- Summary

- Table Of Content

- Methodology

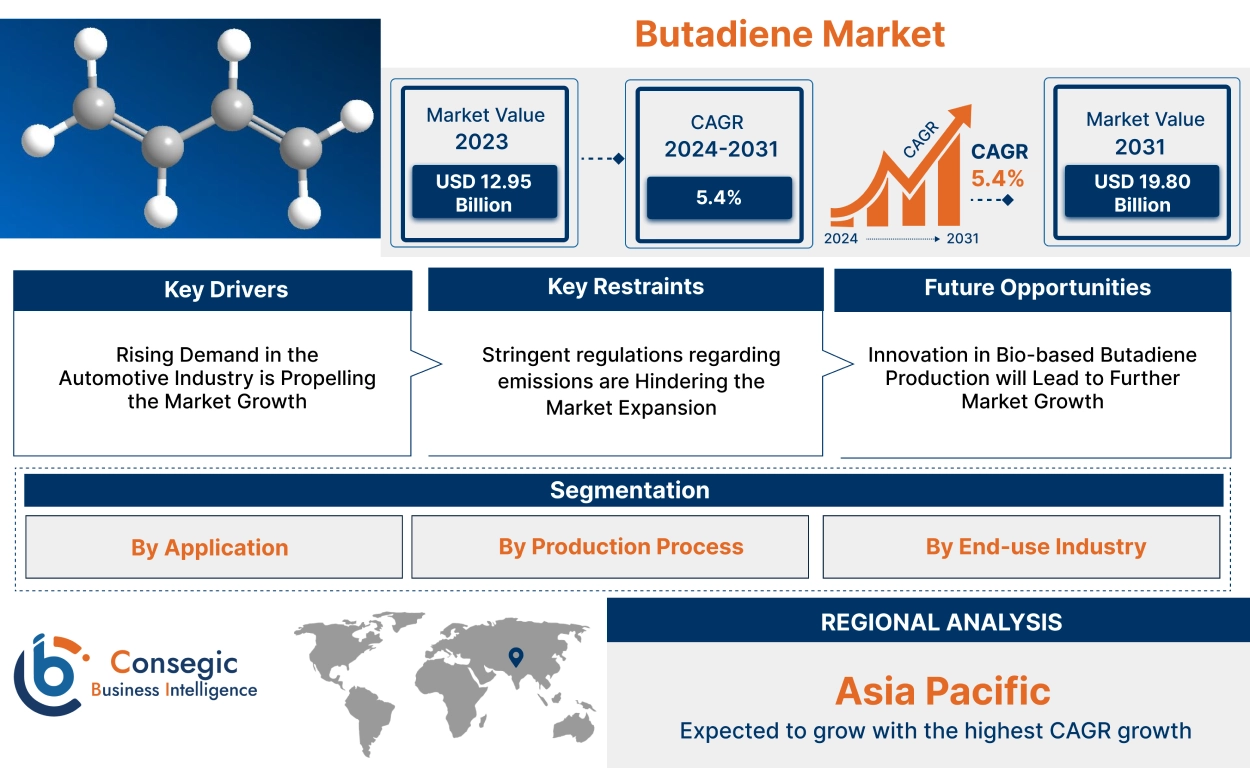

Butadiene Market Size:

Butadiene Market size is estimated to reach over USD 19.80 Billion by 2031 from a value of USD 12.95 Billion in 2023 and is projected to grow by USD 13.43 Billion in 2024, growing at a CAGR of 5.4% from 2024 to 2031.

Butadiene Market Scope & Overview:

Butadiene is a colorless yet highly volatile gas with an aroma faintly reminiscent of flowers. As an essential component in synthetic rubber production, this petrochemical allows for tires, hoses, belts and other fundamental automotive components to be manufactured on a mass scale, vital for personal and freight transport. Further uses include resins for plastics such as acrylonitrile-butadiene-styrene, ubiquitous in appliances, electronics, and construction materials. They are used by different industries such as chemical, plastics, polymer, automotive, and industrial applications.

