- Summary

- Table Of Content

- Methodology

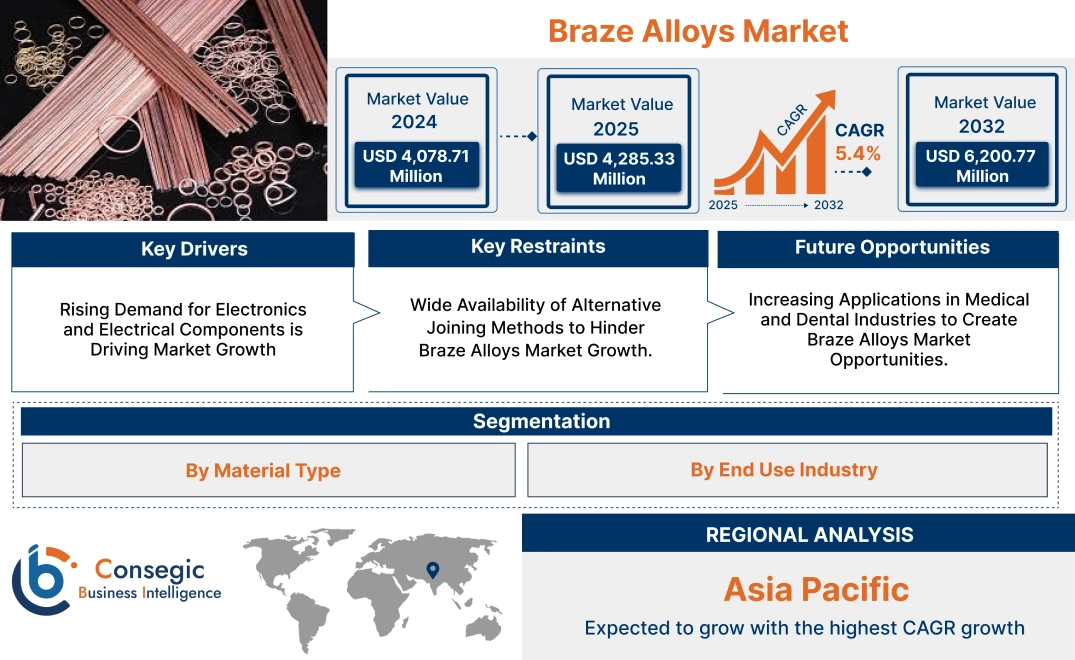

Braze Alloys Market Size:

The Braze Alloys Market size is growing with a CAGR of 5.4% during the forecast period (2025-2032), and the market is projected to be valued at USD 6,200.77 Million by 2032 from USD 4,078.71 Million in 2024. Additionally, the market value for the 2025 attributes to USD 4,285.33 Million.

Braze Alloys Market Scope & Overview:

Brazing alloys are defined as filler metals which are used during the brazing process. The brazing process is a technique that is used to join metals. This process is conducted by melting a filler metal and allowing it to flow into the gap between workpieces. Brazing involves heating the filler metal to a temperature that is above its melting point. There are several types of brazing alloys available across the globe. A few of the specific braze alloys are copper-based, silver-based, nickel-based, aluminum-based, gold-based, and others. These alloys find applications in several sectors such as automotive, aerospace, electronics, amongst others.

