- Summary

- Table Of Content

- Methodology

Aluminum Slugs Market Size:

Aluminum Slugs Market size is estimated to reach over USD 6,015.48 Million by 2032 from a value of USD 3,890.26 Million in 2024 and is projected to grow by USD 4,038.80 Million in 2025, growing at a CAGR of 5.6% from 2025 to 2032.

Aluminum Slugs Market Scope & Overview:

Aluminum slugs are pre-formed, solid pieces of aluminum widely used as raw materials in manufacturing processes. They are valued for their lightweight nature, excellent corrosion resistance, and malleability. These slugs are produced in varying shapes and sizes to cater to diverse industry requirements. Key features of aluminum slugs include high thermal and electrical conductivity, uniform surface finish, and exceptional durability. Their non-toxic properties make them suitable for applications requiring safety and compliance. Additionally, aluminum slugs ensure efficient material usage, reducing production waste in downstream processes.

The benefits of aluminum slugs include enhanced operational efficiency, improved product quality, and lower material costs during manufacturing. Their versatility allows for seamless shaping and finishing to meet specific product trends. Applications of aluminum slugs are extensive, including the production of aerosol cans, beverage bottles, tubes, capacitors, and automotive parts. End-use industries include packaging, automotive, electronics, and consumer goods, emphasizing their critical role in both industrial and consumer-oriented sectors.

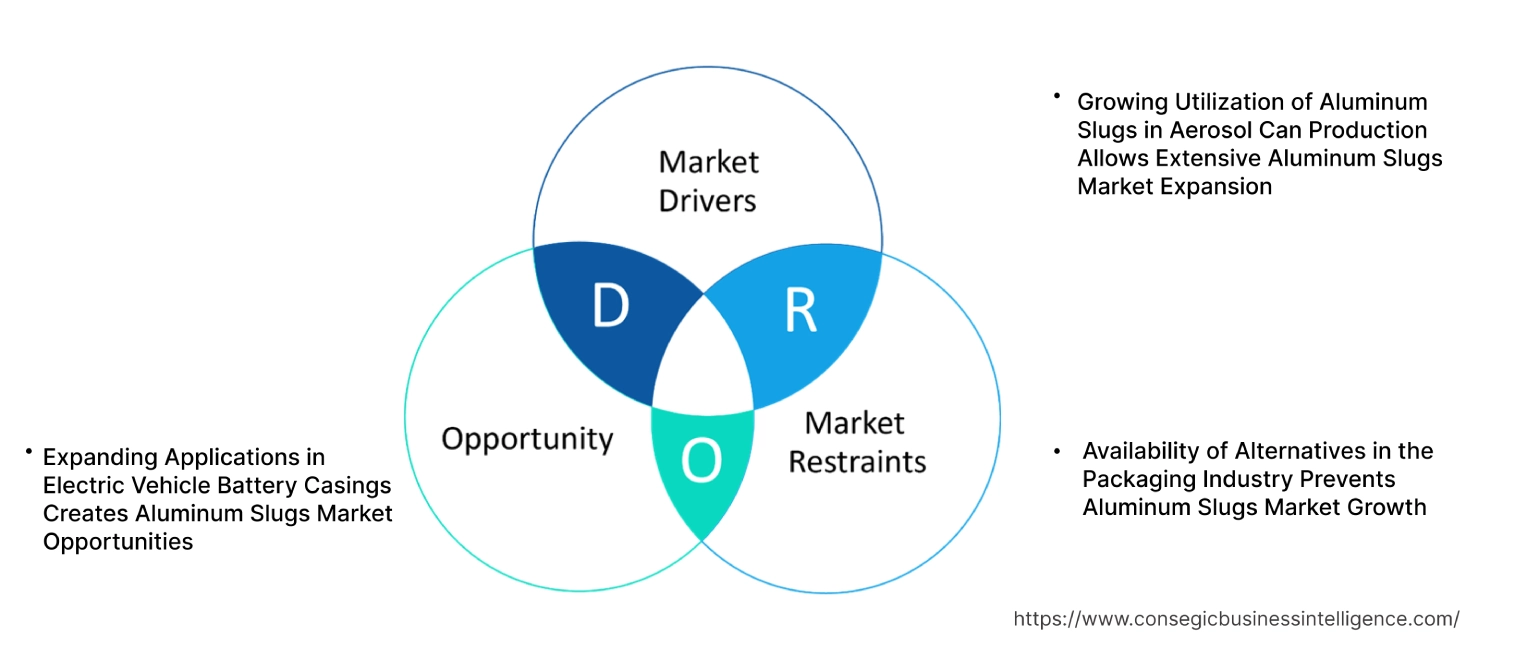

Key Drivers:

