- Summary

- Table Of Content

- Methodology

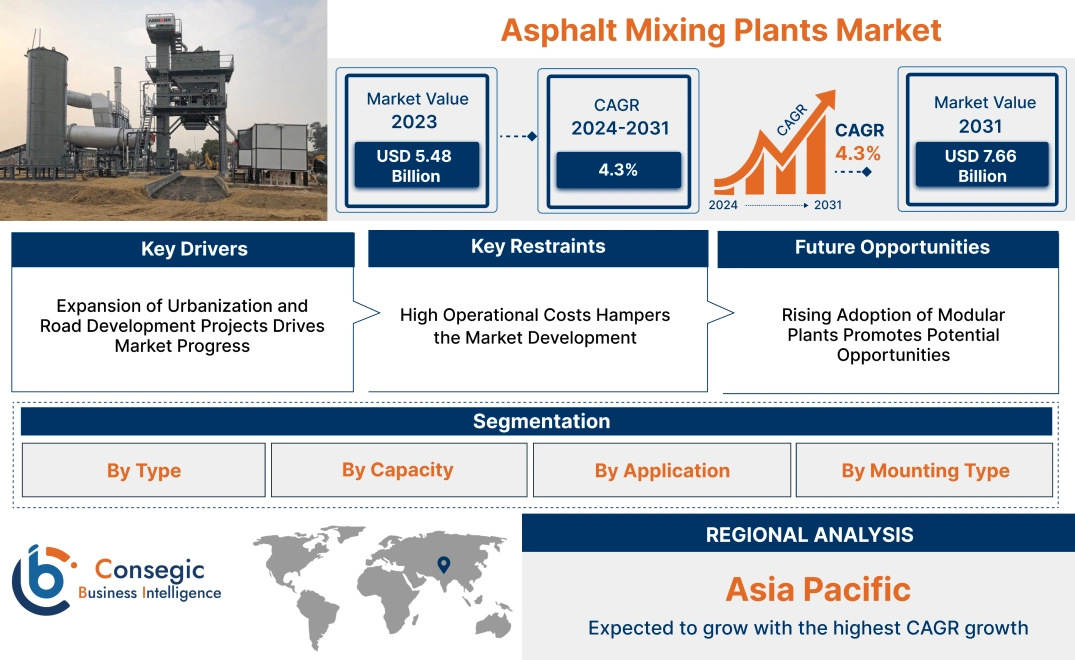

Asphalt Mixing Plants Market Size:

Asphalt Mixing Plants Market size is estimated to reach over USD 7.66 Billion by 2031 from a value of USD 5.48 Billion in 2023 and is projected to grow by USD 5.62 Billion in 2024, growing at a CAGR of 4.3% from 2024 to 2031.

Asphalt Mixing Plants Market Scope & Overview:

Asphalt mixing plants are specialized equipment used to produce asphalt concrete by combining aggregates, bitumen, and filler materials in specific proportions. These plants are designed to ensure uniform mixing and temperature control, producing high-quality asphalt suitable for road construction, airport runways, parking lots, and other infrastructure projects. Available in stationary, portable, and mobile configurations, these plants cater to a wide range of project requirements and operational conditions.

These plants are equipped with components such as drying drums, mixers, conveyors, and storage silos, ensuring efficient production processes and consistent output. Modern asphalt mixing plants also incorporate advanced technologies for precision control and environmental compliance, enhancing operational efficiency while minimizing emissions and material wastage.

End-users of these plants include construction companies, road maintenance contractors, and infrastructure development firms that rely on reliable asphalt production systems to meet project specifications and timelines. These solutions are critical in ensuring durable and long-lasting asphalt surfaces for various applications.

