- Summary

- Table Of Content

- Methodology

Aramid Prepreg Market Size:

Aramid Prepreg Market size is growing with a CAGR of 8.7% during the forecast period (2025-2032), and the market is projected to be valued at USD 6,321.73 Million by 2032 from USD 3,251.60 Million in 2024. Additionally, the market value for the 2025 attributes to USD 3,523.30 Million.

Aramid Prepreg Market Scope & Overview:

Aramid prepreg is a composite material. The production process involves coating aramid fibers with resin such as epoxy or phenolic. The epoxy resin provides high strength, phenolic resin offers fire resistance, and polyimide resin withstands extreme temperatures. Later, they are cured for strength and stability. These prepregs are made from two types of aramid fibers. Para-aramid, which is very strong and resistant to flames. Another is meta-aramid, which is chemicals and abrasion resistance. These prepregs are used in aerospace and defense, and meta-aramid, which is heat-resistant and used in protective clothing. These prepregs are used in aircraft parts, ballistic protection, car components, sports equipment, and industrial applications such as conveyor belts and electrical insulation due to their durability and lightweight properties.

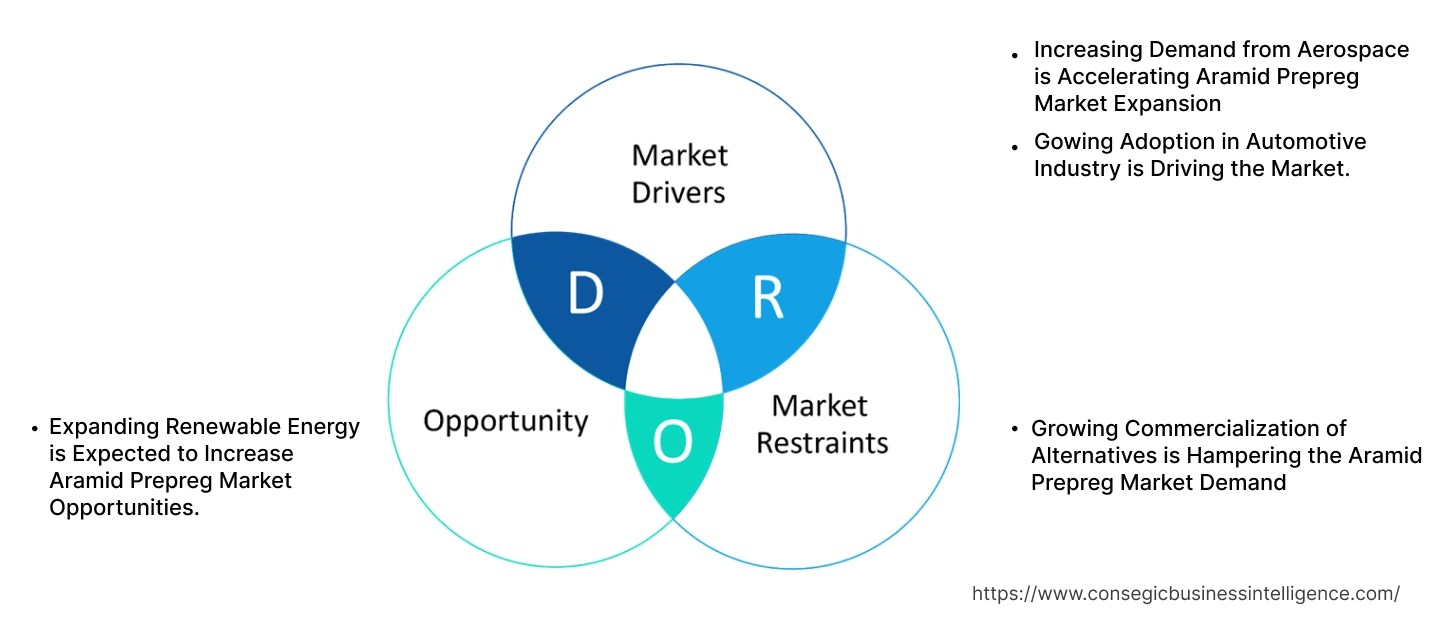

Key Drivers:

