- Summary

- Table Of Content

- Methodology

Beverage Carton Packaging Machinery Market Size:

The Beverage Carton Packaging Machinery Market size is estimated to reach over USD 1,513.66 Million by 2032 from a value of USD 1,048.28 Million in 2024 and is projected to grow by USD 1,078.87 Million in 2025, growing at a CAGR of 4.7% from 2025 to 2032.

Beverage Carton Packaging Machinery Market Scope & Overview:

The beverage carton packaging machinery focuses on the development and deployment of machinery designed for producing, filling, and sealing carton-based packaging for beverages. These machines enable efficient and high-speed packaging of various liquids, including juices, dairy products, and alcoholic beverages, while maintaining product freshness and quality. Key characteristics of packaging machinery include automation capabilities, precision filling, and compatibility with diverse carton designs and materials. The benefits include enhanced production efficiency, reduced packaging waste, and extended shelf life for packaged beverages. Applications span the packaging of non-alcoholic beverages, dairy products, and liquid foods. End-users include beverage manufacturers, food processing companies, and contract packaging providers, driven by rising beverage carton packaging machinery market demand for sustainable packaging solutions, increasing consumption of packaged beverages, and advancements in automated and energy-efficient packaging technologies.

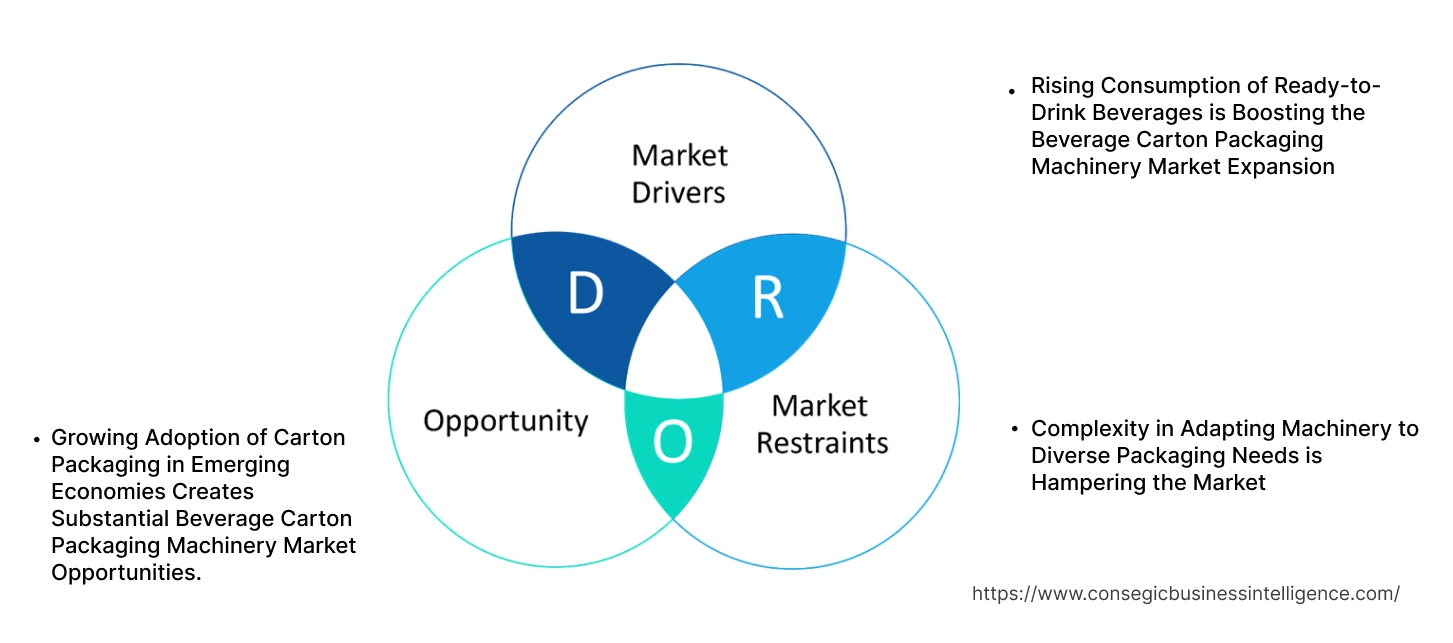

Key Drivers:

