- Summary

- Table Of Content

- Methodology

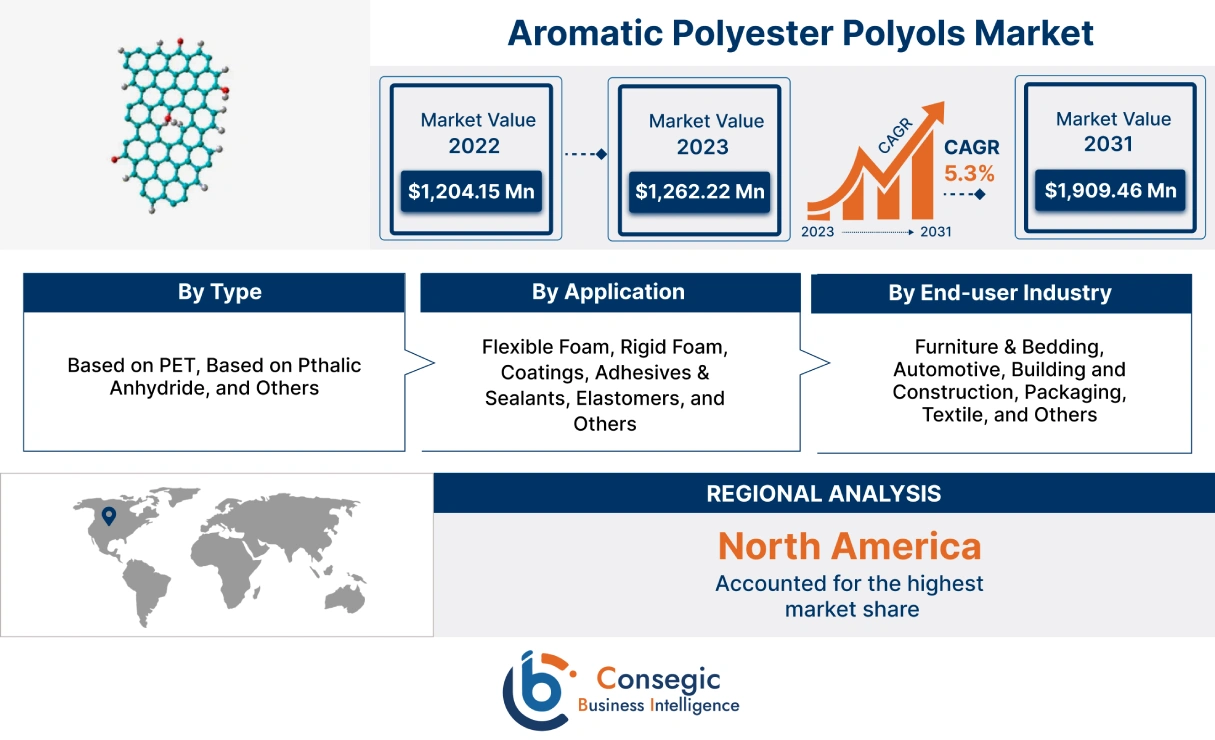

Aromatic Polyester Polyols Market Size :

Consegic Business Intelligence analyzes that the aromatic polyester polyols market is growing with a CAGR of 5.3% during the forecast period (2023-2031). The market accounted for USD 1,204.15 million in 2022 and USD 1,262.22 million in 2023, and the market is projected to be valued at USD 1,909.46 Million by 2031.

Aromatic Polyester Polyols Market Scope & Overview:

Aromatic polyester polyols are a type of polyol that is made from a combination of aromatic diacids and glycols. Aromatic polyester polyols are used to produce rigid polyurethane foam insulation that is highly effective at preventing heat loss. This type of insulation is commonly used in buildings and construction applications, such as walls, roofs, and floors.

Aromatic polyester polyols are used in a variety of applications where durability and sustainability are important factors, such as automotive interiors, footwear, and industrial seals. As consumers become more aware of the environmental impact of their choices, the demand for aromatic polyester polyols is continuously to growing.