Butadiene Market Insights:

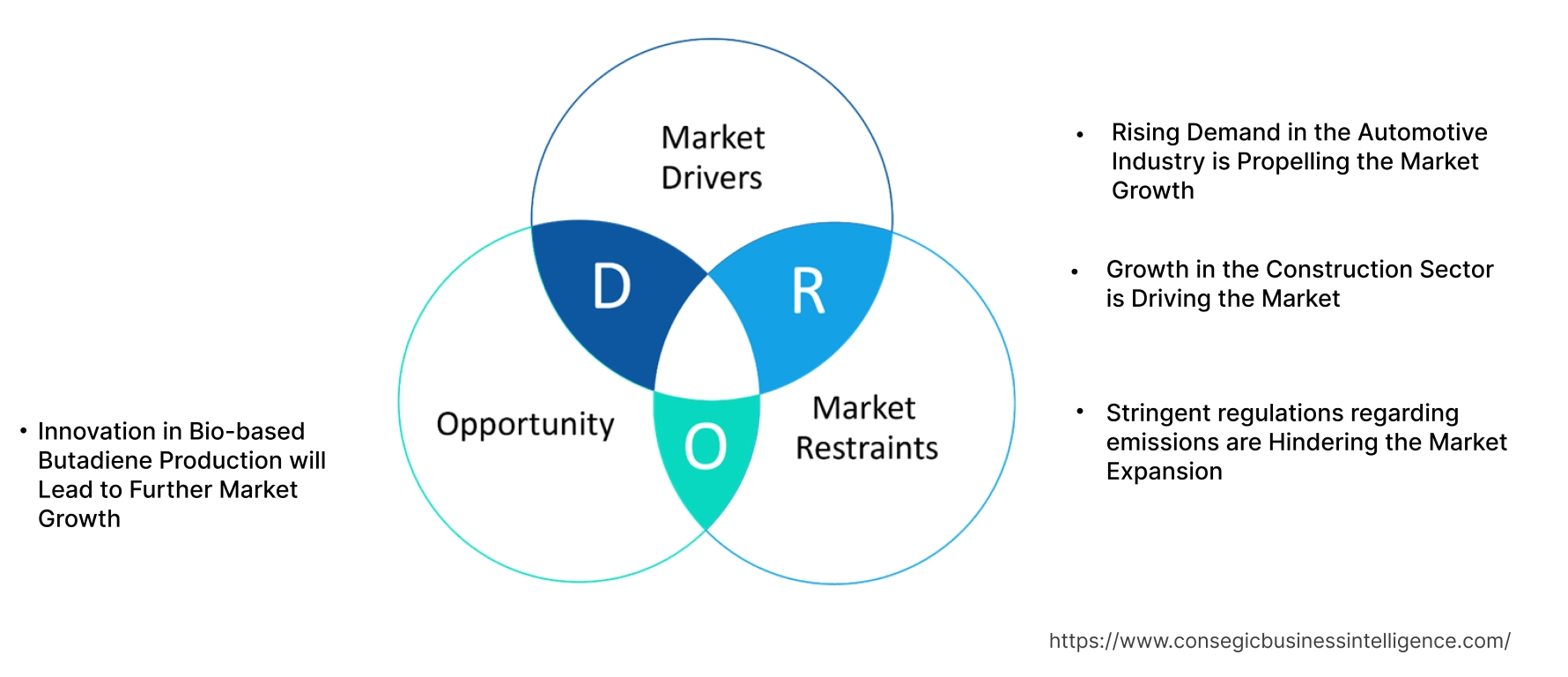

Key Drivers:

Rising Demand in the Automotive Industry is Propelling the Market Growth

Butadiene is critical for generating manufactured rubbers employed in automobile tires. These rubbers supply advanced longevity, grip, and protective characteristics, which users and directives increasingly call for. Advanced technologies like high-performance polymers and combinations improve car direction, fuel efficiency, and protection. As electric cars become more widespread, there is a push for improved performance materials that offer better protection, durability, and efficiency, driving further creative progression in the market. Elements like seals, gaskets, and tubes necessitate butadiene-dependent substances to meet performance standards, like resistance to extreme temperatures, chemicals, and wear and tear.

- In 2023, according to the research by IFPEN, butadiene is primarily used as a monomer to create a number of significant polymers, it is still essential to use this compound alone among C4 hydrocarbons in the petrochemical process. Its significance in industrial relevance is shown by its wide range of applications, which include its pivotal role in the synthesis of synthetic rubber, which is essential to the production of tires.

Therefore, according to the analysis, the demand is rising in the automotive sector significantly influencing the butadiene market growth, driving innovations, and increasing production.

