- Summary

- Table Of Content

- Methodology

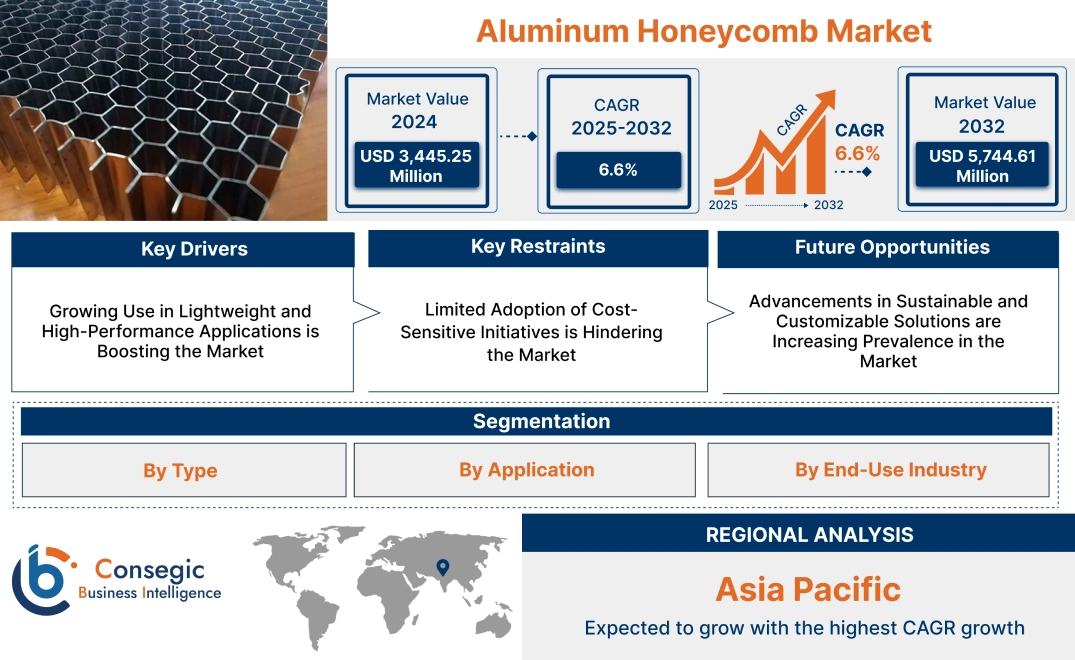

Aluminum Honeycomb Market Size:

Aluminum Honeycomb Market size is estimated to reach over USD 5,744.61 Million by 2032 from a value of USD 3,445.25 Million in 2024 and is projected to grow by USD 3,611.25 Million in 2025, growing at a CAGR of 6.6% from 2025 to 2032.

Aluminum Honeycomb Market Scope & Overview:

The aluminum honeycomb is a lightweight, high-strength structure composed of hexagonal aluminum cells, widely used in industries requiring superior mechanical properties and structural efficiency. Aluminum honeycomb panels offer exceptional strength-to-weight ratios, corrosion resistance, and thermal conductivity, making them ideal for applications in aerospace, automotive, construction, and defense sectors. Key characteristics include high rigidity, fire resistance, and compatibility with various materials such as composites and metals. The benefits include enhanced structural performance, reduced material usage, and improved energy efficiency in design and manufacturing. Applications span aircraft interiors, automotive components, building facades, and energy absorption systems. End-users include aerospace manufacturers, automotive companies, and construction firms, driven by increasing demand for lightweight materials, advancements in material engineering, and the growing focus on sustainability in industrial applications.