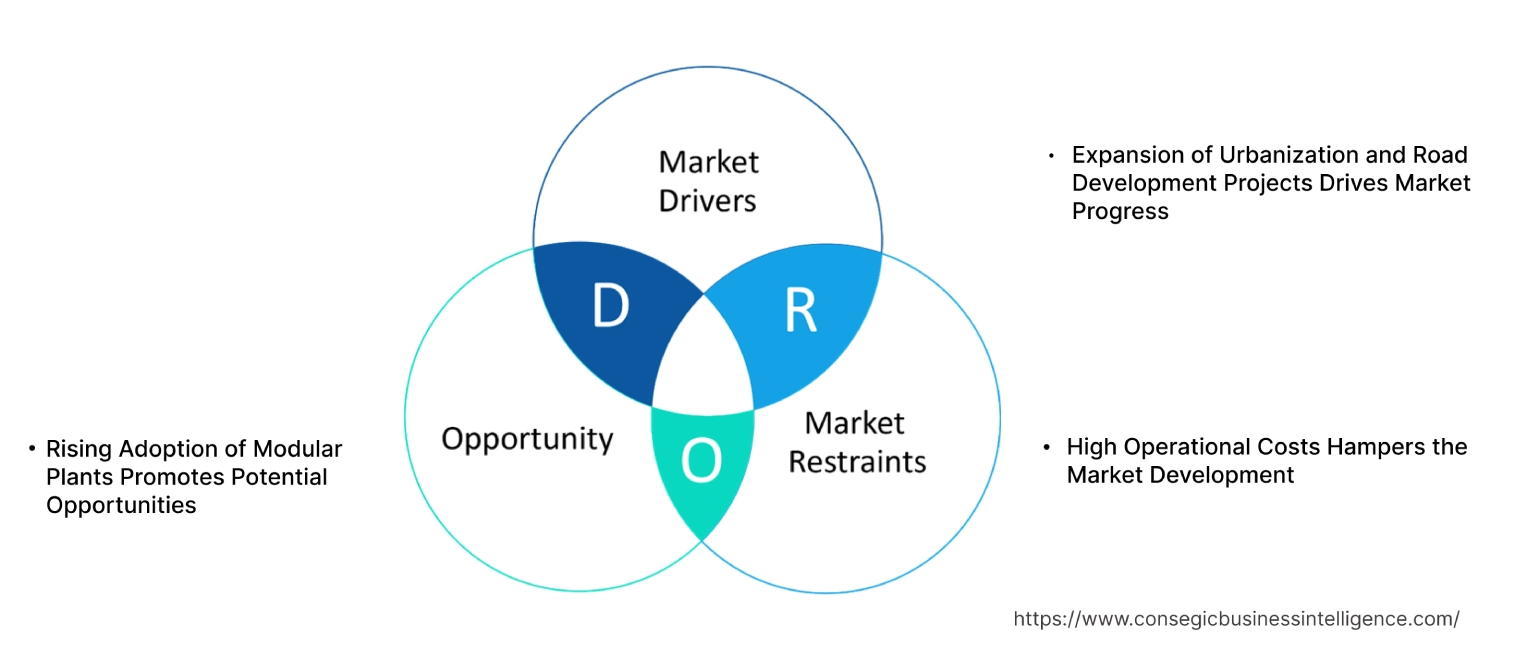

Asphalt Mixing Plants Market Dynamics - (DRO) :

Key Drivers:

Expansion of Urbanization and Road Development Projects Drives Market Progress

As cities expand and rural areas become more connected, governments and private sectors are heavily investing in infrastructure projects, including highways, expressways, and smart city developments. These projects require high-quality, durable, and cost-effective road materials, boosting the demand for advanced asphalt production solutions capable of meeting large-scale requirements. In developing regions, the push for improved transportation networks is particularly strong, with governments prioritizing road expansion to enhance trade, reduce congestion, and improve regional connectivity. Similarly, developed nations are focusing on upgrading aging infrastructure, such as repairing and resurfacing existing roads, bridges, and highways. Asphalt production plants with high capacity, rapid deployment capabilities, and advanced technologies to produce customized mixes are essential to meet the diverse requirements of these projects. Their ability to deliver efficiency, quality, and cost-effectiveness makes them indispensable in meeting the growing demands of urbanization and large-scale road development initiatives, driving the asphalt mixing plants market growth.

Key Restraints :

High Operational Costs Hampers the Market Development

The high operational costs associated with asphalt production plants pose a significant restraint for their widespread adoption, particularly among small and medium-sized contractors. These plants require substantial energy inputs, such as fuel or electricity, to maintain the high temperatures necessary for asphalt production. Rising energy prices further exacerbate this issue, significantly increasing overall operational expenses. In addition to energy costs, maintenance and repair of advanced equipment, such as mixers, dryers, and emission control systems, contribute to the financial burden. Frequent upkeep is essential to ensure consistent performance and compliance with regulatory standards, but these expenses strain the budgets of smaller firms. Furthermore, the integration of modern features like automation, IoT, and recycling capabilities, while enhancing efficiency, increases initial setup and ongoing operational costs. These high expenses create barriers for cost-sensitive markets and limit the ability of smaller companies to compete with larger, well-funded players, hindering the overall asphalt mixing plants market demand.

