- Summary

- Table Of Content

- Methodology

Boron Nitride Market Scope & Overview:

The boron nitride focuses on the production and application of boron nitride, a versatile chemical compound with exceptional thermal, electrical, and mechanical properties. Available in forms such as hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN), this compound is widely used in industries requiring high-performance materials.

Key characteristics include high thermal conductivity, electrical insulation, chemical inertness, and superior lubricating properties, making it suitable for demanding environments. The benefits of this include enhanced durability, reduced friction, and improved thermal management in industrial and electronic applications.

Applications span electronics, aerospace, cosmetics, automotive, and metallurgy for uses such as heat dissipation, cutting tools, coatings, and lubricants. End-users include electronics manufacturers, aerospace companies, and industrial product developers, driven by increasing growth for advanced materials, technological advancements, and growing industrial applications in emerging economies.

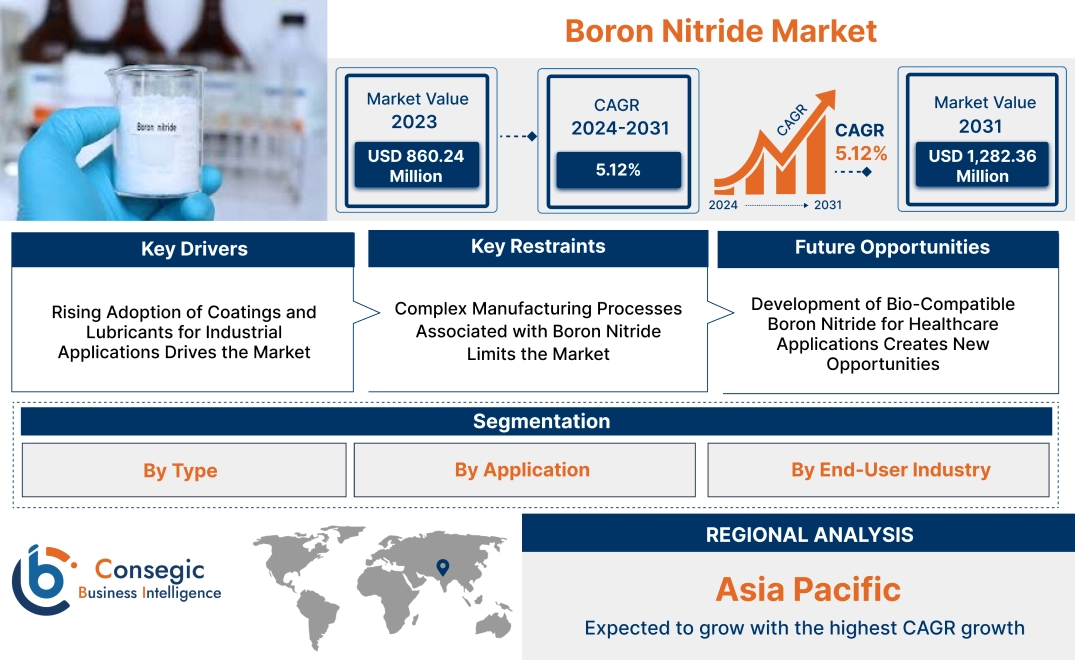

Boron Nitride Market Size:

Boron Nitride Market size is estimated to reach over USD 1,282.36 Million by 2031 from a value of USD 860.24 Million in 2023 and is projected to grow by USD 888.94 Million in 2024, growing at a CAGR of 5.12% from 2024 to 2031.

Key Drivers:

Rising Adoption of Coatings and Lubricants for Industrial Applications Drives the Market

Boron nitride’s exceptional properties, including high-temperature stability, chemical inertness, and excellent lubrication capabilities, are driving its adoption in industrial coatings and lubricants. In the aerospace and automotive sectors, boron nitride-based coatings are widely used to enhance the durability and performance of components subjected to extreme temperatures and corrosive environments. These coatings provide a protective layer that minimizes wear and tear, ensuring longer operational lifespans for machinery and tools.