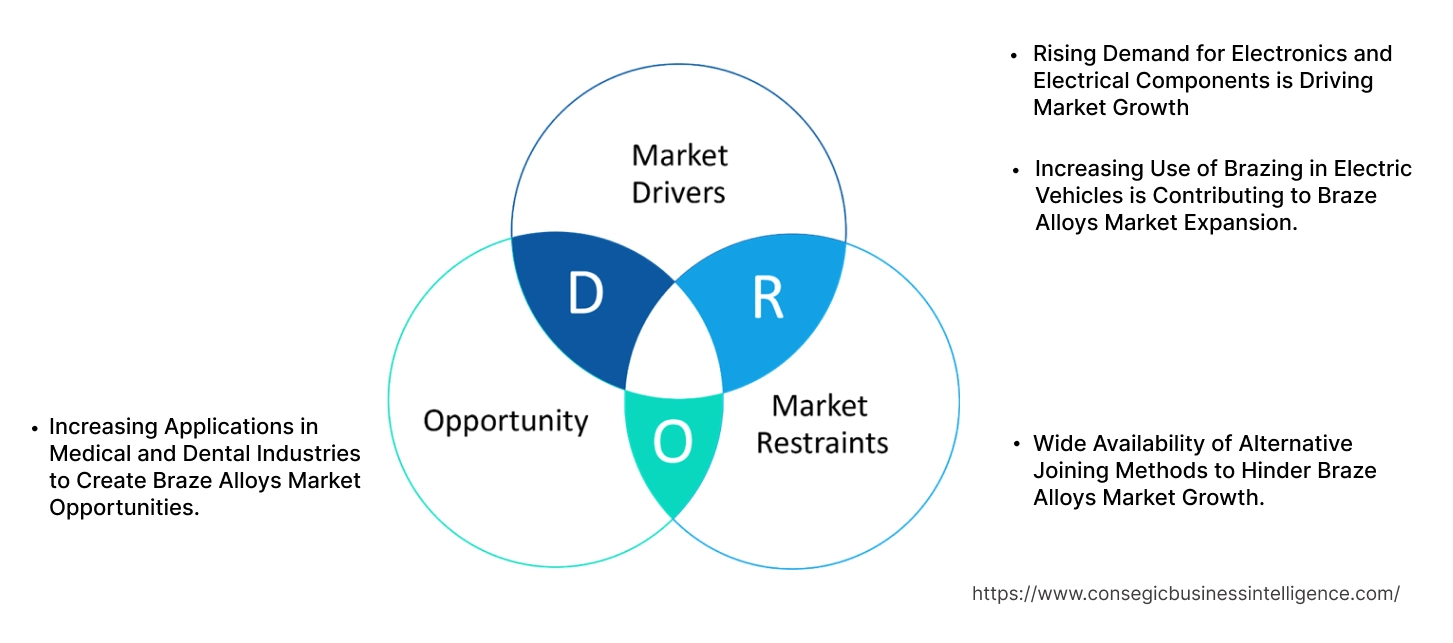

Key Drivers:

Rising Demand for Electronics and Electrical Components is Driving Market Growth

Electronic devices are experiencing strong demand due to the increase in complex nature of these devices. Braze alloys help by offering reliable and specific methods of joining. This method for joining is required by a lot of circuits and components of complex nature.

- For instance, in 2023, according to Business Standards, the demand for sub-assemblies and components contributed to approximately more than 40% of the electronic production across the globe.

Thus, as the growing requirement for consumer electronics is contributing to the braze alloys market demand. This is showcasing a positive impact on the position of this alloys in the electronics and electrical sector.

Increasing Use of Brazing in Electric Vehicles is Contributing to Braze Alloys Market Expansion.

Electric vehicles require thermal management for battery safety and performance. Braze alloys help to address this concern by incorporation of aluminum-based alloys in the production of cooling system for these batteries. Hence, as the requirement for electric vehicles grows, the trend for braze alloy also increases.

- For instance, in 2023, according to EV Volume, roughly around 14.2 million new plug-in hybrids and battery electric vehicles were sold. This represented an increase of 35% compared to the previous year.

Thus, as the requirement in the EV sector is expected to drive substantially, the requirement for brazing alloys is on a positive side, leading to market growth.

Key Restraints:

Wide Availability of Alternative Joining Methods to Hinder Braze Alloys Market Growth.

The availability of alternative methods for joining metals offers hindrance to market growth. A few of these alternatives are the welding process, soldering process, amongst others. The welding process is of less expensive nature as it is mainly suited for bigger workplaces. Additionally, soldering is preferred due to the convenience it provides in the electronics sector. This competition from alternative methods creates concerns related to price. Moreover, it also requires the manufacturer of braze alloys to showcase a distinct feature apart from its alternatives to gain more market share. Thus, due to the factors mentioned, wide availability of alternatives is acting as a restraint to the braze alloys market growth.

