- Summary

- Table Of Content

- Methodology

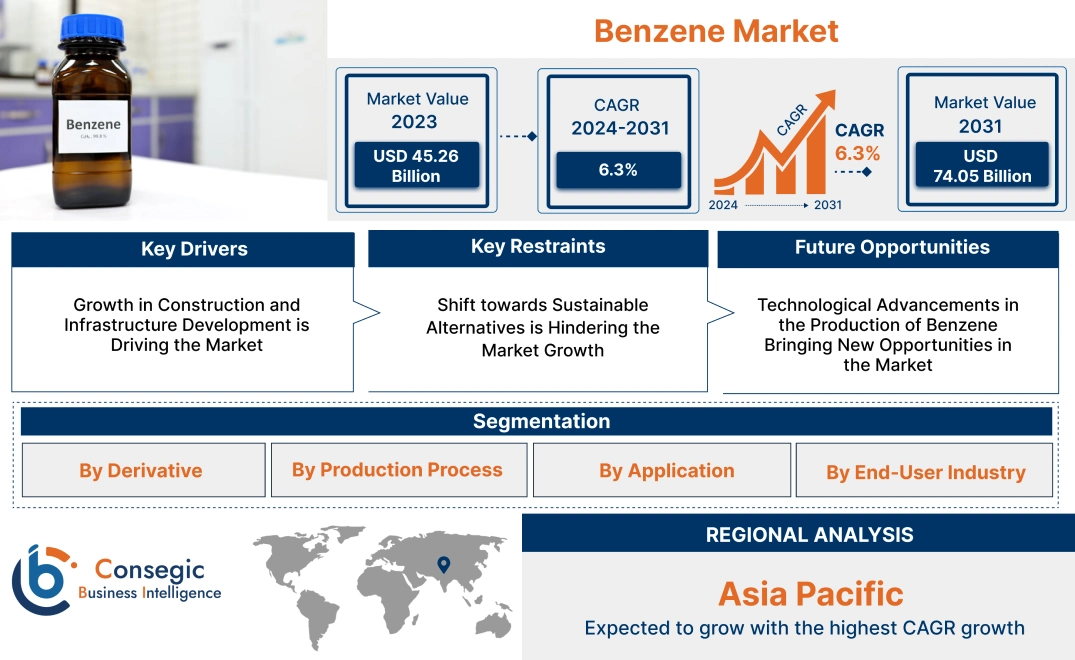

Benzene Market Size:

Benzene Market size is estimated to reach over USD 74.05 Billion by 2031 from a value of USD 45.26 Billion in 2023 and is projected to grow by USD 47.33 Billion in 2024, growing at a CAGR of 6.3% from 2024 to 2031.

Benzene Market Scope & Overview:

Benzene, a fundamental organic compound and key building block in industries is a colorless aromatic liquid distinguished by its sweet smell. The role of it in industrial chemistry cannot be understated, making it instrumental in fueling scientific and technological progress. As a precursor, it facilitates the synthesis of diverse chemicals. It serves as a fundamental starting point for styrene, cyclohexane, phenol, and aniline - essential building blocks that enable innumerable materials in the modern world. Due to its versatile chemical properties, it finds applications across various industries such as chemical, automotive, textile, construction, and pharmaceutical.

Benzene Market Insights:

