- Summary

- Table Of Content

- Methodology

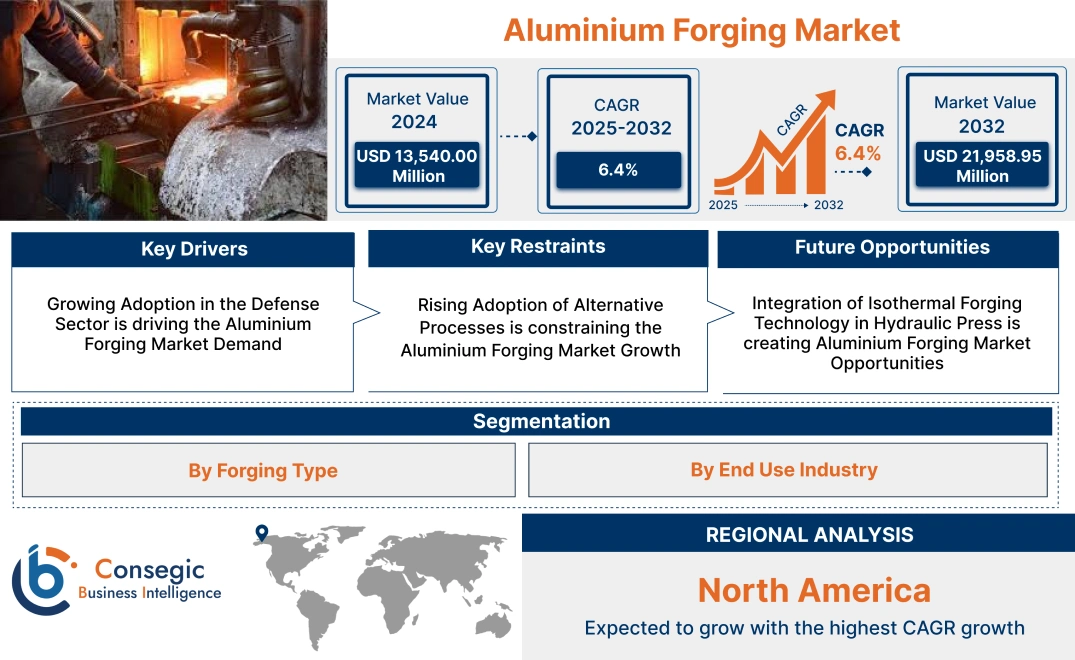

Aluminium Forging Market Size:

Aluminium forging market size is estimated to reach over USD 21,958.95 Million by 2032 from a value of USD 13,540.00 Million in 2024, growing at a CAGR of 6.4% from 2025 to 2032.

Aluminium Forging Market Scope & Overview:

Aluminium forging is the process of shaping aluminium into different forms and sizes by applying pressure using a forging press or hammer. It is a common manufacturing process used in various industries, such as automotive, oil and gas, aerospace and defense, construction, and others. During the forging process, aluminium is heated to its recrystallization temperature, ranging from 350°C up to 500°C (662°F up to 932°F). It is then subjected to pressure from forging equipment that pounds and hammers the aluminium workpiece into a die. The aluminium forging includes different forging types such as open-die forging, closed-die forging, spin forging, the ring rolled forging, and others. Forged aluminium components offer various benefits such as being light in weight, corrosion-resistant, and extremely durable, further driving the market.