Future Opportunities :

Increasing Applications in Medical and Dental Industries to Create Braze Alloys Market Opportunities.

The usage of braze alloys in the field of medical and dental is increasing due to the biocompatibility these alloys provide. A few of these alloys are copper-based, silver-based, gold-based, amongst others. These features make them a suitable option for their usage in medical devices and implants.

- For instance, according to American Dental Association, in the U.S. the dental spending grew by 2.5% in 2023 prior to 2022. This included an increase in investments related to medical devices, including usage of braze alloys.

Therefore, the rising requirement for advanced medical devices and implants is having a positive impact on the market across the globe.

Braze Alloys Market Segmental Analysis :

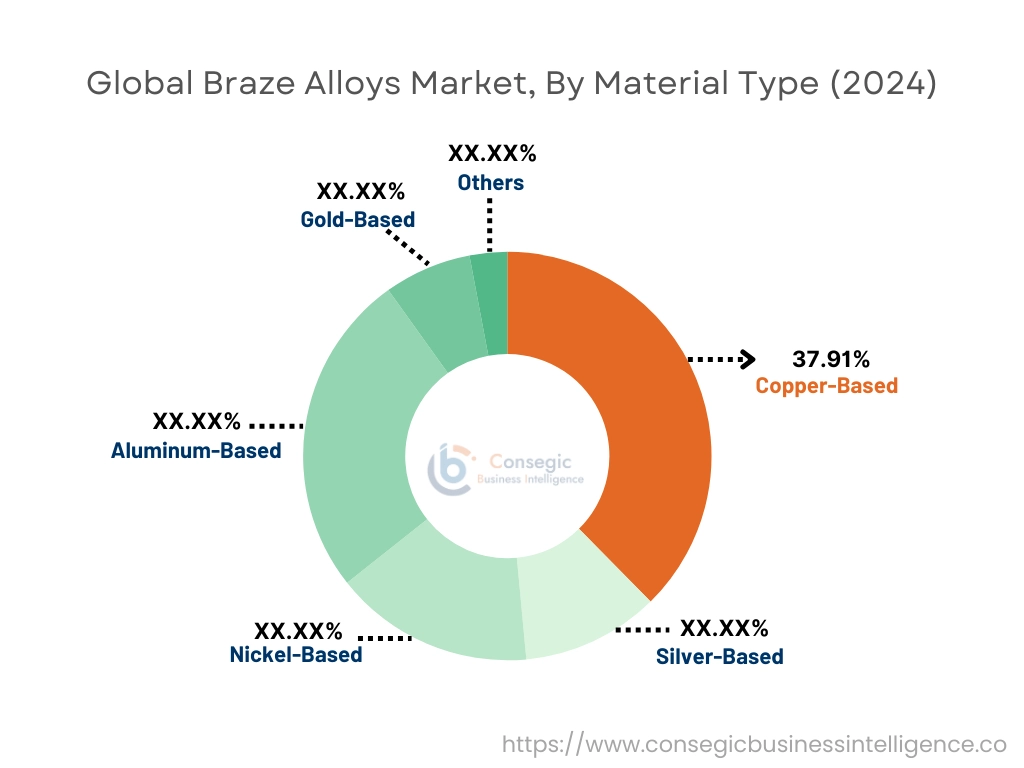

By Material Type:

Based on Material Type, the market is categorized into copper-based, silver-based, nickel-based, aluminum-based, gold-based, and others.

Trends in Material Type:

- The growing demand for copper-based alloys in order to join conductor and others electrical parts.

- The rise in usage of silver-based alloys due to their wetting properties along with their flowability.

The copper-based segment accounted for the largest braze alloys market share of 37.91% in 2024.

