- Summary

- Table Of Content

- Methodology

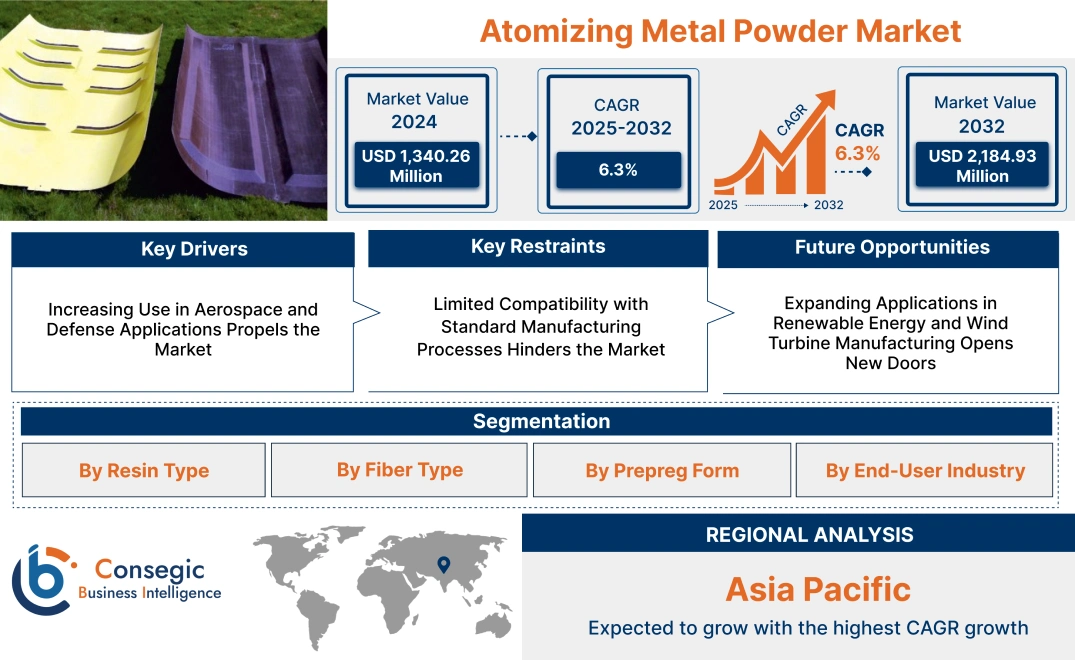

BMI Prepreg Market Size:

BMI Prepreg Market size is estimated to reach over USD 2,184.93 Million by 2032 from a value of USD 1,340.26 Million in 2024 and is projected to grow by USD 1,400.82 Million in 2025, growing at a CAGR of 6.3% from 2025 to 2032.

BMI Prepreg Market Scope & Overview:

The bismaleimide (BMI) resin-based prepregs, which are advanced composite materials used for high-performance applications requiring superior thermal and mechanical properties. BMI prepregs are reinforced with fibers like carbon or glass and are known for their high strength-to-weight ratio, excellent heat resistance, and durability. Key characteristics include their ability to withstand extreme temperatures, resistance to chemical degradation, and low moisture absorption, making them ideal for demanding applications. The benefits include enhanced structural integrity, weight reduction, and prolonged service life in challenging environments. Applications span aerospace, automotive, defense, and electronics, where lightweight and durable materials are critical. End-users include aerospace manufacturers, automotive OEMs, and defense contractors, driven by the increasing adoption of lightweight materials in advanced manufacturing, rising demand for fuel-efficient vehicles and aircraft, and advancements in composite material technologies.