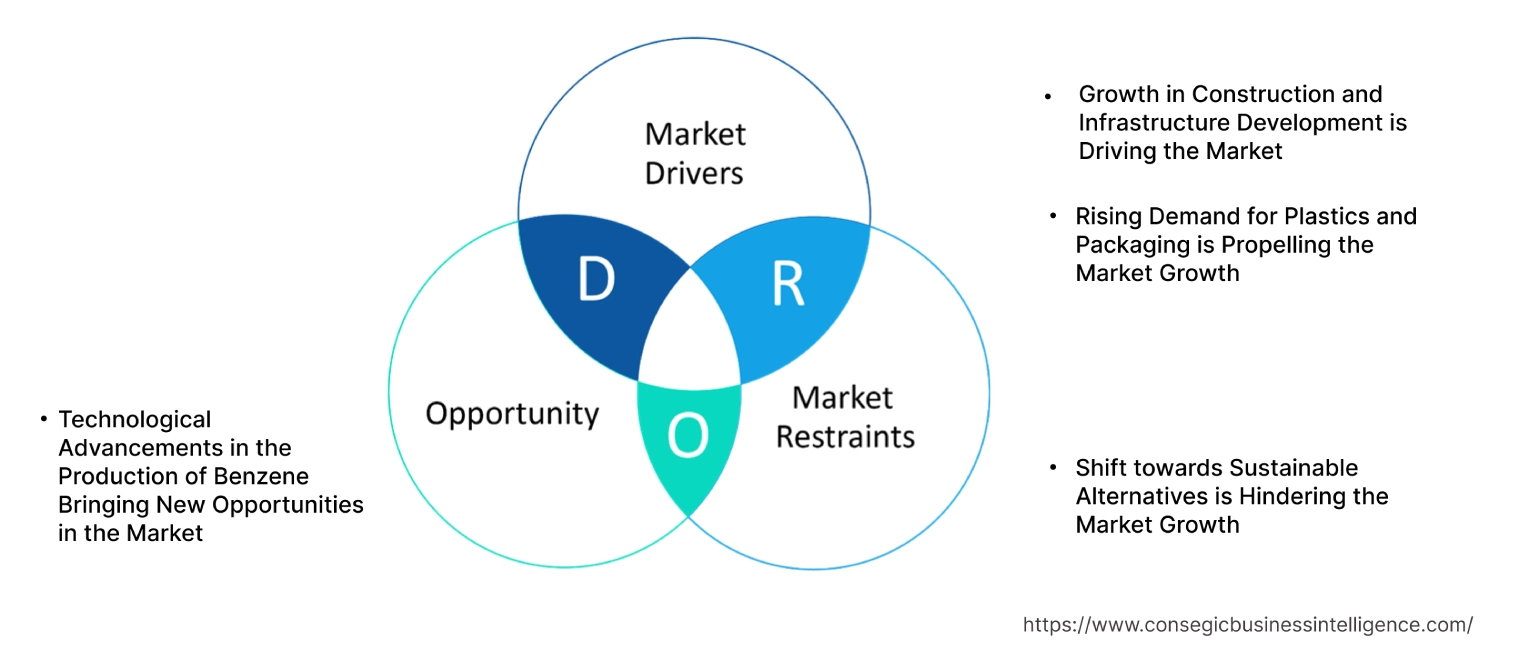

Key Drivers:

Growth in Construction and Infrastructure Development is Driving the Market

Populations hastily migrate from country to city, drastically enhancing urbanization's pace. This migration pattern amplifies requirements for homes, companies, and infrastructural ventures. Butadiene derivatives and benzene products applied in concrete supplements enhance functionality, longevity, and opposition to environmental influences. Advancing fabrication techniques such as prefabrication and modular unit assembly heightens competency and output.

Therefore, the growth in construction and infrastructure development is a major driver of benzene market growth.

Rising Demand for Plastics and Packaging is Propelling the Market Growth

Benzene plays a crucial role in the synthesis of various chemicals and materials, including those applied in plastics and packaging. Innovations in plastic technology, involving novel formulations and applications, stimulate the need for raw materials like benzene. It serves as a pioneer in generating styrene, which then produces polystyrene, a ubiquitous plastic in packaging materials, disposable eating utensils, and insulation. The wrappings for personal care items such as shampoos, lotions, and cosmetics regularly incorporate plastics derived from the compound's conversion.

Therefore, the rising usage of plastics and packaging significantly impacts the benzene market demand, as it is a key raw material for producing various types of plastics.

