- Summary

- Table Of Content

- Methodology

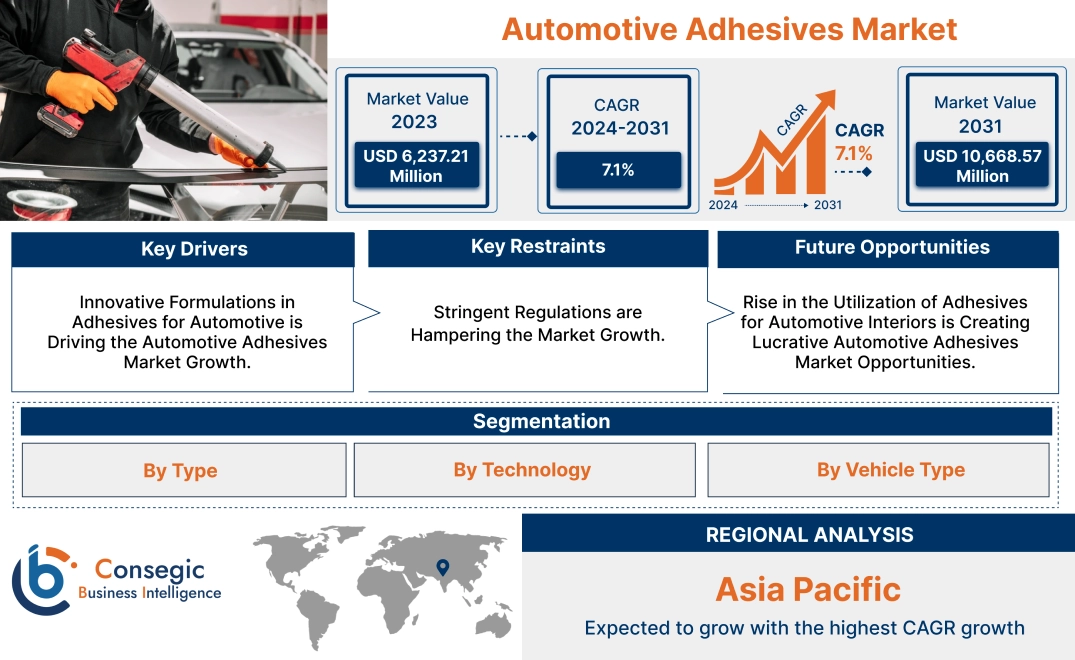

Automotive Adhesives Market Size:

Automotive Adhesives Market size is growing with a CAGR of 7.1% during the forecast period (2024-2031), and the market is projected to be valued at USD 10,668.57 Million by 2031 from USD 6,237.21 Million in 2023.

Automotive Adhesives Market Scope & Overview:

Automotive adhesives refer to a specialized bonding agent used in the automotive sector to securely attach various components of a vehicle such as panels trim seals and even structural parts. These adhesives are formulated to provide strong durable bonds that are able to withstand the harsh conditions of automotive environments including temperature fluctuations vibration and exposure to moisture chemicals and UV rays. They are available in a variety of types including epoxy adhesives, polyurethane adhesives, acrylic adhesives, and silicon adhesives among others, and they offer advantages over traditional mechanical fastening methods such as welding or rivets by providing a lighter, more flexible, and more aesthetically pleasing solution for vehicle assembly and repair. These adhesives are suitable for commercial and passenger vehicles.

