- Summary

- Table Of Content

- Methodology

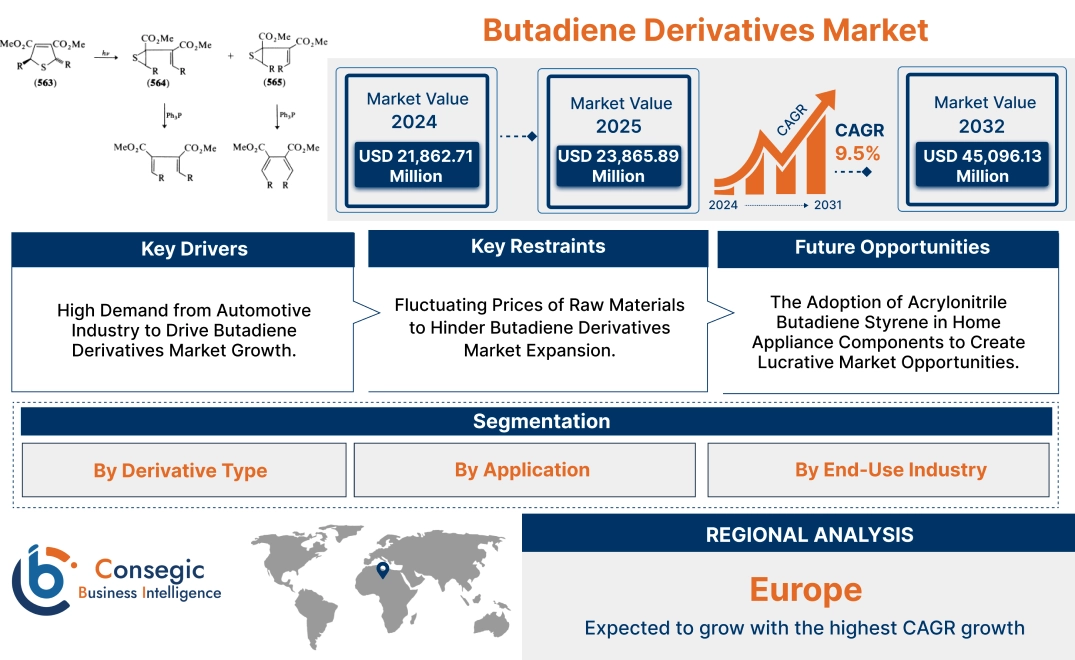

Butadiene Derivatives Market Size:

The Butadiene Derivatives Market size is growing with a CAGR of 9.5% during the forecast period (2025-2032), and the market is projected to be valued at USD 45,096.13 Million by 2032 from USD 21,862.71 Million in 2024. Additionally, the market value for 2025 attributed to USD 23,865.89 Million.

Butadiene Derivatives Market Scope & Overview:

Butadiene is a chemical compound with the formula C4H6. It is a colorless gas with a characteristic odor. Butadiene derivatives is a group chemical compounds that are derived from butadiene. They are copolymers produced by reaction of butadiene with styrene and acrylonitrile. The types of derivatives are styrene butadiene rubber (SBR), polybutadiene rubber (PBR), acrylonitrile butadiene styrene (ABS), nitrile butadiene rubber (NBR), and more. These derivatives are used in several applications including tires, seals, & interior components for automotives, roofing materials, flooring, pipes, adhesives, & insulation for construction, toys, packaging, & other consumer products. By end use industry, these derivatives are used in automotive, construction, electronics, consumer goods, and others.