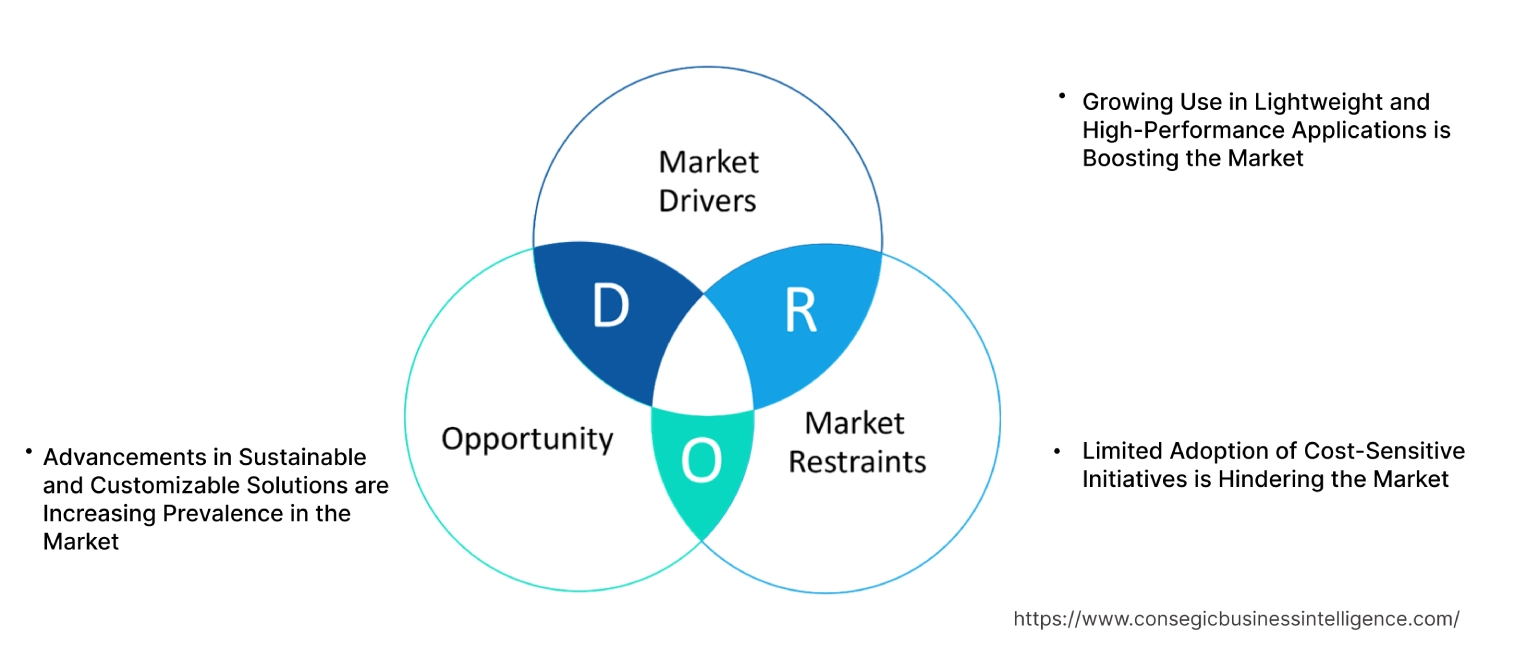

Key Drivers:

Growing Use in Lightweight and High-Performance Applications is Boosting the Market

Aluminum honeycomb structures are becoming essential in industries like aerospace, automotive, and construction due to their high strength-to-weight ratio and excellent energy absorption capabilities. These materials offer significant advantages in reducing overall weight while maintaining structural integrity, making them ideal for fuel-efficient vehicles, high-performance aircraft, and load-bearing construction elements. Additionally, their thermal conductivity and corrosion resistance enhance their applicability in diverse operating environments.

Trends in lightweight material innovation and energy-efficient designs are driving the adoption of aluminum honeycomb panels as manufacturers prioritize sustainability and performance. The analysis highlights that these materials align with global aluminum honeycomb market efforts to reduce carbon footprints by improving energy efficiency in transportation and infrastructure development.