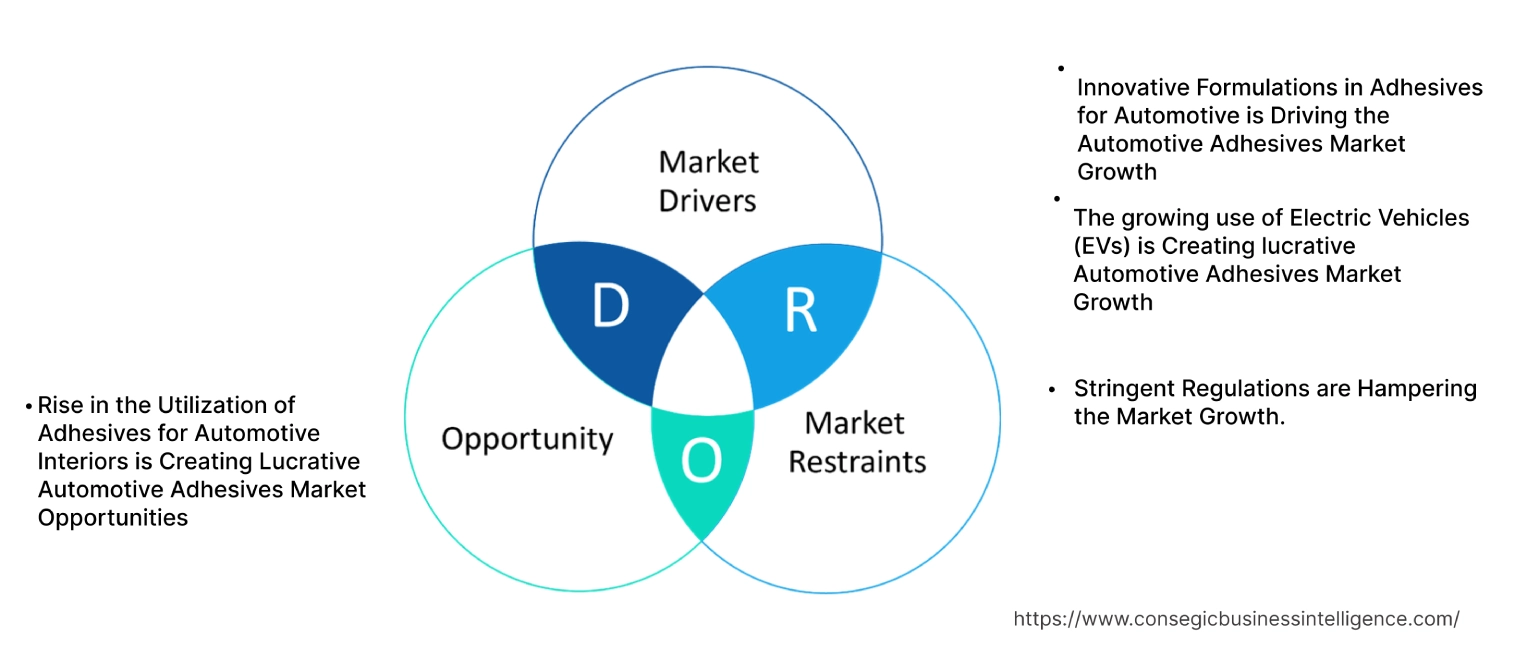

Automotive Adhesives Market Dynamics - (DRO) :

Key Drivers:

Innovative Formulations in Adhesives for Automotive is Driving the Automotive Adhesives Market Growth.

Advancements in adhesive technology are driving a significant rise in the market. Innovative formulations enable the use of adhesives in diverse automotive applications, from structural bonding to interior and exterior components. High-performance adhesives offer numerous advantages over traditional mechanical fasteners, including improved design flexibility, enhanced aesthetics, and reduced weight.

Additionally, adhesives play a crucial role in assembling battery modules and packs, ensuring structural integrity, thermal management, and electrical insulation. Various manufacturers are introducing advanced adhesive solutions for various battery applications.

For instance,

- In May 2023, Henkel introduced a novel innovation for electric vehicle (EV) battery systems called Loctite TLB 9300 APSi, which is a novel injectable thermally conductive adhesive. This novel solution addresses the critical challenge of thermal management in EV batteries, enabling efficient heat dissipation and enhancing overall battery performance.

Thus, the advancements in adhesive solutions for automotive applications are driving the automotive adhesives market expansion.

The growing use of Electric Vehicles (EVs) is Creating lucrative Automotive Adhesives Market Growth.