Increasing Demand from Aerospace is Accelerating Aramid Prepreg Market Expansion

Aerospace refers to companies that design and manufacture aircraft, spacecraft and related parts. Aramid prepreg are used in aircraft fuselage, panels, interior structures, wing components, and engine parts. They make airplanes lighter. This improves fuel efficiency. Its high strength and impact resistance enhances safety. They protect against damage from debris or extreme conditions. There is rising demand for air travel which has led to sector growth.

For instance,

- Airbus delivered 661 commercial aircraft in 2022, which was an 8% increase from 2021. This has increased utilization of prepregs made from aramid fibers in production of aircraft components, thus driving market share.

Overall, the increasing demand from the aerospace sector is significantly boosting the aramid prepreg market expansion.

Gowing Adoption in Automotive Industry is Driving the Market.

Prepregs made from aramid fibers are used in cars for lightweight body panels, brake pads, clutch plates, and structural reinforcements. They are increasingly adopted for usage in suspension components as well. They make vehicles stronger and safer. These materials resist heat, wear, and impact, improving durability and performance. Rising disposable incomes have led to growing consumer demand in mobility solutions, leading to increased production.

For instance,

- According to Just Auto & Leasing LLC, the passenger car production of UK increased by 16.8% in year 2023. This has required prepregs made from aramid in production of car components.

Thus, growing adoption in the automotive sector is accelerating the global aramid prepreg market growth.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Aramid Prepreg Market Demand

The market faces competition from other substitutes available in the market. This includes carbon fiber and glass fiber. Carbon fiber is stronger and stiffer than aramid fiber. This makes it a popular choice for aerospace and high-performance automotive applications. Glass fiber is cheaper and widely available. This makes it a cost-effective alternative for industries that do not need extreme strength or heat resistance. Industries prefer these materials because they are easier to process and are lighter. Additionally, metal alloys such as aluminum and titanium are still widely used in aerospace and automotive applications due to their strength and recyclability. The growing development of bio-based composites also creates competition, as industries look for more sustainable options. Hence, the growing commercialization of alternatives is hampering the aramid prepreg market demand.

Future Opportunities :

Expanding Renewable Energy is Expected to Increase Aramid Prepreg Market Opportunities.

Renewable energy comes from natural sources such as the sun, wind, and water that do not run out. Prepregs developed from aramid fibers are used in wind turbine blades, and solar panel frames. They make wind turbines stronger, lighter, and more durable. This helps them last longer. These materials also resist heat, chemicals, and wear. This ensures reliable performance in harsh environments. More governments are investing in wind and solar energy to reduce pollution and fight climate change.

For instance,

- According to Environment+Energy Leader, the wind energy sector is expected to grow by 10.2% by 2034. This will require lighter and stronger turbine blades, thus creating potential for the market.

Overall, expanding renewable energy sector is expected to increase renewable energy market opportunities.

Aramid Prepreg Market Segmental Analysis :

By Fiber Type:

Based on fiber type, the market is categorized into para-aramid and meta-aramid.

Trends in Fiber Type:

- Para-aramid fibers such as Kevlar continue to dominate in applications requiring high modulus. This includes ballistic protection, ropes, tires, and aerospace components.

- Manufacturers are focusing on developing new para-aramid grades with improved properties. This includes higher tenacity, better fatigue resistance, and enhanced processability.

The para-aramid segment accounted for the largest market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- Para-aramid is a strong and lightweight synthetic fiber. It dominated the market trends.

- It is known for its high tensile strength and heat resistance. It is commonly used in tough and durable materials.

- It is stronger than steel by weight. Also, it withstands high temperatures. It has the capability to absorb energy from shocks and impacts

- It is used in aerospace, military armor, automotive parts, and industrial applications.