Key Restraints:

Limited Adoption of Cost-Sensitive Initiatives is Hindering the Market

Despite its advantages, aluminum honeycomb structures face challenges in cost-sensitive markets, where traditional materials like steel or wood are often preferred for their affordability. The relatively high production costs associated with precision manufacturing and specialized equipment limit the widespread adoption of these advanced materials in budget-constrained industries and regions.

In addition, a lack of awareness and technical expertise about the benefits and applications of aluminum honeycomb compounds the issue, particularly in emerging economies. Addressing these barriers requires investments in education, cost optimization strategies, and localized production to make these materials more accessible and appealing to cost-sensitive markets.

Future Opportunities :

Advancements in Sustainable and Customizable Solutions are Increasing Prevalence in the Market

The honeycomb market is experiencing significant innovation in the development of sustainable and customizable solutions. Manufacturers are introducing eco-friendly materials and recyclable honeycomb panels that meet the growing demand for environmentally conscious construction and manufacturing practices. These innovations align with aluminum honeycomb market trends in green building and sustainability, appealing to industries striving to meet regulatory and consumer-driven environmental standards.

Customization has also become a key focus, with advancements in technology enabling manufacturers to produce panels tailored to specific applications. Variations in cell size, thickness, and material coatings allow aluminum honeycomb to cater to unique industry requirements, from automotive crash structures to decorative architectural elements. The analysis underscores that these developments are expanding the market potential for aluminum honeycomb, particularly in applications where both performance and sustainability are prioritized.

Aluminum Honeycomb Market Segmental Analysis :

By Type:

Based on type, the market is segmented into non-perforated aluminum honeycomb and perforated aluminum honeycomb.

The non-perforated aluminum honeycomb segment accounted for the largest revenue aluminum honeycomb market share in 2024.

- Non-perforated aluminum honeycomb is widely used across various industries due to its high strength-to-weight ratio, durability, and excellent structural integrity.

- It is extensively applied as a core material in aerospace and automotive components, where lightweight and rigid structures are essential.

- Non-perforated aluminum honeycomb also offers superior thermal and mechanical properties, making it a preferred choice for applications such as panels, floorboards, and energy-absorbing structures.

- The increasing aluminum honeycomb market opportunities for lightweight and energy-efficient materials in aerospace and automotive industries have solidified the dominance of this segment in the market trends.

The perforated aluminum honeycomb segment is anticipated to register the fastest CAGR during the forecast period.

- Perforated aluminum honeycomb is gaining traction due to its ability to enhance ventilation, sound absorption, and moisture resistance.

- These honeycombs are ideal for applications where airflow and acoustic insulation are critical, such as soundproofing panels and HVAC systems.

- The increasing use of perforated honeycomb in aerospace for airflow management in aircraft interiors and in construction for soundproof walls and ceilings has driven its adoption.

- Additionally, advancements in manufacturing techniques to improve the performance and customization of perforated honeycomb products are expected to fuel the aluminum honeycomb market growth of this segmental analysis.