The expanding electric vehicle (EV) sector is creating a surge in requirement for novel automotive adhesives. EVs, with their unique design and lightweight components, require advanced bonding solutions. These adhesives play a crucial role in assembling battery packs, securing lightweight components, and ensuring watertight seals. They are used to bond components like battery cells, modules, and enclosures, ensuring structural integrity and watertight seals. Adhesives also secure lightweight components, reducing vehicle weight and improving energy efficiency. Additionally, they are employed for thermal management, electrical insulation, and vibration damping, contributing to the overall performance and safety of EVs. This has led to the rise in the use of electric vehicles in various countries.

For instance,

- According to the data published by the International Energy Agency in 2023, the electric vehicle (EV) is accelerating, with global sales surging to nearly 14 million units in 2023. The electric car sales were 3.5 million higher than in 2023. The rise is influenced by the use of novel solutions such as adhesives as they offer exceptional properties.

Thus, the rapid expansion of the electric vehicle (EV) sector is driving a surge in demand for innovative adhesives for automotive.

Key Restraints :

Stringent Regulations are Hampering the Market Growth.

Stringent government regulations significantly hinder the automotive adhesives market demand. These regulations often involve complex testing and certification procedures. Manufacturers comply with standards and protocols, including material safety data sheets, environmental impact assessments, and rigorous performance testing. These comprehensive evaluations are time-consuming and costly, extending product development cycles and increasing overall production expenses. Additionally, these regulations often impose strict limitations on the types of materials and chemicals that are used in adhesive formulations, further restricting the options available to manufacturers.

Furthermore, variations in regulatory standards across different regions complicate the global market for automotive adhesives. These factors contribute to the slowing rise of the market.

Future Opportunities :

Rise in the Utilization of Adhesives for Automotive Interiors is Creating Lucrative Automotive Adhesives Market Opportunities.

The automotive sector is increasingly utilizing adhesives for interior applications, significantly creating lucrative automotive adhesives market opportunities. Adhesive bonding creates smooth, visually appealing joints that elevate the overall aesthetic appeal of the automotive interior. This enables designers to explore innovative shapes and contours, for automotive design. Additionally, adhesives distribute pressure more evenly across bonded surfaces, improving structural integrity and durability. Manufacturers are introducing novel adhesive solutions for various automotive applications.

For instance,

- In 2024, Covestro introduced Dispercoll U, which enables the formulation of tailored adhesives for specific automotive interior applications, contributing to the production of high-quality, durable, and efficient vehicles.

As consumers require more enhanced interiors, the need for high-performance adhesives for automotive continues to rise, presenting lucrative opportunities for manufacturers.

Automotive Adhesives Market Segmental Analysis :

