- Summary

- Table Of Content

- Methodology

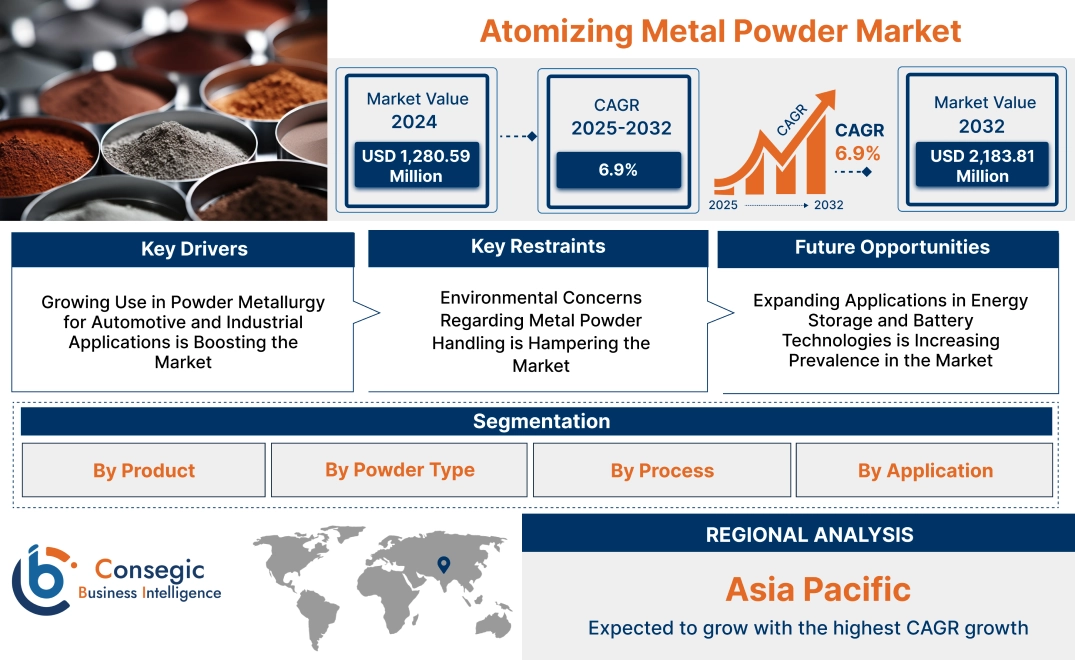

Atomizing Metal Powder Market Size:

Atomizing Metal Powder Market size is estimated to reach over USD 2,183.81 Million by 2032 from a value of USD 1,280.59 Million in 2024 and is projected to grow by USD 1,346.13 Million in 2025, growing at a CAGR of 6.9% from 2025 to 2032.

Atomizing Metal Powder Market Scope & Overview:

The atomizing metal powder is created through atomization processes, such as water, gas, or plasma atomization. These powders are valued for their high purity, uniform particle size, and excellent flowability, making them essential in industries requiring precision and high-performance materials. Key characteristics of atomized metal powders include excellent compressibility, spherical or irregular particle shapes, and compatibility with additive manufacturing, powder metallurgy, and thermal spray coatings. The benefits include enhanced material properties, improved production efficiency, and suitability for advanced manufacturing techniques. Applications span automotive components, aerospace parts, 3D printing, electronics, and coatings. End-users include automotive manufacturers, aerospace companies, electronics producers, and additive manufacturing firms, driven by the increasing adoption of powder-based technologies, rising demand for lightweight materials, and advancements in metal powder production for industrial applications.

Key Drivers:

Growing Use in Powder Metallurgy for Automotive and Industrial Applications is Boosting the Market

Atomized metal powders are becoming increasingly significant in powder metallurgy, a key process in manufacturing high-precision components for automotive and industrial applications. These powders enable the creation of complex parts, such as gears, bearings, and sintered products, with minimal material wastage and enhanced mechanical properties. In the automotive sector, lightweight and durable components produced through powder metallurgy contribute to improved fuel efficiency and performance, aligning with industry trends toward sustainability and energy efficiency.