Future Opportunities :

Rising Adoption of Modular Plants Promotes Potential Opportunities

The increasing advancements in modular asphalt plants are creating significant opportunities in the market, particularly for regions with diverse and dynamic construction demands. Modular plants are designed with a focus on scalability, flexibility, and efficiency, allowing contractors to customize production capacities based on project requirements. These systems enable quick assembly and disassembly, making them ideal for projects in remote locations, temporary road construction, or areas with limited infrastructure. Innovations in modular plant design include advanced features such as energy-efficient dryers, integrated recycling systems, and IoT-enabled monitoring for enhanced operational control. These features reduce energy consumption, optimize raw material usage, and ensure consistent asphalt quality, meeting the growing need for sustainable production processes. Additionally, modular plants offer cost advantages, as their scalable configurations eliminate the need for overinvestment in large-scale systems for smaller projects. The ability to transport and deploy modular plants rapidly provides a competitive edge for contractors, particularly in emerging economies and regions with dispersed infrastructure projects. These advancements are reshaping the market by promoting efficiency, sustainability, and adaptability in asphalt production, unlocking significant asphalt mixing plants market opportunities.

Asphalt Mixing Plants Market Segmental Analysis :

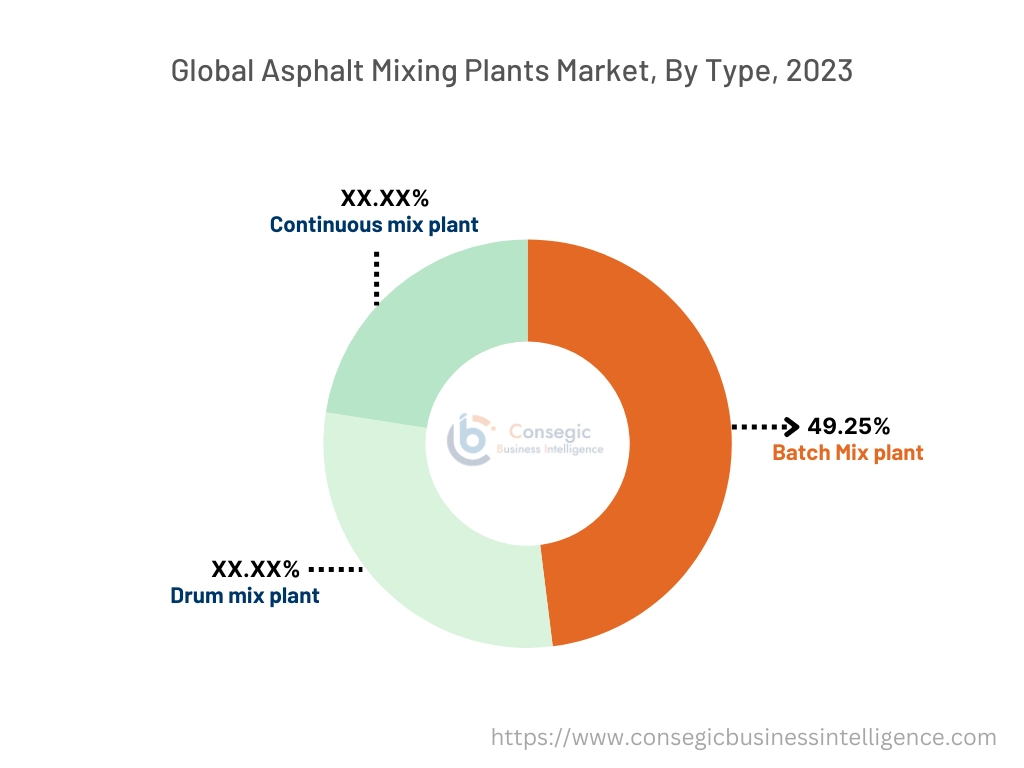

By Type:

Based on type, the market is segmented into batch mix plant, drum mix plant, and continuous mix plant.

The batch mix plant segment accounted for the largest revenue of 49.25% of the total asphalt mixing plants market share in 2023.

- Batch mix plants are widely preferred due to their ability to produce high-quality asphalt mixes with precise composition and consistency.