Aromatic Polyester Polyols Market Insights :

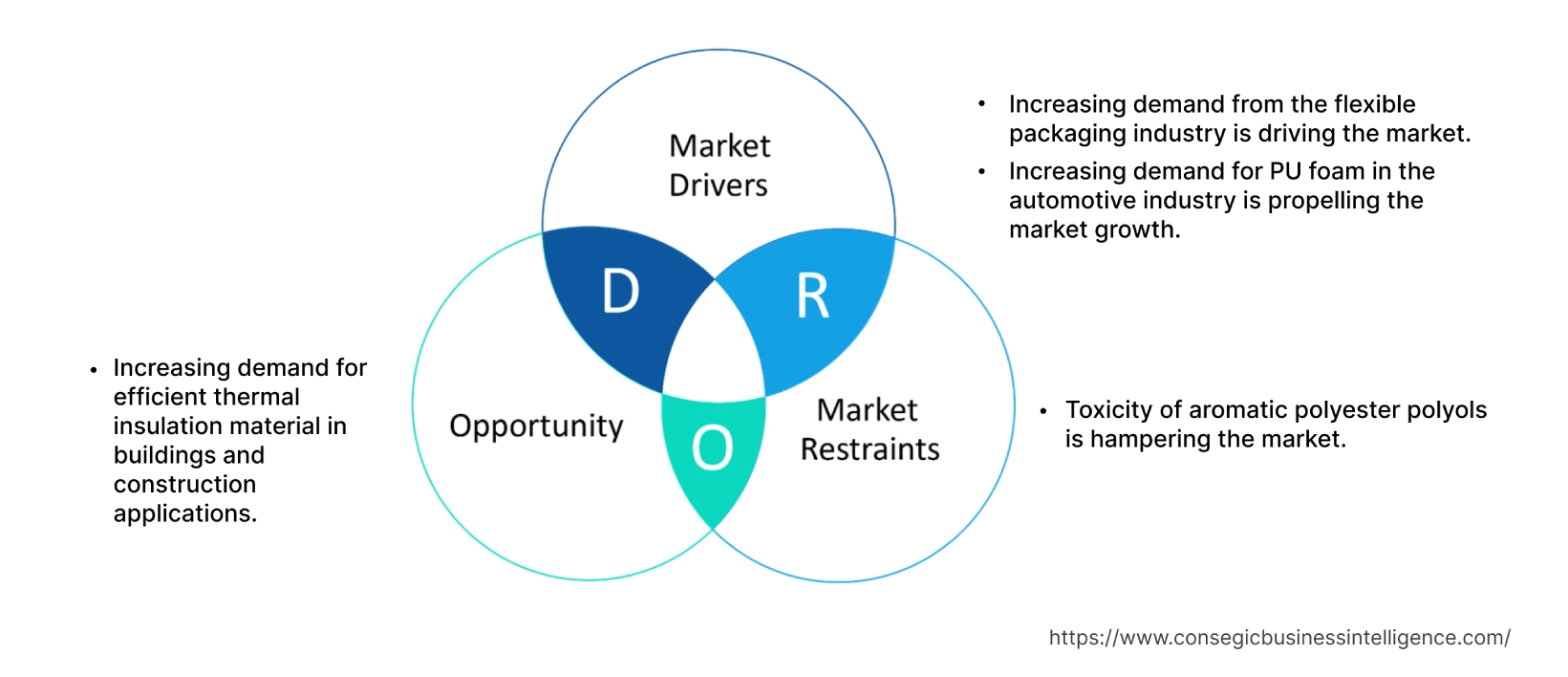

Key Drivers :