In the field of lubricants, boron nitride serves as a dry lubricant, offering superior performance in applications where conventional oil-based lubricants fail due to heat or chemical exposure. Its use in metalworking and machining processes reduces friction and improves efficiency, aligning with industrial boron nitride market trends focused on optimizing performance and reducing maintenance costs.

The growing emphasis on sustainability has further highlighted boron nitride as an eco-friendly alternative to traditional materials in coatings and lubricants.

Key Restraints :

Complex Manufacturing Processes Associated with Boron Nitride Limits the Market

The production of boron nitride involves sophisticated synthesis methods, such as chemical vapor deposition and high-temperature sintering, which require advanced equipment and expertise. These processes not only increase production costs but also limit scalability, particularly in regions with underdeveloped manufacturing infrastructure. Additionally, the need for high-purity raw materials further adds to the complexity and cost of production, making it less accessible for cost-sensitive applications.

The technical challenges associated with producing boron nitride in various forms, such as powders, films, or ceramics, also hinder its widespread adoption. Industries aiming to integrate boron nitride into their processes must invest in specialized equipment and training, creating additional barriers to entry. Overcoming these manufacturing hurdles through innovation and process optimization will be critical for expanding the market’s reach and application potential.

Future Opportunities :

Development of Bio-Compatible Boron Nitride for Healthcare Applications Creates New Opportunities

The healthcare sector is emerging as a promising area for boron nitride due to its biocompatibility, chemical inertness, and exceptional mechanical properties. These characteristics make it an ideal material for advanced medical technologies, including drug delivery systems, diagnostic tools, and biomedical implants.

Boron nitride’s ability to form nanostructures, such as nanotubes and nanosheets, has garnered attention for use in targeted drug delivery and cancer therapy, where its high surface area and inert nature enhance treatment precision and effectiveness.Additionally, boron nitride coatings are being explored for use in medical implants, such as orthopedic and dental devices, to improve their durability and compatibility with biological tissues.

Trends in healthcare innovation suggest increasing integration of boron nitride-based materials into next-generation medical solutions. Research and analysis highlight that as healthcare demands for advanced materials continue to evolve, boron nitride’s role in creating safer, more effective, and sustainable medical technologies will expand, presenting significant opportunities for boron nitride market growth.

Top Key Players and Market Share Insights:

The boron nitride market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global boron nitride market. Key players in the boron nitride industry include -

- Saint-Gobain S.A. (France)

- 3M Company (United States)

- Shin-Etsu Chemical Co., Ltd. (Japan)

- C. Starck GmbH (Germany)

- UK Abrasives (United States)

- Denka Company Limited (Japan)

- Momentive Performance Materials Inc. (United States)

- Höganäs AB (Sweden)

- Henze Boron Nitride Products AG (Germany)

- Showa Denko K.K. (Japan)

Boron Nitride Market Segmental Analysis :

