- Summary

- Table Of Content

- Methodology

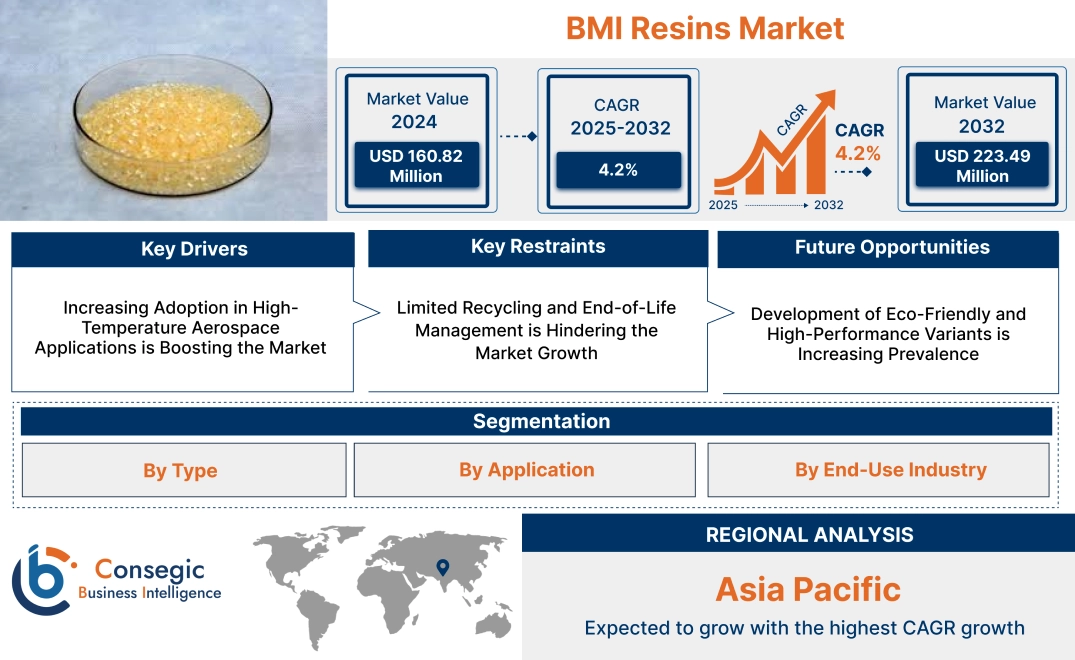

BMI Resins Market Size:

BMI Resins Market size is estimated to reach over USD 223.49 Million by 2032 from a value of USD 160.82 Million in 2024 and is projected to grow by USD 164.71 Million in 2025, growing at a CAGR of 4.2% from 2025 to 2032.

BMI Resins Market Scope & Overview:

The BMI (Bismaleimide) resins are high-performance thermosetting polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance. BMI resins are widely used in industries requiring materials capable of withstanding extreme environmental conditions while maintaining structural integrity. Key characteristics of BMI resins include high glass transition temperature, low dielectric constant, and excellent resistance to moisture and chemicals. These properties make them ideal for demanding applications in aerospace, defense, automotive, and electronics. The benefits include enhanced durability, weight reduction compared to metals, and long-term performance in harsh environments. Applications span aircraft components, automotive structural parts, circuit boards, and defense systems, where advanced materials are critical. End-users include aerospace manufacturers, automotive OEMs, and electronic component producers, driven by increasing demand for lightweight and high-strength materials, advancements in resin processing technologies, and the rising need for fuel-efficient vehicles and energy-efficient systems.

Key Drivers:

Increasing Adoption in High-Temperature Aerospace Applications is Boosting the Market

BMI (Bismaleimide) resins are becoming essential in the aerospace sectors for applications requiring exceptional thermal stability and mechanical strength. These resins are commonly used in structural components like aircraft wings, engine nacelles, and heat shields, where materials must endure extreme temperatures, high stress, and environmental exposure. Their lightweight properties and ability to maintain integrity under harsh conditions make them ideal for improving the efficiency and reliability of aerospace systems.

Trends in advanced material technologies are driving the integration of BMI resins in next-generation aircraft designs, as manufacturers prioritize weight reduction to enhance fuel efficiency and reduce emissions. Analysis highlights that BMI resins are a critical component in achieving the performance and safety standards required for high-temperature aerospace applications, positioning them as a key enabler in the sector's technological advancements.