- These plants are ideal for large-scale infrastructure projects, including highways and airport runways, where quality and performance are critical.

- The ability to produce asphalt in batches allows for customization of mix designs, catering to specific project requirements.

- The segment's dominance is supported by its compatibility with advanced automation technologies, ensuring operational efficiency and reduced wastage, contributing significantly to the asphalt mixing plants market expansion.

The Continuous Mix Plant segment is expected to register the fastest CAGR during the forecast period.

- Continuous mix plants are favored for their ability to produce asphalt at a consistent rate, making them suitable for long-duration projects with minimal mix variations.

- These plants are often used in rural and semi-urban areas where project scales are moderate, and cost-efficiency is a priority.

- The increasing adoption of portable continuous mix plants enhances their accessibility for projects in remote locations.

- As per asphalt mixing plants market analysis, the rapid expansion of this segment is driven by its simplicity in operation and lower initial investment compared to batch mix plants.

By Capacity:

Based on capacity, the market is segmented into Below 80 TPH, 80-240 TPH, and Above 240 TPH.

The 80-240 TPH segment accounted for the largest revenue of the total asphalt mixing plants market share in 2023.

- Asphalt plants with a capacity of 80-240 TPH are extensively used in medium to large-scale infrastructure projects, including road construction and urban development.

- This capacity range strikes a balance between production efficiency and operational cost, making it a popular choice among construction companies.

- The segment is further supported by the increasing number of public-private partnerships in infrastructure development, particularly in developing regions.

- As per asphalt mixing plants market trends, manufacturers are introducing modular designs in this capacity range to enhance scalability and transportability for diverse project requirements.

The Above 240 TPH segment is expected to register the fastest CAGR during the forecast period.

- High-capacity plants exceeding 240 TPH are essential for mega infrastructure projects, such as airport construction and large highway networks.

- These plants are equipped with advanced automation and control systems, ensuring consistent quality and high productivity.

- Increasing investments in large-scale infrastructure development, particularly in emerging economies, are driving the adoption of high-capacity plants.

- The rapid progress of this segment is fueled by its ability to meet the asphalt requirements of extensive, time-sensitive projects, driving asphalt mixing plants market growth through its enhanced capacity for high-output production and reliability in large-scale construction and infrastructure projects.

By Application:

Based on application, the market is segmented into road construction, airport construction, building construction, and others.

The road construction segment held the largest market share in 2023.

- Road construction is the primary application for asphalt mixing plants, driven by continuous investments in highway and expressway projects worldwide.

- Governments across various regions are emphasizing infrastructure expansion to improve connectivity and boost economic growth.

- The ability of asphalt mixing plants to produce durable and high-performance asphalt mixes makes them indispensable for road construction projects.

- The dominance of this segment is supported by the increasing focus on road rehabilitation and maintenance activities, particularly in developed economies, driving asphalt mixing plants market demand.

The airport construction segment is expected to register the fastest CAGR during the forecast period.

- Airport construction projects require specialized asphalt mixes with high durability and load-bearing capacity for runways and taxiways.

- The growing number of airport proliferation projects globally, particularly in emerging economies, is boosting the adoption of asphalt mixing plants for this application.

- Advanced technologies in asphalt production, such as warm-mix and recycled asphalt, are gaining traction in airport construction due to their environmental benefits.

- The rapid development of this segment reflects the rising need for high-quality asphalt solutions tailored to meet stringent aviation industry standards, driving asphalt mixing plants market expansion.

By Mounting Type:

Based on mounting type, the market is segmented into stationary, mobile, and portable.

The stationary segment accounted for the largest revenue share in 2023.

- Stationary asphalt plants are preferred for large-scale infrastructure projects where long-term, high-capacity production is required.

- These plants offer advanced automation, precision, and customization options, ensuring optimal performance for complex projects.

- The dominance of stationary plants is driven by their high durability and ability to handle a diverse range of mixed designs.

- As per asphalt mixing plants market trends, stationary plants are extensively used in urban and industrial construction projects, including highways, bridges, and urban development.

The mobile segment is expected to register the fastest CAGR during the forecast period.

- Mobile asphalt plants offer flexibility and ease of transportation, making them ideal for projects in remote or temporary locations.

- These plants are designed for quick setup and dismantling, ensuring minimal downtime and enhanced project efficiency.