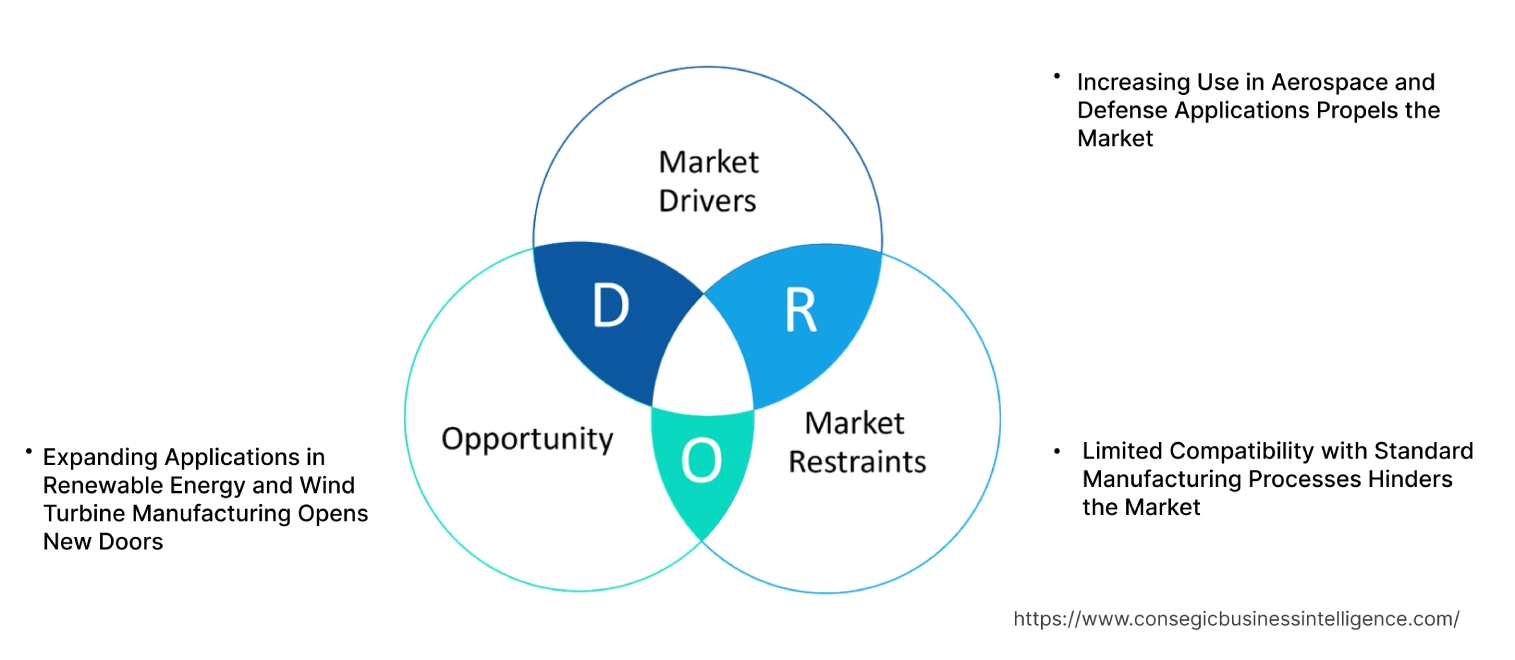

Key Drivers:

Increasing Use in Aerospace and Defense Applications Propels the Market

BMI prepregs are becoming increasingly essential in aerospace and defense applications due to their exceptional thermal resistance, mechanical strength, and lightweight properties. These materials are extensively used in structural components such as aircraft wings, fuselages, engine nacelles, and missile casings, where the ability to endure high temperatures and extreme stress is crucial. BMI prepregs also provide superior fatigue resistance, making them ideal for components subjected to repeated stress cycles.

Trends in lightweight materials and advanced combat technologies are driving the adoption of BMI prepregs, especially as the aerospace and defense industries prioritize efficiency, durability, and enhanced performance. Analysis highlights that these materials play a pivotal role in reducing aircraft weight, improving fuel efficiency, and ensuring the reliability of mission-critical systems, positioning BMI prepregs as a cornerstone of next-generation aerospace and defense engineering.

Key Restraints:

Limited Compatibility with Standard Manufacturing Processes Hinders the Market

One of the primary challenges facing BMI prepregs is their limited compatibility with conventional manufacturing systems. These materials require specialized curing processes, often involving high temperatures and pressures, which are not readily available in standard production facilities. This incompatibility necessitates significant investments in custom equipment, tooling, and operator training, creating barriers for manufacturers seeking to adopt BMI prepregs.

