- Summary

- Table Of Content

- Methodology

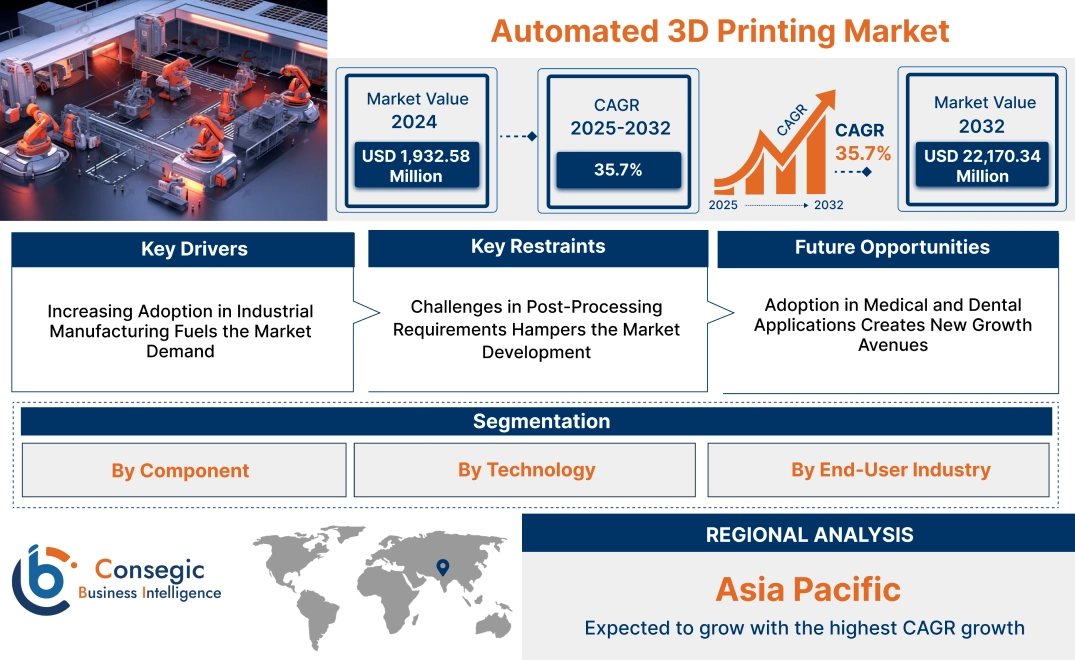

Automated 3D Printing Market Size:

Automated 3D Printing Market size is estimated to reach over USD 22,170.34 Million by 2032 from a value of USD 1,932.58 Million in 2024 and is projected to grow by USD 2,587.30 Million in 2025, growing at a CAGR of 35.7% from 2025 to 2032.

Automated 3D Printing Market Scope & Overview:

Automated 3D printing involves the integration of advanced automation technologies into the 3D printing process to streamline production workflows and enhance efficiency. This approach combines robotics, software, and hardware systems to automate tasks such as material handling, part removal, and post-processing. It is widely utilized across industries including automotive, aerospace, healthcare, and consumer goods for efficient manufacturing of complex components.

These systems are designed to operate with minimal human intervention, ensuring consistent quality and precision. Automated setups often include features like automated build plate changes, real-time monitoring, and integration with factory automation systems, enabling scalable and flexible production. The ability to manage large-scale production while maintaining accuracy makes these systems ideal for industrial applications.

End-users of these technologies include manufacturers, prototyping firms, and research institutions requiring high efficiency and precision in the production of complex parts. Automated 3D printing plays a crucial role in advancing additive manufacturing capabilities across various sectors.