- Copper-based alloys hold prominence due to the features it provides. A few of these features are less expensive in nature, versatile amongst others

- Their usage across several sectors, such as electrical and electronics, automotive, amongst others is growing.

- One of the key factors is the increasing requirement for electrical components and devices. These alloys are used for copper conductors and other electrical parts.

- Furthermore, the rising use of copper-based alloys in HVAC systems is attributing to the development of the market.

- For instance, according to WebFx, roughly around 3 million units of HVAC are replace on a yearly basis. The wide utilization of copper-based braze alloys for joining components in these HVAC systems has led to market development.

- As a result, based on the above-mentioned factors, copper-based alloy segment is dominating the braze alloys market demand.

The silver-based segment is expected to be the fastest growing segment over the forecast period.

- The silver-based segment is experiencing development due to the rise in its inclusion in the aerospace sector.

- These alloys provide features such as high strength, corrosion resistance amongst others. These make them a suitable option for usage in aerospace as well as other sectors. A few of these other industries incudes medical devices, and automotive

- In addition to this, the use of silver-based alloys in jewelry and decorative items is having a positive impact on market development.

- Moreover, the focus on research and development efforts by key manufacturers in order to improve their properties is attributing to the segment development.

- As per the market analysis, these factors contribute to the fastest rate of the silver-based segment within the Braze Alloys market trend.

By End-Use Industry:

The end use industry segment is categorized into automotive, aerospace, electronics and electrical, construction, healthcare, and others.

Trends in the End Use Industry:

- The increasing requirement and use of braze alloy for complex components in EV.

The electronics and electrical segments accounted for the largest market share in 2024.

- The wide application of braze alloy, particularly copper-based and aluminum-based alloys for manufacturing in electronic and electrical sector is growing.

- These braze alloys offer characteristics from connectors to power devices as well as semiconductors. They provide reliable joints and make sure the device performance is high along with factors such as safety and durability.

- In addition, large-scale production of several electronic components and parts has a direct impact on the requirement for these alloys.

- Moreover, the focus of key players towards technological advancements within the electronics sector are further attributing to market growth.

- Thus, as per the market analysis, due to the above-mentioned factors and trends, the electronics and electricals segments dominate the braze alloys market trends.

The aerospace segment is expected to be the fastest growing segment over the forecast period.

- The increase in global air travel along with the rise in aircraft production have led to the requirement for specialized brazing alloys.

- The performance needs of the aerospace sector for components such as engine parts and heat shields require the use of brazing alloys. These alloys are preferred due to their high resistance of temperature amongst others.

- For instance, Morgan Advanced Materials recently launched Ultinex®. It is a brazing technology that is used to join ceramics to metal and primarily caters to the aerospace sector.

- Therefore, as per analysis and trends, the aerospace segment is expected to be lucrative over the forecast period.