Additionally, the precise handling and storage requirements for BMI prepregs add logistical complexity, further restricting their use in industries where scalability and cost efficiency are critical. Trends in manufacturing innovation highlight the need for advanced systems that can streamline the processing of BMI prepregs without compromising their performance, underscoring the importance of technological advancements to overcome this limitation.

Future Opportunities :

Expanding Applications in Renewable Energy and Wind Turbine Manufacturing Opens New Doors

The renewable energy sector presents a growing opportunity for BMI prepregs, particularly in the development of wind turbine blades and structural components. The high mechanical strength, lightweight nature, and environmental resistance of BMI prepregs make them ideal for manufacturing durable and efficient wind energy systems. These properties contribute to longer operational lifespans and improved performance in challenging environmental conditions, such as high winds and temperature fluctuations.

Trends in clean energy development and sustainability initiatives are driving the adoption of advanced materials like BMI prepregs in renewable energy projects. Analysis suggests that manufacturers focusing on creating tailored solutions for the renewable energy sector, such as optimizing BMI prepregs for larger and more efficient wind turbines, will be well-positioned to capture emerging BMI prepregs market opportunities. This expansion aligns with global efforts to transition toward greener energy sources and reduce environmental footprints.

BMI Prepreg Market Segmental Analysis :

By Resin Type:

Based on resin type, the BMI prepreg market is segmented into bismaleimide (BMI) resin and modified BMI resin.

The bismaleimide (BMI) resin segment accounted for the largest revenue share in 2024.

- Bismaleimide (BMI) resin is widely used in high-performance applications requiring excellent thermal stability, mechanical strength, and chemical resistance.

- It is extensively utilized in aerospace and defense components such as structural parts, wings, and fuselages, where durability and reliability are critical.

- The demand for BMI resin in the aerospace and automotive sectors, driven by the increasing need for lightweight and high-strength materials, has solidified its dominance.

- Additionally, its superior performance under high temperatures makes it suitable for applications in electrical and electronic components, further boosting its adoption.

The modified BMI resin segment is anticipated to register the fastest CAGR during the forecast period.

- Modified BMI resins offer enhanced toughness, improved process ability, and better flexibility compared to standard BMI resins.

- These properties make them highly suitable for applications in automotive, electrical, and electronics industries, where impact resistance and ease of fabrication are critical.

- The increasing focus on advanced materials for lightweight and high-performance components, coupled with growing adoption in emerging markets, is expected to drive significant growth in this segment.