Growing Utilization of Aluminum Slugs in Aerosol Can Production Allows Extensive Aluminum Slugs Market Expansion

The increasing trend for aluminum slugs in aerosol can manufacturing is a major factor contributing to the aluminum slugs market growth. Aluminum slugs are a preferred raw material for producing aerosol cans due to their lightweight, corrosion resistance, and excellent malleability, which ensure durability and cost-efficiency. In the personal care industry, for instance, aerosol cans are widely used for packaging deodorants, hair sprays, and shaving foams. This high utilization enhances the aluminum slugs market demand in this sector.

Thus, the rising adoption of aluminum slugs for aerosol production significantly boosts the aluminum slugs market.

Key Restraints:

Availability of Alternatives in the Packaging Industry Prevents Aluminum Slugs Market Growth.

The presence of alternative materials, such as plastic and tin, for packaging applications, poses a challenge to the aluminum slugs market. Plastic, being lightweight and cost-effective, is extensively used in the production of bottles and containers for various consumer goods. Similarly, tin offers high durability and is employed in specialty packaging. These materials compete directly with aluminum slugs in terms of affordability and availability, limiting their adoption. For instance, plastic packaging is widely adopted in regions with cost-sensitive consumers, reducing the demand for aluminum slugs.

Therefore, the availability of alternative materials acts as a restraint to the aluminum slugs market growth.

Future Opportunities :

Expanding Applications in Electric Vehicle Battery Casings Creates Aluminum Slugs Market Opportunities

The growing adoption of electric vehicles (EVs) is expected to open new opportunities for aluminum slugs in battery casing applications. Aluminum is increasingly being used in EV battery casings due to its lightweight properties, excellent thermal conductivity, and resistance to corrosion, which are critical for enhancing vehicle performance and ensuring battery safety. For example, automakers are exploring innovative designs that integrate aluminum-based components to improve EV energy efficiency and durability.

This emerging application of aluminum slugs in the EV industry presents substantial growth as an aluminum slugs market opportunity in the near future.

Aluminum Slugs Market Segmental Analysis :

By Shape:

Based on shape, the aluminum slugs market is segmented into rectangular, flat, round, and others.

Round aluminum slugs accounted for the largest revenue in the aluminum slugs market share in 2024.

- Round slugs are primarily used in the production of beverage cans, aerosol containers, and collapsible tubes.

- Their uniform shape allows for seamless processing in extrusion machines, enhancing manufacturing efficiency.

- They are highly preferred in industries requiring precise dimensional accuracy, ensuring compatibility with automated production lines.

- Round slugs also offer superior material utilization, reducing waste during production.

- Therefore, according to aluminum slugs market analysis, the widespread applicability and efficiency of round aluminum slugs in high-demand industries such as beverage and personal care make them the dominant segment in terms of revenue.

Flat aluminum slugs are anticipated to register the fastest CAGR during the forecast period.

- Flat slugs are versatile and often used in the automotive and electrical sectors, where they are further processed into components like capacitor housings and vehicle parts.

- Their simple geometry supports customization and diverse applications, catering to the increasing trend for lightweight materials.

- The rise in electric vehicle production and consumer electronics is expected to propel the trend for flat aluminum slugs.

- Thus, according to aluminum slugs market analysis, the versatility and expanding application base of flat aluminum slugs drive their rapid growth in the market.

By Alloy Type:

Based on alloy type, the aluminum slugs market is segmented into pure aluminum, aluminum-magnesium alloys, and others.

Pure aluminum accounted for the largest revenue in aluminum slugs market share in 2024.

- It is widely used due to its high ductility, corrosion resistance, and lightweight properties.

- Pure aluminum slugs are preferred in food and beverage packaging, ensuring safety and compliance with health regulations.

- Their recyclability aligns with the sustainability goals of several end-user industries.

- Therefore, according to market analysis, the inherent physical properties and alignment with eco-friendly practices position pure aluminum as the leading segment.

Aluminum-magnesium alloys are anticipated to register the fastest CAGR during the forecast period.

- These alloys offer enhanced strength and durability, making them ideal for automotive components and industrial applications.

- Their superior resistance to corrosion supports their use in harsh environments.

- The increasing aluminum slugs market trend for lightweight materials in the transportation and construction sectors fuels the growth of this segment.