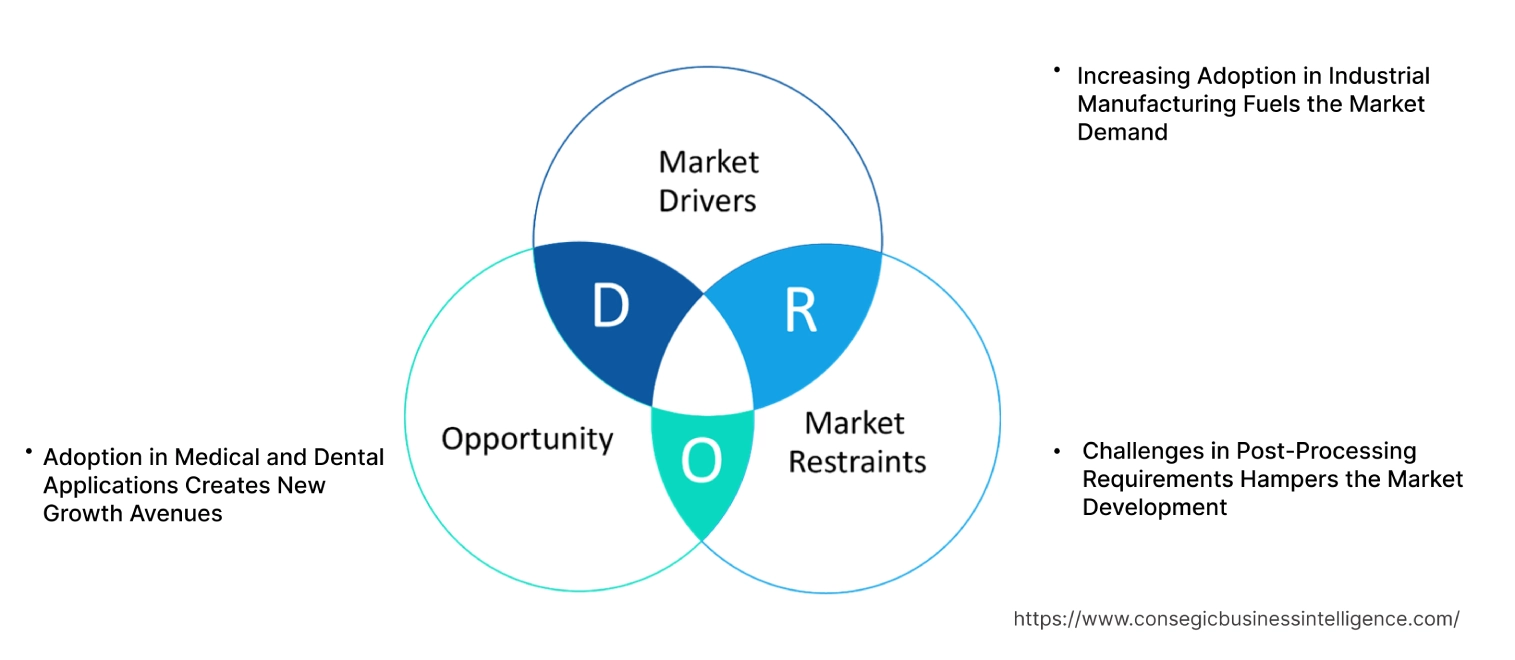

Key Drivers:

Increasing Adoption in Industrial Manufacturing Fuels the Market Demand

The adoption of automation in 3D printing is transforming industrial manufacturing by enhancing efficiency and precision. Automated systems streamline workflows, minimize human intervention, and reduce production errors, resulting in optimized operations. Industries such as aerospace, automotive, and healthcare are increasingly utilizing these solutions for rapid prototyping, lightweight component production, and customization. For example, automated 3D printing enables aerospace manufacturers to create intricate, lightweight parts that reduce fuel consumption, while the healthcare sector leverages it for patient-specific implants and surgical models.

Furthermore, the ability to handle complex geometries and mass customization without significant cost increases has made 3D printing indispensable in modern manufacturing. This trend aligns with the growing demand for scalable, precise, and time-efficient production methods, driving significant growth in the industrial sector. As automation continues to advance, its integration into 3D printing processes is redefining the future of manufacturing, driving the automated 3D printing market growth.

Key Restraints:

Challenges in Post-Processing Requirements Hampers the Market Development

One of the significant limitations of 3D printing is the need for extensive post-processing to achieve the desired part quality. Tasks such as heat treatment, polishing, support removal, or machining are often necessary to improve surface finish, enhance strength, or meet specific functional requirements. These added operations increase production time, labor costs, and overall complexity in the manufacturing workflow. For industries seeking rapid production and cost efficiency, the reliance on post-processing limits the scalability and appeal of 3D printing technologies.

Additionally, the lack of standardization in post-processing methods for different materials and applications further complicates the process, creating barriers to broader adoption in industries requiring streamlined workflows. This restraint underscores the need for advancements in both printing and post-processing technologies to fully unlock the potential of 3D printing solutions. Thus, the aforementioned factors are hindering the automated 3D printing market demand.