Key Restraints :

Shift towards Sustainable Alternatives is Hindering the Market Growth

The shift towards sustainable choices provides numerous difficulties for benzene, which is a key raw material in manufacturing numerous standard plastics and chemicals. The rise in green chemistry initiatives is pushing for the development and adoption of safer, more sustainable chemicals. This trend diverts investment and research away from traditional benzene-based processes and products. Advances in technology and chemistry are leading to the development of alternative materials and processes that do not rely on the compound. These innovations are gradually replacing traditional applications of the compound.

Therefore, the production faces challenges from the declining usage of benzene-based plastics, the advent of bio-based and biodegradable polymers, and the growing use of recycled resources.

Future Opportunities :

Technological Advancements in the Production of Benzene Bringing New Opportunities in the Market

Developing improved catalysts for manufacturing practices, such as the transformation of naphtha, will bring about higher yields and diminished manufacturing costs. Implementing cutting-edge process oversight and automation systems will optimize productive proficiency, minimize human mistakes, and fortify safety. Bio-based manufacturing approaches, using renewable resources like biomass or bio-waste, can lessen reliance on fossil fuels and reduce carbon pollution.

Therefore, the market analysis shows that enhanced production technologies, sustainable practices, new applications, digital transformation, and expansion into emerging markets offer significant opportunities.

Benzene Market Segmental Analysis :

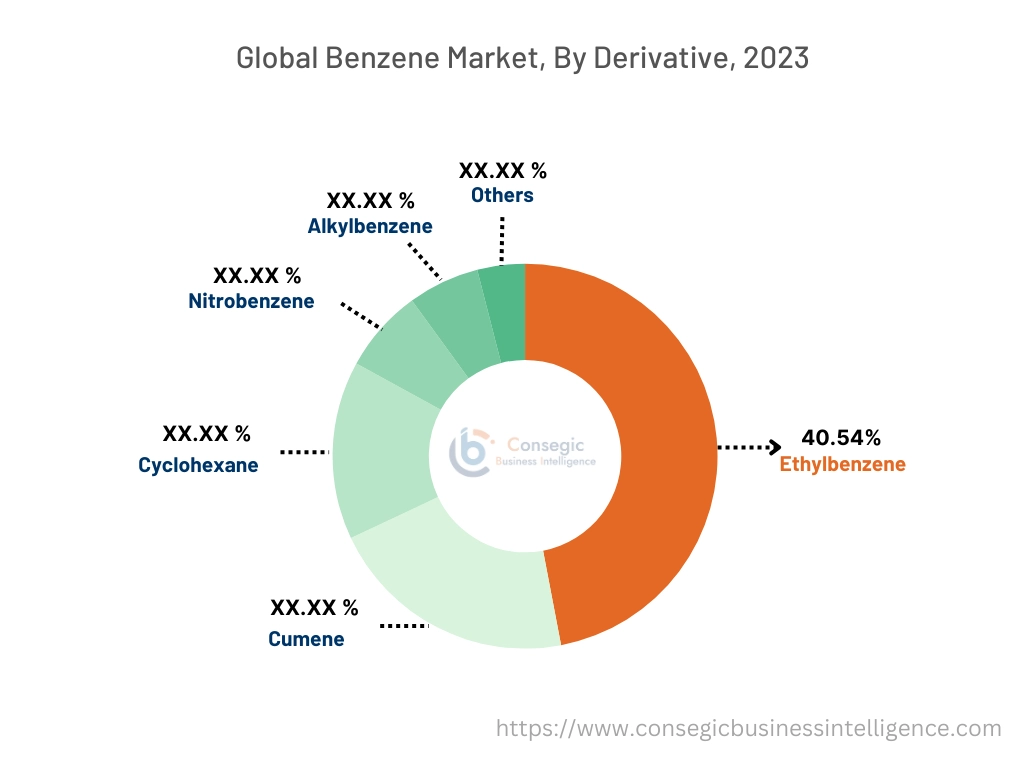

By Derivative:

Based on derivatives the market is segmented into Ethylbenzene, Cumene, Cyclohexane, Nitrobenzene, Alkylbenzene, and others.