- Due to rising fuel costs and growing environmental concerns, there has been the growing adoption of electric vehicles.

- For instance, according to Cardino, the registration of electric increased by 63.8% in year 2023 when compared to previous year. This has led to increased production of it, and prepregs are used for lightweighting components.

- Overall, as per the market analysis, the increased adoption of electric vehicles is driving a segment in aramid prepreg market growth.

By Resin Type:

Based on resin type, the market is categorized into epoxy, phenolic, polyimide, and others.

Trends in Resin Type:

- Research is focused on developing toughened epoxy resins to improve the impact of resistance and damage tolerance of prepreg composites.

- Phenolic resins are increasingly preferred when fire resistance and low smoke generation are critical such as in aerospace interiors.

The epoxy segment accounted for the largest market share in 2024

- Epoxy segment dominated the aramid prepreg market trends. Epoxy is a strong and durable material.

- It is used to bond aramid fibers in prepregs. It provides excellent toughness and durability. Also, it withstands extreme conditions.

- It is used in aerospace components, military body armor, high-performance sporting goods, and recreational marine components.

- Growing interest in outdoor recreation has led to more people seeking water-based activities. This increased marine boats production.

- For instance, according to National Marine Manufacturers, U.S. recreational boat and marine engine exports increased by 17.6% in year 2022 when compared to previous year. They required aramid prepreg coated with epoxy resin.

- According to market analysis, the growing adoption in marine components is driving the segmental growth in the market.

The phenolic segment is expected to grow at the fastest CAGR over the forecast period.

- Phenolic resin is emerging in market trends. It is heat-resistant and fireproof material.

- It enhances strength and safety in high-temperature applications. It also provides durability and impact resistance. It protects against harsh chemicals.

- Phenolic resin prepregs made of aramid are used in aerospace, automotive, and industrial applications.

- They are ideal for aircraft interiors, fireproof panels, protective clothing, and vehicle components that need strong, heat-resistant materials.

- Continuous improvements in aramid fiber and prepreg technology, including enhanced resin systems and manufacturing processes, expand the range of applications. This will drive the segment for the upcoming years.