Industries focusing on cost-effective manufacturing techniques are leveraging the advantages of powder metallurgy, such as reduced production times and lower material costs. Analysis suggests that the increasing atomizing metal powder market opportunities in the adoption of advanced powder processing techniques in industrial machinery and electric vehicle components continues to highlight the critical role of atomized metal powders in modern manufacturing practices.

Key Restraints:

Environmental Concerns Regarding Metal Powder Handling is Hampering the Market

The handling and processing of atomized metal powders raise significant environmental and safety concerns. Fine metal powders, particularly reactive materials like aluminum and titanium, present risks such as dust generation, inhalation hazards, and potential explosion under certain conditions. These challenges necessitate advanced safety protocols, such as controlled environments, proper ventilation systems, and rigorous handling standards to mitigate risks.

Additionally, regulatory frameworks targeting workplace safety and environmental sustainability impose strict guidelines for managing and disposing of metal powders. Industries using these materials face increased scrutiny, requiring investment in safety measures and compliance systems. Trends in environmental awareness and workplace safety underscore the importance of addressing these challenges to ensure the sustainable use of atomized metal powders in various applications.

Future Opportunities :

Expanding Applications in Energy Storage and Battery Technologies is Increasing Prevalence in the Market

Atomized metal powders are gaining traction in energy storage applications, particularly in the development of advanced batteries and fuel cells. Their excellent thermal conductivity, uniform particle size, and ability to enhance energy density make them ideal for components such as battery electrodes and hydrogen fuel cells. These properties are critical for improving the efficiency and longevity of energy storage systems, which are central to the renewable energy and electric vehicle sectors.

Trends in clean energy and electrification are driving the exploration of atomized metal powders for high-performance energy solutions. Analysis highlights the increasing role of these powders in addressing challenges such as energy efficiency and sustainability, making them indispensable in emerging technologies. As industries focus on optimizing battery performance and integrating renewable energy systems, atomized metal powders offer significant potential to support advancements in energy storage and sustainability.

Atomizing Metal Powder Market Segmental Analysis :