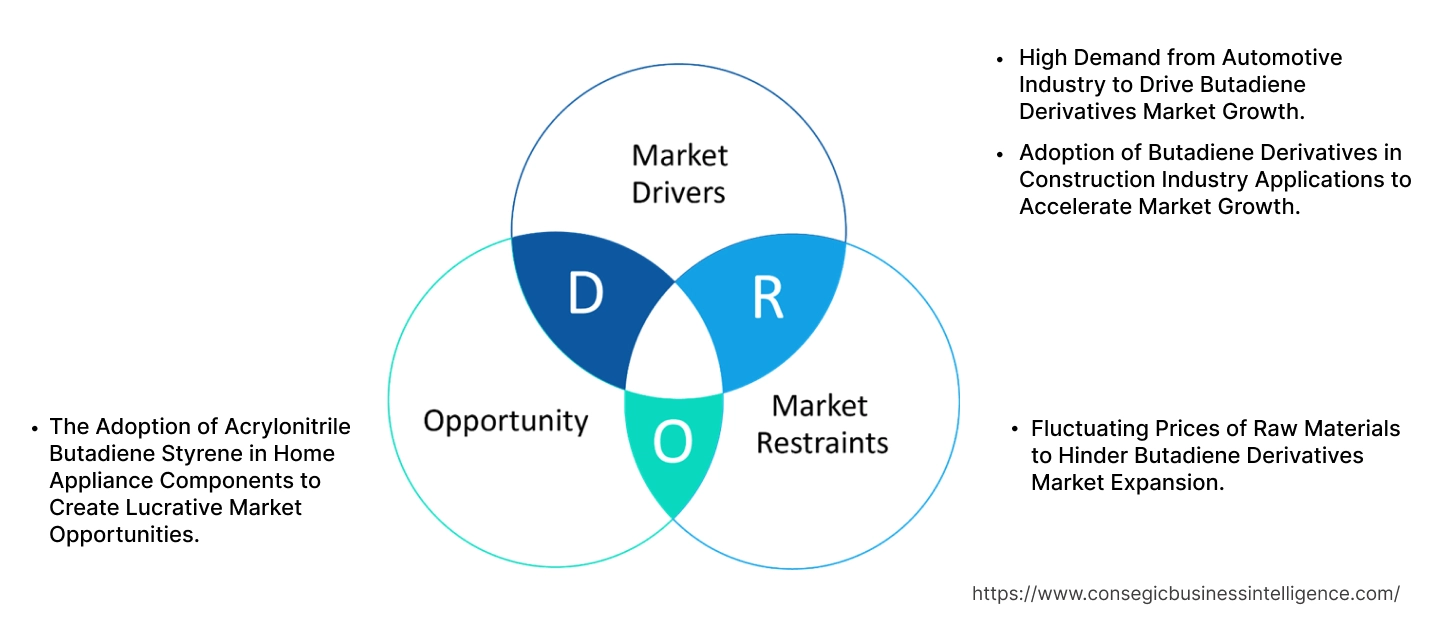

Key Drivers:

High Demand from Automotive Industry to Drive Butadiene Derivatives Market Growth.

The high adoption of butadiene derivatives in automotive components, particularly in tires, is driving market growth. A large share of styrene-butadiene rubber and polybutadiene rubber is used in tire manufacturing, both for new vehicles and the replacement tire market. Various other rubber components in automobiles, such as hoses, belts, seals and gaskets rely on the flexibility and durability of SBR. Additionally, rubber components are crucial for vibration dampening in engine mounts and suspension systems. ABS is widely used in car interiors, including dashboards, instrument panels, door panels, and console. Moreover, the significant growth in manufacturing of automotives is driving the requirement for butadiene derivatives.

- For instance, according to the data provided by TD Economics, automotive production activity has grown significantly with 15.6 million vehicles produced in North America in 2023, a 9.6% gain relative to 2022. U.S. light vehicles sales in turn grew 12.7% in 2023.

This demand from the automotive sector positively impacts on the butadiene styrene market growth.

Adoption of Butadiene Derivatives in Construction Industry Applications to Accelerate Market Growth.

ABS is a material of choice for pipes and fittings due to its impact resistance, durability, and ease of processing making them suitable for plumbing, drainage, and ventilation systems. Styrene butadiene rubber is widely used in roofing membranes for weather protection and enhanced durability, as well as in sealants and adhesives for bonding roofing materials. Several factors drive this adoption including the performance benefits of butadiene derivatives, such as durability, ease of installation, cost-effectiveness, and design flexibility. Hence, considering the characteristic functionalities, manufacturers are increasingly utilizing derivatives in construction materials.

- For instance, in September 2024, Danfoss Power Solutions announced the launch of its Aeroquip by Danfoss GH493 four-wire spiral rubber hose, made from SBR. This premium hydraulic hose meets construction sector standards in flexibility, lifetime, and working pressure.

Thus, due to the above-mentioned factors, the utilization of butadiene derivatives in construction applications is contributing to the market expansion.

Key Restraints:

Fluctuating Prices of Raw Materials to Hinder Butadiene Derivatives Market Expansion.