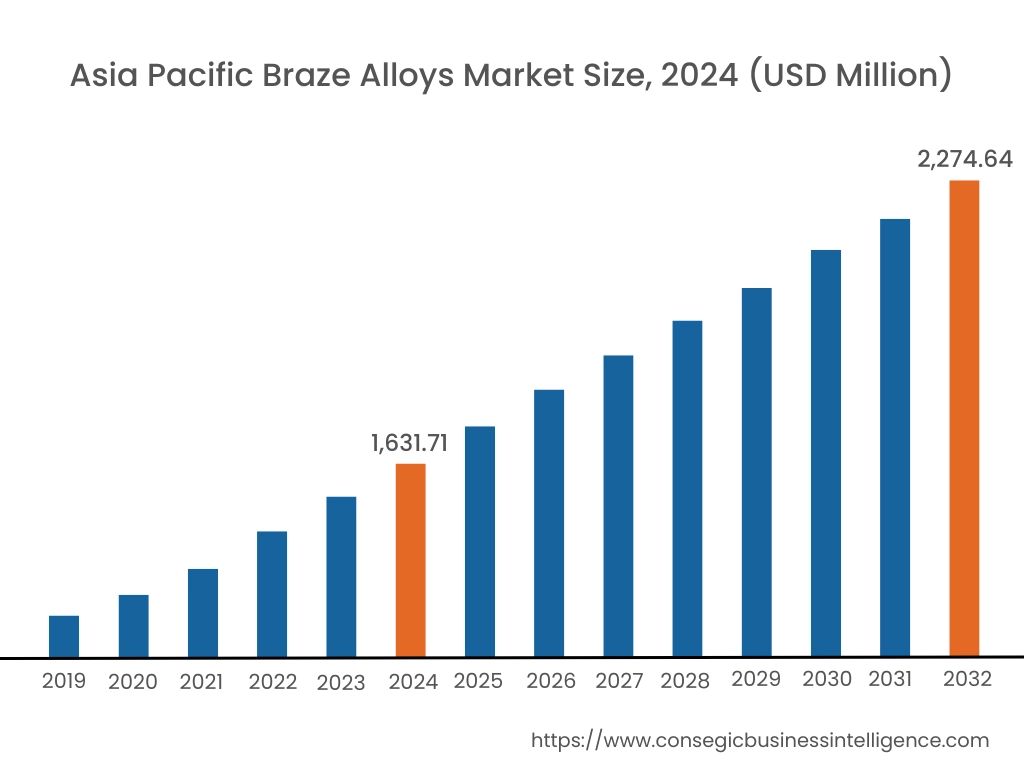

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

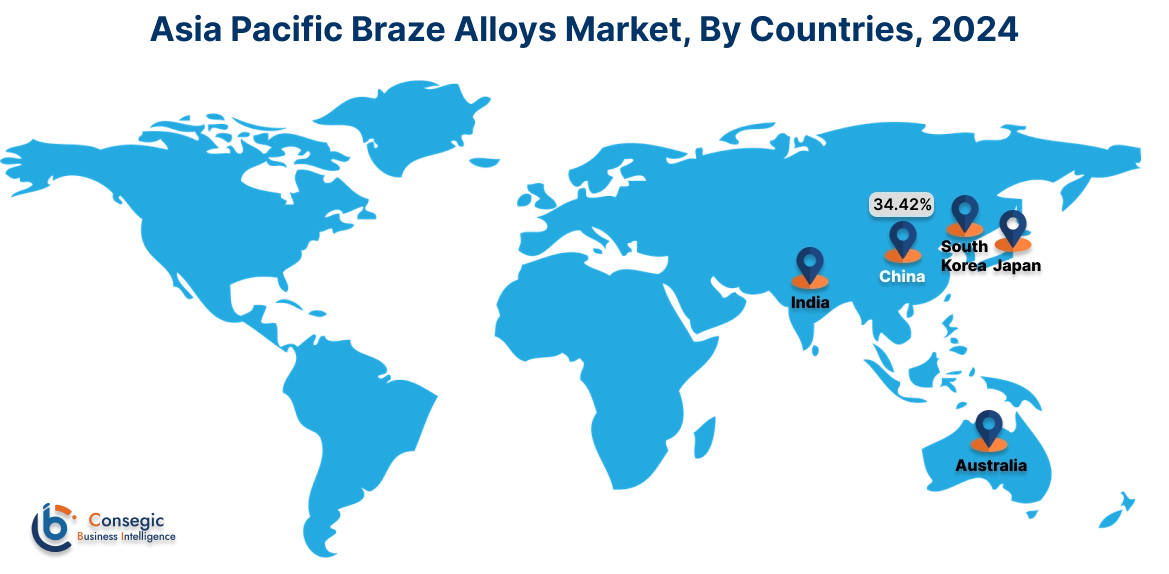

In 2024, Asia Pacific accounted for the highest braze alloys market share at 40.01% and was valued at USD 1,631.71 Million and is expected to reach USD 2,274.64 Million in 2032. In Asia Pacific, China accounted for the market share of 34.42% during the base year of 2024.