Key Restraints:

Limited Recycling and End-of-Life Management is Hindering the Market Growth

One of the significant challenges facing the BMI resins market is the lack of efficient recycling and end-of-life management solutions. As thermosetting polymers, BMI resins cannot be melted and reformed, making them difficult to recycle or repurpose after their useful life. This limitation creates concerns about waste management, particularly in industries where sustainability and regulatory compliance are becoming increasingly important.

The absence of scalable recycling methods adds complexity for industries like aerospace and automotive, where the environmental impact of materials is under scrutiny. Trends in circular economy practices and stricter environmental regulations are intensifying the need for sustainable disposal solutions. Addressing these challenges requires innovation in recycling technologies or the development of alternatives that maintain the high-performance properties of BMI resins while offering greater end-of-life flexibility.

Future Opportunities :

Development of Eco-Friendly and High-Performance Variants is Increasing Prevalence

Advancements in polymer chemistry are enabling the creation of eco-friendly BMI resin variants that maintain superior performance characteristics while addressing environmental concerns. These innovations include bio-based formulations and resins designed for reduced carbon footprints, aligning with global sustainability initiatives. Such developments are particularly relevant for industries like aerospace and automotive, which are under increasing pressure to adopt environmentally responsible materials.

Trends in green manufacturing and regulatory compliance present significant opportunities for BMI resin manufacturers to expand their product offerings. Analysis suggests that eco-friendly BMI resins not only meet evolving environmental standards but also open new avenues for applications in sectors prioritizing sustainable practices. By focusing on high-performance, environmentally compatible solutions, manufacturers can strengthen their market presence and cater to the growing emphasis on sustainable materials in industrial applications.

BMI Resins Market Segmental Analysis :

By Type:

Based on type, the market is segmented into thermosetting and thermoplastic.

The thermosetting BMI resins segment accounted for the largest revenue of BMI resins market share in 2024.

- Thermosetting BMI resins are extensively used in high-performance applications requiring superior thermal stability, mechanical strength, and resistance to chemical degradation.

- These resins are commonly utilized in aerospace, automotive, and industrial manufacturing for composite materials, adhesives, and tooling applications.

- Their ability to withstand extreme temperatures and provide excellent durability makes them ideal for producing structural components and high-stress parts.

- The increasing adoption of thermosetting BMI resins in the aerospace and defense sector for manufacturing lightweight and robust components has driven the dominance of this segment portrayed in the market analysis.

The thermoplastic BMI resins segment is anticipated to register the fastest CAGR during the forecast period.

- Thermoplastic BMI resins offer advantages such as reprocessability, toughness, and enhanced impact resistance, making them suitable for applications in automotive and electronics industries.

- These resins are widely used in advanced manufacturing processes such as injection molding and 3D printing to produce complex and lightweight parts.

- The growing demand for thermoplastic BMI resins in applications requiring flexibility and ease of processing, coupled with advancements in resin technology, is expected to propel the rapid BMI resins market growth of this segment.