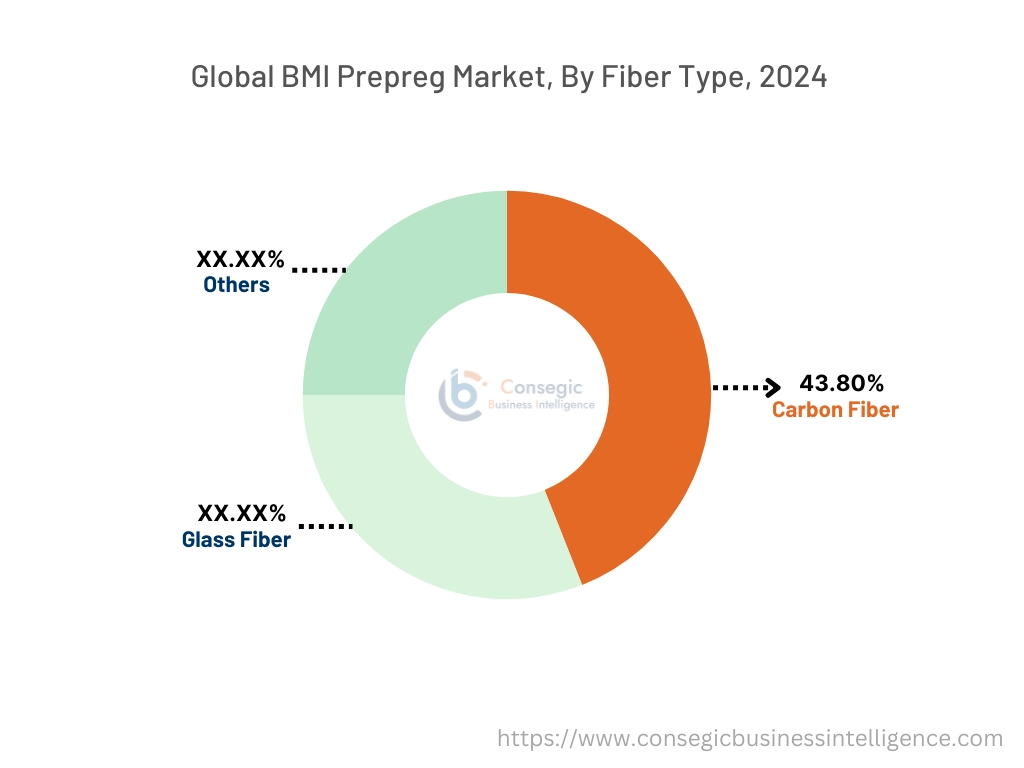

By Fiber Type:

Based on fiber type, the BMI prepreg market is segmented into carbon fiber, glass fiber, and others.

The carbon fiber segment accounted for the largest revenue of 43.80% share in 2024.

- Carbon fiber-based BMI prepregs are widely used in aerospace, automotive, and defense industries due to their exceptional strength-to-weight ratio, thermal stability, and resistance to corrosion.

- These materials are integral in manufacturing aircraft structural parts, automotive body panels, and wind turbine blades, where performance and durability are essential.

- The rising demand for lightweight materials to improve fuel efficiency and reduce carbon emissions has driven the adoption of carbon fiber-based BMI prepregs.

- Additionally, advancements in carbon fiber production techniques have made these materials more accessible, further boosting their market share.

The glass fiber segment is anticipated to register the fastest CAGR during the forecast period.

- Glass fiber-based BMI prepregs are gaining traction due to their cost-effectiveness, high mechanical strength, and electrical insulation properties.

- These prepregs are extensively used in electrical and electronics applications, including circuit boards and insulating components.

- The growing BMI prepregs market demand for glass fiber in automotive and construction industries, where cost-efficiency and performance are priorities, is driving segment growth.

- Additionally, advancements in glass fiber manufacturing technologies are expected to further enhance its market penetration.

By Prepreg Form:

Based on the prepreg form, the BMI prepreg market is segmented into sheet, tape, roll, and towpreg.

The sheet segment accounted for the largest revenue of BMI prepregs market share in 2024.

- BMI prepreg sheets are widely used in aerospace and automotive industries for producing large structural components such as panels, wings, and body parts.

- These sheets offer uniform properties, ease of handling, and compatibility with automated manufacturing processes, making them ideal for high-volume production.

- The increasing adoption of prepreg sheets in manufacturing lightweight and durable components has driven their dominance in the market.

- Additionally, the growing use of automated layup techniques in aerospace and automotive industries is further boosting the BMI prepregs market demand for sheets.

The towpreg segment is anticipated to register the fastest CAGR during the forecast period.

- Towpregs, which consist of fiber tows pre-impregnated with resin, are gaining popularity due to their flexibility and suitability for advanced manufacturing processes such as filament winding and automated fiber placement.

- These forms are extensively used in producing cylindrical and tubular components such as rocket casings, pressure vessels, and structural frames.

- The increasing adoption of towpregs in aerospace, defense, and industrial applications, coupled with advancements in automated manufacturing technologies, is expected to drive significant BMI prepregs market growth in this segment’s trends.

By End-User Industry:

Based on end-use, the BMI prepreg market is segmented into aerospace & defense, automotive, electrical & electronics, manufacturing, and others.

The aerospace & defense segment accounted for the largest revenue of BMI prepregs market share in 2024.

- The aerospace and defense sectors is the largest consumer of BMI prepregs, driven by the need for lightweight, durable, and high-performance materials.

- BMI prepregs are extensively used in aircraft components such as fuselages, wings, and engine nacelles, as well as in defense equipment like missiles and radar domes.

- The increasing production of commercial and military aircraft, coupled with advancements in composite materials, has significantly boosted the trends for BMI prepregs in this segment.

- Additionally, the focus on fuel efficiency and reducing emissions in the aviation sector further supports the dominance of this segment.

The automotive segment is anticipated to register the fastest CAGR during the forecast period.