Increasing demand from the flexible packaging industry is driving the market

Aromatic polyester polyols are commonly used as adhesives in flexible packaging applications such as food products, packaged consumer goods, supplements, and others. It provides flexibility, chemical resistance, and protection from damage that occurs during the transportation of products. Also, polyester polyol adhesives make packaging cost-efficient and significantly easier to transport compared to rigid packaging. Significant growth in the flexible packaging industry is boosting the demand for aromatic polyester polyols across the globe. For instance, according to the report by the Flexible Packaging Association, the U.S. flexible packaging industry is estimated to be USD 39 billion in sales for 2021, up from USD 34.8 billion in 2020, and industry volume is estimated to be 13.5 million tons of shipments in 2021. Furthermore, aromatic polyester polyols are used to produce polyurethane (PU) foams which are one of the most used packing foams. Moreover, PU foams have many desirable attributes for packaging such as lightweight, durability, flame retardancy, and others. For this reason, increasing demand from the flexible packaging industry is driving the market growth.

Increasing demand for PU foam in the automotive industry is propelling the market growth

Aromatic polyester polyols are primarily used to design rigid polyurethane (PU) foams in the automotive industry. It is used to produce automotive interiors, seating, dashboards, door panels, and others. Moreover, PU foam is used in the automotive industry due to its consistent quality, better cost efficiency, mechanical properties, flame resistance, and others. Also, polyurethane foam protects the car engine from heat, wear, and tear, and absorbs sounds and vibrations. Furthermore, PU foam is filled with tires to reduce punctures and improve the longevity of the product. As a result, the various applications of PU foam in the automotive industry make it a vital component of the automotive industry. For instance, according to a report by the Euromoulders Association in July 2023, there is approximately 25kg of PU foam in every automobile. Hence, the various applications of PU foams in the automotive industry are driving the demand for aromatic polyester polyols.

Key Restraints :

Toxicity of aromatic polyester polyols is hampering the market

Aromatic polyester polyols derivatives are a vital component in various industries; however, the toxicity of these compounds poses risks to human health and the environment. Production of these compounds involves the use of toxic compounds like terephthalic acid. According to the Environment Protection Agency, exposure to 5% terephthalic acid induced carcinogenic (cancer causing) effects in animal studies. Also, low exposure to raw materials of aromatic polyester polyols can irritate the eyes, throat, and respiratory tract.

On the other hand, aromatic polyester polyols are widely used to make PU foams. The manufacture of PU foam produces large amounts of wastewater from which a fraction can be recycled. Also, PU foams are notoriously difficult to recycle owing to their chemically cross-linked structures. Moreover, incineration of PU foams releases hazardous chemicals such as isocyanates, hydrocyanic acid, and dioxins. As a result, the toxicity of aromatic polyester polyols to the environment and human health is hampering the market growth.

Future Opportunities :

Increasing demand for efficient thermal insulation material in buildings and construction applications

Aromatic polyester polyols are used to produce many insulation products which are vital in various building and construction applications. Also, these compounds improve the thermal and mechanical properties of insulation materials. The use of aromatic polyester polyols in insulation applications has been gaining popularity due to their low cost and excellent thermal properties. Aromatic polyester polyols are also being used in the development of new and innovative thermal insulation products, such as aerogel-based insulation and vacuum insulation panels. These products offer even better thermal insulation performance than traditional aromatic polyester polyol-based insulation materials, and they are expected to drive further growth of the APPO market in the coming years. Various companies involved in the production of innovative building materials are focusing on the development of new products. For instance, in August 2020, Armacell, a global leader in energy efficiency, launched the next generation of aerogel blankets. The blankets are flexible and can be used for dual-temperature and cryogenic applications. Thus, the increasing use of aromatic polyester polyol derivatives in thermal insulation is likely to shape the market in the forecast year.