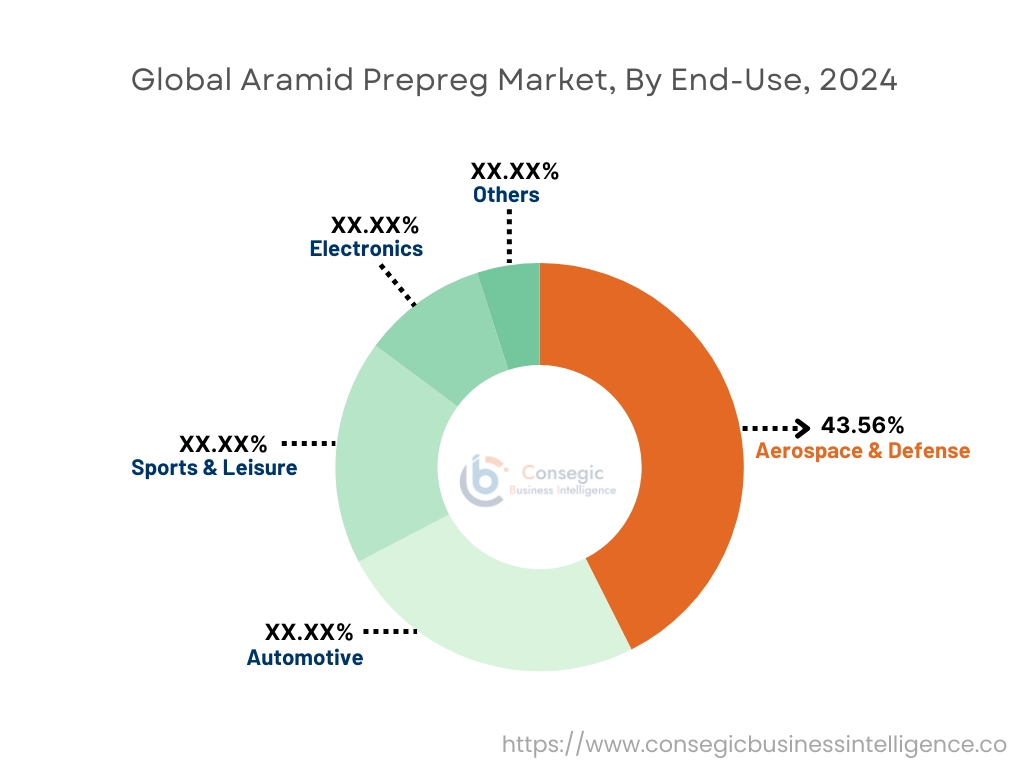

By End Use:

Based on end-use, the market is categorized into aerospace & defense, automotive, sports & leisure, electronics, and others.

Trends in the End-Use:

- Prepreg made from aramid fibers are increasingly adopted in various sports and leisure products such as skis, kayaks, helmets, and racquets to enhance performance and durability.

- Growing usage of para-aramid fiber prepreg in body armor, helmets, and vehicle armor due to security concerns globally.

The aerospace & defense segment accounted for the largest market share of 43.56% in 2024.

- The aerospace and defense segment dominated the aramid prepreg market trends. It encompasses the production of aircraft, spacecraft, weapons, and other military equipment.

- Prepregs made from aramid fibers are used extensively in this sector due to their exceptional strength-to-weight ratio and high impact resistance.

- It provides high thermal stability. They are crucial for lightweighting aircraft components such as fuselage, wings, interiors.

- They are also used in ballistic protection in body armor and helmets.They absorb significant impact energy. This offers protection against collisions.

- Overall, as per the market analysis, rising defense budgets, advancements in military technology, and rising demand for travel will drive the segmental growth in the aramid prepreg industry.

The sports & leisure segment is expected to grow at the fastest CAGR over the forecast period.

- The sports & leisure sector is emerging in market trends. The sector includes equipment, gear, and activities related to sports, fitness, and outdoor recreation.

- Aramid prepregs are used in helmets, bicycles, tennis rackets, skis, and protective gear.

- They make sports equipment lighter, stronger, and more durable. Their high impact resistance improves safety by absorbing shocks and protecting athletes.

- There is rising health awareness, which has led to an increase in participation in sports. This has required sports equipment.

- For instance, in 2022, according to the European Commission, the EU countries produced 4.8 million of pairs of skis and snowboards. This creates potential for the segment.

- Thus, according to market analysis, the expanding sports & leisure sector will drive segmental growth for the forecasted years.