- The automotive sectors is increasingly adopting BMI prepregs for manufacturing lightweight and high-strength components, including body panels, frames, and chassis.

- The rising trends for electric vehicles (EVs) and the need to enhance fuel efficiency in traditional vehicles have driven the adoption of composite materials in the automotive sector.

- BMI prepregs offer superior mechanical and thermal properties, making them ideal for high-performance and energy-efficient vehicles.

- Moreover, the growing BMI prepregs market trends of vehicle electrification and the increasing focus on reducing carbon emissions are expected to propel significant growth in this segment.

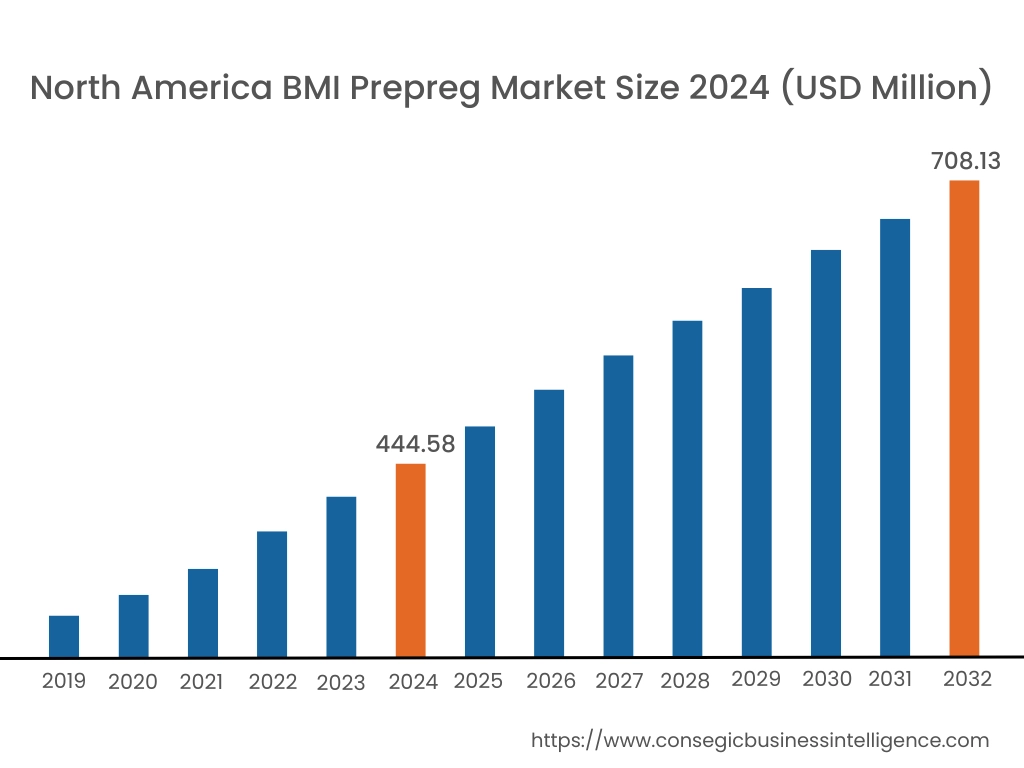

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 444.58 Million and is expected to reach USD 708.13 Million in 2032. In North America, the U.S. accounted for the highest share of 72.40% during the base year of 2024. North America holds a significant stake in the BMI (Bismaleimide) prepreg market analysis, driven by strong demand from the aerospace, defense, and automotive sectors. The U.S. dominates the region due to extensive use of BMI prepregs in advanced composite applications, particularly in military and commercial aircraft for lightweight and high-temperature-resistant components. The growing opportunities for electric vehicles (EVs) further supports the market by leveraging BMI prepregs in structural and thermal applications. Canada contributes through its aerospace and defense industries, adopting BMI prepregs for high-performance composites. However, the high costs of production and raw materials may limit broader adoption in cost-sensitive sectors.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 6.7% over the forecast period. In the BMI prepreg market analysis, fueled by rapid industrialization, increasing investments in aerospace and defense, and growing automotive production in China, India, and Japan. China dominates the region with large-scale adoption of BMI prepregs in military and commercial aviation, as well as in electric vehicles. India’s expanding defense and aerospace industries support the use of BMI prepregs in lightweight and high-strength components. Japan focuses on high-precision applications in aerospace and electronics, leveraging BMI prepregs for their superior thermal and mechanical properties. However, limited domestic production capabilities and dependence on imported raw materials may hinder BMI prepregs market growth in emerging economies.