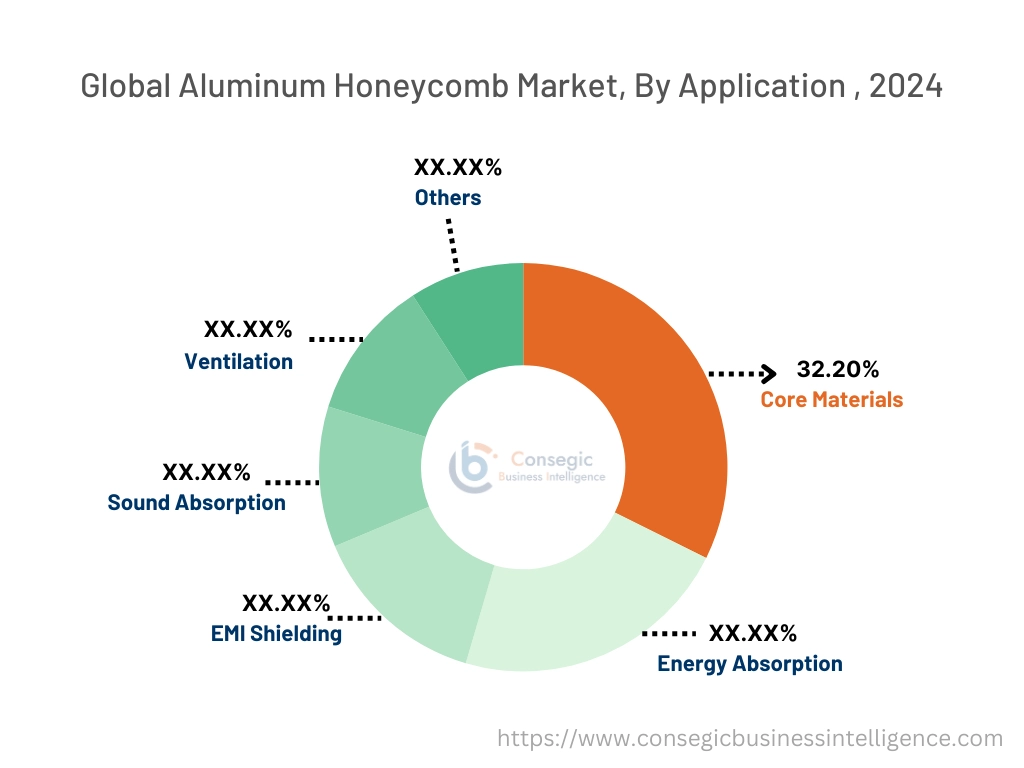

By Application:

Based on application, the market is segmented into core materials, energy absorption, EMI shielding, sound absorption, ventilation, and others.

The core materials segment accounted for the largest revenue of 32.20% in the aluminum honeycomb market share in 2024.

- Aluminum honeycomb is extensively used as a core material in sandwich panels, providing high stiffness and strength while keeping the structure lightweight.

- This application is critical in aerospace, automotive, and construction industries, where performance and weight reduction are priorities.

- The use of aluminum honeycomb as a core material enhances the structural integrity of products such as aircraft panels, automotive body parts, and building claddings.

- The rising adoption of advanced composite materials in manufacturing has further driven the aluminum honeycomb market demand for aluminum honeycomb as a core material.

The sound absorption segment is anticipated to register the fastest CAGR during the forecast period.

- Aluminum honeycomb structures are increasingly used for sound absorption in industries such as construction, aerospace, and automotive.

- The hexagonal cell structure effectively reduces noise levels by absorbing sound waves, making it suitable for soundproof walls, acoustic panels, and HVAC systems.

- The growing focus on improving acoustic performance in buildings, transportation, and industrial facilities has driven the adoption of aluminum honeycomb for sound absorption applications.

- Furthermore, the rise in environmental noise regulations is expected to boost this segment's growth during the forecast period.

By End-Use Industry:

Based on end-use, the market is segmented into aerospace, automotive, construction, marine, defense, packaging, and others.

The aerospace segment accounted for the largest revenue share in 2024.

- The aerospace sector is a key consumer of aluminum honeycomb due to its lightweight, high strength, and corrosion-resistant properties.

- It is used in aircraft interiors, fuselage panels, and wing structures to reduce overall weight and improve fuel efficiency.

- The growing aluminum honeycomb market demand for commercial and defense aircraft, coupled with advancements in aerospace manufacturing technologies, has driven the adoption of aluminum honeycomb materials in this sector.

- Additionally, the stringent safety and performance standards in the aerospace sectors further reinforce the use of aluminum honeycomb products trends.

The automotive segment is anticipated to register the fastest CAGR during the forecast period.

- The automotive sector is increasingly adopting aluminum honeycomb for lightweight components such as crash structures, body panels, and energy absorbers.

- The need for weight reduction to improve fuel efficiency and comply with emission regulations has accelerated the trends for honeycomb materials in electric vehicles (EVs) and traditional automobiles.