Butadiene is primarily a byproduct of crude oil refining. Its price is directly linked to crude oil prices, which are volatile. Several factors including geopolitical conflicts, government regulations on the environmental effects caused by the production of crude oil, and the availability of alternative materials are leading to their price sensitivity. Additionally, geopolitical conflicts are the major factor leading to the supply chain disruption of crude oil further resulting in fluctuations in their final prices. Consequently, the rise or fall in crude oil prices affects the production of butadiene and its derivatives. The instability in prices disrupts the budgeting and planning for manufacturers relying on butadiene derivatives as they face unpredictable cost fluctuations. Thus, the fluctuating prices of raw materials negatively impacts butadiene derivatives market expansion.

Future Opportunities :

The Adoption of Acrylonitrile Butadiene Styrene in Home Appliance Components to Create Lucrative Market Opportunities.

The rise in developments of home appliances using ABS is expected to support the market over the forecast period. ABS serves as a versatile thermoplastic polymer for various home appliance applications. It is utilized for the production of plastic components for home appliances such as appliance control panels, appliance housing, washing machine parts, and refrigerator lines among others. Its high impact resistance, rigidity, and dimensional stability are crucial characteristics for home appliance components. ABS withstands wear and tear, making it a material of choice for producing long-lasting appliance parts. As a result, the key players operating in home appliances are increasingly adopting ABS.

- For instance, in May 2024, BSH Home Appliances has selected ABS resin by ELIX Polymers for the stand, arm and other components of the latest BOSCH Stand Mixer. ELIX Polymers has created a specialized, custom-made ABS P3H-AT CR25 in multiple colors.

Thus, developments of home appliances using ABS are creating butadiene derivatives market opportunities over the upcoming period.

Butadiene Derivatives Market Segmental Analysis :

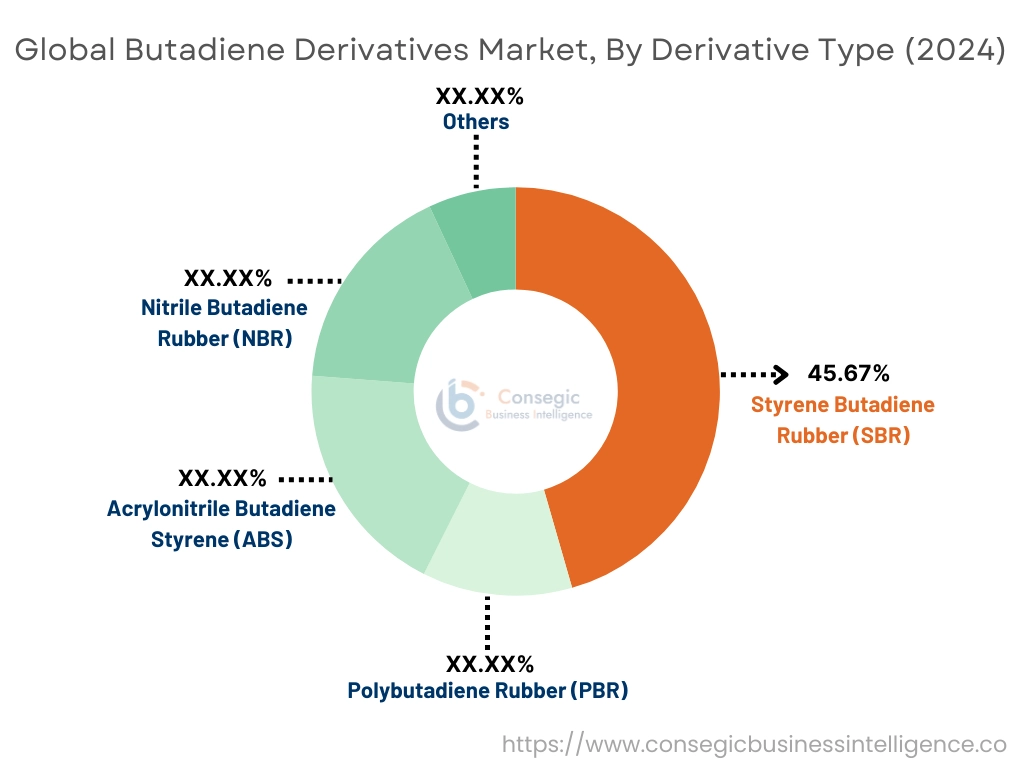

By Derivative Type:

Based on derivative type, the market is categorized into styrene butadiene rubber (SBR), polybutadiene rubber (PBR), acrylonitrile butadiene styrene (ABS), nitrile butadiene rubber (NBR), and others.

Trends in the Derivative Type:

- The emphasis on the high-performance tires made with solution SBR, which offers lower rolling resistance.