Asia Pacific is of prominence due to the fact that it being a well-established region for the production of several electronics and electrical components and parts. Asia Pacific countries such as China, Japan, South Korea are some of the biggest manufacturing hubs for a wide range of consumer devices amongst others.

- For instance, according to the OEC, there was an increase in exports from South Korea’s Electronics and electrical machinery between Nov 2023 to Nov 2024. This increase attributed to roughly USD 2.7 Billion showcasing the growing requirement for these sectors in South Korea.

Thus, due to these factors, the requirement for braze alloy is expected to be the largest in Asia Pacific.

In Europe, the braze alloys industry is experiencing the fastest growth with a CAGR of 7.4% over the forecast period. The increase in the need for battery cooling systems that have very complex designs has led to the requirement for braze alloys. These alloys are used mainly to join the aluminum-based components for them to provide safety and generate higher performance. Moreover, the manufacturers in European countries such as Germany, France are focusing on developing lightweighting components in order to increase the efficiency. They are developing these components with the help of these alloys. Therefore, based on the market analysis, as the requirement for electric vehicles in these European countries is growing, the need for these alloys is also expected to rise over the forecast period.

The North American Braze Alloys market analysis is driven by the increase in trends for these alloys for additive manufacturing (AM). Additive manufacturing helps in the production of complex components that require specialized joining alloys. Brazing is one of the most suitable processes for the joining of dissimilar metals or metals that need superior strength joints. Furthermore, brazing plays a critical role in joining the multiple materials used in AM-fabricated components. It is widely used for sectors like aerospace and automotive. Thus, as per the braze alloys market analysis, due to the above-mentioned factors. Thus, these factors are driving the braze alloys market expansion.

In Latin American braze alloys market, there has been a rising inclination towards the usage of braze alloy in dental and medical applications contributing towards creating lucrative braze alloys market opportunities. The increase in need for medical implants is having a positive impact on market development due to their property of corrosion resistance and biocompatibility amongst others. A few of the medical implants are orthopedic or dental related amongst others. In addition to this, the rise in technological advancements in brazing techniques is creating new areas for generating more market revenue.

In the Middle East and Africa, there has been an increasing rate of adoption for materials of lightweight nature. The inclusion of these lightweight materials into several sectors is one of the key factors driving market development in this region. In GCC Countries, in the automotive industry, there is wide usage of aluminum-based braze alloys as there is a need for joining of lightweight components of vehicles. This aligns with the emission standards set by their government. Similarly, their application in the aerospace sector for joining materials such as aluminum and titanium in spacecraft and aircraft is attributing to the market growth in this region.

Top Key Players and Market Share Insights:

The Global Braze Alloys Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Braze Alloys market. Key players in the Braze Alloys industry include-

- Wall Colmonoy Corporation (U.S.)

- Johnson Matthey PLC (UK)

- Morgan Advanced Materials plc. (UK)

- Oerlikon Metco (Switzerland)

- Bellman-Melcor LLC (U.S.)

- Hobart Brothers (U.S.)

- Indian Solder and Braze Alloys Pvt. Ltd. (India)

- Harris Product Groups (U.S.)

- Lucas Milhaupt (U.S.)

Braze Alloys Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6,200.77 Million |

| CAGR (2025-2032) | 5.4% |

| By Material Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Braze Alloys market? +

In 2024, the Braze Alloys market is USD 4,078.71 Million.

Which is the fastest-growing region in the Braze Alloys market? +

Europe is the fastest-growing region in the Braze Alloys market.

What specific segmentation details are covered in the Braze Alloys market? +

By Material Type and End Use Industry segmentation details are covered in the Braze Alloys market.

Who are the major players in the Braze Alloys market? +

Wall Colmonoy Corporation (U.S.), Johnson Matthey PLC (UK), Hobart Brothers (U.S.), Indian Solder and Braze Alloys Pvt. Ltd. (India), Harris Product Groups (U.S.), Lucas Milhaupt (U.S.) are some of the major players in the market.