Aromatic Polyester Polyols Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2017-2031 |

| Market Size in 2031 | USD 1,909.46 Million |

| CAGR (2023-2031) | 5.3% |

| By Type | Based on PET, Based on Pthalic Anhydride, and Others |

| By Application | Flexible Foam, Rigid Foam, Coatings, Adhesives & Sealants, Elastomers, and Others |

| By End-user Industry | Furniture & Bedding, Automotive, Building and Construction, Packaging, Textile, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | Stepan Company, BASF SE, Purinova SP, Synthesia Technology Group, Emery Oleochemicals, Huntsman International LLC, Coim Group, XUCHUAN CHEMICAL(SUZHOU) CO., LTD, Arkema, and Evonik Industries AG |

Aromatic Polyester Polyols Market Segmental Analysis :

By Type :

The type of segmentation is categorized into based on PET, based on phthalic anhydride, and others. In 2022, PET based aromatic polyester polyols accounted for the highest market share in the aromatic polyester polyol market. They are viscous, transparent liquids that can be colorless to light brown. These compounds have high tensile strength, abrasion resistance, and high flame retardancy making them ideal in construction and automotive industries. Moreover, PET based aromatic polyester polyols can be obtained from recycled PET plastics making them cost efficient. Key manufacturers such as Portal Produktowy Group, have successfully manufactured aromatic polyester polyols from recycled PET.

However, phthalic anhydride based aromatic polyester polyols are expected to have the highest CAGR in the forecast year. Phthalic anhydride based polyester polyols are shown to have better performance and enhanced stability as compared to other polyols. Furthermore, these polyols are more resistant to hydrolysis than PET-based polyols. As a result, the better stability and performance of phthalic anhydride-based aromatic polyester polyols are likely to shape the market in the future.

By Application :

The application segment is categorized into flexible foam, rigid foam, coatings, adhesives, sealants, elastomers, and others. In 2022, the rigid foam segment accounted for the highest market share in the aromatic polyester polyols market. Aromatic polyester polyols are a critical component of rigid foams owing to their consistent quality and low additive requirements. These compounds are used to make rigid polyurethane foam which is a vital compound for many industries such as furniture and bedding, automotive, building and construction, packaging, textile, and others. Furthermore, rigid foams provide structural support, soundproofing, and thermal insulation to buildings which makes them a staple in all construction applications. The increasing focus of the companies involved in the production of rigid foam for the development of their business segment is driving the segment growth. For instance, in January 2023, INDEVCO North America acquired Perma R Products. The acquisition expanded INDEVCO Building Products' product offering and distribution of rigid foam insulation and building envelope products across North America. The acquisition also gave INDEVCO access to new customer segments. Moreover, increasing awareness about energy efficiency and sustainability is driving the demand for rigid foams.

However, the aromatic polyester polyol polymers segment is expected to grow at the fastest CAGR over the forecast period. The growing automotive industry is heavily reliant on elastomers based on aromatic polyester polyols. These elastomers are lightweight, easy to process, recyclable, durable, and flexible making them an ideal choice for a variety of industries. As a result, the increasing use of elastomers is likely to shape the market in the forecast year.