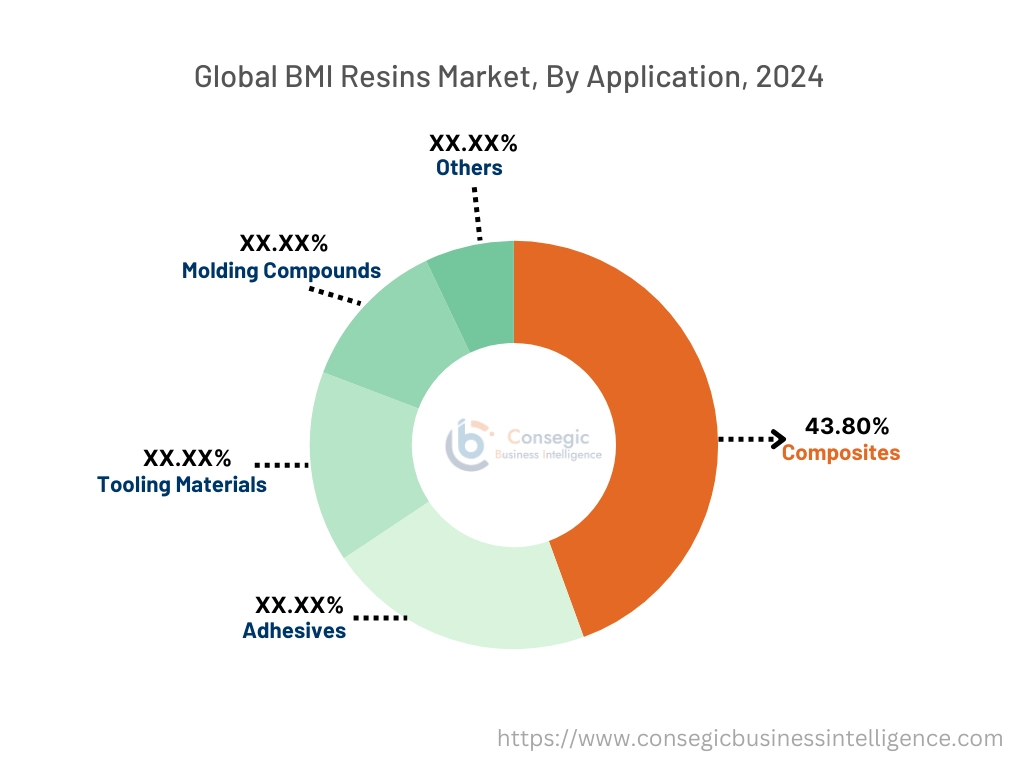

By Application:

Based on application, the market is segmented into composites, adhesives, tooling materials, molding compounds, and others.

The composites segment accounted for the largest revenue of 43.80% of BMI resins market share in 2024.

- BMI resins are a critical component in the production of high-performance composites used across industries such as aerospace, automotive, and energy.

- These resins enhance the thermal stability, mechanical strength, and chemical resistance of composite materials, making them suitable for structural components, airframes, and wind turbine blades.

- The rising trends for lightweight and durable materials in aerospace and automotive applications has significantly boosted the adoption of BMI resins in composite manufacturing.

- Additionally, the growing focus on renewable energy projects, such as wind power, is further driving BMI resins market demand for composite materials.

The adhesives segment is anticipated to register the fastest CAGR during the forecast period.

- BMI resin-based adhesives are widely used in high-performance bonding applications requiring durability, heat resistance, and excellent mechanical properties.

- These adhesives are commonly applied in aerospace, automotive, and industrial manufacturing for bonding metals, composites, and plastics.

- The increasing adoption of advanced adhesives in the assembly of lightweight vehicles and aircraft has driven trends in this segment.

- Furthermore, the rising use of BMI resin adhesives in electronics for bonding high-temperature components is expected to propel BMI resins market growth during the forecast period.

By End-User Industry:

Based on end-use, the market is segmented into aerospace & defense, automotive, electronics, industrial manufacturing, energy & power, and others.

The aerospace & defense segment accounted for the largest revenue share in 2024.

- The aerospace and defense sector is a major consumer of BMI resins due to their exceptional thermal and mechanical properties.

- These resins are widely used in manufacturing structural components, engine parts, and adhesives for aircraft, spacecraft, and military equipment.

- The increasing BMI resins market trends for fuel-efficient and lightweight materials in the aerospace sectors, coupled with rising defense investments globally, has driven the adoption of BMI resins.

- Additionally, advancements in composite materials for high-performance aerospace applications have further strengthened this segment's dominance in the market.

The automotive segment is anticipated to register the fastest CAGR during the forecast period.

- BMI resins are increasingly used in the automotive sectors for producing lightweight and high-strength components, such as body panels, chassis parts, and structural adhesives.

- These materials help enhance fuel efficiency, reduce emissions, and improve vehicle performance.

- The growing adoption of electric vehicles (EVs) and the trends for advanced materials in vehicle electrification are key drivers of this segment.

- Furthermore, the rising focus on sustainability and the use of resins in producing recyclable and durable components are expected to propel significant BMI resins market opportunities in the automotive sector.