- Thus, according to market analysis, the combination of strength, lightweight nature, and industrial trend contributes to the rapid expansion of aluminum-magnesium alloys in the market.

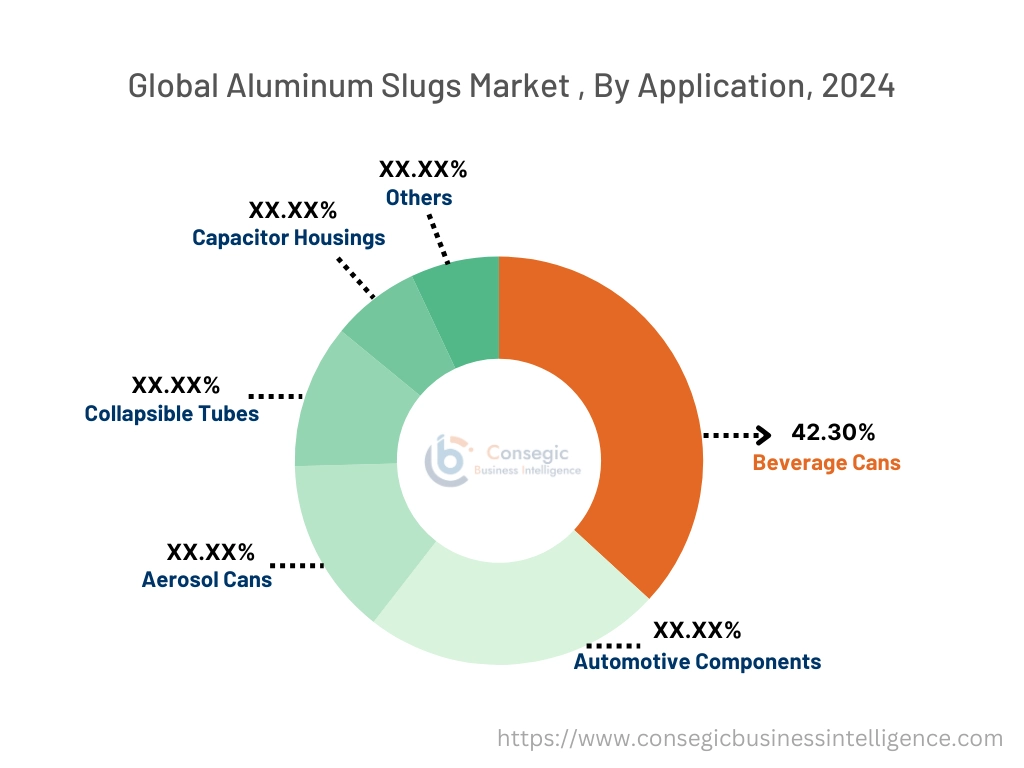

By Application:

Based on application, the aluminum slugs market is segmented into beverage cans, automotive components, aerosol cans, collapsible tubes, capacitor housings, and others.

Beverage cans accounted for the largest revenue share of 42.30% in 2024.

- Aluminum slugs are extensively used to manufacture beverage cans due to their lightweight, corrosion-resistant, and recyclable nature.

- The growing consumption of canned beverages globally has significantly increased the demand for this application.

- Their ability to preserve the flavor and quality of beverages further enhances their preference among manufacturers.

- Therefore, according to market analysis, the large-scale adoption of aluminum slugs in beverage packaging underpins their leading position in the market.

Automotive components are anticipated to register the fastest CAGR during the forecast period.

- Aluminum slugs are used to produce various lightweight parts, such as airbags, fuel tanks, and heat shields.

- The increasing emphasis on fuel efficiency and the rising adoption of electric vehicles drive the trend for lightweight aluminum components.

- Their corrosion resistance and recyclability also support the growing trend of sustainability in the automotive sector.

- Therefore, according to market analysis, the rising focus on energy efficiency and sustainable manufacturing propels the growth of aluminum slugs in the automotive sector.

By End-User Industry:

Based on the end-user industry, the aluminum slugs market is segmented into pharmaceutical, automotive, food & beverage, cosmetic & personal care, and electrical & electronics.

The food & beverage industry accounted for the largest revenue share in 2024

- Aluminum slugs are widely used in packaging solutions for beverages, and canned food, and collapsible tubes for sauces and creams.

- Their non-reactive properties ensure product safety and extended shelf life.

- The growing demand for convenient and sustainable packaging in the food & beverage sector has reinforced their adoption.

- Therefore, according to market analysis, the significant reliance on aluminum packaging solutions in food and beverage applications secures their dominant position in the market.