- The inclination towards development of recycled acrylonitrile butadiene styrene.

The styrene butadiene rubber (SBR) segment accounted for the largest market share of 45.67% in 2024.

- Styrene butadiene rubber (SBR) holds the dominant position in the market. It is available in two main forms.

- Emulsion SBR offers a good balance of abrasion resistance and flexibility. Solution SBR is known for its superior performance due to its better wet grip and lower rolling resistance.

- SBR's key properties include abrasion resistance, flexibility even at low temperatures, ease of processing, and cost-effectiveness.

- Due to these characteristics this derivative of butadiene is widely used in tire manufacturing, footwear, hoses, belts, adhesives, sealants amongst others.

- Thus, the growing requirement from end-use sectors are primary factors supporting the necessity of styrene butadiene rubber.

- Collectively, aforementioned factors support segment towards upward trajectory in the overall market for butadiene derivatives.

The acrylonitrile butadiene styrene (ABS) segment is expected to grow at the fastest CAGR in the forecast period.

- Exceptional versatility and wide range of applications are the key pointers supporting the segment towards upward trajectory in future years.

- Several properties of ABS, including impact resistance, toughness, rigidity, and processability, make it suitable for several sectors.

- Additionally, the preference towards lightweighting in automotive and electronics favors its adoption.

- Technological advancements leading to improved ABS grades, growing focus on the development of recycled ABS along with its adoption in the production of home appliance components are creating upward trajectory of segment.

- For instance, as per data released by TNO, in March 2024, company's goal is to introduce innovative technology by 2030 that employs dissolution to recycle ABS in a circular manner. Presently, the company is collaborating with ABS producer ELIX Polymers to assess the feasibility of implementing the process to recycle ABS polymers sourced from end-of-life electronics.

- Thus, considering these factors, the acrylonitrile butadiene styrene (ABS) segment is expected to register high CAGR in the forecast years.

By Application:

The application segment is categorized into automotive components, electronics appliances, packaging materials, adhesives & sealants, pipes & fittings, material handling equipment, and others.

Trends in the Application

- Advancements in electronics and appliance design influences the adoption of specialized grades of derivatives.

- Focus towards eco-friendly adhesives and sealants influence the formulations developed using bio-based derivatives of butadiene.

The automotive components segment accounted for the largest butadiene derivatives market share in 2024.

- Automotive components are dominating the market due to the critical role of butadiene derivatives in tire manufacturing.

- They are extensively incorporated in vehicle interiors and exterior components.

- In vehicle interiors, they are used in dashboard assemblies, center consoles, door panels, seat belt components, and instrument panel housings among others. Exterior applications include grilles, mirror housings, and wheel covers.

- Automotive components must meet stringent performance and durability standards. This requires derivatives of butadiene with specific properties tailored to the application, such as high abrasion resistance for tires, impact resistance for interior parts, and heat resistance for under-the-hood components.

- Furthermore, the growing adoption of sustainable materials for automotive components is fueling the segment towards upward

- For instance, June 2023, MBA Polymers UK, launched a UL-certified acrylonitrile butadiene styrene product, ABS 4125 UL, that contains more than 95% recycled content and is used in the manufacturing of automobile components.

- Owing to the above-mentioned factors, the automotive components segment states it’s prominence in the overall butadiene derivatives market demand.

The electronic appliances segment is expected to grow at the fastest CAGR over the forecast period.

- The electronic appliances segment is expected to grow at the fastest rate due to the increasing adoption in household appliances and electronic devices.

- Butadiene derivative serve crucial role in the development of electrical appliances, owing to the combination of mechanical, thermal, and electrical properties.

- SBR, PBR, NBR, and ABS are widely used in electronic enclosures, computer keyboards, remote controls, phone cases, audio/video equipment housings, power sockets, and phone chargers among others.

- Thus, due to the above-mentioned factors, the electronic appliances segment is expected to register the fastest CAGR over the forecast period in the overall butadiene derivatives market demand.

By End-Use Industry:

Based on end use industry, the market is categorized into automotive, construction, electronics, consumer goods, and others.

Trends in the End Use Industry:

- The trend towards lighter vehicles to improve fuel economy supporting the use of rubber in automotives.

- There is growing trend in electronics towards smaller, lighter, and more portable devices.

The automotive segment accounted for the largest market share in 2024.

- Automotive industry is a major consumer of these derivatives, particularly in tires and various plastic components.

