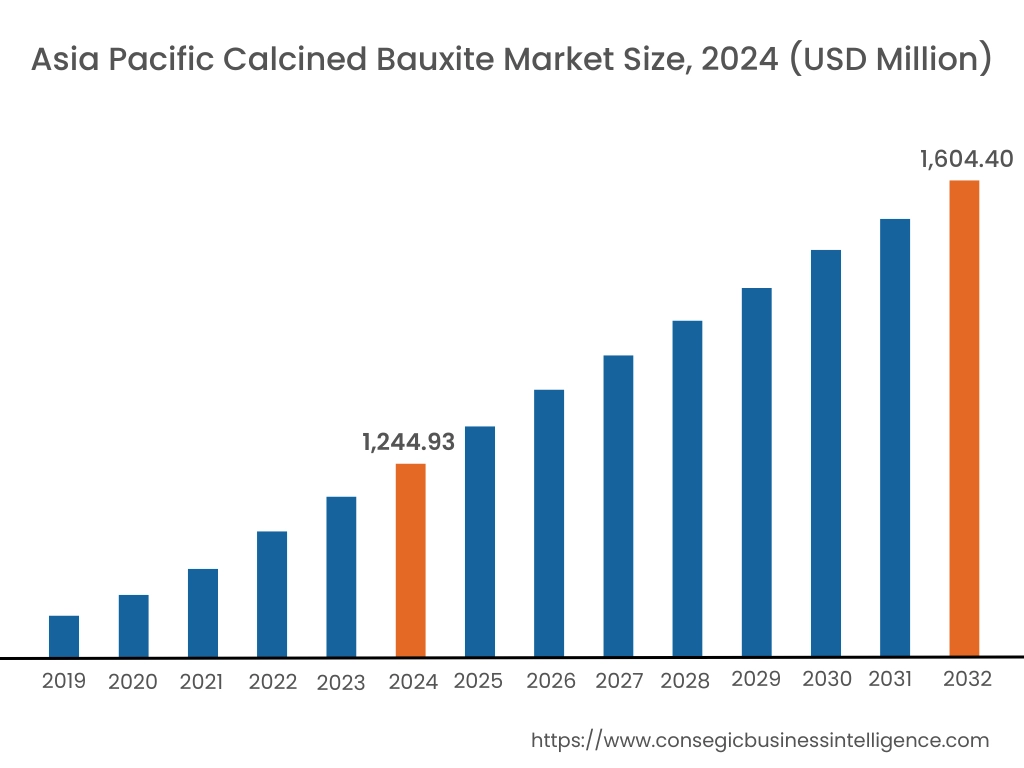

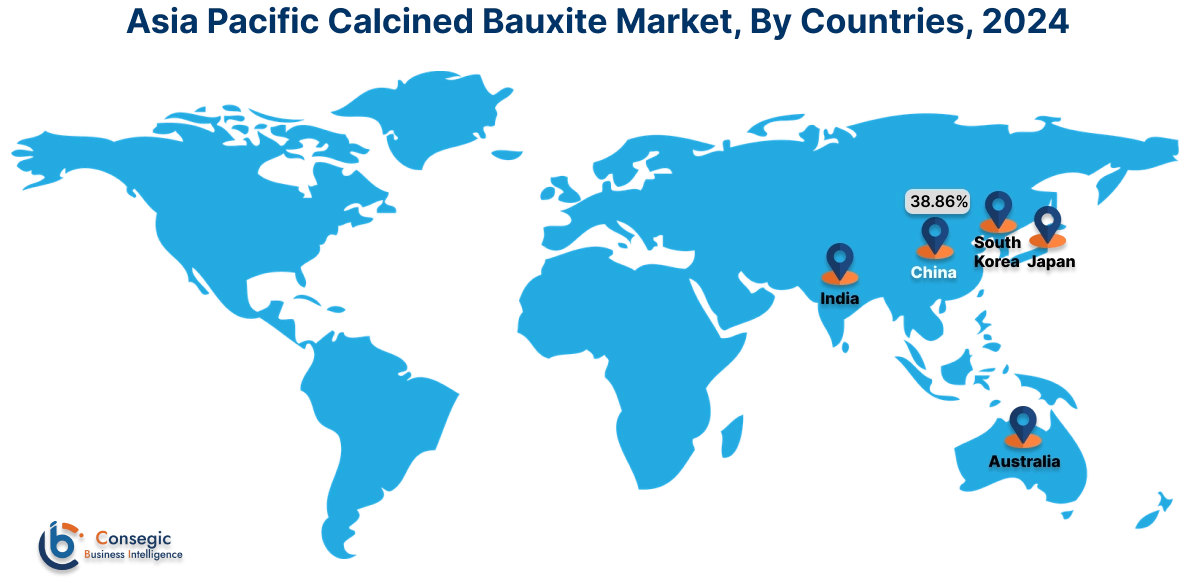

In 2024, Asia Pacific accounted for the highest calcined bauxite market share at 44.67% and was valued at USD 1,244.93 Million and is expected to reach USD 1,604.40 Million in 2032. In Asia Pacific, the China accounted for the largest share of 38.86% during the base year of 2024.