Future Opportunities :

Adoption in Medical and Dental Applications Creates New Growth Avenues

The healthcare and dental sectors are rapidly adopting automated 3D printing for producing customized prosthetics, implants, and surgical instruments. The precision offered by automated systems is critical for patient-specific solutions, ensuring an accurate fit and enhanced functionality. In dental applications, 3D printing is transforming the production of crowns, bridges, and aligners, enabling faster and more cost-effective workflows.

Additionally, the ability to create complex geometries allows the production of lightweight yet durable surgical tools and implants, improving procedural efficiency and patient outcomes. Automated workflows further streamline production, reducing lead times and minimizing human error. This growing integration of 3D printing in medical and dental fields aligns with the sector's focus on personalized care and precision medicine, significantly driving automated 3D printing market opportunities.

Automated 3D Printing Market Segmental Analysis :

By Component:

Based on components, the market is segmented into hardware, software, and services.

The hardware segment accounted for the largest revenue of the total automated 3D printing market share in 2024.

- Advanced hardware components such as printers, robots, and conveyors ensure seamless automation in 3D printing workflows, enhancing operational efficiency.

- Printers equipped with high-speed and precision capabilities dominate the segment, catering to diverse industrial applications such as automotive and aerospace.

- Robotic systems integrated with conveyors enable automated material handling, reducing manual intervention and operational downtime.

- As per analysis of segmental trends, the dominance of the hardware segment is driven by technological advancements and increased adoption of automation systems in large-scale manufacturing, contributing to the automated 3D printing market expansion.

The software segment is expected to register the fastest CAGR during the forecast period.

- Workflow software optimizes production processes by streamlining scheduling, monitoring, and execution of 3D printing tasks.

- Control software ensures precise operation of hardware components, improving accuracy and minimizing errors in production.

- Integration of AI and machine learning in software enhances real-time analytics and predictive maintenance capabilities.

- As per the automated 3D printing market trends, the rapid adoption of software solutions reflects the increasing focus on digital transformation and end-to-end automation in manufacturing industries.

By Technology:

Based on technology, the market is segmented into stereolithography (SLA), selective laser sintering (SLS), electron beam melting (EBM), fused deposition modeling (FDM), digital light processing (DLP), laser metal deposition (LMD), PolyJet printing, laminated object manufacturing (LOM), and others.

The stereolithography (SLA) segment accounted for the largest revenue of the total automated 3D printing market share in 2024.

- SLA technology is preferred for producing high-resolution prototypes and detailed parts, making it suitable for industries such as healthcare and consumer electronics.

- Its ability to process a wide range of photopolymers enhances flexibility in material selection, driving adoption across various applications.

- The technology’s precision and surface finish quality make it ideal for customized manufacturing and small-batch production.

- As per the automated 3D printing market analysis, the dominance of SLA is attributed to its established use in prototyping and expanding applications in end-use industries.

The fused deposition modeling (FDM) segment is projected to grow at the fastest CAGR during the forecast period.

- FDM is widely used in education, healthcare, and automotive industries for cost-effective and user-friendly 3D printing solutions.

- The increasing availability of high-performance thermoplastics such as ABS and PLA expands its use in diverse applications.

- Technological advancements have improved print speed and material compatibility, further supporting the adoption of FDM.

- The segment’s rapid growth is driven by its affordability, versatility, and accessibility for both industrial and consumer applications, which further fuels the automated 3D printing market demand.