Growth in the Construction Sector is Driving the Market

While the trend in the sector influences the growing need for butadiene-derived materials, especially those employed in construction substances and uses the design area has embraced fresh technologies that necessitate superior materials. Butadiene-founded polymers and rubbers are utilized in high-functionality elements, like state-of-the-art coatings and composite components, which improve the longevity and resilience of construction initiatives. Renovations and refurbishments of present structures also contribute to the growth of the founded merchandise. This involves the implementation of adhesives, and sealants, along with other elements in maintenance tasks. Large-scale infrastructure projects, like highways, airports, and public buildings, turn to these materials as a result of their durability and performance traits.

- In 2023, ARLANXEO's diverse category contains butadiene rubber goods branded as Buna, applicable to tires as well as medical, pharmaceutical, chewing gum, and customized plastics. Within their rubber manufacturing sector, three Ziegler-Natta catalyst configurations are utilized to develop BUNA classifications through polymerization.

Therefore, according to the analysis, the trend in the construction sector directly impacts the butadiene market by increasing the demand for these products used in construction materials, adhesives, sealants, and coatings.

Key Restraints :

Stringent regulations regarding emissions are Hindering the Market Expansion

Stringent regulations regarding emissions have a significant impact on the butadiene market, shaping production processes, product formulations, and overall market dynamics. Installing novel emission supervision technologies or changing present processes bring about momentary interruptions in output. This disturbs the supply chains and potentially results in postponements or diminished productive ability.

- In October 2023, according to the article the increasing emphasis on environmental sustainability in contemporary times has significantly shaped the landscape of tire tread compounds. Passenger cars contribute majorly, accounting for approximately 13% of total CO2 emissions within the EU. Given that a passenger car's tire tread plays a substantial role in fuel consumption due to its impact on rolling resistance, developing innovative tire tread formulations is crucially important in endeavoring to shrink the carbon footprint.

Therefore, while stringent emissions regulations are essential for reducing environmental impact and promoting public health, they also pose several constraints for the butadiene industry.

Future Opportunities :

Innovation in Bio-based Butadiene Production will Lead to Further Market Growth

Innovation in bio-based butadiene creation symbolizes crucial progress in the chemical business. These are derived from restorative assets, such as plant biomass or natural waste, instead of fossil fuels. This technique aims to reduce the ecological footprint of the compound by decreasing ozone-harming substance discharges and reliance on non-sustainable resources. Developments in bio-catalysis include utilizing normal or designed proteins to encourage substance responses that will deliver this compound from bio-based resources. Natural waste from farming and mechanical forms be utilized as feedstock, offering a maintainable choice for the creation while diminishing waste.

Therefore, innovation in bio-based production represents a promising shift towards more sustainable chemical manufacturing.

Butadiene Market Segmental Analysis :