Trends in the Derivative:

- Innovations in ethylbenzene production and styrene manufacturing processes can lead to more efficient and cost-effective operations.

The ethylbenzene component accounted for the largest revenue share of 40.54% in 2023.

- Ethylbenzene is primarily used in the production of styrene, which is a vital monomer for producing polystyrene and other styrene-based polymers. Styrene is used extensively in packaging, construction materials, automotive parts, and consumer goods.

- It is used in various industrial applications, including solvents and chemical intermediates.

- The automotive sector's expansion and the need for lightweight and durable materials contribute to the higher consumption of styrene-based products and, consequently, ethylbenzene.

- For instance, as stated by S&P Global, styrene production is the primary factor that determines ethylbenzene demand because almost all ethylbenzene produced worldwide is utilized in its manufacturing.

- Thus, ethylbenzene accounted for the largest revenue due to its critical role in styrene production and its applications in various industries, including plastics, construction, and automotive.

The cumene component segment is anticipated to register the fastest CAGR during the forecast period.

- Cumene is primarily used to produce phenol , which is a crucial raw material in the manufacture of various chemicals, including bisphenol A, used in polycarbonate plastics and epoxy resins.

- Cumene is also used in the production of acetone, which is a solvent and a key ingredient in the production of various chemicals, including methyl methacrylate and isopropyl alcohol.

- The increasing use of polycarbonate plastics and epoxy resins, which are derived from BPA. These materials are widely used in consumer goods, electronics, and medical devices.

- For instance, ExxonMobil continues to be one of the leading cumene catalyst suppliers in the world. ExxonMobil catalysts have successfully created high-quality cumene from every commercial grade of propylene, and the cumene product has been used as a feedstock for all major phenol process technologies.

- Thus, the cumene due to its critical role in the production of phenol and acetone, is expected to drive the benzene market opportunities.

By Production Process:

Based on the production process the market is segmented into pyrolysis, catalytic reforming, steam cracking, toluene disproportionation, toluene hydrodealkylation, and others.

Trends in the Production Process:

- The expanding petrochemical sector, driven by increasing usage of plastics, synthetic fibers, and other chemical products, is fueling the need for more benzene production, further boosting the toluene segment.

- Ongoing improvements in catalytic reforming technologies, such as enhanced catalysts and more efficient processes, will further solidify its position in the market.

The catalytic reforming component accounted for the largest revenue in the year 2023.

- Catalytic reforming is a chemical process used to convert naphtha, a low-value feedstock, into high-octane gasoline components and valuable aromatic compounds, including benzene.

- The process also produces high-octane gasoline components, which are essential for improving the performance and efficiency of motor fuels.

- Besides benzene, catalytic reforming produces other valuable aromatic compounds like toluene and xylene, which are important for various industrial applications.

- Thus, catalytic reforming due to its efficiency in converting low-value naphtha into high-value benzene and other aromatic compounds boosts the benzene market demand.

The toluene disproportionation component segment is anticipated to register the fastest CAGR during the forecast period.

- Toluene disproportionation is a chemical reaction that is transformed into a mixture of benzene and xylenes in the presence of a catalyst, typically a zeolite or metal-based catalyst.

- Toluene disproportionation enhances the value of toluene by converting it into high-value products such as benzene and xylenes. This value addition makes the process economically attractive.

- The xylenes produced are used in the manufacture of polyester fibers, films, and as solvents in various applications.

- For instance, Ataman Chemicals uses p-xylene which is the principal precursor of terephthalic acid and dimethyl terephthalate, both monomers are used for the production of PET plastic bottles and polyester clothing.