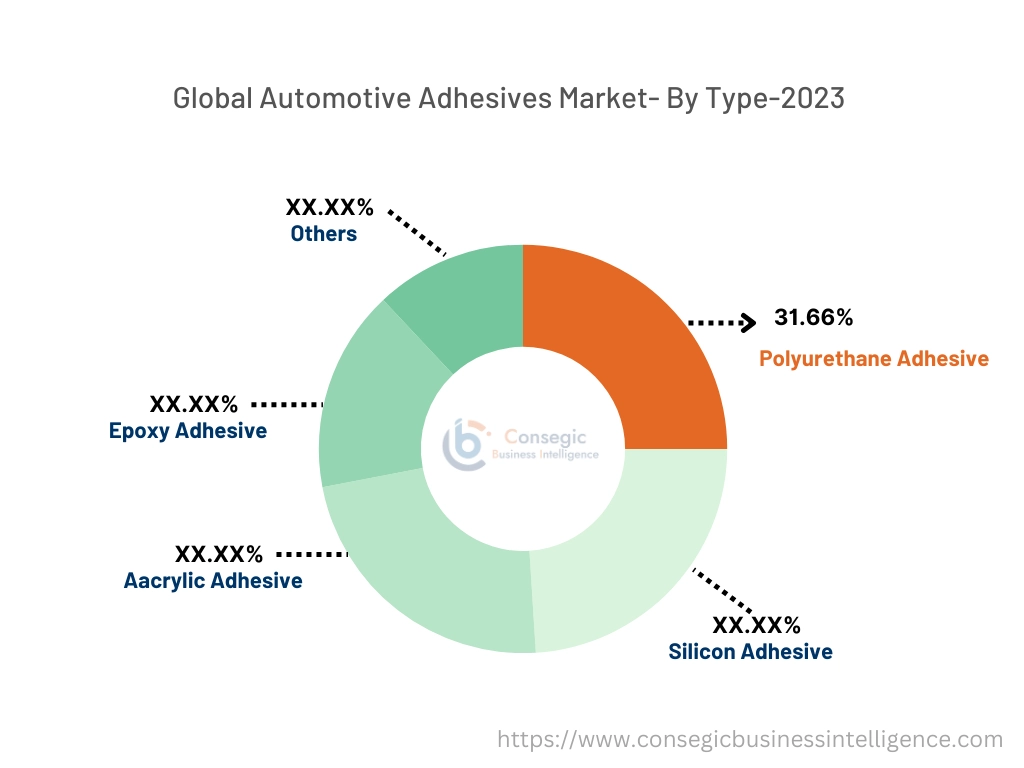

By Type:

Based on type, the market is categorized into silicon adhesive, polyurethane adhesive, acrylic adhesive, epoxy adhesive, and others.

Trends in the Type:

- Ongoing research and development are leading to the development of polyurethane adhesives with enhanced properties, such as improved heat resistance, chemical resistance, and impact strength.

- New curing technologies, such as UV curing and microwave curing, are enabling faster curing times and improved performance for epoxy adhesives.

The polyurethane adhesive segment accounted for the largest market share of 31.66% in 2023.

- Polyurethane adhesives are a type of polymer-based adhesive that offers a wide range of properties, making them versatile for various applications.

- Polyurethane adhesives are a versatile class of adhesives known for their excellent adhesion to a wide range of substrates, including metals, plastics, wood, and rubber.

- They offer a combination of properties such as high strength, flexibility, durability, and resistance to environmental factors.

- Polyurethane adhesives are widely used in various industries, including automotive.

- They are particularly popular in automotive applications due to their ability to bond different materials and withstand harsh environmental conditions.

- Manufacturers are introducing novel polyurethane adhesives to balance thermal conductivity with high mechanical strength in electronic vehicles.

- For instance, in 2023, Bostik and Polytec PT introduced their new range of Thermal Conductive Adhesives (TCAs). XPU TCA 202 is a dual-component, polyurethane-based adhesive engineered for efficient heat dissipation in battery pack assemblies

- Thus, based on the analysis, the use of polyurethane adhesives in electric vehicle applications is driving the share of the market.

The epoxy adhesives segment is expected to grow at the fastest CAGR over the forecast period.

- Epoxy adhesives have become necessary in the automotive sector due to their exceptional properties.

- They offer excellent adhesion to a wide range of substrates, including metals, plastics, and composites.

- Epoxy adhesives are known for their high strength, durability, and resistance to environmental factors such as temperature extremes, moisture, and chemicals.

- They are widely used in various automotive applications, including structural bonding, sealing, and encapsulation.

- In particular, epoxy adhesives are crucial in electric vehicle (EV) manufacturing, where they are used to bond battery cells, modules, and enclosures, ensuring optimal performance and safety.

- As per the analysis, their ability to withstand high temperatures and vibrations makes them ideal for automotive environments, thus driving the automotive adhesives market demand.

By Technology:

Based on technology, the market is categorized into hot-melt, solvent-borne, water-borne, and others.

Trends in Technology:

- The focus on sustainability is driving the development of even more eco-friendly water-borne adhesives with reduced environmental impact.

- Manufacturers are developing low-VOC solvent-borne adhesives to meet stringent environmental regulations.

The water-borne segment accounted for the largest automotive adhesives market share in 2023 and is expected to grow at the fastest CAGR over the forecast period.

- Water-borne adhesives have gained significant development in the automotive sector due to their environmental friendliness and performance benefits.

- These adhesives, formulated with water as the primary component, offer several advantages over traditional solvent-based adhesives.

- They are less volatile, reducing harmful emissions and improving indoor air quality.

- Water-borne adhesives also offer excellent adhesion to a variety of substrates, including plastics, metals, and textiles.

- They are widely used in automotive interior applications such as bonding headliners, door panels, and seat covers.