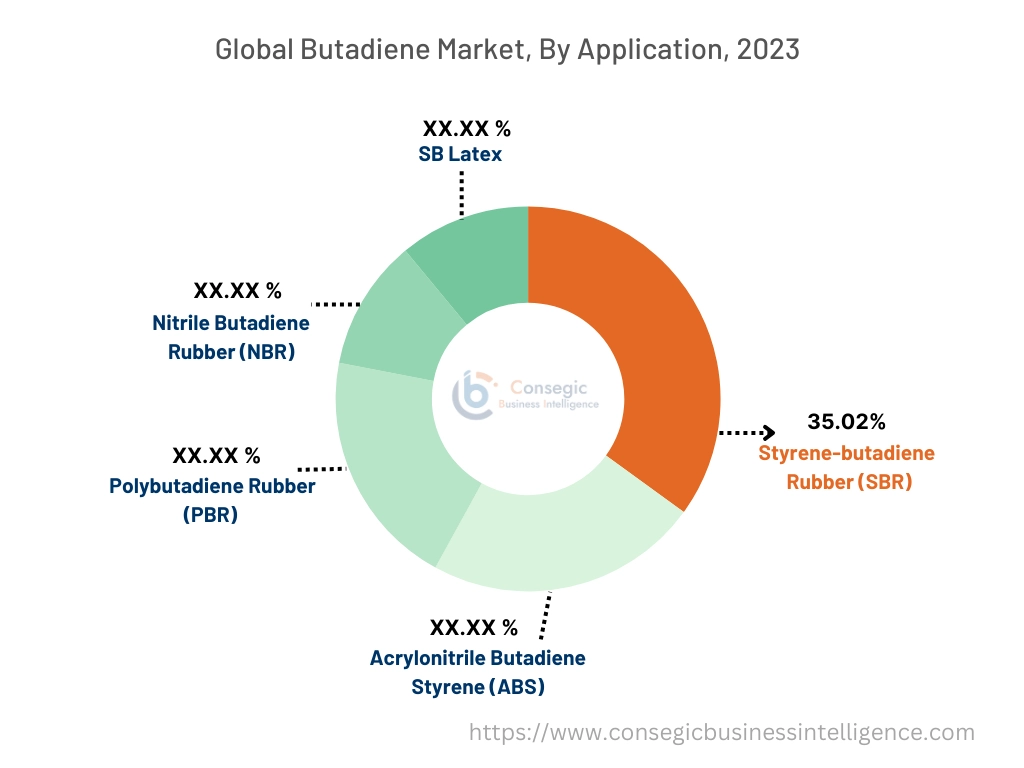

By Application:

Based on application the market is segmented into Styrene-butadiene rubber (SBR), Acrylonitrile Butadiene Styrene (ABS), Polybutadiene Rubber (PBR), Nitrile Butadiene Rubber (NBR), SB Latex, and others.

Trends in the Application:

- Ongoing advancements in SBR production technology and formulation enhance its properties and expand its applications, maintaining its competitive edge in the market.

The styrene-butadiene rubber (SBR) accounted for the largest revenue share of 35.02% in the year 2023.

- SBR is a widely used synthetic rubber with extensive applications across various industries, primarily due to its versatile properties and performance characteristics.

- It maintains flexibility at various temperatures, enhancing its performance in different environmental conditions.

- The largest application of SBR is in tire manufacturing, where it is used in the tread and sidewalls of tires. SBR offers excellent abrasion resistance, durability, and performance characteristics that make it ideal for automotive tires.

- It is also utilized in adhesives, coatings, and other industrial products. Its properties make it suitable for use in a wide range of applications where flexibility and durability are required.

- For instance, according to TRP polymer solutions SBR has stood the test of time as an indispensable feedstock for our modern world. Its stability, resilience, and versatility have allowed it to permeate industries as diverse as transportation, footwear manufacturing, machinery production, and construction.

- Thus, as per the segmental analysis, SBR is driven by its widespread use in tire manufacturing, automotive components, and various industrial applications.

The acrylonitrile butadiene styrene (ABS) segment is anticipated to register the fastest CAGR during the forecast period.

- ABS is widely used in the production of durable and aesthetically pleasing consumer electronics and household appliances. Its strength, impact resistance, and ease of processing make it ideal for these applications.

- It is used extensively in automotive interior components such as dashboards, trim, and panels. Its ability to be molded into complex shapes and its resistance to impact and wear make it suitable for these applications.

- The rise of 3D printing and additive manufacturing has increased the butadiene market demand for ABS as it is one of the most commonly used materials in 3D printers due to its excellent printability and finish.

- The automotive market growth is driven by technological opportunities and increasing vehicle production, contributing to the butadiene market share for ABS in automotive components.

- For instance, Ruitai Mould uses ABS pellets or granules for molding. Since moisture can lower the quality of the finished product, they make sure the ABS material is dry and free of moisture. This can be accomplished by utilizing a dehumidifier or drying the ABS pellets in a hopper.

- Thus, according to the butadiene market analysis the ABS segment is poised to register the fastest CAGR during the forecast period due to its versatile applications, favorable material properties, and growing demand in key industries.

By Production Process:

Based on the production process the market is segmented into the Oxo-Diene Process, Extraction Process, Dehydrogenation Process, and Ethanol to Butadiene (ETB) Process.

Trends in the Production Process:

- Innovations and improvements in the oxo-diene process could have enhanced its competitiveness, leading to its dominance in the market.

The oxo-diene process accounted for the largest revenue share in the year 2023.

- The oxo-diene process, also known as the Oxo process or hydroformylation process, involves the production of the compound through the catalytic reaction of butene with synthesis gas.

- The oxo-diene process is known for its high yield of the compound, making it economically attractive compared to other methods.

- The oxo-diene process offers high conversion rates of butenes, leading to cost efficiency in production.

- The global butadiene market, driven by the automotive and industrial sectors, reinforces the importance of the oxo-diene process in meeting market needs.