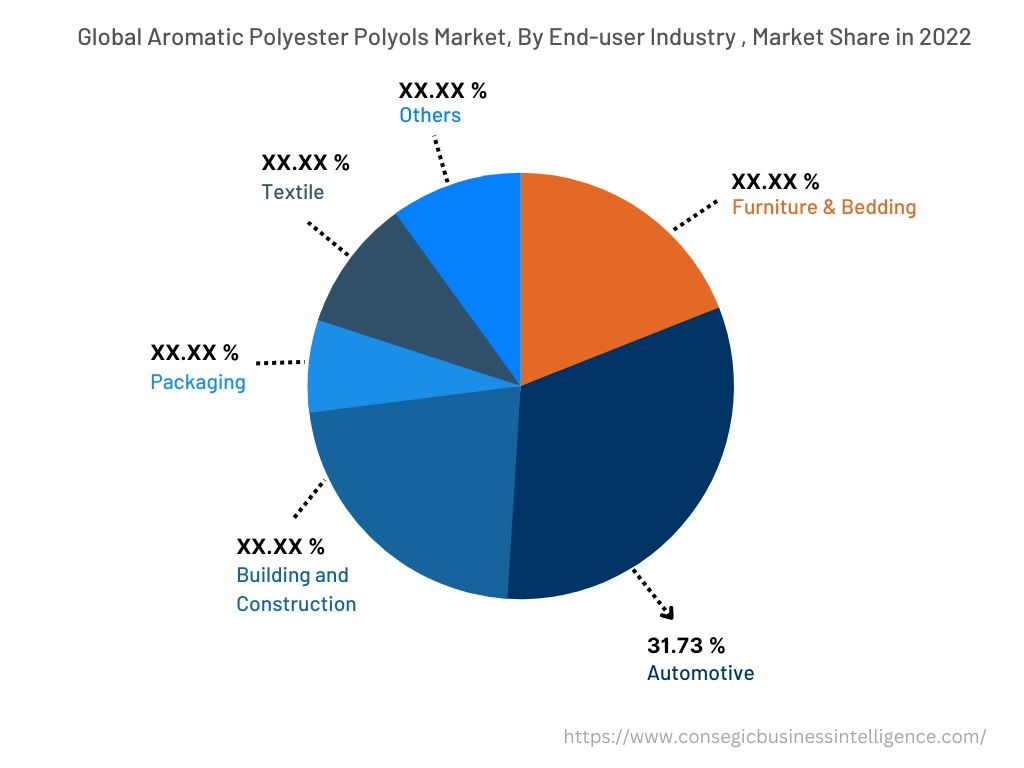

By End-Use-Industry :

The end use industry segment is categorized into furniture and bedding, automotive, building and construction, packaging, textile, and others. In 2022, the building and construction segment accounted for the highest market share of 31.73% in the end use industry segment. Aromatic polyester polyols are widely used in the building and construction industry due to their low molecular weight, consistent quality, better cost efficiency, and thermal resistance. Moreover, PU foams made from aromatic polyester polyols are used in the construction industry for insulation, adhesives, sealant, soundproofing, structural stability, and waterproofing. Significant growth in the construction industry is driving the demand for PU foams which is boosting the market growth. For instance, according to a report by the U.S. Census Bureau in 2023, total construction spending during August 2023 was estimated at USD 1,983.5 billion, 7.4 percent above August 2022 at USD 1,847.3 billion. Thus, the growing demand for PU foams from the construction industry is driving the demand for aromatic polyester polyols from building and construction industry across the globe.

However, the automotive segment is expected to grow at the fastest CAGR over the forecast period in the aromatic polyester polyol market. Aromatic polyester polyols are used in automotive applications to improve insulation and are used as adhesives. Increasing automotive production is driving the demand for aromatic polyols from industry. For instance, according to the report by the European Automobile Manufacturers Association in May 2023, in 2022, 85.4 million motor vehicles were produced around the world, an increase of 5.7% compared to 2021. Thus, the growing automotive industry and increasing application of these compounds in automotive applications is expected to boost the market growth in the forecast year.