- Furthermore, the use of aluminum honeycomb in advanced safety systems for impact energy absorption and crash protection is expected to drive its growth in the automotive sector.

- The rising focus on vehicle electrification and lightweight materials is a major factor propelling this segment’s expansion.

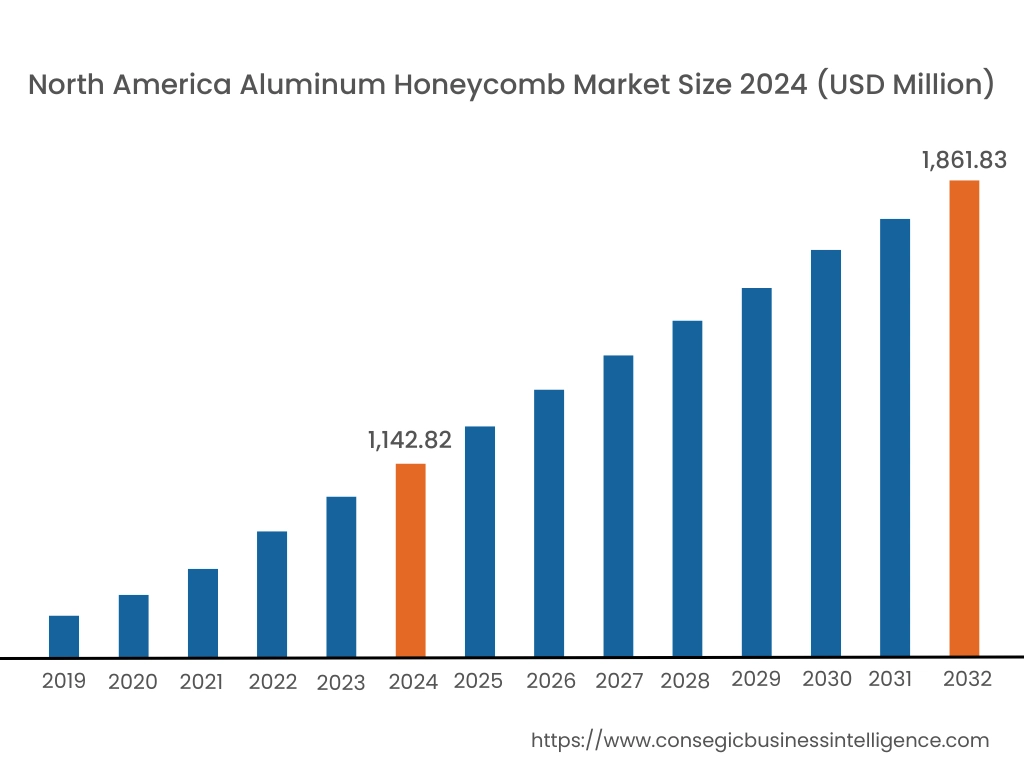

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America was valued at USD 1,142.82 Million and is expected to reach USD 1,861.83 Million in 2032. In North America, the U.S. accounted for the highest share of 71.50% during the base year of 2024. North America holds a significant share in the aluminum honeycomb market analysis, driven by its well-established aerospace, automotive, and construction industries. The U.S. leads the region, with a high demand for lightweight and high-strength materials in aerospace applications such as aircraft panels, wings, and interiors. The growing focus on energy efficiency in automotive manufacturing also supports the adoption of aluminum honeycomb in vehicle body structures. Canada contributes to the market with its expanding use of aluminum honeycomb in the construction sector for energy-efficient building materials. However, high production costs and fluctuating raw material prices may pose challenges to the market.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 7.0% over the forecast period. In the aluminum honeycomb market analysis, fueled by rapid industrialization, urbanization, and increasing investments in aerospace, construction, and transportation in China, India, and Japan. China dominates the market with extensive use of aluminum honeycomb in high-speed trains, construction panels, and aircraft manufacturing. India’s growing infrastructure and automotive sectors drive the adoption of aluminum honeycomb for lightweight and energy-efficient materials. Japan focuses on high-precision applications in electronics, aerospace, and renewable energy, leveraging aluminum honeycomb for its superior strength-to-weight ratio. However, cost sensitivity in emerging markets and dependence on imports for advanced manufacturing equipment may hinder growth in some areas.