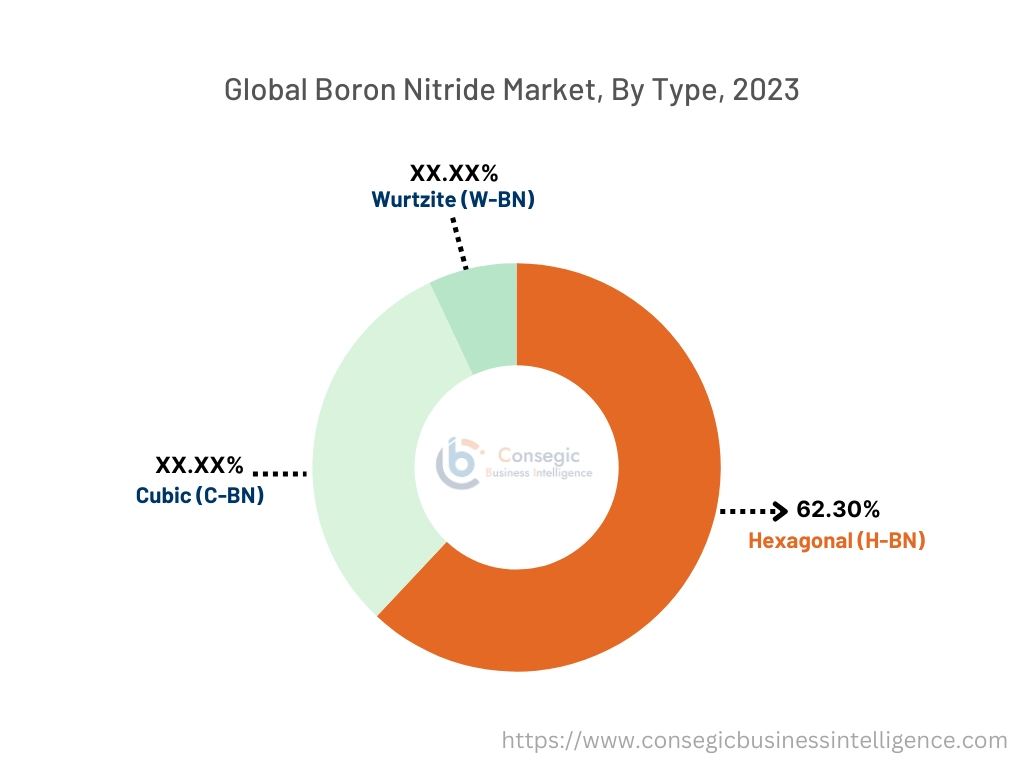

By Type:

Based on type, the market is segmented into hexagonal (h-BN), cubic (c-BN), and wurtzite (w-BN).

The hexagonal boron nitride (h-BN) segment accounted for the largest revenue of 62.30% in the Boron Nitride Market share in 2023.

- Hexagonal is widely utilized for its excellent lubricating properties, chemical inertness, and high thermal stability.

- It is the preferred choice in applications such as coatings, lubricants, and electrical insulation.

- The rising trends of replacing traditional materials with advanced ceramics in thermal management solutions have driven the boron nitride market demand for h-BN.

- Additionally, its increasing boron nitride market opportunities in electronics and automotive sectors to enhance operational efficiency supports its dominance.

- Hexagonal boron nitride market analysis leads surge due to its versatile applications in multiple industries and its superior thermal and chemical properties.

The cubic boron nitride (c-BN) segment is anticipated to register the fastest CAGR during the forecast period.

- Cubic boron nitride, known for its exceptional hardness, is extensively used in abrasives and cutting tools.

- The trends of adopting high-performance cutting materials in manufacturing and industrial processes have significantly boosted demand for c-BN.

- Additionally, advancements in synthesis technologies to improve the availability of high-purity c-BN products further support its growth.

- Cubic boron nitride is expected to grow rapidly, driven by its critical role in high-precision machining and industrial applications.

By Application:

Based on application, the market is segmented into coatings and lubricants, electrical insulation, abrasives and cutting tools, cosmetics, and others.

The coatings and lubricants segment accounted for the largest revenue in the boron nitride market share in 2023.

- Boron nitride’s lubricating and thermal stability properties make it ideal for high-performance coatings and lubricants used in industrial machinery and automotive components.

- The trends of adopting environmentally friendly lubricants and durable coatings to enhance equipment lifespan have propelled the demand for boron nitride in this segment.

- Additionally, its growing use in the aerospace and defense sectors for high-temperature applications further supports its dominance.

- Coatings and lubricants dominate the market, supported by increasing adoption in industrial and automotive sectors for performance enhancement.

The abrasives and cutting tools segment is anticipated to register the fastest CAGR during the forecast period.

- Boron nitride’s exceptional hardness, particularly in cubic form, makes it indispensable for cutting tools and abrasive applications.

- The trends of adopting advanced machining techniques in manufacturing, aerospace, and automotive industries drive a surge in this segment.

- Furthermore, the increasing focus on precision engineering and reduced material wastage supports the boron nitride market growth of this application.

- Abrasives and cutting tools are expected to grow rapidly, driven by the growth of high-precision machining solutions in industrial applications.

By End-User:

Based on the end-user industry, the market is segmented into electronics, aerospace, automotive, healthcare, and others.

The electronics segment accounted for the largest revenue share in 2023.

- Boron nitride is widely used in the electronics sectors for thermal management and electrical insulation in semiconductors and LED components.