- The increasing adoption of mobile plants is supported by the growing number of rural and semi-urban road construction projects globally.

- As per asphalt mixing plants market analysis, manufacturers are focusing on developing compact and lightweight mobile plants to meet the rising preference for portable solutions in the construction industry.

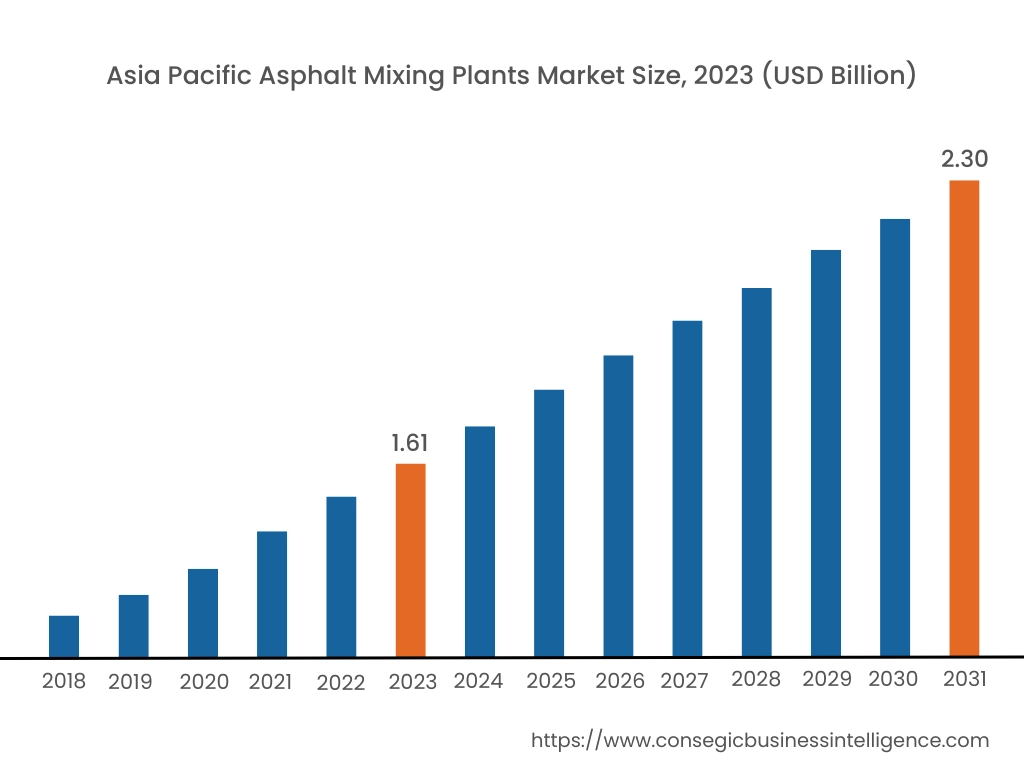

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 1.61 Billion in 2023. Moreover, it is projected to grow by USD 1.65 Billion in 2024 and reach over USD 2.30 Billion by 2031. Out of these, China accounted for the largest share of 41.5% in 2023. The Asia-Pacific region is witnessing rapid progress in the market, driven by increasing construction activities, infrastructure investments, and urbanization trends. Emerging economies, particularly in Asia-Pacific, Latin America, and Africa, are driving market expansion for asphalt mixing plants. The need for mixing plants is closely tied to infrastructure development initiatives undertaken by governments and private entities. Projects such as road construction, highway extension, airport runway repairs, and urban infrastructure upgrades require asphalt for paving, driving the need for asphalt mixing plants.

North America is estimated to reach over USD 2.52 Billion by 2031 from a value of USD 1.82 Billion in 2023 and is projected to grow by USD 1.87 Billion in 2024. The growth is fueled by government investments in infrastructure projects, including roadways, highways, bridges, and airports. Initiatives such as the Federal Highway Administration's Highway Trust Fund and state-level transportation funding programs allocate substantial budgets for infrastructure improvements, stimulating demand for asphalt production equipment.

Europe holds a significant share of the global asphalt mixing plants market, with countries like Germany, France, and the UK leading in adoption and innovation. The region benefits from a well-established construction sector and a strong emphasis on sustainability. The demand for asphalt mixing plants is driven by the need for road maintenance, resurfacing, and rehabilitation projects across Europe. Aging infrastructure, increasing traffic volumes, and harsh weather conditions necessitate ongoing maintenance and repair efforts, driving the requirement for asphalt production equipment to supply materials for road repairs and upgrades.