The cosmetic & personal care industry is anticipated to register the fastest CAGR during the forecast period.

- Aluminum slugs are extensively used in the production of aerosol cans and collapsible tubes for deodorants, creams, and lotions.

- Their lightweight and aesthetic appeal align with the evolving consumer preference for premium packaging.

- The increasing focus on eco-friendly and recyclable packaging materials further boosts their demand in this sector.

- Thus, according to aluminum slugs market analysis, the dynamic growth of the cosmetic and personal care industry, combined with the push for sustainable packaging, accelerates the adoption of aluminum slugs.

Regional Analysis:

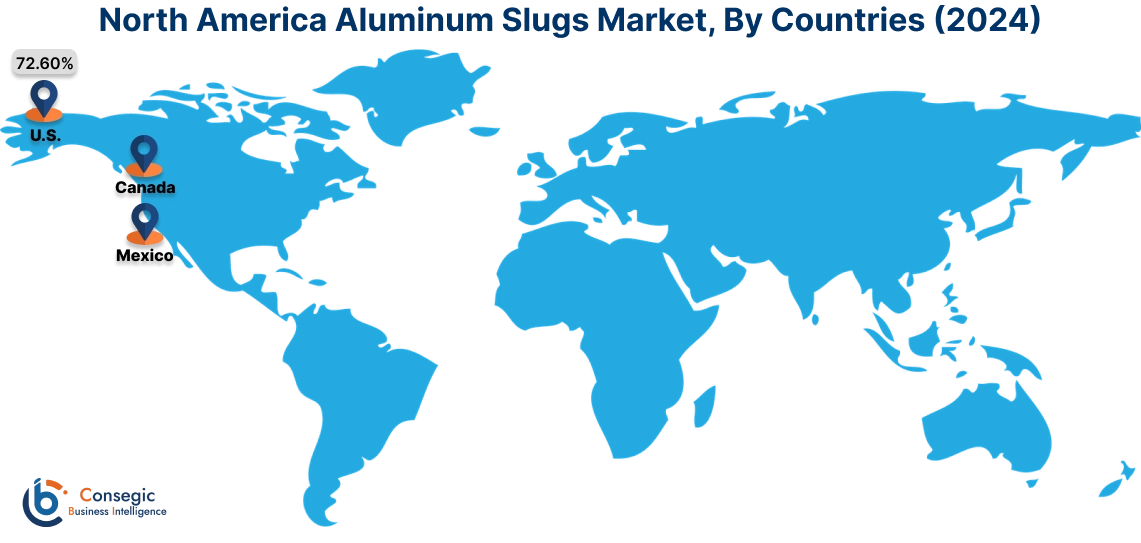

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

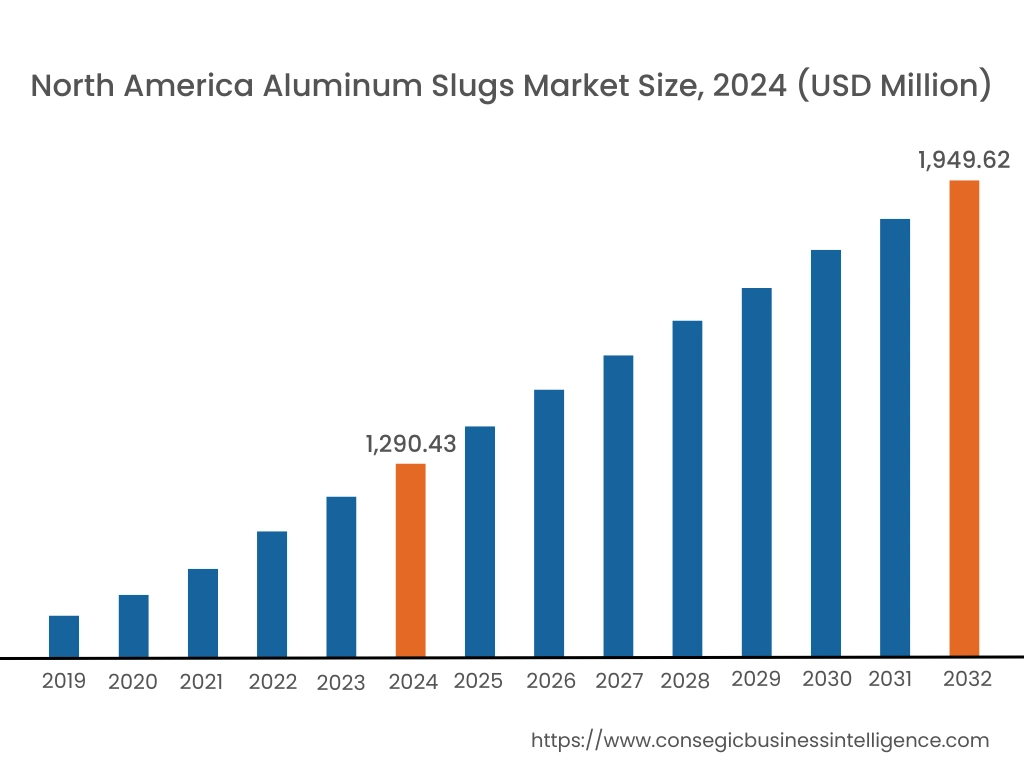

In 2024, North America was valued at USD 1,290.43 Million and is expected to reach USD 1,949.62 Million in 2032. In North America, the U.S. accounted for the highest share of 72.60% % during the base year of 2024. The aluminum slugs market in North America is stable, with the United States and Canada being major contributors. The demand for aluminum slugs is supported by industries such as automotive, packaging, and electronics. The growing adoption of aluminum-based materials in automotive manufacturing for lightweight components and fuel efficiency has increased the demand for aluminum slugs. Additionally, the strong presence of major aluminum producers and established manufacturing facilities further enhances market performance in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 6.0% over the forecast period. Asia-Pacific holds the largest share of the global aluminum slugs market, with China, Japan, and India being the key players. The rapid industrialization and high demand from the automotive and packaging sectors in these countries significantly impact the market. China, in particular, stands out as a dominant producer and consumer of aluminum slugs, driven by its thriving automotive industry and large-scale packaging operations. The region also benefits from lower production costs, making it a hub for aluminum slug manufacturing and export.

In Europe, the aluminum slugs market is characterized by steady demand, particularly in Germany, Italy, and France. The region’s automotive sector, focused on manufacturing lightweight vehicles, drives the need for aluminum slugs. Furthermore, the growing demand for aluminum in packaging, particularly in beverage cans, supports market performance. Europe is also focused on sustainability, with increasing efforts to recycle aluminum and reduce carbon emissions in production, which impacts the demand and production practices of aluminum slugs in the region.