- Additionally, they are employed in exterior applications like bonding exterior trim components.

- Water-borne adhesives contribute to lighter-weight vehicles, improved fuel efficiency, and reduced environmental impact, making them a sustainable choice for the automotive sector.

- Additionally, by offering a balance of performance, safety, and environmental friendliness, water-borne adhesives are utilized for more sustainable automotive landscapes in the coming years.

- Various manufacturers are introducing water-borne adhesives for enhanced automotive applications.

- For instance, in 2023, DuPont introduced MEGUM W-Series adhesives, which is a line of water-borne adhesives that offers enhanced performance, safety, and sustainability. They contribute to the development of more efficient, durable, and environmentally friendly automotive products.

- Thus, based on the analysis, the utilization of water-borne adhesives is driving the automotive adhesives market trends.

By Vehicle Type:

Based on vehicle type, the market is categorized into passenger cars and commercial vehicles.

Trends in the vehicle type:

- The growing trends of EVs have increased the requirement for adhesives in battery assembly, where they are used to bond battery cells, modules, and enclosures.

- The development of autonomous vehicles requires advanced bonding solutions for sensors, lidar systems, and other components, thus driving the automotive adhesives market trend.

The commercial vehicle segment accounted for the largest automotive adhesives market share in the year 2023.

The commercial vehicle segment is further bifurcated into light commercial vehicles and light commercial vehicles.

- Commercial vehicles are motor vehicles used for transporting goods or people for commercial purposes. The dominance of adhesives for automotive in commercial vehicles is driven by their ability to address the unique structural requirements of these large-scale vehicles.

- Commercial vehicles, such as trucks and buses, often require robust bonding solutions to withstand heavy loads, vibrations, and extreme weather conditions.

- Adhesives offer a superior solution by providing strong, durable, and lightweight bonds. By replacing traditional mechanical fasteners like rivets and welds, adhesives contribute to weight reduction, improved fuel efficiency, and enhanced vehicle performance.

- Heavy commercial vehicles are larger commercial vehicles designed for transporting heavy loads over longer distances.

- Light commercial vehicles are smaller commercial vehicles designed for transporting goods over shorter distances. The rise in the use of adhesives in these vehicles offers enhanced features, thus leading to a rise in production.

- For instance, according to the data provided by TD Economics in April 2024, the U.S. light vehicle market, saw a 12.7% increase in sales.

- Thus, as per the analysis, the rise in the utilization of adhesives in automotive is influencing the automotive adhesives market expansion.

The passenger vehicle segment is expected to grow at the fastest CAGR over the forecast period.

- Passenger vehicles are motor vehicles primarily designed for transporting people and their belongings. They are typically designed to seat a limited number of passengers.

- Automotive adhesives play a critical role in modern vehicle manufacturing, offering significant advantages over traditional mechanical fasteners.

- They are employed to bond a diverse range of components, including interior trim, exterior panels, and structural elements.

- By providing strong, durable, and lightweight bonds, adhesives contribute to improved vehicle performance, fuel efficiency, and safety.

- Additionally, they enable innovative designs, reduce manufacturing costs, and enhance the overall aesthetics of vehicles.

- As the automotive sector continues to evolve, the requirement for advanced adhesive solutions is expected to grow, driving further innovation and sustainability trends.