Rising Consumption of Ready-to-Drink Beverages is Boosting the Beverage Carton Packaging Machinery Market Expansion

The growth in popularity of ready-to-drink (RTD) beverages, such as juices, plant-based drinks, functional beverages, and milk products, is shaping significant trends in the beverage carton packaging machinery market. RTD products are favored for their convenience, extended shelf life, and innovative formulations that cater to health-conscious consumers. Packaging machinery plays a crucial role in enabling manufacturers to efficiently package these beverages while maintaining freshness, hygiene, and quality.

The growing diversification of RTD beverage portfolios requires machinery capable of handling a wide range of carton sizes, shapes, and materials. The dominance highlights the shift toward aseptic packaging, which extends product shelf life without preservatives, further driving the need for advanced carton packaging machinery. As consumers increasingly prefer portable and eco-friendly beverage options, the role of efficient and versatile machinery becomes essential for meeting production requirements and supporting innovation in the beverage sector.

Key Restraints:

Complexity in Adapting Machinery to Diverse Packaging Needs is Hampering the Market

One of the primary challenges for the beverage carton packaging machinery market is the complexity involved in adapting machinery to meet diverse packaging requirements. Beverage manufacturers are continually introducing new packaging formats to cater to evolving consumer preferences, including unique carton designs, varied sizes, and enhanced functionalities such as resealable closures. Machinery needs to be versatile enough to handle these variations without compromising efficiency or precision.

Frequent adjustments and reconfigurations of machinery to accommodate changing packaging trends can result in increased downtime and operational inefficiencies. Additionally, the integration of advanced features, such as smart packaging elements or multi-layered cartons for improved insulation, adds to the technical complexity of the machinery. Addressing these challenges through modular designs and automated adjustment capabilities is critical for maintaining productivity and minimizing disruptions in the production process.

Future Opportunities :

Growing Adoption of Carton Packaging in Emerging Economies Creates Substantial Beverage Carton Packaging Machinery Market Opportunities.

Factors such as urbanization, rising disposable incomes, and a growing middle-class population are driving increased consumption of packaged beverages in these regions. Carton packaging is gaining traction as a sustainable and cost-effective alternative to plastic bottles and cans, aligning with global trends favoring environmentally friendly packaging solutions.

The growing beverage industry in these economies requires machinery that is both scalable and cost-efficient to meet rising production volumes. Beverage carton packaging machinery market trends indicate that manufacturers focusing on flexible and user-friendly machinery tailored to the needs of these markets can capitalize on the expanding adoption of carton packaging. Furthermore, government initiatives promoting sustainable practices and investments in local manufacturing infrastructure are expected to further boost the uptake of carton packaging machinery in these regions.

Beverage Carton Packaging Machinery Market Segmental Analysis :

By Type:

Based on type, the market is segmented into horizontal end side-load cartoner, top-load cartoner, wraparound cartoner, vertical leaflet, and vertical sleeve.

The horizontal end side-load cartoner segment accounted for the largest revenue in beverage carton packaging machinery market share in 2024.

- Horizontal end-side-load cartoners are extensively used in beverage packaging due to their ability to handle high-speed operations with precision and flexibility.

- These machines accommodate a variety of carton shapes and sizes, catering to the diverse requirements of the beverage industry, particularly in large-scale manufacturing facilities.

- The trends of automating production processes in the beverage sector to meet increasing consumer development and reduce operational costs significantly drive adoption in this segment.

- Horizontal end side-load cartoners are also preferred for their ability to handle secondary packaging processes, such as shrink-wrapping, further enhancing their efficiency and versatility.

- Hence, horizontal end side-load cartoners lead the market due to their flexibility, speed, and efficiency in catering to large-scale production needs.

The wraparound cartoner segment is anticipated to register the fastest CAGR during the forecast period.