- For instance, Mettler Toledo states that hydroformylation, otherwise known as oxo synthesis, is a chemical reaction where carbon monoxide and hydrogen are added to an unsaturated compound that is usually an alkene or alkyne. The reaction selectivity is prioritized, sacrificing speed for enantiomeric excess. Additional approaches continue to be explored aiming to balance both selectivity and rate through clever catalysis design and reaction engineering.

- Thus, in 2023, the oxo-diene process accounted for the largest revenue in the butadiene market due to its high efficiency, economic viability, and ability to produce high-purity butadiene.

The extraction process segment is anticipated to register the fastest CAGR during the forecast period.

- Extraction processes are used to purify it from other co-products in the chemical plant, ensuring a high-purity output that is crucial for downstream applications.

- Innovations in extraction technology, such as improved solvents and more efficient adsorption materials, are enhancing the performance and cost-effectiveness of extraction processes.

- New developments in extraction technology, such as improved solvents and more efficient separation techniques, are driving the trend in this segment.

- The integration of automation and advanced control systems in extraction processes improves efficiency and reduces operational costs.

- For instance, according to Google systems for disentangling and cleansing butadiene and isoprene from a composite of C4 hydrocarbons containing the compound and a mixture of C5 hydrocarbons holding isoprene are attainable. The scheme will further contain a C5 washer column washing residuals, an absorption column taking in gases, and a distillation column bringing everything into place.

- Thus, according to the analysis the extraction process segment is expected to register the fastest CAGR during the forecast period due to advancements in extraction technologies, increased demand for high-purity butadiene, and the need for efficient and sustainable production methods.

By End Use Industry:

Based on the end-use industry the market is segmented into Automotive, Construction, Consumer Goods, Electrical & Electronics, Healthcare, and others.

Trends in the End Use Industry:

- The automotive market is increasingly focusing on sustainability, leading to innovations and opportunities in production and use, such as the development of bio-based and recyclable synthetic rubbers.

The automotive accounted for the largest revenue share in the year 2023.

- The largest application of butadiene in the automotive market is in the production of synthetic rubber for tires. It is a key monomer in the production of SBR, which is critical for tire performance.

- Butadiene-based synthetic rubbers are used in various interior components such as dashboards, seals, gaskets, and weatherstripping due to their durability and resistance to aging.

- Butadiene market opportunities are rising due to disposable incomes in emerging markets which contributes to increased vehicle sales, further driving the size of the butadiene market.

- For instance, Omnexus states that SBR is a widely used general-purpose rubber. The reason for its success is its unique properties and diverse applications. Also, it is the only material that exhibits long-range elasticity.

- Thus, as per the analysis the automotive sector accounted for the largest revenue share in the market due to its extensive use in tire manufacturing and automotive components.

The construction segment is anticipated to register the fastest CAGR during the forecast period.

- Butadiene-based polymers, such as SBR and other synthetic rubbers, are used in adhesives and sealants. These materials provide excellent bonding strength and flexibility, essential for various construction applications.

- Butadiene-based polymers are used in concrete additives to improve the performance of concrete, enhancing its flexibility, strength, and resistance to environmental conditions.

- Governments and regulatory bodies are implementing stricter building standards and regulations, which increases the need for high-quality, reliable construction materials.

- There is a growing emphasis on sustainable construction practices, leading to increased use of advanced materials that include butadiene-based components.

- For instance, J Flex Rubber Products produces synthetic rubber which stems from a hydrocarbon blend commonly derived from petroleum or coal resources. The polymer chains concatenate under raised temperatures and pressures to synthesize diverse formulations befitting versatile applications.

- Thus, according to the analysis trend the construction segment is anticipated to register the fastest CAGR during the forecast period due to increased infrastructure development, technological advancements, and a growing emphasis on sustainability.