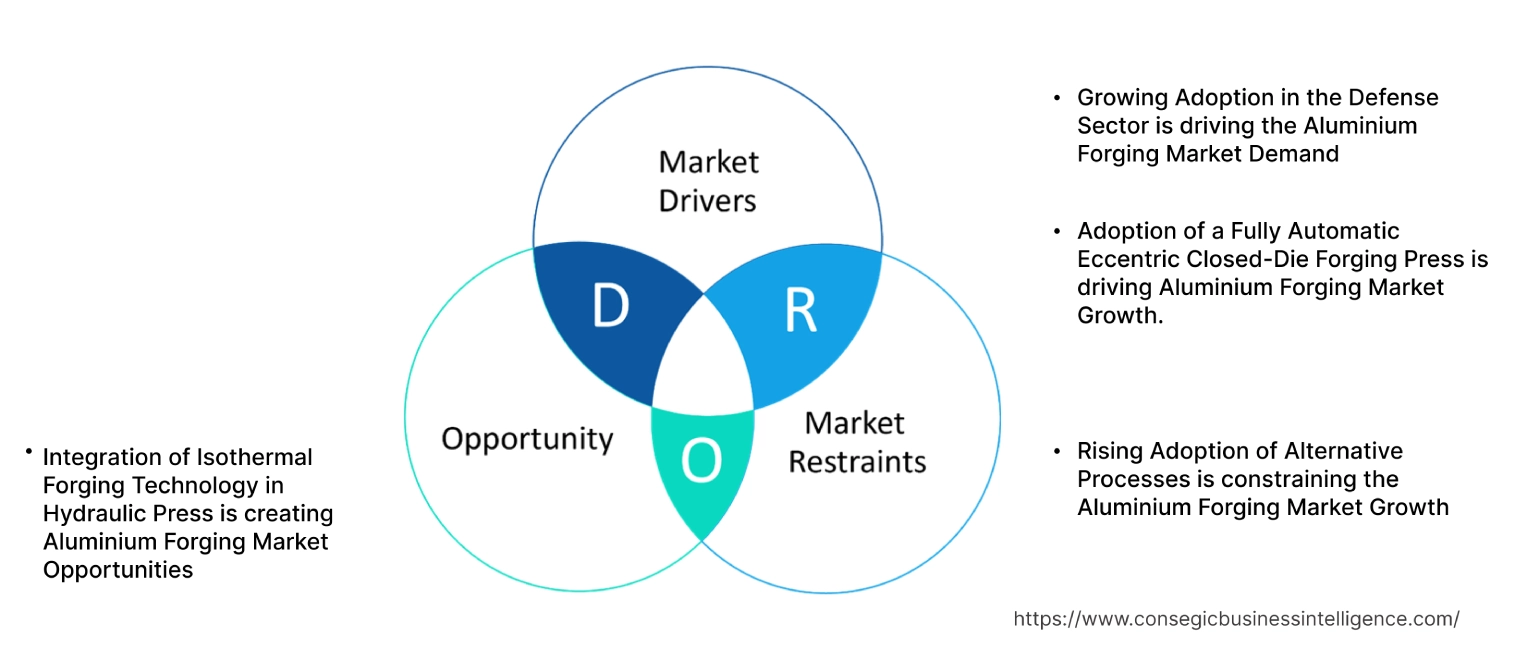

Key Drivers:

Growing Adoption in the Defense Sector is driving the Aluminium Forging Market Demand

Growth in adoption in the defense sector is significantly driving the market, particularly in the aerospace and defense sectors. Aluminium forging offers the strength and reliability needed for critical components such as armored vehicles, aircraft, artillery systems, and others in defense production. Forged aluminum components also provide excellent resistance to corrosion, which is vital in harsh environmental conditions faced by defense equipment, further driving the market.

- In 2023, according to the Press Information Bureau of India, the value of defense production in India is recorded as USD 14.9 Billion. It reflects a growth of 16.7% over the defense production of the year 2022. Aluminium forging is used in the defense sector to manufacture lightweight, durable, and high-strength aluminium components required in armored vehicles, aircraft, artillery systems, and others. Thus, the surge in defense production is further propelling the market.

In conclusion, the surge in defense production is driving the aluminium forging market expansion due to the requirement for high-strength and lightweight aluminium components.

Adoption of a Fully Automatic Eccentric Closed-Die Forging Press is driving Aluminium Forging Market Growth.