- The trends of miniaturizing electronic devices and the increasing need for efficient heat dissipation have driven demand for boron nitride in this sector.

- Additionally, its compatibility with advanced manufacturing processes, such as 3D printing, further supports its adoption.

- The electronics sector leads the market, supported by the rising trends of integrating advanced thermal management materials in compact electronic devices.

The aerospace segment is anticipated to register the fastest CAGR during the forecast period.

- The aerospace sector relies on boron nitride for its thermal and structural properties, which are critical in high-temperature and high-pressure environments.

- The increasing demand for lightweight and durable materials in aerospace manufacturing, coupled with advancements in material engineering, has propelled this segment.

- Furthermore, its use in protective coatings for aircraft engines and components aligns with the growing boron nitride market trends of adopting advanced materials in the aerospace sectors.

- The aerospace segment is expected to grow rapidly, driven by increasing growth for lightweight, high-performance materials in aircraft manufacturing.

Boron Nitride Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 1,282.36 Million |

| CAGR (2024-2031) | 5.12% |

| By Type |

|

| By Application |

|

| By End-user Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

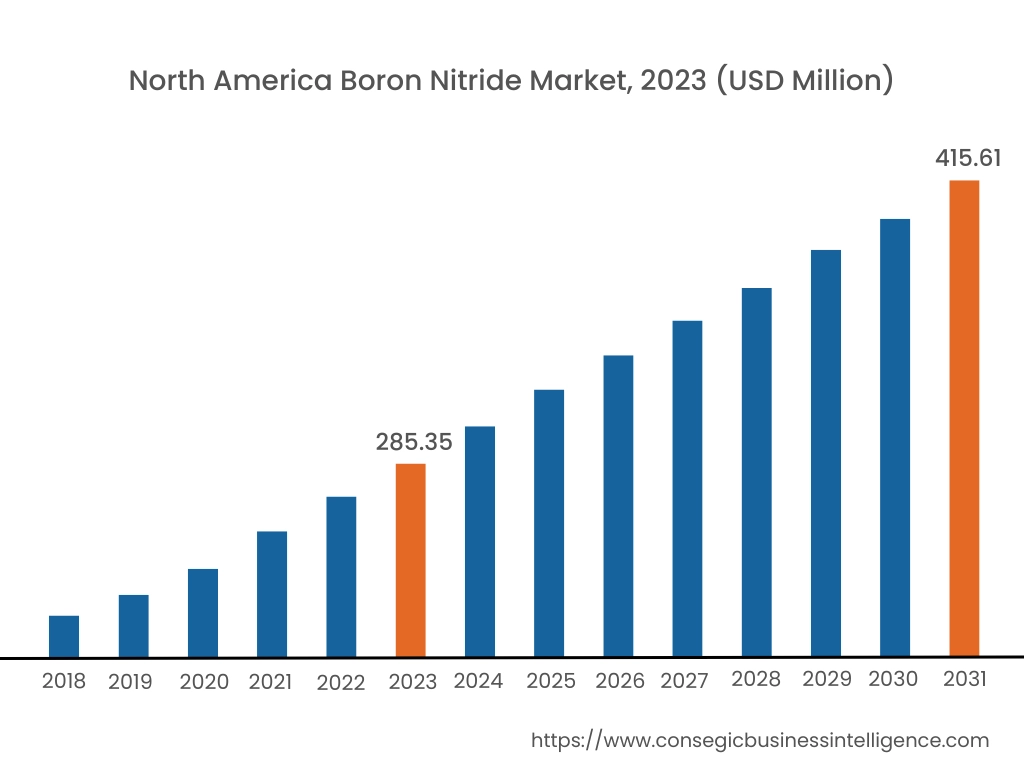

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 285.35 Million and is expected to reach USD 415.61 Million in 2031. In North America, the U.S. accounted for the highest share of 71.30% during the base year of 2023. North America holds a significant share in the boron nitride market analysis, driven by advanced applications in electronics, aerospace, and industrial sectors. The U.S. leads the region with increasing adoption of boron nitride in thermal management materials for electronics and as a lubricant in high-temperature industrial processes. Its use in cutting tools and coatings further enhances its importance in the manufacturing and aerospace industries. Canada contributes through the growing use of ceramics and industrial applications. However, the high cost of boron nitride materials and the complexity of manufacturing processes may limit market expansion.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.6% over the forecast period. Asia-Pacific is the fastest-growing region in the market, as per the analysis it is fueled by rapid industrialization and the expansion of electronics, automotive, and ceramics industries in China, Japan, and South Korea. China dominates the market due to its large-scale production capabilities and growing use of boron nitride in thermal management solutions for electronics and industrial applications. Japan’s focus on high-performance materials for semiconductors and coatings enhances demand for boron nitride. South Korea leverages boron nitride in advanced electronics and energy storage systems. India is also witnessing rising use of boron nitride in ceramics and lubricants, driven by its growing industrial base. However, fluctuating raw material prices and limited awareness about advanced applications may restrict adoption in some parts of the region.