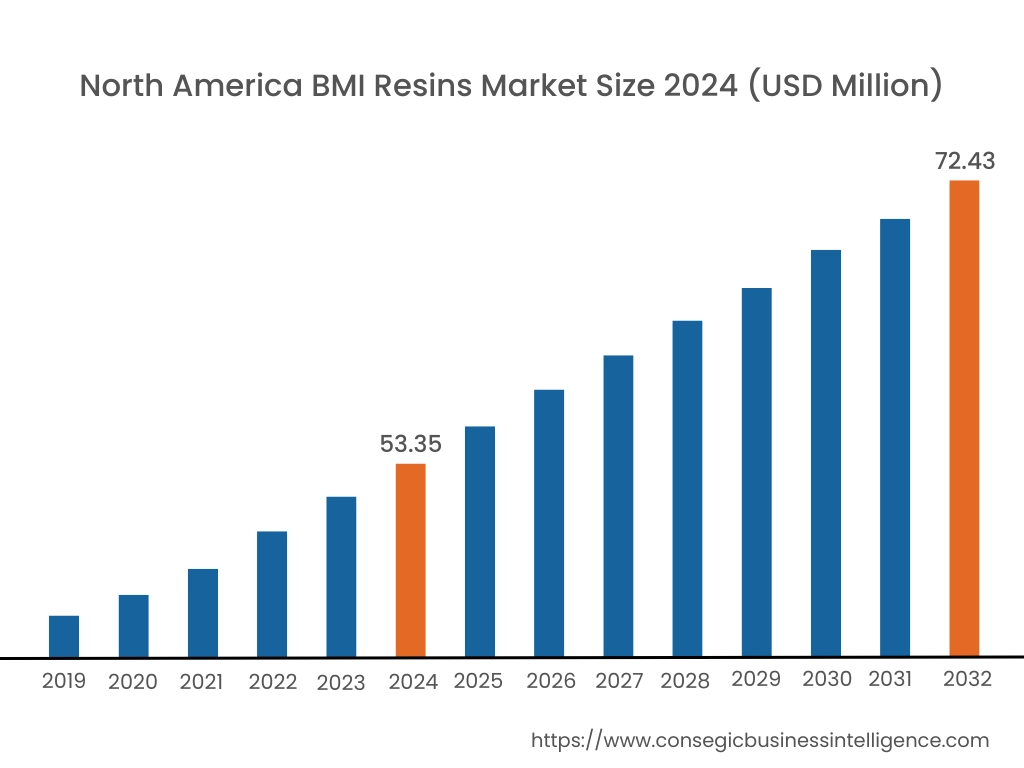

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

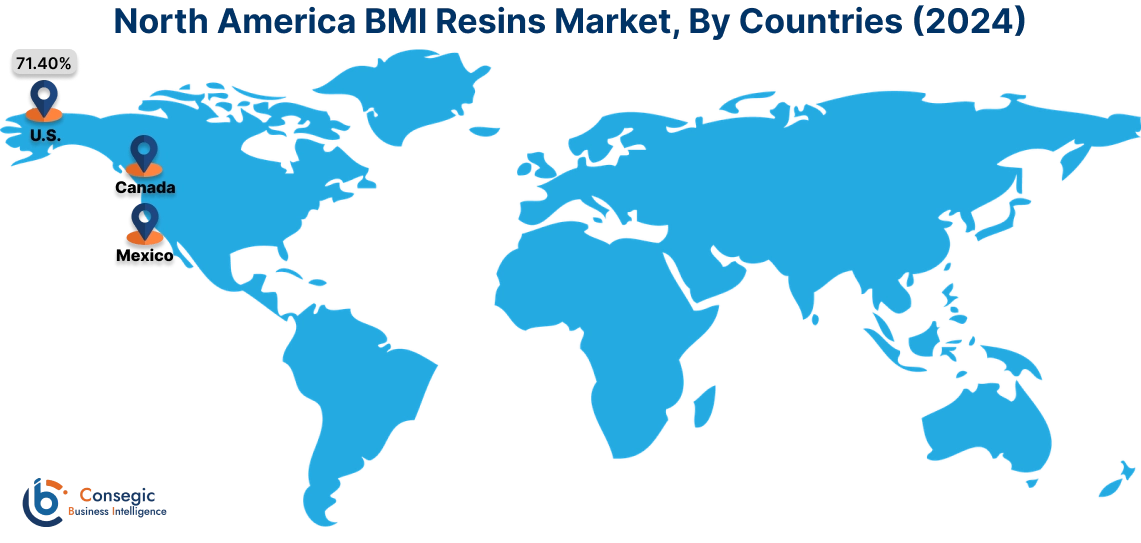

In 2024, North America was valued at USD 53.35 Million and is expected to reach USD 72.43 Million in 2032. In North America, the U.S. accounted for the highest share of 71.40% during the base year of 2024. North America holds a significant share in the BMI (Bismaleimide) resins market analysis, driven by its well-established aerospace, defense, and automotive industries. The U.S. leads the region with high development for trends in advanced composites for military and commercial aircraft, spacecraft, and automotive applications requiring lightweight, high-strength, and heat-resistant materials. The growing adoption of BMI resins in electric vehicles (EVs) to improve efficiency and thermal management further supports the market. Canada contributes with increasing use of global BMI resins market in its aerospace and renewable energy sectors. However, the high cost of production and specialized manufacturing processes may limit broader adoption.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 4.6% over the forecast period. In the BMI resins market analysis, fueled by rapid industrialization, growing investments in aerospace and defense, and expanding automotive production in China, India, and Japan. China dominates the region with extensive use of BMI resins in military and commercial aviation, as well as in electric vehicle components. India’s expanding defense and aerospace industries drive demand for BMI resins in advanced composites for lightweight and durable equipment. Japan focuses on precision applications in aerospace, electronics, and industrial sectors, leveraging BMI resins for their superior thermal and mechanical properties. However, limited domestic production capabilities and high raw material costs may hinder BMI resins market expansion in emerging markets.

Europe is a prominent market, supported by advanced aerospace, automotive, and renewable energy sectors. As per the analysis countries like Germany, France, and the UK are major contributors. Germany drives trends with its strong automotive and aerospace industries, focusing on lightweight materials to enhance fuel efficiency and performance. France emphasizes the use of BMI resins in the aerospace sector, particularly for thermal-resistant components in high-performance aircraft. The UK is witnessing growth in defense and renewable energy applications, including wind turbine manufacturing. However, strict EU regulations on chemical manufacturing and environmental sustainability may create challenges for manufacturers in the region.

The Middle East & Africa region is witnessing steady growth in the market, driven by increasing investments in aerospace, defense, and infrastructure projects. Countries like Saudi Arabia and the UAE are adopting BMI resins for high-performance composites in defense equipment and aerospace components. In Africa, South Africa is emerging as a market, utilizing BMI resins in lightweight materials for industrial and transportation applications. However, limited access to advanced manufacturing facilities and reliance on imported materials may restrict broader market expansion in the region.