A fully automatic eccentric closed-die forging press uses an automation system and eccentric drive systems to produce complex components with minimal waste. It is driving the market by enabling precision, efficiency, and scalability. Their ability to handle high-volume production with consistent quality enhances the aluminium forging process.

- In 2022, Pacific Precision Forging Company expanded in aluminium forging technology with a fully automatic eccentric closed-die forging press. The forging press is available with a press force of 31.5 MN. It uses automation systems and eccentric drive systems in aluminium forging, enhancing its quality. It is further driving the market, by minimizing waste and enabling precision in the aluminium forging process.

Thus, the adoption of a fully automatic eccentric closed-die forging press is driving the market through minimal waste and enhancing quality.

Key Restraints :

Rising Adoption of Alternative Processes is constraining the Aluminium Forging Market Growth

While Aluminium forging offers high precision, strength, and durability, there are manufacturing processes like Aluminium casting,3D Aluminium printing, and others for producing aluminium components. Furthermore, aluminium casting is widely used in applications where intricate shapes or large volumes of aluminium components are required at a lower cost. The casting process also manufactures aluminium components with fine finishes or complex geometries that are difficult to produce with aluminium forging. Additionally, 3D Aluminium printing is rapidly advancing, offering the ability to produce lightweight and complex parts with less material waste and lower production costs.

Thus, alternatives such as Aluminium casting,3D Aluminium printing, and others are constraining the aluminium forging market demand, by offering low cost and less material waste.

Future Opportunities :

Integration of Isothermal Forging Technology in Hydraulic Press is creating Aluminium Forging Market Opportunities

Isothermal forging is a specialized technology in which the workpiece and the die that shapes the aluminium are maintained at the same temperature throughout the operation. The integration of Isothermal forging technology in the hydraulic press is transforming the aluminium forging market by enabling the production of high-precision, high-strength forged aluminium components. This technology is particularly valuable for industries like aerospace and automotive, where lightweight and high-performance aluminium components are essential. It will enhance control over the aluminium forging process, expanding the production of complex geometries and reducing waste.

- In 2024, ALD Vacuum Technologies is partnered with Safran Aircraft Engines to deliver an isothermal forging technology, to be integrated into a hydraulic press. It will enable the production of high-precision, high-strength forged aluminium components under vacuum and hot isothermal conditions, further creating market opportunities.

Thus, the integration of isothermal forging with a hydraulic press is creating aluminium forging market opportunities, through the production of high-quality and complex components.

Aluminium Forging Market Segmental Analysis :

By Forging Type:

By forging type, the market is divided into open-die forging, closed-die forging, spin forging, ring rolled forging, and others.

Trends in Forging Type

- According to aluminium forging market trends, closed-die forging is widely used in aluminium forging, providing high-quality and precise components.

- Use of ring rolled forging is rising, providing high strength and lightweight components as per market trends.

The closed die forging accounted for the largest market share in the year 2024.

- The closed die forging is the dominant forging type in aluminium forging due to its ability to produce highly precise and complex components.

- This process involves placing aluminium in the shape of the desired part and compressing it under high pressure, forcing the material to fill the cavity.

- It is widely used in industries like automotive, aerospace, and others to provide components in suspension systems, wheel rims, and others. Companies are expanding their closed die forging capacity to cater to rising proliferation in these industries.

- In 2024, Balu Forge announced an expansion with the establishment of a closed die-forging facility with a capacity of 72,000 tons annually. It includes the acquisition of three new forging production lines: a 16-ton closed die forging hammer, a 10-ton closed die forging hammer, and an 8,000-ton capacity mechanical press. It will result in the proliferation of the market, by producing highly precise and complex aluminium components.

- Thus, closed die forging is widely used forging due to its ability to produce high-quality components.

The ring-rolled forging is expected to grow at the fastest CAGR over the forecast period.

- The ring-rolled forging is used to manufacture seamless rings with high strength, precision, and durability.