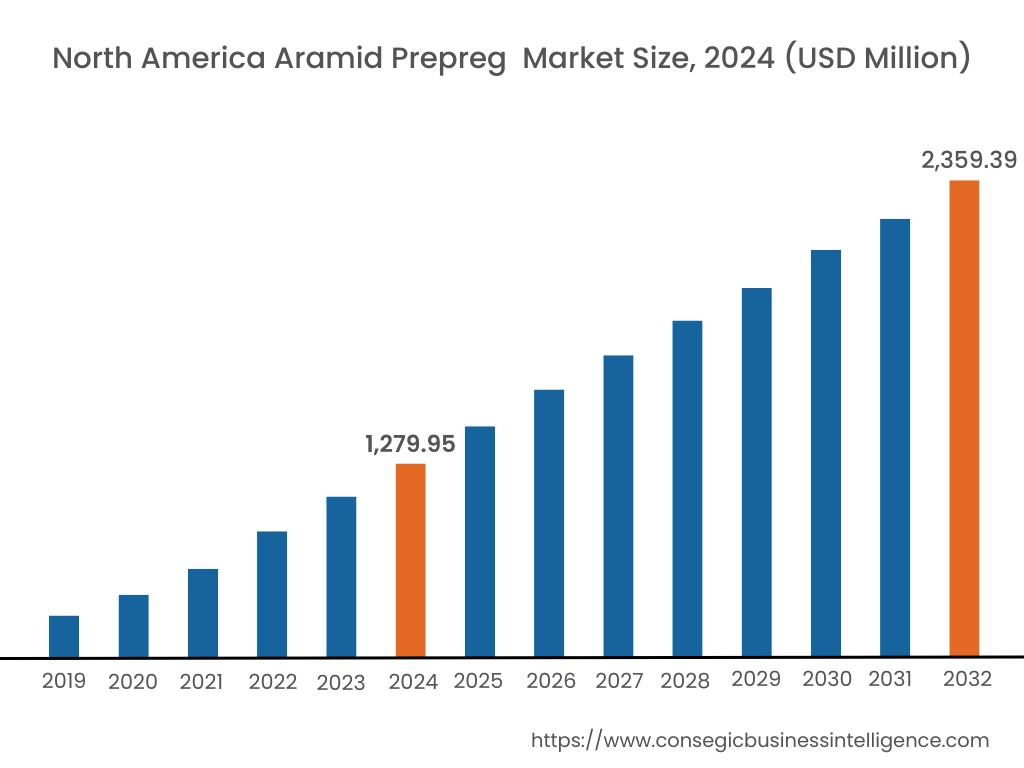

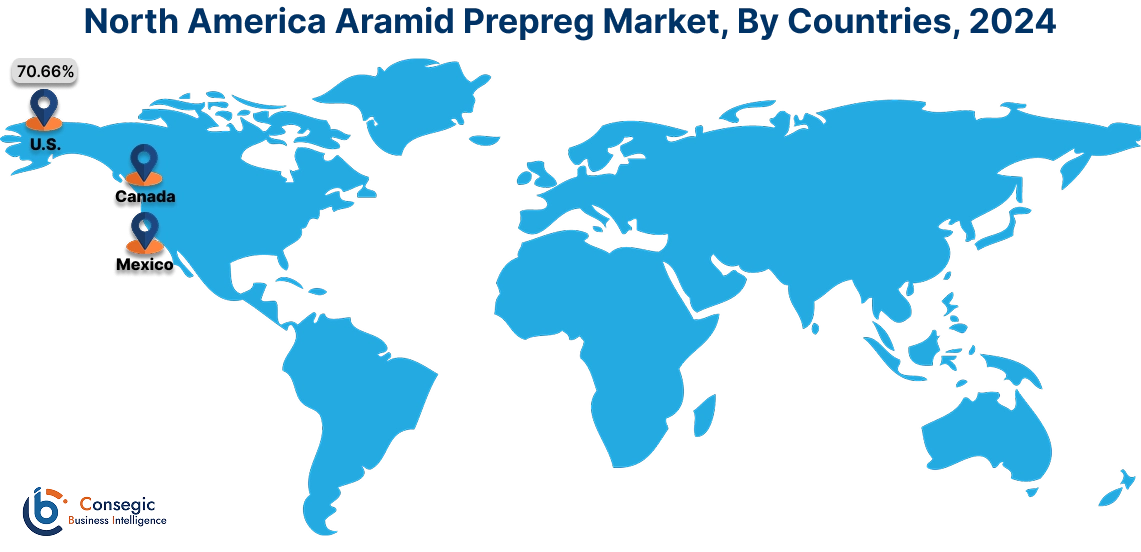

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest aramid prepreg market share at 39.37% and was valued at USD 1,279.95 Million and is expected to reach USD 2,359.39 Million in 2032. In North America, the U.S. accounted for the aramid prepreg market share of 70.66% during the base year of 2024. Companies such as Boeing and Lockheed Martin are increasing production, requiring strong and lightweight materials. Aramid prepreg help reduce aircraft weight, improve fuel efficiency, and enhance safety with fire-resistant properties.

For instance,

- Boeing, in 2023, delivered a total of 528 aircraft in 2023, marking a 10% increase compared to the previous year's deliveries. This is driving the market in the region.