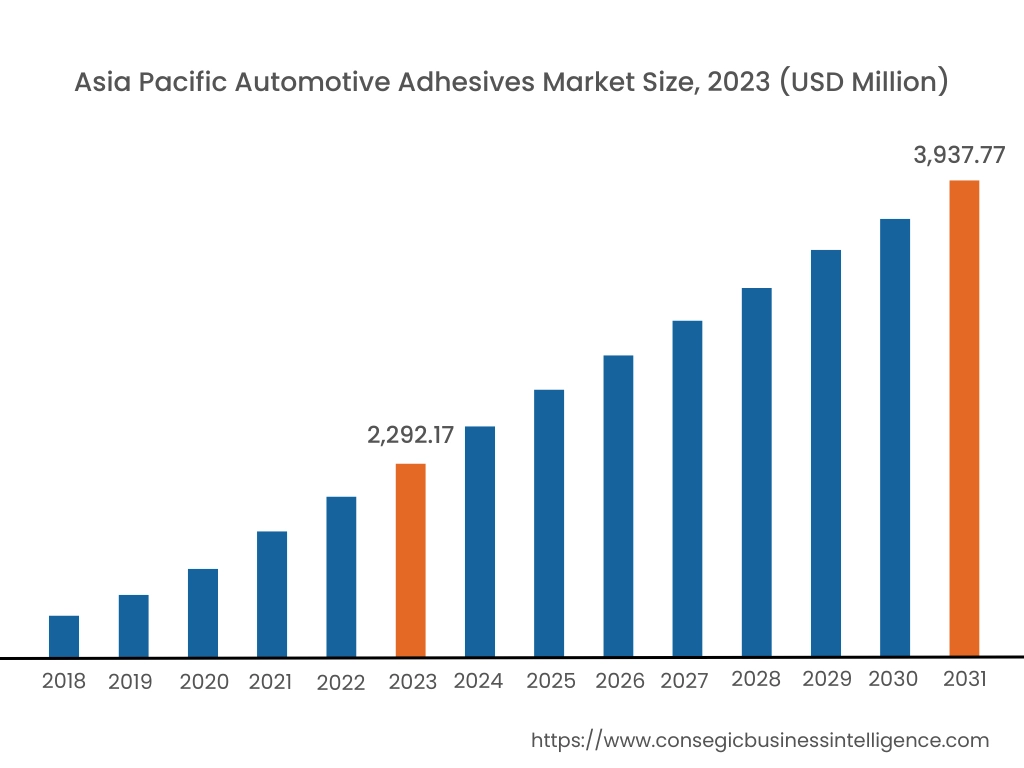

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, Asia Pacific accounted for the highest market share at 36.75% and was valued at USD 2,292.17 Million and is expected to reach USD 3,937.77 Million in 2031. In Asia Pacific, China accounted for the highest market share of 23.11% during the base year of 2023.

The Asia-Pacific region is a major center for automotive manufacturing, with countries such as China, Japan, South Korea, and India emerging as key players. As the need for vehicles continues to grow, so does the demand for high-performance automotive adhesives. These adhesives are used in a wide range of automotive applications, offering enhanced properties such as improved bond strength, durability, and resistance to environmental factors. They contribute to lighter-weight, more fuel-efficient, and safer vehicles. The region's focus on electric vehicle adoption is driving the requirement for advanced adhesive solutions. These properties lead to the development of novel production sites of adhesives for automotive applications.

For instance,

- In 2023, Henkel initiated construction on a new manufacturing facility for its Adhesive Technologies business unit within Yantai Chemical Sector Park, Shandong Province, China. This new plant, named 'Kunpeng,' is a significant investment of approximately USD 126.05 million and will bolster Henkel's production capacity for high-impact adhesive products in China. The facility aims to optimize the supply network and cater to the increasing requirements from both domestic and international markets of automotive, equipment manufacturing, and others.

Thus, as per the automotive adhesives market analysis, these factors are driving the utilization of adhesives for various automotive applications.

The North American market is experiencing the fastest growth with a CAGR of 7.7% over the forecast period. The North American automotive sector is a major global player, characterized by a strong focus on innovation, safety, and sustainability. Automotive adhesives play a crucial role in this sector, enabling the production of high-quality, efficient, and environmentally friendly vehicles. These adhesives are used in a wide range of applications, including bonding interior and exterior components, sealing joints, and assembling battery packs for electric vehicles. As the region continues to drive the adoption of advanced technologies, such as autonomous driving and electrification, the requirement for high-performance, sustainable, and cost-effective adhesives is expected to grow. This presents significant trends for adhesive manufacturers to develop innovative solutions that meet the evolving needs of the North American automotive market.