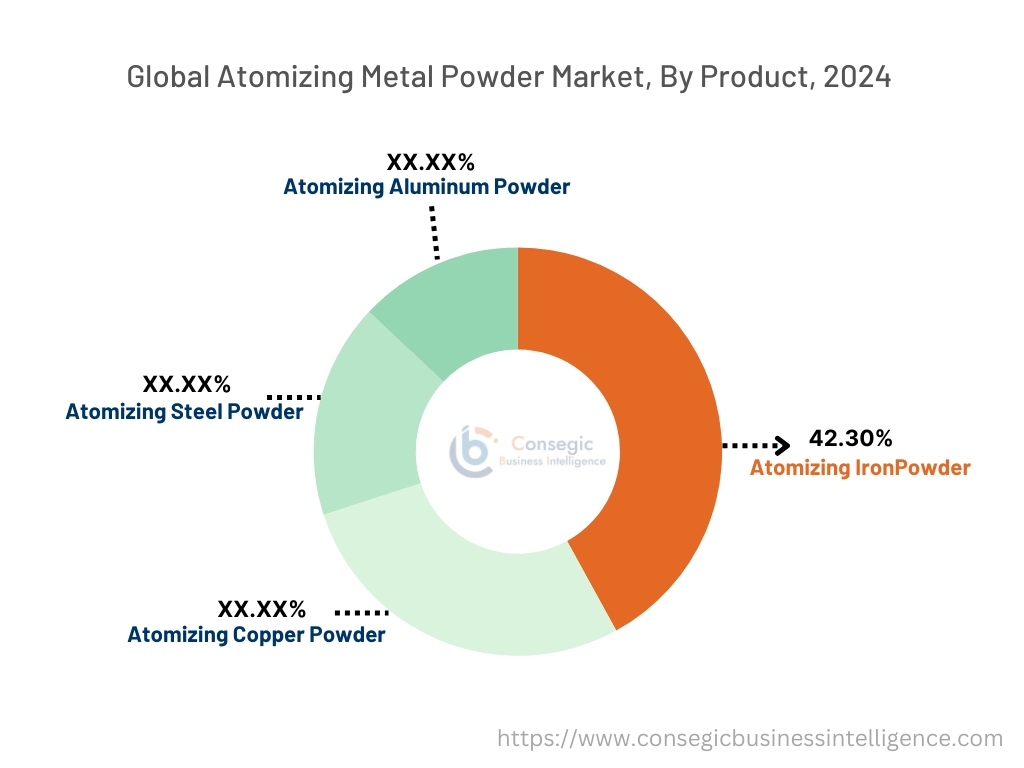

By Product:

Based on product, the atomized metal powder market is segmented into atomizing iron powder, atomizing copper powder, atomizing steel powder, and atomizing aluminum powder.

The atomizing iron powder segment accounted for the largest revenue share of 42.30% in 2024.

- Atomizing iron powder is widely used in industries such as powder metallurgy, automotive, and construction due to its excellent compressibility, sintering properties, and cost-effectiveness.

- It is a key material in the production of structural parts, magnetic components, and welding electrodes.

- The increasing opportunities in the adoption of powder metallurgy techniques in the automotive sector for manufacturing lightweight and durable components has driven the atomizing metal powder market trends for atomizing iron powder.

- Additionally, advancements in sintering technologies and the rising use of iron powder in additive manufacturing are further boosting its atomizing metal powder market expansion.

The atomizing aluminum powder segment is anticipated to register the fastest CAGR during the forecast period.

- Atomizing aluminum powder is gaining traction due to its high strength-to-weight ratio, corrosion resistance, and thermal conductivity.

- These properties make it ideal for applications in additive manufacturing, coatings, and thermal spraying.

- The growing atomizing metal powder market trends for lightweight materials in aerospace and automotive industries, coupled with the increasing adoption of aluminum powder in 3D printing for customized and complex part manufacturing, is driving its growth.

- Additionally, its use in advanced coatings and energy storage systems is expected to further propel the segment’s advancement.

By Powder Type:

Based on powder type, the atomized metal powder market is segmented into iron powder, copper powder, aluminum powder, zinc powder, titanium powder, and others.

The iron powder segment accounted for the largest revenue of atomizing metal powder market share in 2024.

- Iron powder dominates the market due to its widespread application in powder metallurgy, magnetic materials, and welding.

- Its cost-effectiveness, recyclability, and versatility make it a preferred choice for manufacturing automotive components, machinery parts, and electronic devices.

- The increasing trends for iron powder in the automotive sector for producing lightweight parts and improving fuel efficiency has significantly contributed to its dominance.

- Additionally, the rising use of iron powder in 3D printing and additive manufacturing processes is further boosting its atomizing metal powder market demand.

The titanium powder segment is anticipated to register the fastest CAGR during the forecast period.

- Titanium powder is increasingly being adopted in aerospace, medical, and additive manufacturing applications due to its excellent strength, lightweight, and biocompatibility properties.

- It is widely used in producing high-performance components such as turbine blades, medical implants, and aerospace parts.

- The rising focus on 3D printing for manufacturing complex and customized parts, along with the growing atomizing metal powder market trends for titanium powder in medical and dental applications, is driving this segment’s rapid development.

- Moreover, advancements in powder production technologies are expected to enhance the quality and availability of titanium powder, further fueling its atomizing metal powder market expansion.

By Process:

Based on the process, the atomized metal powder market is segmented into water atomization, gas atomization, centrifugal atomization, ultrasonic atomization, and others.

The water atomization segment accounted for the largest revenue share in 2024.