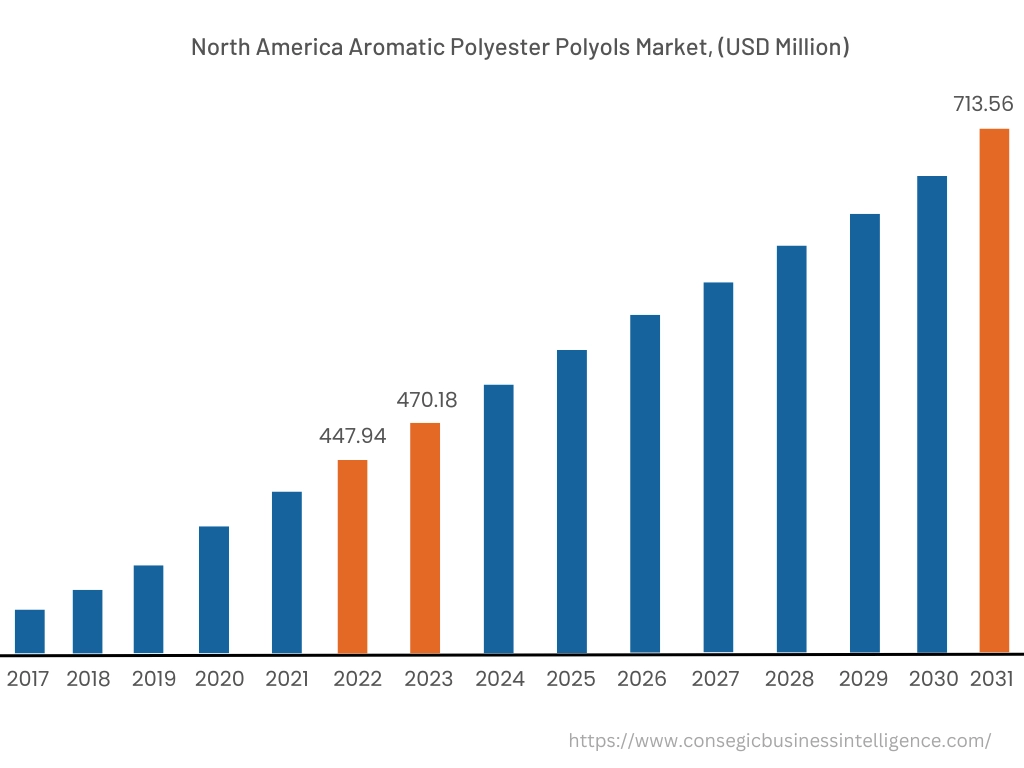

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

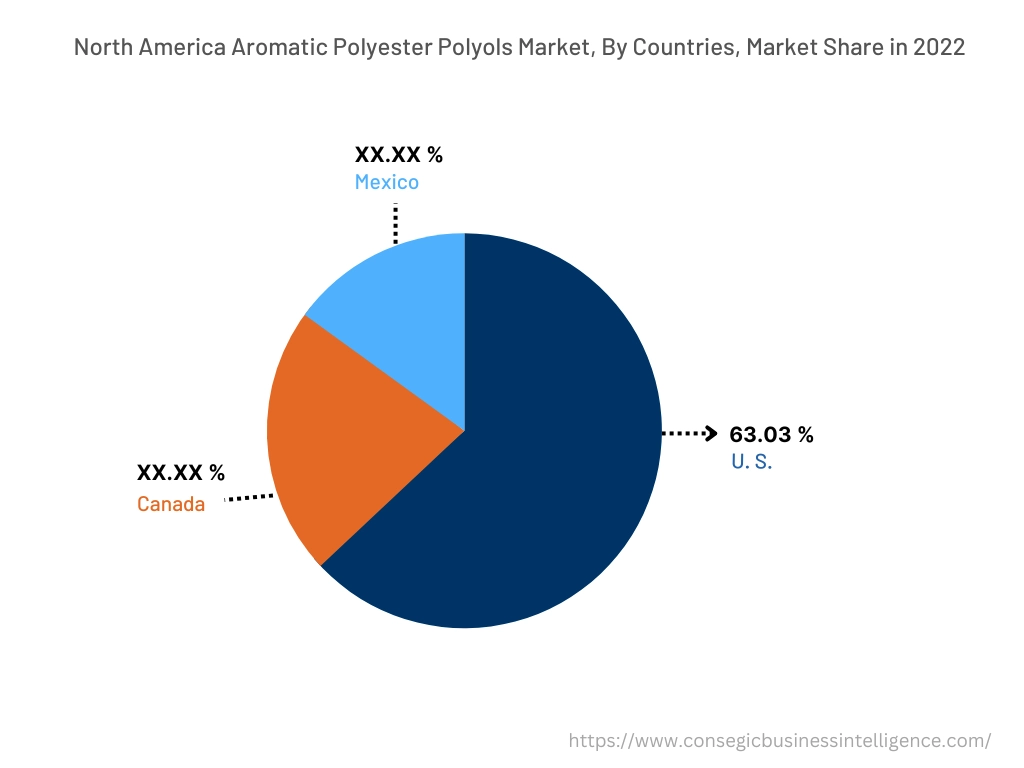

In 2022, North America accounted for the highest market share at 37.20% valued at USD 447.94 Million in 2022 and USD 470.18 Million in 2023, it is expected to reach USD 713.56 Million in 2031. In North America, the U.S. accounted for the highest market share of 63.03% in the base year 2022. The construction industry in North America is growing rapidly, driven by factors such as population growth, urbanization, and increasing disposable incomes. Increasing investments for the construction of energy efficient buildings are driving the market growth. For instance, according to the United Nations Environment Program in November 2022, the investments in building energy efficiency have gone up by unprecedented levels, rising by 16 percent in 2021 over 2020 levels to USD 237 billion. This growth of the building and construction industry is driving demand for aromatic polyester polyols, which are used in a variety of construction applications, such as rigid foam insulation for buildings and elastomers for roofing and flooring materials.

Furthermore, the Asia Pacific region is expected to witness significant growth over the forecast period, growing at a CAGR of 5.7% during 2023-2031. The significant growth in automotive industries across the region is increasing demand for aromatic polyester polyols. For instance, according to a study by the International Trade Administration of the U.S. in 2023, China continues to be the world's largest vehicle market by both annual sales and manufacturing output, with domestic production expected to reach 35 million vehicles by 2025. Thus, the significant growth in the automotive industry is expected to create opportunities for growth in the aromatic polyester polyols market over the forecast period.

Top Key Players & Market Share Insights:

The aromatic polyester polyols market is highly competitive, with several large players and numerous small and medium-sized enterprises. These companies have strong research and development capabilities and a strong presence in the market through their extensive product portfolios and distribution networks. The market is characterized by intense competition, with companies focusing on expanding their product offerings and increasing their market share through mergers, acquisitions, and partnerships. The key players in the market include-