- Thus, toluene disproportionation due to its significant role in producing valuable products drives the benzene market opportunities.

By Application:

Based on application the market is segmented into plastics, synthetic fibers, rubber, solvents, detergents, and others.

Trends in the Application:

- Benzene is utilized in the production of styrene, which is then combined with other chemicals to produce synthetic rubber.

The plastics component accounted for the largest revenue of the overall benzene market share in 2023.

- Benzene is a key raw material for producing several important polymers and plastics. It serves as a building block for creating styrene, which is essential for polystyrene, and other plastic polymers.

- Produced from styrene, polystyrene is used in various applications including packaging materials, disposable cutlery, and insulation.

- The rising usage of packaging materials, particularly in food and beverage, consumer goods, and pharmaceuticals, drives the consumption of plastics.

- The automotive sector uses a range of benzene-based plastics, including ABS, for manufacturing components that require durability and impact resistance.

- For instance, Omnexus states that acrylonitrile butadiene styrene, an impact-resistant thermoplastic owing to its rigidity and resilience against impact, abrasion, and stress, ABS enjoys widespread application in electronic enclosures, automotive components, consumer goods, and toys such as Legos.

- Thus, plastics due to their crucial role in producing a wide range of plastic materials used across various industries, are expected to drive the benzene market growth.

The synthetic fibers component segment is anticipated to register the fastest CAGR during the forecast period.

- Benzene is a key raw material in producing PTA (purified terephthalic acid) and DMT (dimethyl terephthalate), which are essential for manufacturing polyester fibers.

- The shift towards synthetic fibers in fashion and everyday clothing due to their affordability, durability, and ease of care drives significant demand.

- The use of synthetic fibers in home furnishings such as rugs, curtains, and upholstery supports the market. They are also used in automotive interiors, including seat covers, carpets, and upholstery.

- For instance, SONGWON develops, manufactures, and supplies a broad variety of polymer stabilizers that protect synthetic fibers and plastics against thermal and oxidation degradation during processing and use, thereby prolonging the life of the end product.

- Thus, as per the market trends analysis, synthetic fibers due to their significant role in the production of essential textiles and industrial materials, are driving the benzene market trends.

By End-User Industry:

Based on the end-user industry the market is segmented into the chemical, textile, pharmaceutical, and others.

Trends in the End-User Industry:

- Innovations in recycling technologies and waste management can contribute to more sustainable chemical production processes.

The chemical sector accounted for the largest revenue of the total benzene market share in 2023.

- Benzene serves as an intermediate in the synthesis of various organic compounds and chemicals, making it integral to multiple sectors within the chemical sector.

- The expanding industrial base and growth in various sectors such as automotive, construction, and consumer goods drive the demand for benzene as a raw material for essential chemicals.

- For instance, as per Prime Scholars benzene plays a pivotal role in the synthesis of many indispensable industrial chemicals. The solvent is necessary for innumerable formulations, such as paints, varnishes, glues, and cleansers.

- Thus, the chemical sector accounted for the largest revenue share in the benzene market due to its essential role in producing a wide range of chemicals and industrial products.

The automotive sector segment is anticipated to register the fastest CAGR during the forecast period.

- Benzene is a raw material in the production of synthetic rubber, particularly styrene-butadiene rubber (SBR) and butadiene rubber, which are used in automotive tires and components.

- Benzene-derived chemicals are used in producing various automotive plastics and resins, including ABS, polycarbonate, and epoxy resins, which are critical for manufacturing automotive parts and interiors.

- Stringent safety and emissions regulations drive the need for high-quality materials that meet performance and regulatory requirements. Benzene-derived materials play a crucial role in meeting these standards.

- For instance, TRP rubber solutions use styrene-butadiene rubber as it is predominantly used as a key constituent in pneumatic automobile tires owing to its wear resistance and versatility as a substitute for natural rubber in many applications.