The rising steel production is the key factor that is leading to the upward market trajectory of calcined bauxite in Asia Pacific. The steel sector is the key end-user of refractory materials, and calcined bauxite is a crucial component in many of these refractories. Asia Pacific serves as one of the key steel-producing regions. Countries such as China, India, Japan, and South Korea have large and growing steel sector. As steel production increases in the region, it creates need for refractory materials further influencing adoption of this bauxite. The rise in steelmaking capacity and the operation of existing plants at higher utilization rates both contribute to this increased need.

- For instance, according to the analysis published by World Steel Association AISBL, China, India, and Japan were key steel producing countries globally in 2024. China's steel production increased by 11.8%, whereas India's output increased by 9.5% rise compared to December 2023.

Therefore, as per market analysis, growing steel production supports in calcined bauxite market trend in Asia Pacific region.

In Europe the calcined bauxite market analysis is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. Shift towards development of oil and gas through unconventional resources serves a prominent role calcined bauxite market growth in Europe. As conventional oil and gas reserves in Europe decline, there's a growing interest in exploiting unconventional resources such as shale gas and tight oil. These unconventional extraction methods rely heavily on hydraulic fracturing, a process that requires substantial amounts of proppants to keep fractures open and allow for the flow of hydrocarbons. Calcined bauxite is a suitable material for proppants, and thus, the increasing focus on unconventional resources in Europe is creating new market opportunities for companies.

The need for high-quality abrasives and refractories is one of the primary factors creating upward market trajectory across North America. North America has a well-established manufacturing sector, encompassing sectors such as automotive, aerospace, metal fabrication, and general industrial goods. These areas rely heavily on abrasives for various processes, including grinding, cutting, polishing, and surface preparation. The need for high-quality abrasives results in the requirement for calcined bauxite, as a key material in their production. The expanding machinery, automotive, medical, and construction sectors within the U.S. are significantly contributing to the calcined bauxite market demand across North America.

The growing emphasis on infrastructure development is a prominent trend that drives the calcined bauxite market trend in Latin America. This trend is influenced because countries in the region are experiencing construction rise, encompassing residential, commercial, and industrial projects, as well as investments in transportation infrastructure including roads, bridges, and railways. This construction activity fuels a high necessity for cement. As this bauxite is a key component in certain cement types, increased need for cement positively impacts higher bauxite consumption. Furthermore, as infrastructure develops, safety becomes a greater priority, leading to increased use of calcined bauxite in anti-skid surfaces for roads, walkways, and other areas. Consequently, the above-mentioned factors support market in Latin America.

The Middle East and African market is led by the high contribution of oil and gas sector. The oil and gas sector holds significant share in many MEA countries. This sector requires large quantities of various materials, including proppants used in hydraulic fracturing. Calcined bauxite is used as a proppant in hydraulic fracturing operations to keep fractures open in the rock formation. The oil and gas sector also supports petrochemicals and refining operations that use bauxite in various applications, including refractories. Owing to these factors, the market for calcined bauxite in the Middle East and Africa is expected to grow at a considerate rate.

Top Key Players & Market Share Insights:

The global Calcined Bauxite Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Calcined Bauxite market. Key players in the Calcined Bauxite industry include-

- Great Lakes Minerals, LLC (United States)

- LKAB (Sweden)

- Bautek Minerals Industries (Brazil)

- Hodge Clemco Ltd (United Kingdom)

- Sibelco (Belgium)

- First Bauxite (United States)

- Mineore Enterprises Private Limited (India)

- Bosai Minerals Group Co., Ltd. (China)

- RAWMIN (India)

- Sinocean Industrial Limited (China)

Recent Industry Developments :

Expansion:

- In April 2024, Bautek Minerals Industries announced rise of calcined bauxite production capacity from 60,000tpy to 80,000tpy.

Acquisition:

- In March 2022, First Bauxite, announced acquisition of US Ceramics LLC. The company has greatly reinforced and expanded its production potential by acquiring ceramic proppant producer US Ceramics LLC. This provides FBX with its own calcination facilities, to enable supply of calcined refractory grades to the US market.

Calcined Bauxite Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3,811.40 Million |

| CAGR (2025-2032) | 4.0% |

| By Grade |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Calcined Bauxite market? +

In 2024, the Calcined Bauxite market is USD 2,786.95 Million.

Which is the fastest-growing region in the Calcined Bauxite market? +

Europe is the fastest-growing region in the Calcined Bauxite market.

What specific segmentation details are covered in the Calcined Bauxite market? +

By Grade and Application segmentation details are covered in the Calcined Bauxite market.

Who are the major players in the Calcined Bauxite market? +

Great Lakes Minerals, LLC (United States), LKAB (Sweden), First Bauxite (United States) are some of the major players in the market.