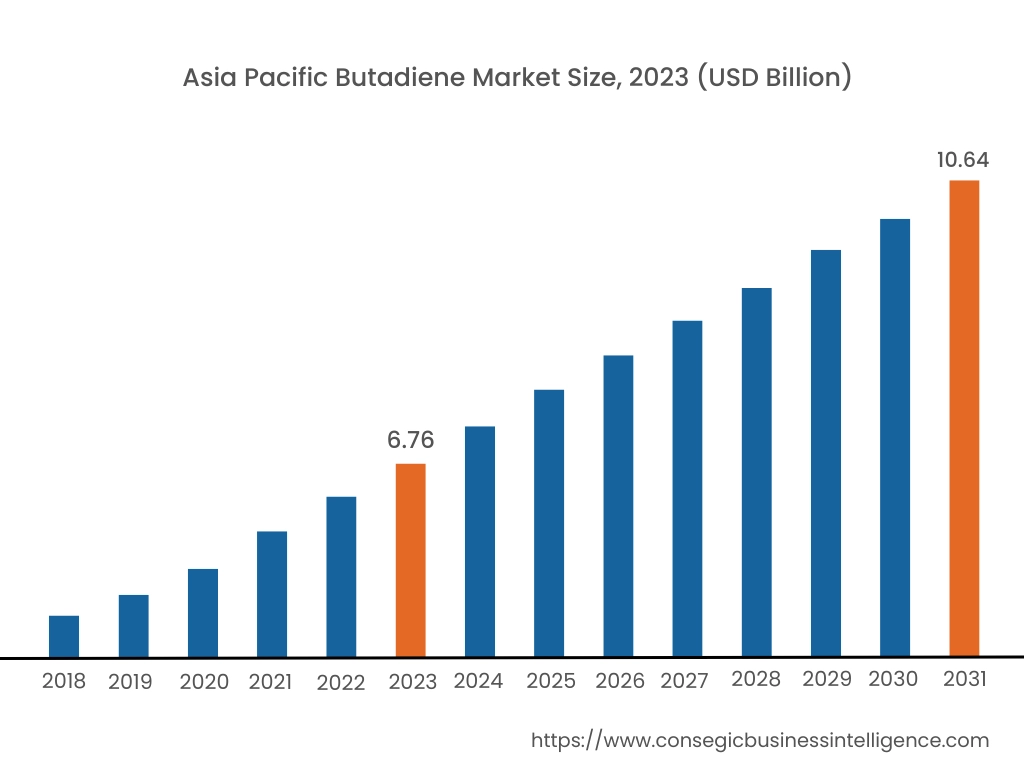

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

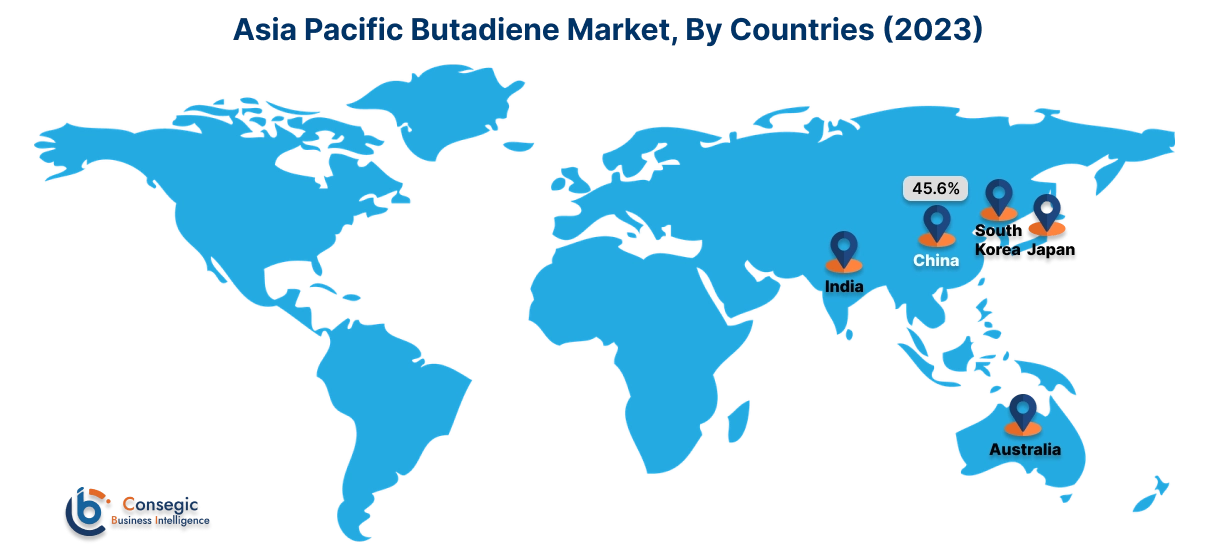

Asia Pacific region was valued at USD 6.76 Billion in 2023. Moreover, it is projected to grow by USD 7.02 Billion in 2024 and reach over USD 10.64 Billion by 2031. Out of this, China accounted for the maximum revenue share of 45.6%.