- The process involves rolling heated aluminium between tow dies to create rings of varying diameters, thicknesses, and profiles.

- This forging type is particularly popular in industries like aerospace, power generation, oil and gas, and others for applications such as turbine rings, bearings, flanges, and others.

- Aluminium’s lightweight and corrosion-resistant properties make it ideal for ring-rolled forging. With a growing preference for lightweight components in aerospace and renewable energy sectors, the need for ring-rolled aluminium forging is rising.

- Thus, ring-rolled forging is growing rapidly due to the demand for lightweight components and applications in industries like aerospace, renewable energy, and others as per current trends.

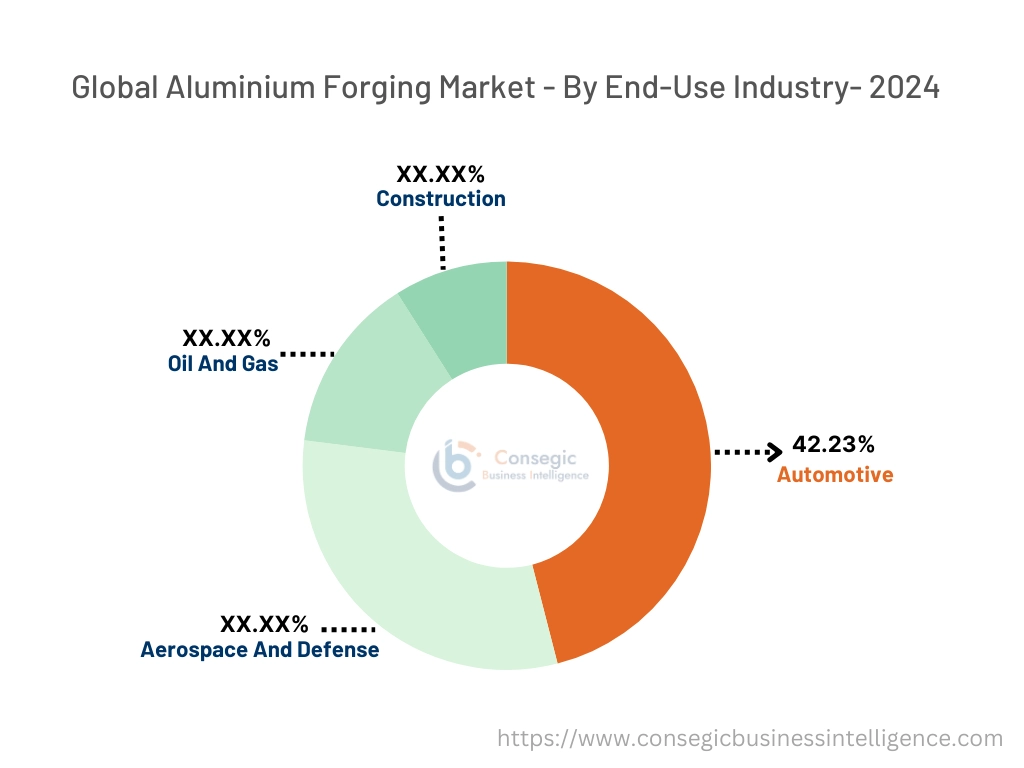

By End-Use Industry:

By end-use industry, the market is divided into automotive, oil and gas, aerospace and defense, construction, and others.

Trends in End-Use Industry

- As per aluminium forging market trends, aluminium forging is widely used in the automotive industry to provide high-strength and lightweight automotive parts.

- In the aerospace and defense industry, the use of aluminium forging is propelling due to the demand for durable and corrosion resistance components as per the latest trends.

The automotive industry accounted for the largest market share of 42.23% in the year 2024.

- Aluminium forging is extensively used in the automotive industry offering benefits in terms of lightweight, strength, and performance.

- As the automotive sector increasingly shifts towards fuel-efficient and environmentally friendly vehicles, forged aluminium is the primary choice due to its excellent strength-to-weight ratio.