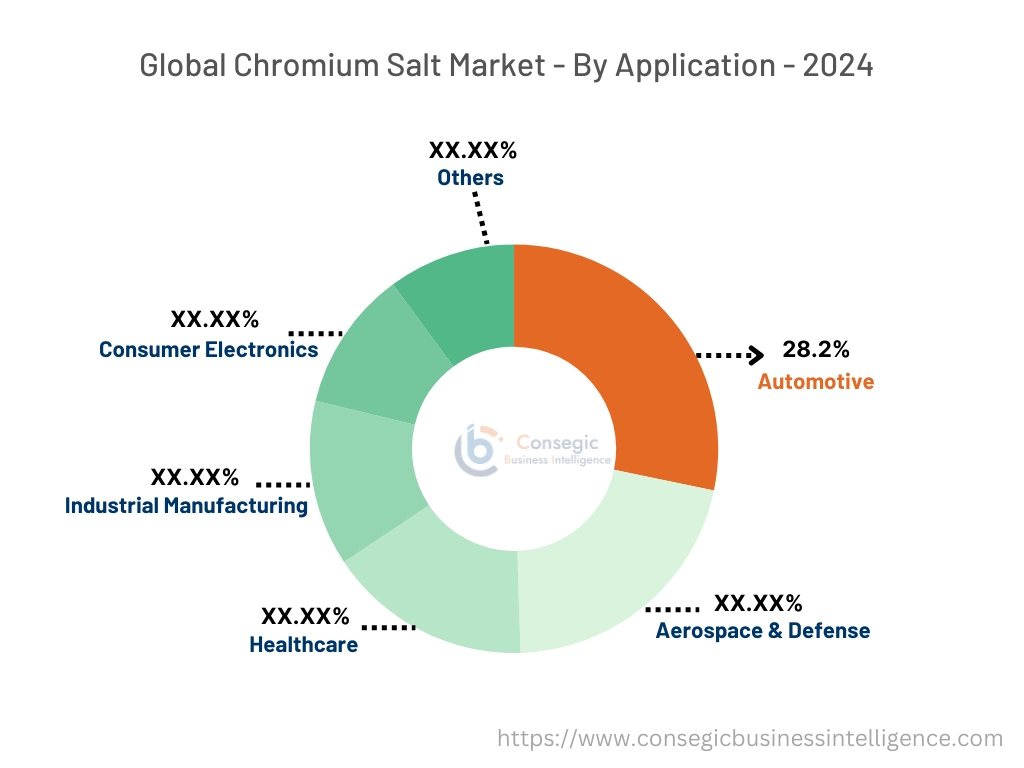

By End User Industry:

Based on end-user industry, the market is segmented into automotive, aerospace & defense, healthcare, industrial manufacturing, consumer electronics, and others.

The automotive segment held the largest revenue of 28.2% share in 2024.

- The use of automated 3D printing in the automotive sector enables rapid prototyping and customized part production, reducing time-to-market.

- Automakers leverage 3D printing for lightweight component manufacturing, enhancing vehicle efficiency and performance.

- The integration of automation ensures high precision and repeatability, meeting the quality standards of the automotive sector.

- The analysis of segmental trends depicts that the dominance of the automotive segment reflects the widespread adoption of 3D printing technologies for innovation and cost optimization, boosting the automated 3D printing market growth.

The healthcare segment is expected to register the fastest CAGR during the forecast period.

- Automated 3D printing facilitates the production of patient-specific implants, prosthetics, and medical devices, improving healthcare outcomes.

- The growing demand for biocompatible materials and precision manufacturing supports its adoption in the medical field.

- Advancements in 3D printing for pharmaceutical applications, such as personalized drug delivery systems, further enhance its use in healthcare.

- As per the automated 3D printing market trends, the rapid growth of the healthcare segment is driven by increasing investments in medical innovation and the need for customized solutions.