The Middle East & Africa region shows promising potential in the asphalt mixing plants market, particularly in countries like Saudi Arabia, the United Arab Emirates, and South Africa. The enlargement of transport infrastructure, urban development projects, and investments in oil & gas sector infrastructure are driving the need for asphalt mixing plants. The extension of road connectivity, mining investments, and growing emphasis on residential and commercial projects drive the product demand across South America.

Latin America is an emerging market, with Brazil and Mexico being the primary growth drivers. The rising adoption of advanced construction equipment, improving infrastructure, and increasing focus on enhancing road networks contribute to the market’s enlargement. Government initiatives aimed at modernizing transportation networks and promoting trade are supporting asphalt mixing plants market opportunities.

Top Key Players & Market Share Insights:

The asphalt mixing plants market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global asphalt mixing plants market. Key players in the asphalt mixing plants industry include –

- Ammann Group (Switzerland)

- Marini (Italy)

- Astec Industries, Inc. (USA)

- Benninghoven GmbH & Co. KG (Germany)

- Parker Plant Ltd. (United Kingdom)

- Lintec & Linnhoff (Singapore)

- Nikko Co., Ltd. (Japan)

- ALmix (USA)

- D&G Machinery (China)

- LUTON Group (China)

Recent Industry Developments :

Product Launches:

- In July 2024, Lintec & Linnhoff successfully installed a CSD2500B asphalt plant remotely for a road project in Bolivia, ensuring high-quality asphalt production. This innovative approach allowed for efficient setup and operation, contributing to the project's success in remote areas. The plant's performance supports Bolivia’s infrastructure development, with Lintec & Linnhoff's reliable technology playing a key role in the project’s timely execution.

- In March 2024, Astec Industries introduced the Remix Cold Central Plant Recycling System, revolutionizing sustainable road construction. This system enhances asphalt recycling by allowing higher quantities of reclaimed asphalt pavement (RAP) to be used in new road projects, contributing to reduced material waste and energy consumption. It aligns with industry goals for more eco-friendly, cost-efficient road construction methods.

Acquisitions & Mergers:

- In October 2024, Construction Partners, Inc. (CPI) reached an agreement to acquire Lone Star Paving for $654 Billion. This acquisition is expected to be immediately accretive to CPI’s earnings and is set to significantly enhance its 2027 growth goals. It will add 10 hot-mix asphalt plants, four aggregate facilities, and one liquid asphalt terminal to CPI’s portfolio. The company anticipates the deal will enhance its capabilities in road construction and paving, further advancing its growth strategy.

Asphalt Mixing Plants Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 7.66 Billion |

| CAGR (2024-2031) | 4.3% |

| By Type |

|

| By Capacity |

|

| By Application |

|

| By Mounting Type |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the asphalt mixing plants market? +

Asphalt Mixing Plants Market size is estimated to reach over USD 7.66 Billion by 2031 from a value of USD 5.48 Billion in 2023 and is projected to grow by USD 5.62 Billion in 2024, growing at a CAGR of 4.3% from 2024 to 2031.

What specific segmentation details are covered in the asphalt mixing plants market report? +

The asphalt mixing plants market report includes segmentation details for type (Batch Mix Plant, Drum Mix Plant, Continuous Mix Plant), capacity (Below 80 TPH, 80-240 TPH, Above 240 TPH), application (Road Construction, Airport Construction, Building Construction, Others), mounting type (Stationary, Mobile, Portable), and region (Asia-Pacific, Europe, North America, Latin America, Middle East & Africa).

Which is the fastest-growing segment in the asphalt mixing plants market? +

The Above 240 TPH segment, based on the capacity, is anticipated to grow rapidly due to its essential role in large-scale infrastructure projects such as airport construction and highway networks.

Who are the major players in the asphalt mixing plants market? +

The major players in the asphalt mixing plants market include Ammann Group (Switzerland), Marini (Italy), Astec Industries, Inc. (USA), Benninghoven GmbH & Co. KG (Germany), Parker Plant Ltd. (United Kingdom), Lintec & Linnhoff (Singapore), Nikko Co., Ltd. (Japan), ALmix (USA), D&G Machinery (China), and LUTON Group (China).