Latin America is an emerging market for BMI resins, with Brazil and Mexico leading the region. Brazil’s growing aerospace and defense industries drive the BMI resins market trends in high-performance composites for aircraft and military equipment. Mexico’s expanding automotive and industrial manufacturing sectors support the adoption of BMI resins for lightweight and heat-resistant components. The region is also exploring the use of BMI resins in renewable energy projects, such as wind turbines. However, economic instability and lack of advanced manufacturing infrastructure may pose challenges to broader market development in the region.

Top Key Players and Market Share Insights:

The BMI resins market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the BMI resins market. Key players in the BMI resins industry include -

- Evonik Industries AG (Germany)

- Hexcel Corporation (USA)

- 3M (USA)

- Northern Composites (USA)

- Teijin Limited (Japan)

- Huntsman International LLC (USA)

- Solvay (Belgium)

- HOS-Technik GmbH (Austria)

- Renegade Materials Corporation (USA)

- Toray TCAC Holding B.V. (Netherlands)

Recent Industry Developments :

Recent Industry Developments:

- In October 2024, MTorres, a Spanish automation provider, has developed an advanced Automated Fiber Placement (AFP) head capable of laying bismaleimide (BMI) resin, specifically for military programs like the Lockheed Martin F-35. This AFP head is part of the TorresFiberLayup system, which will be installed at SABCA's Limburg facility in Belgium. SABCA is responsible for fabricating wing skins and covers for the F-35. The system incorporates MTorres' latest technologies, including patented rotary servo-driven cutting and high-angle clearance, essential for the complex geometries of F-35 components. Additionally, it features exchangeable AFP quick connectors, enabling end effector exchanges in under two minutes. Future upgrades are planned to include online inspection devices and enhanced material layup capabilities.

BMI Resins Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 223.49 Million |

| CAGR (2025-2032) | 4.2% |

| By Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the BMI Resins Market by 2032? +

BMI Resins Market size is estimated to reach over USD 223.49 Million by 2032 from a value of USD 160.82 Million in 2024 and is projected to grow by USD 164.71 Million in 2025, growing at a CAGR of 4.2% from 2025 to 2032.

What are the primary drivers of the BMI Resins Market? +

Key drivers include increasing adoption in high-temperature aerospace applications, growing demand for lightweight materials in automotive manufacturing, and advancements in resin processing technologies.

What are the challenges hindering BMI Resins Market growth? +

Challenges include limited recycling options and end-of-life management for thermosetting polymers, high production costs, and stringent environmental regulations.

Which type of BMI resin dominates the market? +

Thermosetting BMI resins dominate the market due to their superior thermal and mechanical properties, making them suitable for aerospace and defense applications.