- Thus, the segmental analysis shows that the automotive sector due to its significant use of benzene-derived materials in manufacturing various components and systems, is expected to drive the benzene market trends.

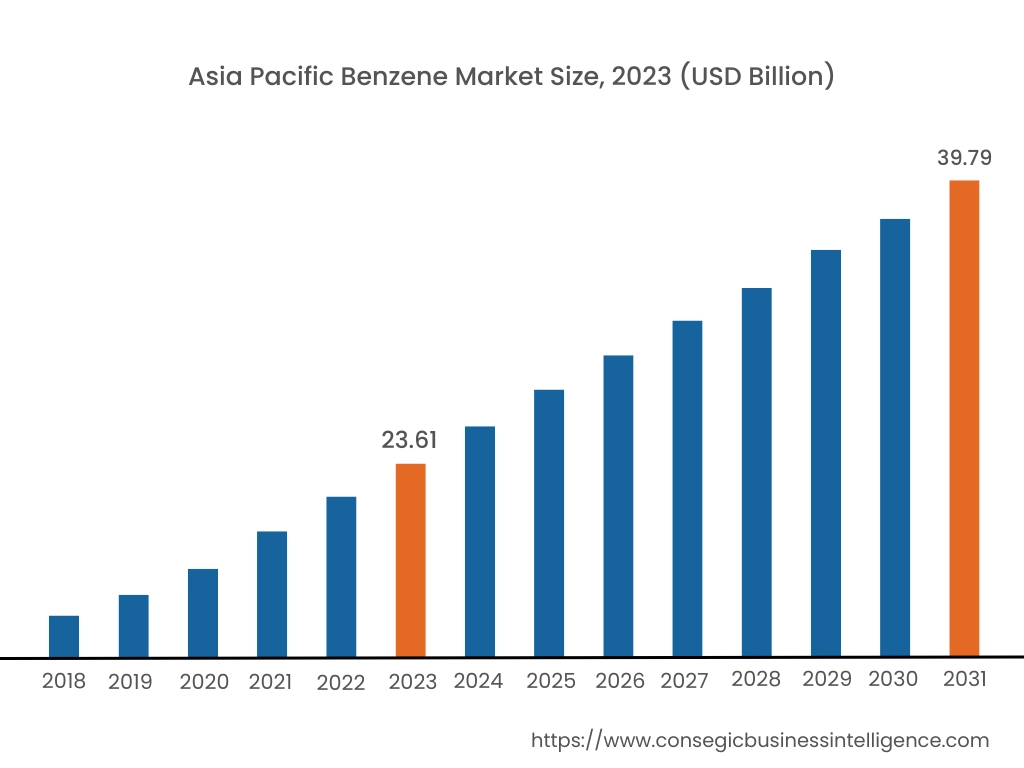

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 23.61 Billion in 2023. Moreover, it is projected to grow by USD 24.75 Billion in 2024 and reach over USD 39.79 Billion by 2031. Out of this, China accounted for the maximum revenue share of 42.4%.

As per the benzene market analysis, the Asia-Pacific region is expected to grow because of the region's increasing usage of this compound in construction and automobile products, as well as the expanding demand for this compound from the flooring and tire industries in developing nations like China and India.

- In July 2022, INEOS agreed to acquire a 50% stake in Shanghai SECCO Petrochemical Company Limited, a subsidiary of China Petroleum & Chemical Corporation (SINOPEC). SECCO currently has a production capacity of 4.2 MMT of petrochemicals - including ethylene, propylene, polyethylene, polypropylene, styrene, polystyrene, acrylonitrile, butadiene, benzene, and toluene.

North America is estimated to reach over USD 16.14 Billion by 2031 from a value of USD 9.56 Billion in 2023 and is projected to grow by USD 10.02 Billion in 2024.