- The automotive sector is increasingly focusing on improving fuel efficiency and reducing emissions. This drives a shift towards lighter vehicles, which positively impacts the use of butadiene derivatives to replace heavier metal components.

- In addition to this, the rise in the adoption of electronic vehicles is a prominent factor. EV tires have different requirements influencing the need for specific rubber types. The overall increase in vehicle demand, including EVs, supports the market.

- For instance, as per data provided by the Government of the UK, sales of electronic vehicles with 327,000 registered in 2021 which is a 77% rise compared to 2020.

- Thus, based on the butadiene derivatives market analysis, the aforementioned factors contribute to automotive as prominent end-use sector.

The electronics segment is expected to grow at the fastest CAGR in forecast years.

- The electronic end use sector is expected to occupy growing contribution to the market.

- The need for electronic devices such as smartphones, laptops, tablets, smart home devices, wearables, and more is expanding. This results in increased need for materials that supports the increased production of these devices, including butadiene derivatives.

- In addition to this, the adoption of smaller, lighter, and more portable devices is increasing. This creates the need for high impact resistant and durable materials such as derivatives of butadiene.

- This analysis positions electronics as a growing end user segment within the dynamic butadiene derivatives

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

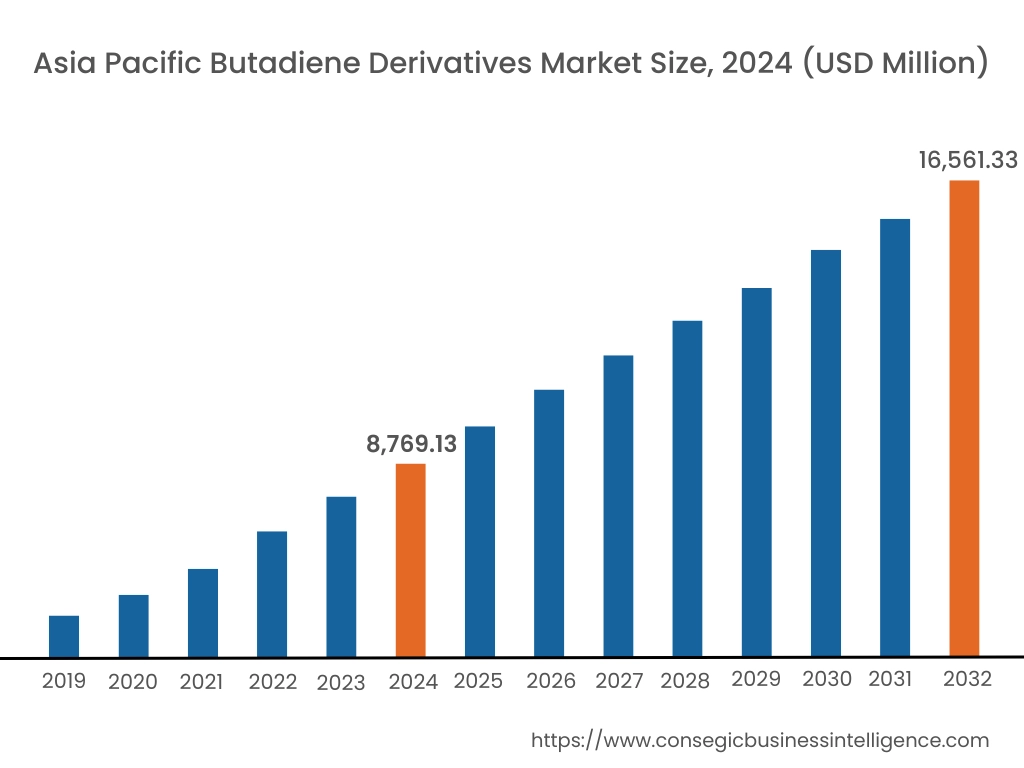

In 2024, Asia Pacific accounted for the highest Butadiene Derivatives market share at 40.11% and was valued at USD 8,769.13 Million and is expected to reach USD 16,561.33 Million in 2032. In Asia Pacific, the China accounted for the largest share of 34.33% during the base year of 2024.

The high automotive production is the key factor that is leading to the upward trajectory of butadiene derivatives market in Asia Pacific. Rapidly accelerating automotive manufacturing for passenger cars and commercial vehicles in countries such as China, India, and South Korea is driving the need for SBR, PBR, NBR, and ABS in the production of automotive parts. A large portion of derivatives of butadiene goes into tire manufacturing. Asia Pacific is also a major producer of tires. The volume of tires needed fuels a huge demand for these rubber derivatives. Collectively, the growing vehicle production creates a higher requirement for butadiene derivatives.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with 11.6% year-on-year growth.