- Water atomization is the most widely used process for producing metal powders due to its cost-effectiveness, scalability, and ability to handle a variety of materials.

- This method is particularly suitable for producing powders with high bulk density and irregular shapes, which are extensively used in powder metallurgy and welding applications.

- The increasing trends for cost-efficient metal powder production techniques in automotive, construction, and machinery industries has driven the adoption of water atomization.

- Additionally, advancements in water atomization technologies to enhance powder quality and production efficiency are further supporting its atomizing metal powder market share.

The gas atomization segment is anticipated to register the fastest CAGR during the forecast period.

- Gas atomization is preferred for producing spherical metal powders with excellent flowability and uniform particle size, which are critical for additive manufacturing, coatings, and thermal spraying applications.

- The growing adoption of 3D printing in aerospace, medical, and industrial sectors has significantly driven the trends for gas-atomized powders.

- Additionally, the rising focus on high-quality and consistent powder production for advanced manufacturing techniques is expected to propel the advancement of this segment.

- Technological advancements in gas atomization, including the use of inert gases to improve powder quality, are further boosting its adoption.

By Application:

Based on application, the atomized metal powder market is segmented into additive manufacturing (3D printing), powder metallurgy, coatings, metal injection molding, thermal spraying, and others.

The powder metallurgy segment accounted for the largest revenue share in 2024.

- Powder metallurgy is a key application for atomized metal powders, as it enables the production of complex and high-strength components with minimal material waste.

- Atomized powders are widely used in the automotive, aerospace, and industrial machinery industries for manufacturing gears, bearings, and structural parts.

- The increasing adoption of powder metallurgy techniques for lightweight and fuel-efficient automotive components has significantly driven the demand for atomized powders in this segment.

- Additionally, advancements in sintering technologies and the growing focus on sustainability in manufacturing processes are further supporting the segment's growth.

The additive manufacturing (3D printing) segment is anticipated to register the fastest CAGR during the forecast period.

- Additive manufacturing relies heavily on high-quality metal powders for producing intricate and customized components in industries such as aerospace, medical, and automotive.

- Atomized metal powders, particularly those produced through gas atomization, are ideal for 3D printing due to their spherical shape and uniform particle size.

- The rising adoption of 3D printing for lightweight and complex part production, coupled with the increasing dominance of sustainable and efficient manufacturing techniques, has fueled the atomizing metal powder market growth of this segment.

- Furthermore, advancements in 3D printing technologies and material innovations are expected to drive significant expansion in the additive manufacturing segment.