- Wraparound cartoners are designed to provide a snug fit around products, ensuring enhanced protection and reducing the risk of damage during transportation.

- They are particularly favored for premium and delicate beverages, aligning with the growing demand for aesthetically pleasing and compact packaging solutions.

- The adoption of wraparound cartoners is also driven by the need to reduce material wastage, contributing to sustainability goals in the beverage sector.

- Advancements in machine designs to handle eco-friendly packaging materials seamlessly further support the beverage carton packaging machinery market growth of this segment.

- Therefore, wraparound cartoners are expected to grow rapidly, driven by their ability to enhance product safety and align with sustainability initiatives in the beverage industry.

By Mode of Operation:

Based on the mode of operation, the market is segmented into automatic and semi-automatic.

The automatic segment accounted for the largest revenue in beverage carton packaging machinery market share in 2024.

- Automatic machines are widely used in large beverage production facilities due to their ability to ensure high-speed operations with minimal manual intervention.

- These machines reduce errors and enhance productivity, making them indispensable for manufacturers aiming to meet stringent quality standards.

- The integration of advanced technologies, such as IoT-enabled sensors and real-time monitoring systems, enhances the reliability and efficiency of automatic machines.

- The beverage carton packaging machinery market trends of investing in fully automated systems to reduce labor costs and increase throughput align with the growing demand for automation in the beverage sectors.

- Thus, the market analysis depicts that the automatic machine dominate in the market, supported by their efficiency, advanced technology integration, and growing adoption in large-scale beverage production.

The semi-automatic segment is anticipated to register the fastest CAGR during the forecast period.

- Semi-automatic machines are preferred by small and medium-scale beverage producers due to their lower initial investment costs and operational flexibility.

- These machines are increasingly adopted in emerging markets, where capital constraints and the need for scalable solutions are prominent.

- Semi-automatic machines also cater to niche beverage categories that require customization, offering manufacturers the ability to adapt to specific packaging requirements.

- The trends of adopting semi-automated solutions for seasonal or limited-edition beverage products further support the growth of this segment.

- Thus, as per segmental analysis, semi-automatic machines are expected to grow rapidly, supported by their affordability, adaptability, and growing adoption in small and medium-scale production facilities.