The European automotive sector is known for its focus on innovation, quality, and sustainability. As a result, based on the automotive adhesives market analysis, the requirement for advanced adhesives for automotive is significant. These adhesives play a crucial role in various applications, including bonding interior and exterior components, sealing joints, and assembling battery packs for electric vehicles. European manufacturers are increasingly adopting adhesive technologies to reduce vehicle weight, improve fuel efficiency, and enhance safety. The region's stringent environmental regulations have led to the development of eco-friendly adhesives with reduced VOC emissions. Additionally, the growing trend of electric vehicles has created a need for adhesives that withstand the unique requirements of battery systems. As the European automotive sector continues to evolve, the requirement for high-performance, sustainable, and cost-effective adhesives is expected to remain strong.

The Middle East and Africa (MEA) regions are experiencing rapid industrialization and urbanization, driving significant growth in the automotive sector. As a result, the requirement for adhesives for automotive is increasing steadily. These adhesives play a crucial role in various automotive applications, including bonding interior and exterior components, sealing joints, and assembling battery packs for electric vehicles. The region's diverse climatic conditions, ranging from extreme heat to cold, pose unique challenges for automotive components. Adhesives offer reliable solutions by providing strong, durable, and weather-resistant bonds. Additionally, as the MEA region embraces sustainable practices, the demand for eco-friendly adhesives is growing. This influences the development of innovative adhesive solutions that meet the specific needs of the region's automotive industry.

The Latin American automotive sector is experiencing significant growth, driven by increasing disposable incomes and rising demand for personal mobility. This growth has led to a corresponding increase in the need for adhesives for automotive. By providing strong, durable, and lightweight bonds, adhesives contribute to improved vehicle performance, fuel efficiency, and safety. Moreover, they enable innovative designs and reduce manufacturing costs. As the Latin American automotive sector continues to expand, driven by factors such as increasing disposable incomes and government initiatives, the demand for high-performance, sustainable, and cost-effective adhesives is poised to grow significantly. This presents a substantial prospect for adhesive manufacturers and suppliers to capitalize on this burgeoning market and contribute to the region's automotive advancements.

Top Key Players & Market Share Insights:

The Automotive Adhesives industry is highly competitive with major players providing precise measurements between objects to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Automotive Adhesives market. Key players in the Automotive Adhesives industry include-

- B. Fuller Company (United States)

- Sika (Switzerland)

- Dow (United States)

- PPG Industries, Inc (United States)

- Huntsman International LLC (United States)

- Bostik (France)

- Henkel Adhesives Technologies India Private Limited (India)

- LG Chem (South Korea)

- DuPont (United States)

- 3M (United States)

Recent Industry Developments :

Partnership:

- In February 2024, Blackbuck EV, a prominent Indian electric vehicle manufacturer, partnered with Sika Automotive, a global leader in sealing, bonding, damping, and reinforcing solutions. This collaboration aims to enhance the lightweight design of Blackbuck's electric vehicle platforms.

- In February 2021, DuPont and the Nissan e.dams Formula E Team announced a technical partnership focused on the development and implementation of advanced adhesive solutions. This collaboration aims to enhance the performance and efficiency of Nissan's Formula E race cars.

Expansion:

- In October 2024, LG Chem announced today that it plans to expand its presence in the global mobility market by supplying thermally conductive adhesives to North American automakers. The company also stated its intention to grow its automotive adhesive business into a multi-million-dollar unit.

Automotive Adhesives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 10,668.57 Million |

| CAGR (2024-2031) | 7.1% |

| By Type |

|

| By Technology |

|

| By Vehicle Type |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Automotive Adhesives market? +

In 2023, the Automotive Adhesives market is USD 6,237.21 million.

Which is the fastest-growing region in the Automotive Adhesives market? +

Asia Pacific is the fastest-growing region in the Automotive Adhesives market.

What specific segmentation details are covered in the Automotive Adhesives market? +

Type, Technology, and Vehicle Type segmentation details are covered in the Automotive Adhesives market

Who are the major players in the Automotive Adhesives market? +

H.B. Fuller Company (United States), Sika (Switzerland), Dow (United States), Bostik (France), Henkel Adhesives Technologies India Private Limited (India), LG Chem (South Korea), DuPont (United States), 3M (United States), PPG Industries, Inc (United States), Huntsman International LLC (United States).