The regional analysis portrays Europe as a prominent market for boron nitride, supported by its advanced automotive, aerospace, and industrial base. Countries like Germany, France, and the UK are key contributors. Germany’s robust automotive sector drives demand for boron nitride in thermal management and lubrication applications, particularly in high-performance engines. France emphasizes the use of boron nitride in aerospace applications due to its lightweight and high-temperature resistance properties. The UK’s focus on advanced manufacturing processes boosts the adoption of precision tools and coatings. However, stringent environmental regulations on raw material sourcing and manufacturing processes could present challenges for the region.

The Middle East & Africa regional analysis is witnessing steady growth in the boron nitride market, driven by increasing industrialization and rising use in oil and gas, aerospace, and defense sectors. Countries like Saudi Arabia and the UAE are focusing on utilizing boron nitride in high-temperature applications and coatings for industrial equipment. In Africa, South Africa is emerging as a market for boron nitride in mining and heavy machinery applications, where its lubricating properties are particularly beneficial. However, limited local production capabilities and reliance on imports for high-purity boron nitride materials may challenge the boron nitride market expansion.

Latin America is an emerging market for boron nitride, with Brazil and Mexico leading the region. Brazil’s growing aerospace and automotive industries utilize boron nitride in thermal management, coatings, and cutting tools. Mexico’s expanding electronics and industrial manufacturing sectors are adopting boron nitride for advanced applications in ceramics and lubricants. The region is also exploring its use in renewable energy systems, particularly for thermal insulation and energy storage. However, economic instability and inconsistent supply chains for raw materials may hinder broader adoption across the region.

Recent Industry Developments :

Innovations:

- In July 2024, UAB researchers developed a switch using hexagonal boron nitride (hBN) that operates at up to 120 GHz, twice the frequency of current silicon-based devices. Unlike traditional switches, it requires no constant power, offering significant energy savings.

- In January 2024, Rice University scientists, led by Kevin Shumard and Professor Angel Martí, developed a novel method using phosphoric acid to purify boron nitride nanotubes (BNNTs). This breakthrough removes impurities, such as boron nitride cages, enhancing the material’s strength and thermal resilience. BNNTs, stronger than steel and capable of withstanding temperatures up to 900°C, hold promise for applications in aerospace, biomedical imaging, and sustainable construction materials.

Key Questions Answered in the Report

What is the projected market size for Boron Nitride by 2031? +

Boron Nitride Market size is estimated to reach over USD 1,282.36 Million by 2031 from a value of USD 860.24 Million in 2023 and is projected to grow by USD 888.94 Million in 2024, growing at a CAGR of 5.12% from 2024 to 2031.

What are the primary drivers of the Boron Nitride market? +

Key drivers include the rising adoption of coatings and lubricants for industrial applications, growing use in the fragrance industry, and expanding applications in electronics, aerospace, and automotive industries due to their high-performance capabilities.

What challenges does the market face? +

The market faces challenges due to complex manufacturing processes, high production costs, and regulatory constraints related to environmental impact and safety standards.

What future opportunities are emerging in the Boron Nitride market? +

The development of bio-compatible Boron Nitride for healthcare applications is a significant opportunity. This includes its potential use in drug delivery systems, diagnostic tools, and biomedical implants.