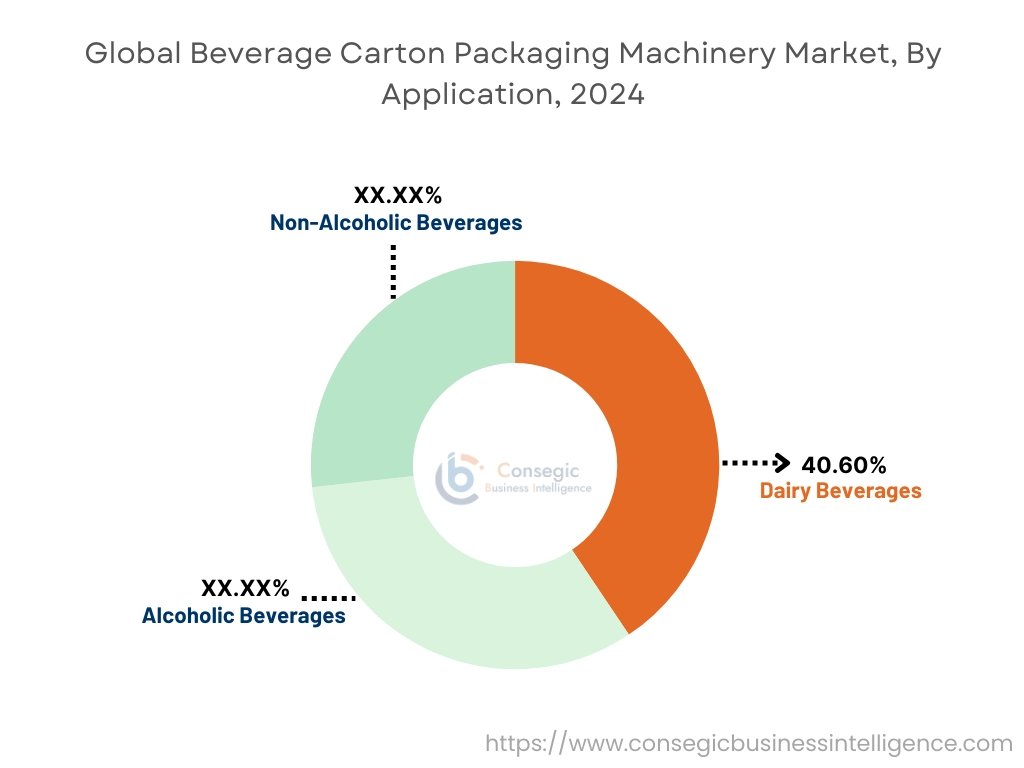

By Application:

Based on application, the market is segmented into dairy beverages, alcoholic beverages, and non-alcoholic beverages.

The dairy beverages segment accounted for the largest revenue share of 40.60% in 2024.

- Dairy beverages require specialized packaging to maintain product freshness and quality, driving development for advanced machinery.

- The trends of increasing consumer preference for ready-to-drink (RTD) dairy beverages, such as flavored milk and yogurt drinks, support the dominance of this segment.

- Packaging machinery designed for aseptic and hygienic operations further ensures the safety and extended shelf life of dairy products.

- The growth in advancement for single-serve and eco-friendly dairy beverage packaging contributes to the adoption of machinery tailored to meet these requirements.

- Dairy beverages lead the beverage carton packaging machinery market expansion, supported by the increasing advancement for hygienic and sustainable packaging solutions in the dairy sector.

The non-alcoholic beverages segment is anticipated to register the fastest CAGR during the forecast period.

- Non-alcoholic beverages, including functional drinks, juices, and ready-to-drink teas, are witnessing a growing consumer surge, driving the need for efficient packaging solutions.

- The dominance of adopting innovative packaging designs to enhance product appeal and convenience aligns with the rise of this segment.

- Growth in focus on sustainable and recyclable packaging materials for non-alcoholic beverages further fuels the demand for advanced packaging machinery.

- Expanding product portfolios in the functional beverage category, coupled with rising health consciousness, adds to the segment’s rising potential.

- Non-alcoholic beverages are expected to grow rapidly, supported by increasing beverage carton packaging machinery market opportunities for functional drinks and innovative, sustainable packaging solutions.