The Middle East and Africa show moderate demand for aluminum slugs, with key markets in the UAE, Saudi Arabia, and South Africa. In the Middle East, the demand is largely driven by the automotive and packaging industries. The increasing development of manufacturing infrastructure in the region has contributed to market growth. However, the market is limited by the region’s smaller production capacity compared to other regions, leading to reliance on imports. The region’s economic diversification efforts also promote growth in industrial sectors that use aluminum slugs.

In Latin America, the aluminum slugs market is growing, with Brazil and Mexico as the primary markets. The automotive industry, particularly in Brazil, drives the demand for aluminum slugs. Additionally, the region’s packaging industry, especially in the food and beverage sector, supports market expansion. The region faces challenges, including economic fluctuations and a reliance on imported materials. However, the increasing demand for lightweight automotive parts and sustainable packaging solutions provides positive prospects for the market in Latin America.

Top Key Players and Market Share Insights:

The global aluminum slugs market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global aluminum slugs market. Key players in the aluminum slugs industry include-

- Constellium (Netherlands)

- UACJ Corporation (Japan)

- Novelis Inc. (United States)

- Sapa Group (Norway)

- ALUMET (United States)

- Alcoa Corporation (United States)

- Rusal (Russia)

- Norsk Hydro ASA (Norway)

- Hydro Aluminium Rolled Products (Norway)

- Aleris Corporation (United States)

Aluminum Slugs Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6,015.48 million |

| CAGR (2025-2032) | 5.6% |

| By Shape |

|

| By Alloy Type |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the aluminum slugs market? +

In 2024, the aluminum slugs market was USD 3,890.26 million.

What will be the potential market valuation for the aluminum slugs market by 2032? +

In 2032, the market size of aluminum slugs market is expected to reach USD 6,015.48 million.

What are the segments covered in the aluminum slugs market report? +

The shape, alloy type, applications, and end-user industry are the segments covered in this report.

Who are the major players in the aluminum slugs market? +

Constellium (Netherlands), UACJ Corporation (Japan), Alcoa Corporation (United States), Rusal (Russia), Norsk Hydro ASA (Norway), Hydro Aluminium Rolled Products (Norway), Aleris Corporation (United States), Novelis Inc. (United States), Sapa Group (Norway), ALUMET (United States) are the major players in the aluminum slugs market.