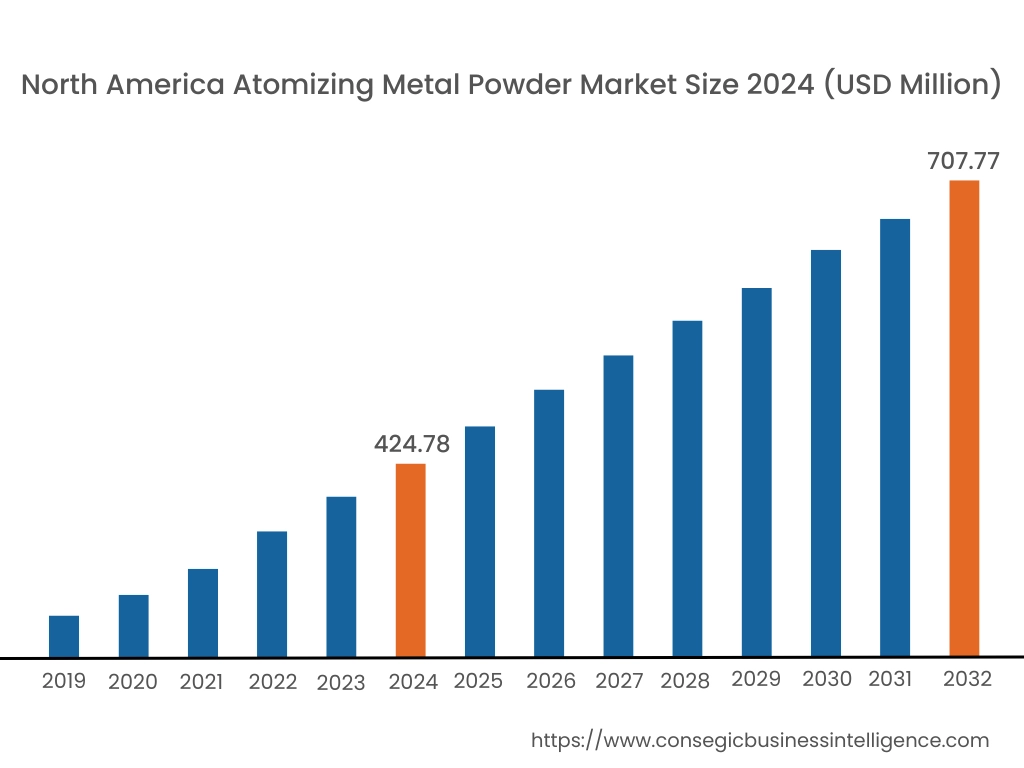

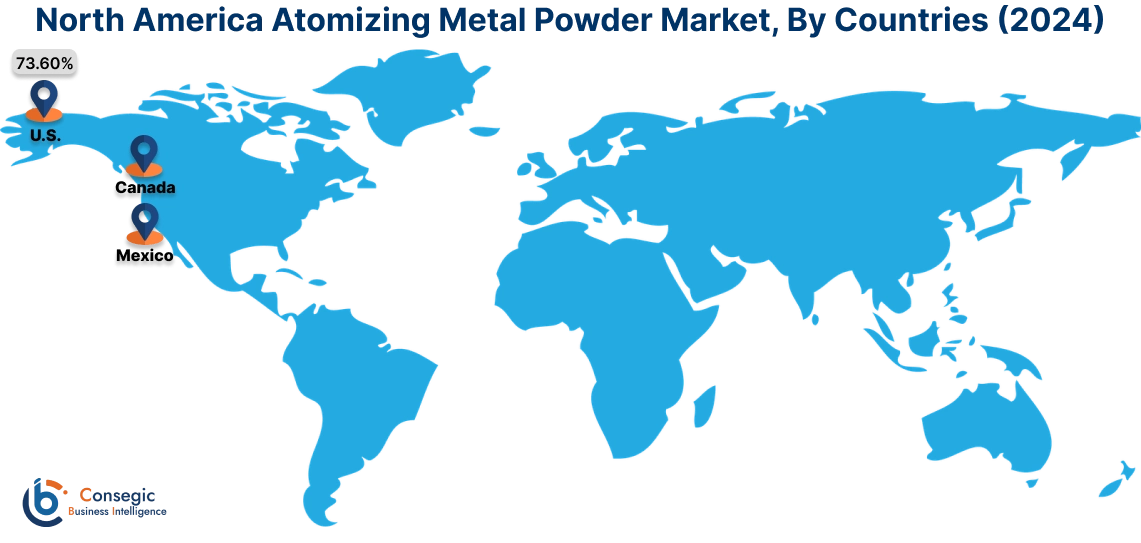

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 424.78 Million and is expected to reach USD 707.77 Million in 2032. In North America, the U.S. accounted for the highest share of 73.60% during the base year of 2024. North America holds a significant stake in the atomizing metal powder market analysis, driven by its well-established aerospace, automotive, and additive manufacturing industries. The U.S. leads the region due to high demand for atomized metal powders in 3D printing, powder metallurgy, and thermal spray applications. The aerospace sector extensively uses these powders to produce lightweight and high-strength components. Canada contributes to the market with its growing adoption of atomized metal powders in industrial manufacturing and renewable energy applications. However, high production costs and energy-intensive processes associated with atomization may challenge atomizing metal powder market growth in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 7.3% over the forecast period. In the atomizing metal powder market analysis, fueled by rapid industrialization, urbanization, and the expanding of the automotive, electronics, and manufacturing sectors in China, India, and Japan. China dominates the market with extensive use of atomized metal powders in additive manufacturing, electronics, and powder metallurgy for automotive parts. India’s growing construction and automotive industries support demand for atomized powders in advanced manufacturing processes. Japan focuses on high-precision applications in electronics, healthcare, and aerospace industries, leveraging atomized powders for superior quality and consistency. However, fluctuating raw material prices and limited technological expertise in emerging markets may hinder growth.