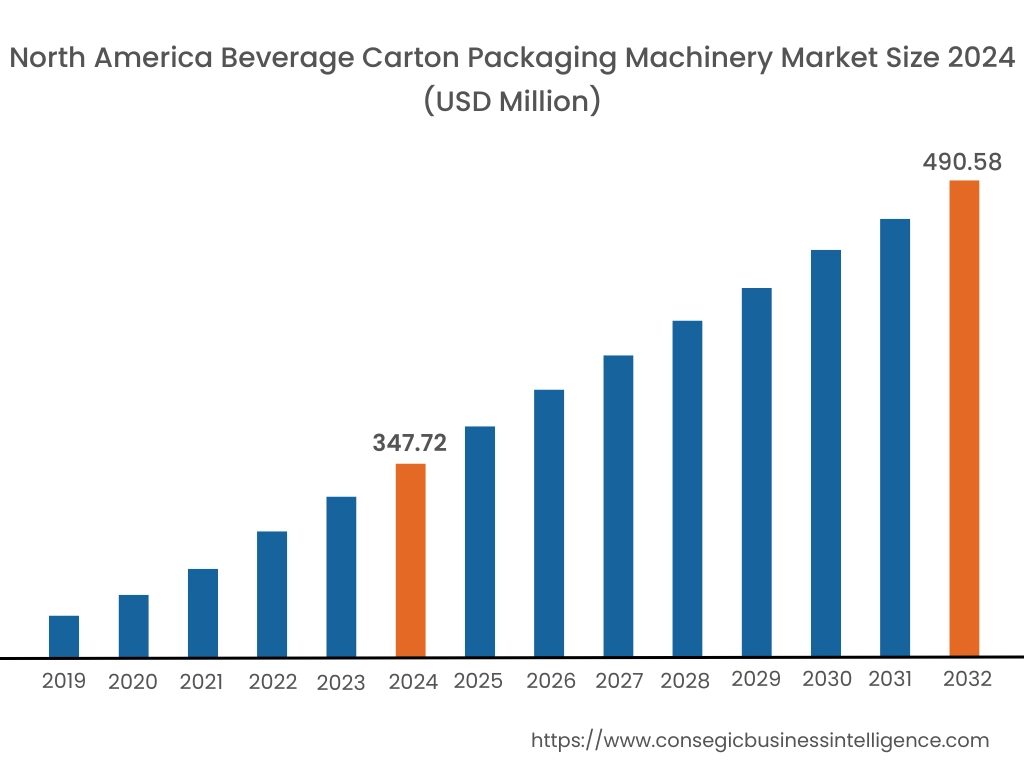

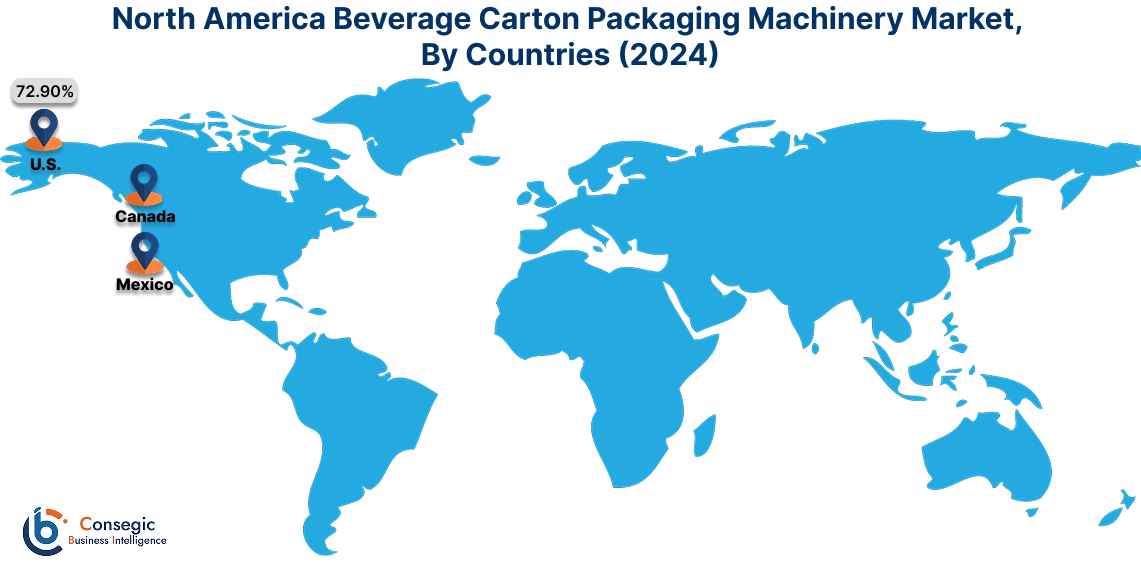

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 347.72 Million and is expected to reach USD 490.58 Million in 2032. In North America, the U.S. accounted for the highest share of 72.90% during the base year of 2024. As per the Beverage Carton Packaging Machinery Market analysis, North America holds a significant share, due to its established beverage sector and growing surge for sustainable packaging solutions. The U.S. leads the region with high adoption of advanced packaging machinery for milk, juice, and ready-to-drink beverages, driven by the shift toward eco-friendly and recyclable carton materials. Canada contributes with increasing investments in automated and high-speed packaging machinery, particularly for the dairy and functional beverage sectors. However, high initial machinery costs and stringent environmental regulations may challenge beverage carton packaging machinery market growth in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 5.1% over the forecast period. The beverage carton packaging machinery market analysis shows that the Asia-Pacific is the largest and fastest-growing region, fueled by rapid industrialization and increasing consumption of packaged beverages in China, India, and Japan. China leads the market with its large-scale production of milk, tea, and fruit juices, requiring high-efficiency packaging machinery to meet aims. India’s expanding dairy and functional beverage sectors are driving the adoption of automated machinery for carton packaging. Japan focuses on precision machinery for premium and innovative beverage packaging solutions. However, challenges such as cost-sensitive markets and limited adoption of advanced machinery in rural areas may restrict growth in certain parts of the region.