Europe is a prominent market for BMI prepregs, supported by its advanced aerospace, automotive, and industrial manufacturing sectors. As per the analysis countries like Germany, France, and the UK are key contributors. Germany leads the market with significant applications in automotive and aerospace, focusing on lightweight composites to enhance fuel efficiency and performance. France emphasizes the use of BMI prepregs in the aerospace sector, particularly for high-performance aircraft and space applications. The UK sees increasing adoption in defense and renewable energy systems, such as wind turbine components. However, stringent EU environmental regulations and high production costs may challenge BMI prepregs market expansion.

The Middle East & Africa region is witnessing steady growth in the Global BMI prepreg market, driven by increasing investments in aerospace, defense, and infrastructure projects. Countries like Saudi Arabia and the UAE are adopting BMI prepregs in defense equipment and high-performance aerospace applications. In Africa, South Africa is an emerging market, leveraging BMI prepregs for lightweight materials in industrial and transportation sectors. However, limited local manufacturing capabilities and reliance on imports for advanced composite materials may restrict broader market development in the region.

Latin America is an emerging market for BMI prepregs, with Brazil and Mexico leading the region. Brazil’s growing aerospace and defense industries drive BMI prepregs market trends in high-performance composites for aircraft and military equipment. Mexico’s expanding automotive and industrial manufacturing sectors support the adoption of BMI prepregs in lightweight and heat-resistant components. The region’s analysis increasingly focuses on renewable energy also promotes the use of BMI prepregs in wind turbine manufacturing. However, economic instability and lack of advanced production infrastructure may pose challenges for BMI prepregs market expansion in smaller economies.

Top Key Players and Market Share Insights:

The BMI Prepreg market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the BMI Prepreg market. Key players in the BMI Prepreg industry include -

- Hexcel Corporation (USA)

- Solvay (Belgium)

- TenCate Advanced Composites (Netherlands)

- SGL Carbon (Germany)

- Cytec Industries Inc. (USA)

- Mitsubishi Chemical Corporation (Japan)

- Renegade Materials Corporation (USA)

- GMS Composites (Australia)

- Toray Industries, Inc. (Japan)

- Teijin Limited (Japan)

Recent Industry Developments :

- In January 2022, CSIR-NAL's Advanced Composites Division (ACD) successfully developed a co-cured engine bay door for the Light Combat Aircraft (LCA) Tejas using Carbon-BMI prepregs. This component is designed to withstand service temperatures up to 200°C, addressing the limitations of traditional carbon-epoxy prepregs that are unsuitable for high-temperature zones near aircraft engines. The BMI engine bay door underwent rigorous qualification tests, including structural loading at 180°C, and received clearance from relevant regulatory authorities for flight operations.

BMI Prepreg Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,184.93 Million |

| CAGR (2025-2032) | 6.3% |

| By Resin Type |

|

| By Fiber Type |

|

| By Prepreg Form |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the BMI Prepreg Market by 2032? +

BMI Prepreg Market size is estimated to reach over USD 2,184.93 Million by 2032 from a value of USD 1,340.26 Million in 2024 and is projected to grow by USD 1,400.82 Million in 2025, growing at a CAGR of 6.3% from 2025 to 2032.

What are the primary drivers for the BMI Prepreg Market? +

Key drivers include increasing demand in aerospace and defense for lightweight and durable components, rising use in automotive for fuel efficiency, and advancements in composite material technologies.

What challenges does the BMI Prepreg Market face? +

The market faces challenges such as limited compatibility with standard manufacturing processes, high production costs, and logistical complexities due to precise handling and storage requirements.

Which resin type dominates the market? +

The bismaleimide (BMI) resin segment dominates the market due to its exceptional thermal stability, mechanical strength, and suitability for aerospace and defense applications.