Europe is a prominent for global atomizing metal powders market, supported by its advanced automotive, aerospace, and industrial sectors. Countries like Germany, France, and the UK are key contributors. Germany drives demand through its robust automotive industry, utilizing atomized powders in sintered parts and additive manufacturing. France emphasizes their use in aerospace applications, particularly for high-performance components requiring superior mechanical properties. The UK focuses on expanding the use of atomized powders in advanced manufacturing processes, including metal injection molding (MIM) and 3D printing. However, strict EU environmental regulations on metal production and energy use may pose challenges for manufacturers.

The Middle East & Africa region is witnessing steady growth in the global atomizing metal powder market, driven by increasing industrial and infrastructure development. Countries like Saudi Arabia and the UAE are adopting atomized powders in energy, oil and gas, and construction applications, particularly for thermal spray coatings and high-performance components. In Africa, South Africa is emerging as a market analysis, leveraging atomized metal powders in mining equipment and industrial machinery production. However, limited local manufacturing capabilities and reliance on imports for advanced metal powders may restrict broader market enlargement in the region.

Latin America is an emerging market for atomizing metal powders, with Brazil and Mexico leading the region. As per the regional analysis Brazil’s expanding automotive and industrial manufacturing sectors drive trends for atomized powders in powder metallurgy and additive manufacturing. Mexico’s growing aerospace and electronics industries further support the adoption of atomized metal powders for precision components and advanced manufacturing. The region is also exploring applications in renewable energy and construction. However, economic instability and lack of advanced production infrastructure may pose challenges for market growth in smaller economies.

Top Key Players and Market Share Insights:

The atomizing metal powder market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the atomizing metal powder market. Key players in the atomizing metal powder industry include -

- Höganäs AB (Sweden)

- GKN Hoeganaes (USA)

- Kymera International (USA)

- Sandvik AB (Sweden)

- Mitsui Mining & Smelting Co., Ltd. (Japan)

- Rio Tinto Metal Powders (Canada)

- Pometon S.p.A. (Italy)

- Kobe Steel, Ltd. (Japan)

- JFE Steel Corporation (Japan)

- Laiwu Iron & Steel Group (China)

Atomizing Metal Powder Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2,183.81 Million |

| CAGR (2025-2032) | 6.9% |

| By Product |

|

| By Powder Type |

|

| By Process |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the Atomizing Metal Powder Market by 2032? +

Atomizing Metal Powder Market size is estimated to reach over USD 2,183.81 Million by 2032 from a value of USD 1,280.59 Million in 2024 and is projected to grow by USD 1,346.13 Million in 2025, growing at a CAGR of 6.9% from 2025 to 2032.

What are the key drivers of the Atomizing Metal Powder Market growth? +

Key drivers include the growing use of atomized metal powders in powder metallurgy for automotive and industrial applications, rising adoption in additive manufacturing (3D printing), and advancements in energy storage and battery technologies.

What challenges are hindering the growth of the market? +

The market faces challenges such as environmental concerns and safety risks related to the handling and processing of fine metal powders, along with strict regulatory compliance requirements.

What opportunities exist in the Atomizing Metal Powder Market? +

Opportunities include expanding applications in energy storage systems, including advanced batteries and hydrogen fuel cells, and the growing adoption of atomized powders in additive manufacturing and renewable energy technologies.