North America is also expected to witness growth during the forecast period due to the increasing packaging, petrochemical, and pharmaceutical industries which are the major end users of the product. According to the U.S. Department of Health & Human Services, this compound is widely used and ranked among the top 20 chemicals for production volume in the country.

- In 2024, Chevron Phillips Chemical Company, states that this compound remains a widely used industrial chemical, fulfilling diverse roles from plastics and fibers to being a gasoline component and excellent solvent, its toxicity raises pressing health and environmental concerns necessitating judicious oversight.

The benzene market analysis depicts that the European region accounts for a significant market share due to the growing usage of the product from various applications, including styrene manufacturing. Latin America, with its diverse economies and expanding industries, holds substantial potential within the ever-changing marketplace. The dynamic region's flourishing manufacturing sector and developing appetite for numerous end-uses contribute markedly to its evolving function.

The regional analysis of the oil-rich Middle East shows that the region remains a premier petrochemical producer, as colossal reserves fuel extensive complex networks. Nations such as dominant Saudi Arabia, the thriving United Arab Emirates, and prospering Qatar house considerable plants extracting benzene as hydrocarbons transform. Meanwhile, accelerating infrastructure development and vehicle ownership throughout the continent drive requirements for benzene-based materials among burgeoning African populaces striving for modernization.

Top Key Players & Market Share Insights:

The Benzene Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global benzene market. Key players in the benzene industry include-

- Aerosol Aromatics GmbH & Co. KG (Germany)

- Dow(US)

- SABIC (Saudi Arabia)

- Petrochemicals Limited (India)

- Indian Oil Corporation Ltd (India)

- Exxon Mobil Corporation (US)

- BASF SE (Germany)

- Repsol (Spain)

- Reliance Industries Limited (India)

- PTT Global Chemical Public Company Borealis AG (Austria)

- BP plc (UK)

- Royal Dutch Shell Plc (Netherlands)

- GS Caltex Corporation (South Korea)

- China Petroleum & Chemical Corporation (China)

- Haldia Limited (Thailand)

Recent Industry Developments :

Partnerships and Collaboration:

- In June 2024, Encina Development Group, LLC (Encina), a producer of ISCC PLUS-certified circular chemicals, and BASF signed a partnership for an extended supply deal of chemically recycled circular benzene obtained from post-consumer end-of-life plastics.

Business Expansions:

- In March 2024, Bodal Chemicals Ltd recently announced the starting up of new projects for specialty benzene downstream products with a capacity of 63,000 MTPA.

Regulations:

- In June 2024, in accordance with a newly finalized EPA rule, U.S. Steel's Clairton Coke Works, the country's largest coke plant, must establish a network of air monitors to record benzene levels across the 392-acre site.

Benzene Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 74.05 Billion |

| CAGR (2024-2031) | 6.3% |

| By Derivative |

|

| By Production Process |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Benzene Market? +

Benzene Market size is estimated to reach over USD 74.05 Billion by 2031 from a value of USD 45.26 Billion in 2023 and is projected to grow by USD 47.33 Billion in 2024, growing at a CAGR of 6.3% from 2024 to 2031.

Which is the fastest-growing region in the benzene market? +

North America is the fastest-growing region in the benzene market.

What specific segmentation details are covered in the benzene market report? +

The specific segment details covered in the benzene market report are derivative, production process, application, and end-user industry.

Who are the major players in the benzene market? +

The major players in the benzene market are Aerosol Aromatics GmbH & Co. KG (Germany), Dow (US)., Reliance Industries Limited (India), SABIC (Saudi Arabia), Petrochemicals Limited (India), Indian Oil Corporation Ltd (India), PTT Global Chemical Public Company Borealis AG (Austria), BP plc (UK), Royal Dutch Shell Plc (Netherlands), GS Caltex Corporation (South Korea), Exxon Mobil Corporation (US), BASF SE (Germany), Repsol (Spain), China Petroleum & Chemical Corporation (China), and Haldia Limited (Thailand)