- Stepan Company

- BASF SE

- XUCHUAN CHEMICAL(SUZHOU) CO., LTD

- Arkema

- Evonik Industries AG

- Purinova SP

- Synthesia Technology Group

- Emery Oleochemicals

- Huntsman International LLC

- Coim Group

Recent Industry Developments :

- In July 2022, Synthesia Technology, a leader in polyurethane systems, polyester polyols, and chemical specialties, plans to build a polyester polyol plant in Little Rock, Arkansas. The $30 million plant will initially be built on about half of the land, with the rest held for future expansion.

- In October 2021, Huntsman Corporation opened a new 22,000-ton aromatic polyester polyols plant in Kuan Yin, Taiwan. The plant is marketed under the "Terol" brand name.

- COIM, an Italian multinational company that produces specialty chemicals, acquired Synres. Synres is a Dutch company that specializes in the production of alkyd and acrylic resins for coatings. COIM plans to expand the Dutch firm with a second plant to make its own products, primarily "Isoexter" and "Diexter" aromatic and aliphatic polyester polyols.

Key Questions Answered in the Report

What was the market size of the aromatic polyester polyols market in 2022? +

In 2022, the market size of aromatic polyester polyols was USD 1,204.15 million.

What will be the potential market valuation for the aromatic polyester polyols industry by 2031? +

In 2031, the market size of aromatic polyester polyols will be expected to reach USD 1,909.46 million.

What are the key factors driving the growth of the aromatic polyester polyols market? +

Increasing demand for aromatic polyester polyols from the packaging industry across the globe is fueling market growth at the global level.

What is the dominant segment in the aromatic polyester polyols market for the end-user industry? +

In 2022, the building and construction segment accounted for the highest market share of 31.73% in the overall Aromatic Polyester Polyols market.

Based on current market trends and future predictions, which geographical region is the dominating region in the Aromatic Polyester Polyols market? +

North America accounted for the highest market share in the overall market.