Europe is a prominent market for beverage carton packaging machinery, supported by its strong emphasis on sustainability and innovation in packaging technology. Countries like Germany, France, and Italy are major contributors. As per the regional analysis Germany, known for its advanced manufacturing sector, adopts highly automated machinery to meet the demand for precision and efficiency in beverage packaging. France focuses on sustainable beverage packaging, boosting the adoption of machinery capable of handling eco-friendly cartons. Italy is a key hub for packaging machinery production, driving regional exports. However, strict EU regulations on packaging waste and rising energy costs may impact machinery adoption in smaller industries.

The Middle East & Africa region is witnessing steady advancements in the beverage carton packaging machinery market, driven by increasing investments in the beverage sectors and growing development for packaged drinks. Countries like Saudi Arabia and the UAE are key contributors, leveraging advanced machinery to support the production of juice, dairy, and water cartons for domestic and export markets. In Africa, South Africa is an emerging market, with rising adoption of automated packaging machinery in the dairy and fruit juice industries. However, limited access to advanced technology and reliance on imported machinery may pose challenges for the market’s expansion in the region.

The analysis portrays, Latin America as an emerging market for beverage carton packaging machinery, with Brazil and Mexico leading the region. Brazil’s thriving dairy and fruit juice industries drive the adoption of efficient packaging machinery to meet growing consumer beverage carton packaging machinery market demand for packaged beverages. Mexico is witnessing increased investments in automated machinery for the production of milk, flavored beverages, and energy drinks. The region is also exploring eco-friendly carton materials, which require advanced machinery for compatibility. However, economic instability and limited infrastructure for advanced manufacturing may hinder market development in some parts of the region.

Top Key Players & Market Share Insights:

The beverage carton packaging machinery market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global beverage carton packaging machinery market. Key players in the beverage carton packaging machinery industry include -

- A. Jones (U.S.)

- Bradman Lake Group Ltd. (U.K.)

- Krones AG (Germany)

- EconoCorp Inc. (U.S.)

- Tishma Technologies (U.S.)

- Jacob White Packaging Ltd. (U.K.)

- Mpac Group plc (U.K.)

- KHS GmbH (Germany)

- Douglas Machine Inc. (U.S.)

- Sidel (France)

Recent Industry Developments :

Product launch:

- In July 2024, Eliter Packaging Machinery has recently introduced the Gran Sonata automatic cartoning machine, featuring a hygienic stainless-steel design and multi-axis servo drive system. This machine is engineered for large-size cartoning and medium-size case packing, aiming to enhance reliability and flexibility in packaging operations. The servo technology allows for recipe-based changeovers, facilitating quick transitions between different products and formats to minimize downtime.

Beverage Carton Packaging Machinery Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1,513.66 Million |

| CAGR (2025-2032) | 4.7% |

| By Type |

|

| By Mode of Operation |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the market size projection for the Beverage Carton Packaging Machinery Market? +

Beverage Carton Packaging Machinery Market size is estimated to reach over USD 1,513.66 Million by 2032 from a value of USD 1,048.28 Million in 2024 and is projected to grow by USD 1,078.87 Million in 2025, growing at a CAGR of 4.7% from 2025 to 2032.

What drives the growth of the market? +

The growth is driven by the rising consumption of ready-to-drink beverages, increased demand for sustainable packaging, and advancements in automation technologies tailored for efficient and hygienic packaging solutions.

What challenges does the market face? +

The market faces challenges like adapting machinery to diverse packaging needs, high initial costs of automation, and stringent sustainability regulations impacting machinery adoption.

Which type of machinery holds the largest market share? +

Horizontal end side-load cartoners lead the market due to their flexibility and high-speed capabilities, making them ideal for large-scale beverage packaging operations.