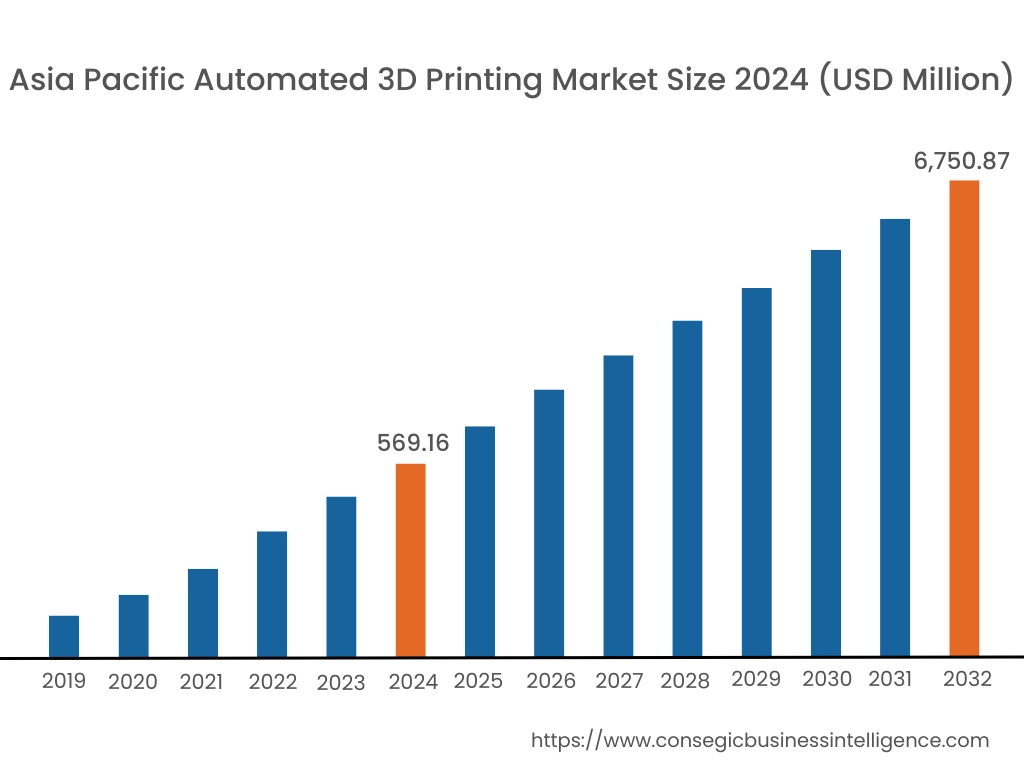

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

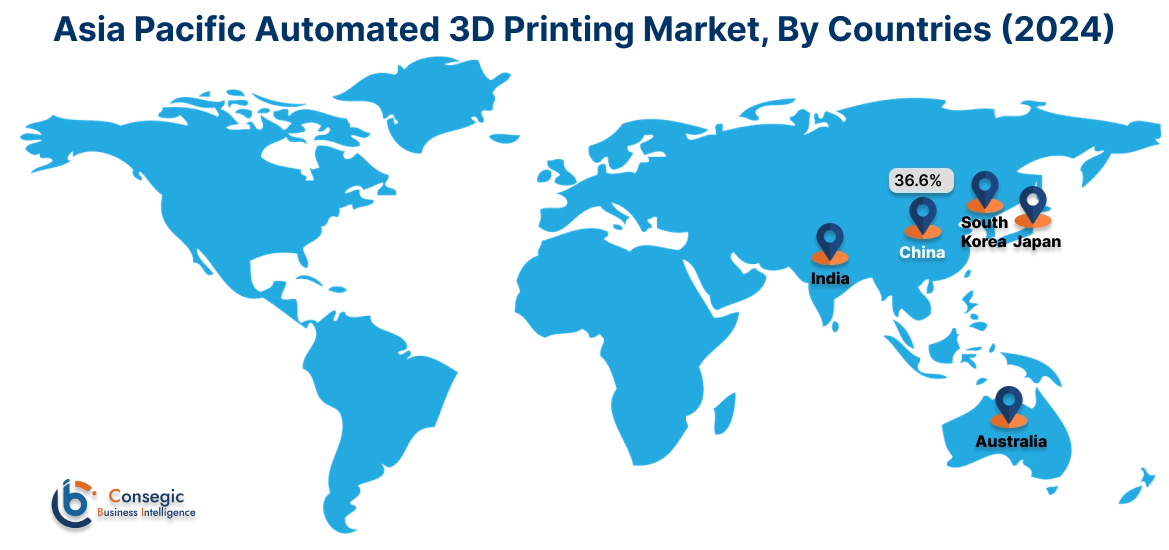

Asia Pacific region was valued at USD 569.16 Million in 2024. Moreover, it is projected to grow by USD 764.14 Million in 2025 and reach over USD 6,750.87 Million by 2032. Out of this, China accounted for the maximum revenue share of 36.6%. The Asia-Pacific region is experiencing rapid advancements in the automated 3D printing market, driven by industrial expansion and technological progress in countries such as China, Japan, and South Korea. The proliferation of consumer electronics and the increasing demand for customized products have intensified the adoption of automated additive manufacturing. Government initiatives supporting industrial automation further influence automated 3D printing market opportunities.