Europe is a prominent market for aluminum honeycomb, supported by its advanced aerospace, defense, and automotive industries. Countries like Germany, France, and the UK are key contributors. Germany drives trends for aluminum honeycomb in automotive applications, focusing on lightweighting and fuel efficiency. France emphasizes its use in aerospace, particularly for aircraft interiors and structural components. The UK sees growing adoption in renewable energy systems and construction projects, where the aluminum honeycomb is used for its thermal insulation and durability. However, compliance with stringent EU environmental and recycling regulations can increase manufacturing costs for market players.

The Middle East & Africa region is witnessing steady growth in the aluminum honeycomb market expansion, driven by increasing opportunities in investments in infrastructure development and energy projects. Countries like Saudi Arabia and the UAE are adopting aluminum honeycomb in architectural applications, including curtain walls, facades, and roofing systems, to enhance thermal efficiency and structural strength. In Africa, South Africa is an emerging market, leveraging aluminum honeycomb in transportation and mining equipment for its durability and lightweight properties. However, limited local manufacturing capabilities and reliance on imports for raw materials and technology may restrict broader aluminum honeycomb market expansion.

Latin America is an emerging market for aluminum honeycomb, with Brazil and Mexico leading the region. As the countries analysis, Brazil’s aerospace and automotive industries drive the aluminum honeycomb market trends for aluminum honeycomb in lightweight structural components and interior panels. Mexico’s growing construction and automotive sectors also support the adoption of aluminum honeycomb in energy-efficient buildings and lightweight vehicles. The region is increasingly exploring sustainable construction materials, further boosting trends for aluminum honeycomb. However, economic instability and lack of advanced manufacturing facilities may pose challenges to aluminum honeycomb market growth across the region.

Top Key Players and Market Share Insights:

The Aluminum Honeycomb market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the Aluminum Honeycomb market. Key players in the Aluminum Honeycomb industry include -

- Alucoil (Spain)

- Argosy International Inc. (USA)

- Universal Metaltek (India)

- Benecor, Inc. (USA)

- Motonity Private Limited (India)

- EconCore NV (Belgium)

- EURO-COMPOSITES (Luxembourg)

- Hexcel Corporation (USA)

- Plascore Inc. (USA)

- Corex Honeycomb (UK)

Recent Industry Developments :

Product Launch:

- In July 2023, Aludecor launched Nexcomb and became the first metal composite panels manufacturer to have its own honeycomb core production in India. Nexcore is lightweight, durable, and possesses high strength.

Aluminum Honeycomb Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 5,744.61 Million |

| CAGR (2025-2032) | 6.6% |

| By Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected size of the Aluminum Honeycomb Market by 2032? +

Aluminum Honeycomb Market size is estimated to reach over USD 5,744.61 Million by 2032 from a value of USD 3,445.25 Million in 2024, growing at a CAGR of 6.6% from 2025 to 2032.

What are the main drivers of the Aluminum Honeycomb Market? +

The main drivers include the growing use of aluminum honeycomb in lightweight and high-performance applications across aerospace, automotive, and construction industries. Its superior strength-to-weight ratio and energy absorption capabilities make it essential for fuel-efficient and structurally efficient designs.

What are the primary restraints affecting the Aluminum Honeycomb Market? +

The primary restraints include limited adoption in cost-sensitive markets due to high production costs and the preference for traditional materials like steel or wood. A lack of technical expertise and awareness further restricts its use in emerging economies.

What future opportunities exist in the Aluminum Honeycomb Market? +

Future opportunities lie in the development of sustainable and customizable solutions, including eco-friendly and recyclable honeycomb panels. The focus on green building practices and customized designs for specific applications is expected to expand market potential.