In addition to this, growing consumer electronics and appliance markets also drives the upward trajectory of market. Therefore, as per market analysis, the increase in automotive production along with the requirement from electronics sector supports in butadiene derivatives market trend in Asia Pacific region.

In Europe the butadiene derivatives market analysis is experiencing the fastest growth with a CAGR of 11.5% over the forecast period. Shift towards development of electronic appliance components using ABS serves a prominent role butadiene derivatives market growth in Europe. Europe has a well-established appliance market. This results in the increasing utilization of ABS in the production of home appliance components, such as washing machine parts, dishwasher components, refrigerator linings, and others. Additionally European consumers and regulations prioritize energy efficiency. ABS contributes to this through its use in refrigerator linings and other insulating components. As a result, key players are focusing on developing electronic appliances by incorporating ABS, further supporting butadiene derivatives market opportunities in Europe.

The growing requirement for butadiene derivatives in construction sector is one of the primary factors fueling the market towards upward trajectory across North America. Requirements for new housing, renovations & remodeling projects, and prefabricated & modular construction drives the need for building materials, including those made from butadiene derivatives. In addition to this, construction of office buildings, retail spaces, hotels, and other commercial structures contributes to the adoption of these derivatives for the production of pipes & fittings, roofing materials, flooring, adhesives and sealants. Collectively, the combination of above-mentioned factors creates upward trajectory of market across North America.

The Middle East and African market is led by the rising demand for consumer goods. Continued economic development in these countries supports the upward trajectory of the consumer goods sector. Rubber and ABS serve as versatile materials widely used in various consumer products such as footwear, packaging materials, toys, sporting goods, and others due to their balance of properties. The rise of e-commerce in the region is further fueling the need for consumer goods, as online shopping becomes more accessible. Owing to these factors, the market for butadiene derivatives in the MEA is growing at considerable rate.

Latin America is an emerging region in the butadiene derivatives market trend, with significant potential for innovation. The Latin American automotive sector is experiencing a significant rise, driven by increasing disposable incomes, government initiatives, and rising requirements for personal mobility. This has led to a corresponding increase in the need for derivatives of butadiene. Additionally, rapid urbanization and infrastructure development are driving the need for efficient transportation solutions. This analysis presents a substantial potential for automotive component manufacturers and suppliers to utilize butadiene derivatives.

Top Key Players and Market Share Insights:

The global Butadiene Derivatives Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Butadiene Derivatives market. Key players in the Butadiene Derivatives industry include-

- ZEON CORPORATION(Japan)

- LG Chem (South Korea)

- Toray Industries (Japan)

- Reliance Industries Limited (India)

- China Petroleum & Chemical Corporation (China)

- ARLANXEO (Netherlands)

- TRP Polymer Solutions Ltd (United Kingdom)

- LANXESS (Germany)

- SABIC (Saudi Arabia)

- INEOS (United Kingdom)

Recent Industry Developments :

Product Launches:

- In June 2024,Trinseo announced the launch of new recycled-containing acrylonitrile-butadiene-styrene (ABS) available under the MAGNUM™ ECO+, MAGNUM CR and TYRIL CR trade names.

Production Expansion:

- In April 2023, Hainan Baling Chemical New Material, a subsidiary of China Petroleum & Chemical Corporation launched production of styrene butadiene copolymer project in Hainan, China. The project targets the annual production capacity of 170,000 tons.

- In February 2023, Arlanxeo, launched a new 65 ktpa production line for polybutadiene rubber in Brazil.

Butadiene Derivatives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 45,096.13 Million |

| CAGR (2025-2032) | 9.5% |

| By Derivative Type |

|

| By Application |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Butadiene Derivatives market? +

In 2024, the Butadiene Derivatives market is USD 21,862.71 Million.

Which is the fastest-growing region in the Butadiene Derivatives market? +

Europe is the fastest-growing region in the Butadiene Derivatives market.

What specific segmentation details are covered in the Butadiene Derivatives market? +

By Derivative Type, Application, and End Use Industry segmentation details are covered in the Butadiene Derivatives market.

Who are the major players in the Butadiene Derivatives market? +

ZEON CORPORATION (Japan), LG Chem (South Korea), ARLANXEO (Netherlands) are some of the major players in the market.