North America is estimated to reach over USD 7,185.41 Million by 2032 from a value of USD 641.05 Million in 2024 and is projected to grow by USD 856.59 Million in 2025. This region commands a substantial share of the automated 3D printing market, propelled by the early adoption of advanced manufacturing technologies and a robust industrial base. The United States, in particular, has integrated automated 3D printing across sectors such as aerospace, automotive, and healthcare. A prominent trend is the incorporation of artificial intelligence and machine learning to enhance printing efficiency and precision. Analysis indicates that the presence of key industry players and continuous investment in research and development bolster the region's market leadership.

Europe represents a significant segment of the global automated 3D printing market, with countries like Germany, France, and the United Kingdom at the forefront of adoption and innovation. The region's focus on Industry 4.0 and sustainable manufacturing practices has accelerated the deployment of automated 3D printing solutions. Analysis reveals a growth in the trend toward utilizing these technologies in the automotive and aerospace industries to achieve complex designs and lightweight components.

The Middle East & Africa region is gradually embracing 3D printing technologies, particularly within the construction and healthcare sectors. Nations like the United Arab Emirates are investing in innovative construction methods, including 3D printing, to achieve ambitious architectural projects. The automated 3D printing market analysis suggests an emerging trend towards adopting 3D printing medical device software to produce medical devices and prosthetics, enhancing healthcare delivery.

Latin America is an emerging market with countries such as Brazil and Mexico contributing to its development. The region's focus on industrial modernization and the automotive sector has spurred interest in automated additive manufacturing solutions. Government policies aimed at enhancing technological capabilities influence automated 3D printing market expansion.

Top Key Players and Market Share Insights:

The automated 3D printing market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global automated 3D printing market. Key players in the automated 3D printing industry include -

- Stratasys Ltd. (USA)

- 3D Systems Corporation (USA)

- EOS GmbH (Germany)

- Universal Robots A/S (Denmark)

- PostProcess Technologies Inc. (USA)

- Materialise NV (Belgium)

- Nikon SLM Solutions Group AG (Germany)

- The ExOne Company (USA)

- Formlabs (USA)

Recent Industry Developments :

Product Launches:

- In June 2024, BigRep launched the VIIO 250, its most automated large-scale FFF 3D printer, tailored for industrial-grade and fiber-reinforced materials. Key features include a 250-liter temperature-controlled build chamber, dual Smart Manufacturing Extruders heating up to 350°C, and innovations like Infinity Box automatic filament handling and Relay Mode for uninterrupted printing. Its HMI interface offers multilingual support and animated guides. Positioned for automotive and industrial manufacturing, it delivers high-resolution parts, 24/7 operation, and energy efficiency.

Automated 3D Printing Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 22,170.34 Million |

| CAGR (2025-2032) | 35.7% |

| By Component |

|

| By Technology |

|

| By End User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the size of the Automated 3D Printing market? +

Automated 3D Printing Market size is estimated to reach over USD 22,170.34 Million by 2032 from a value of USD 1,932.58 Million in 2024 and is projected to grow by USD 2,587.30 Million in 2025, growing at a CAGR of 35.7% from 2025 to 2032.

What are the key segments in the Automated 3D Printing market? +

The Automated 3D Printing market is segmented based on component, technology, and end-user industry. By component, the market includes hardware (printers, robots, conveyors), software (workflow software, control software), and services. The technology segment consists of Stereolithography (SLA), Selective Laser Sintering (SLS), Electron Beam Melting (EBM), Fused Deposition Modeling (FDM), Digital Light Processing (DLP), Laser Metal Deposition (LMD), PolyJet Printing, and Laminated Object Manufacturing (LOM). By end-user industry, the market is divided into automotive, aerospace & defense, healthcare, industrial manufacturing, consumer electronics, and others.

Which segment is expected to grow the fastest in the Automated 3D Printing market? +

The software segment is expected to register the fastest CAGR during the forecast period, driven by the increasing adoption of workflow and control software solutions that help optimize production processes in 3D printing operations.

Who are the major players in the Automated 3D Printing market? +

The major players in the Automated 3D Printing market include Stratasys Ltd. (USA), 3D Systems Corporation (USA), Materialise NV (Belgium), Nikon SLM Solutions Group AG (Germany), The ExOne Company (USA), Formlabs (USA), EOS GmbH (Germany), Universal Robots A/S (Denmark), and PostProcess Technologies Inc. (USA).