Moreover, urban air mobility (UAM) is growing with the rise of electric air taxis and drones for city transport. Lightweight and strong materials such as prepregs made from aramid fibers are essential for building safe, efficient, and energy-saving flying vehicles. Overall, the rising aerospace sector and urban air mobility is driving the market in the region.

In Asia Pacific, the aramid prepreg market is experiencing the fastest growth with a CAGR of 10.1% over the forecast period. The region is seeing rapid increase in advanced materials and manufacturing technologies. Countries such as China, Japan, and South Korea are investing in new composite materials to improve product performance. This is driving the market in the region. Innovations in resin systems and automated prepreg production are making these materials stronger, lighter, and more cost-effective. This is a driving need in industries such as aerospace, automotive, and renewable energy. Moreover, many APAC countries are increasing their defense budgets to strengthen national security. Prepregs made from aramid are used in military aircraft, bulletproof vests, and armored vehicles due to their high strength, lightweight nature, and heat resistance.

Europe's aramid prepreg market analysis states that several factors are responsible for the progress of the market in the region. Europe is leading the shift to electric vehicles (EVs) as governments push for cleaner transportation. Stricter emission laws and incentives for adoption are driving need for lightweight materials such as Aramid Prepreg. These materials help reduce vehicle weight, improving battery efficiency and overall performance. Moreover, Europe has strong workplace safety regulations, increasing the requirements for protective gear. These prepregs are used in firefighter suits and industrial safety clothing due to their high strength and heat resistance.

The Middle East and Africa (MEA) aramid prepreg market analysis states that the region is also witnessing several trends for notable surge. Countries such as South Africa, Egypt, and Saudi Arabia are investing in wind farms to produce clean electricity. Prepregs made from aramid fibers are used in wind turbine blades because they are strong, lightweight, and durable. Moreover, governments and companies in MEA are increasing investments in eco-friendly materials to support green initiatives. These prepregs are seen as a sustainable option because they are long-lasting and improve energy efficiency in various applications.

Latin America's aramid prepreg market size is also emerging. Countries such as Brazil, Argentina, and Mexico have strong need for high-performance sports equipment. Prepregs from aramid fibers are used in bicycles, tennis rackets, skis, because they are lightweight, strong, and durable. Moreover, the marine industry in Latin America is expanding due to growing tourism, fishing, and commercial shipping. These prepregs are used in boats, yachts, and marine structures because they resist water, corrosion, and high impact. Their lightweight nature helps improve fuel efficiency and speed.

Top Key Players & Market Share Insights:

The Aramid Prepreg market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Aramid Prepreg market. Key players in Aramid Prepreg industry include-

- Hexcel Corporation (U.S.)

- Axiom Materials, Inc. (U.S.)

- Lincoln Composite Materials (U.S.)

- Arvind Composites (India)

- CIT Composite Materials (Italy)

- Mitsubishi Chemical (Japan)

- Toray Industries (Japan)

- SGL CARBON SE (Germany)

- Solvay SA (India)

- Krempel GmbH (Germany)

Aramid Prepreg Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6,321.73 Million |

| CAGR (2025-2032) | 8.7% |

| By Fiber Type |

|

| By Resin Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Aramid Prepreg market? +

In 2024, the Aramid Prepreg market is USD 3,251.60 Million.

Which is the fastest-growing region in the Aramid Prepreg market? +

Asia Pacific is the fastest-growing region in the Aramid Prepreg market.

What specific segmentation details are covered in the Aramid Prepreg market? +

Fiber Type, Resin Type, and End-Use segmentation details are covered in the Aramid Prepreg market.

Who are the major players in the Aramid Prepreg market? +

Hexcel Corporation (U.S.), Axiom Materials, Inc. (U.S.), Mitsubishi Chemical (Japan), Toray Industries (Japan), SGL CARBON SE (Germany), Solvay SA (India), and Krempel GmbH (Germany) are some major players in the market.