Asia-Pacific is currently the leading player in the butadiene market and is expected to experience the highest growth rate in the coming years. It is a crucial raw material used to produce synthetic rubbers, particularly SBR and PBR. These synthetic rubbers are used extensively in the automotive market to manufacture tires, hoses, and various parts. Countries such as China and India continue to witness rapid industrialization and urbanization due to the butadiene market expansion in automobiles and automotive components are expected to rise in the region.

- In November 2023, the groundbreaking ceremony commenced on a joint venture between Tatneft and the Smruk-Kazyna to construct an expansive butadiene plant in Kazakhstan, as announced by President Kassym-Jomart Tokayev. Construction has now started on the Kazakh-Russian facility that will generate up to three hundred forty thousand metric tons annually of this compound through the partnership with Tatneft.

North America is estimated to reach over USD 4.31 Billion by 2031 from a value of USD 2.84 Billion in 2023 and is projected to grow by USD 2.94 Billion in 2024.

In North America, the market is expected to grow significantly over the forecasted period. The automotive sector drives the market growth for the compound in the region. As vehicle production increases to meet consumer demand, particularly in the United States and Canada, there is a corresponding rise in the need for high-performance tires and other rubber components.

- In 2024, The Butadiene Product Stewardship Guidance Manual was prepared as a collaboration between market experts seeking to educate those interacting with the compound. Prized for its low mass and high versatility, the compound finds wide use as the basic monomer in an assortment of manufactured polymers and copolymers while fulfilling an essential function in the synthesis of certain industrial chemicals.

Europe is predicted to have a significant increase throughout the projection period as a result of the widespread use of this compound and its derivatives in the manufacturing of auto parts such as wheel covers, dashboard trims, tires, and other components. Germany is the top-ranking nation due to its rising automobile exports.

The Middle East, with its significant oil and gas reserves, is a major player in the petrochemical market. Countries like Saudi Arabia, the United Arab Emirates (UAE), and Qatar have substantial production capacities. In Africa, the production is more limited compared to the Middle East. However, countries like South Africa have some petrochemical activities, contributing to the regional supply.

In Latin America, Brazil has significant chemical production capabilities, including butadiene. The automotive sector in Latin America, particularly in countries like Brazil and Mexico, is a significant consumer of this compound.

Top Key Players & Market Share Insights:

The butadiene market is highly competitive with major players providing this chemical to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the butadiene market. Key players in the butadiene industry include--

- TPC Group (U.S)

- China Petroleum and Chemical Corporation (China)

- Shell plc (UK)

- China National Petroleum Corporation (China)

- Formosa Plastics Corporation (US)

- INEOS Group Ltd. (UK)

- Exxon Mobil Corporation (US)

- ZEON Corporation (Japan)

- Shanghai Petrochemical (China)

Recent Industry Developments :

Product Launches:

- In January 2024, Michelin, alongside partners IFPEN and Axens, officially launched France's first industrial-scale pilot facility for producing bio-based butadiene from biomass-derived ethanol at its expansive Bassens site near Bordeaux. With support from ADEME, the French Agency for Environment and Energy Management, the collaborators aim to refine and commercialize this sustainable process to synthesize the compound using renewable plant sources rather than petrochemicals.

Product Expansions:

- In January 2024, Evonik announced the expansion of its capacities for hydroxyl-terminated polybutadienes (HTPB) in Central and South AmericaThis market aims to meet the growing butadiene market trend in polybutadiene products, crucial in aerospace, defense, and electronics for applications like solid rocket fuels and adhesives.

Butadiene Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 19.80 Billion |

| CAGR (2024-2031) | 5.4% |

| By Application |

|

| By Production Process |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Butadiene Market? +

Butadiene Market size is estimated to reach over USD 19.80 Billion by 2031 from a value of USD 12.95 Billion in 2023 and is projected to grow by USD 13.43 Billion in 2024, growing at a CAGR of 5.4% from 2024 to 2031.

What specific segmentation details are covered in the butadiene market report? +

The specific segment details that are covered in the butadiene market report are application, production process, and end-use industry.

Who are the major players in the butadiene market? +

The major players in the butadiene market are TPC Group (US), China Petroleum and Chemical Corporation (China), INEOS Group Ltd. (UK), Shell plc (UK), China National Petroleum Corporation (China), Formosa Plastics Corporation (US), Exxon Mobil Corporation (US), ZEON Corporation (Japan), and Shanghai Petrochemical (China)

Which region will lead the global butadiene market? +

The Asia Pacific region will lead the global butadiene market.