- Forged aluminium components are used in critical parts such as engine blocks, suspension systems, wheel rims, and others in the automotive sector, reducing weight and improving fuel efficiency.

- The precision and high strength of forged aluminium also ensure automotive parts meet stringent safety standards while enhancing vehicle performance.

- Hence, aluminium forging is widely used in the automotive industry due to its excellent durability and lightweight capability.

The aerospace and defense industry is expected to grow at the fastest CAGR over the forecast period.

- Aluminium forging is extensively being used in the aerospace and defense industry to produce lightweight, durable, and high-strength components.

- The corrosion resistance and excellent strength-to-weight ratio of aluminium forging are ideal for use in aerospace and defense applications.

- Forged aluminium parts are integral to artillery gun platforms, missile parts, armored vehicles, and others, offering superior performance under extreme conditions.

- For instance, in 2024, Bharat Forge partnered with US defense companies AM General and Mandus Group to co-develop advanced artillery gun platforms. Forged aluminium components are used in artillery gun platforms to reduce weight, enhancing their mobility and operational efficiency without compromising durability.

- In conclusion, the use of aluminium forging is rising in the aerospace and defense industry to produce durable and high-strength components as per current trends.

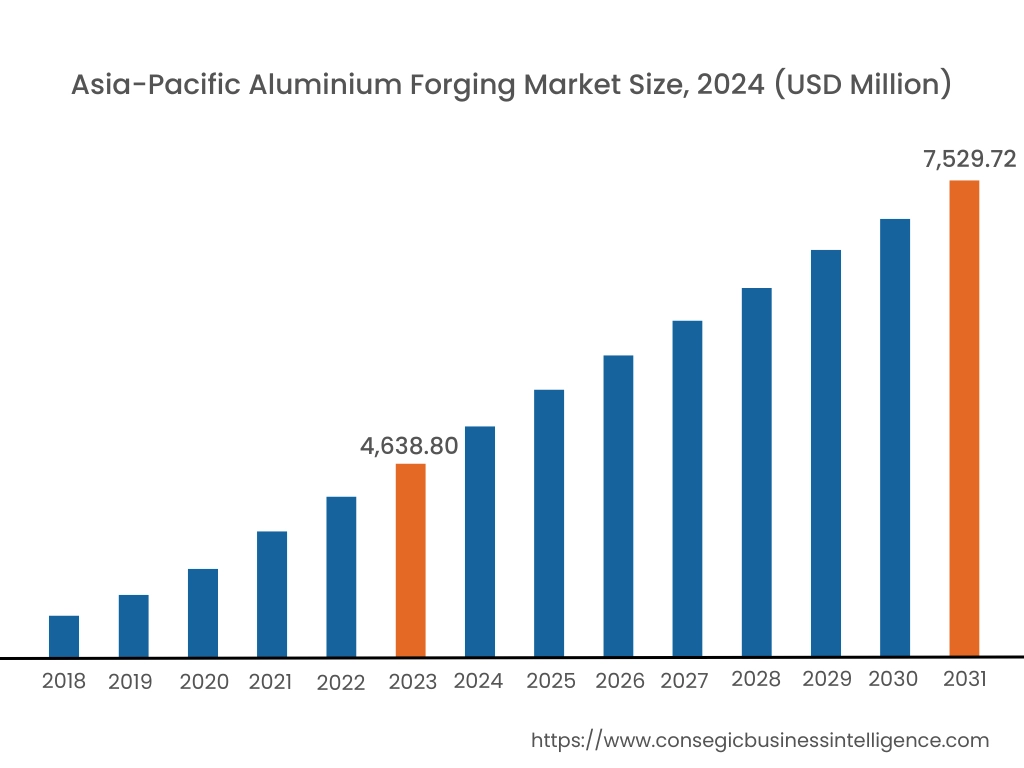

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

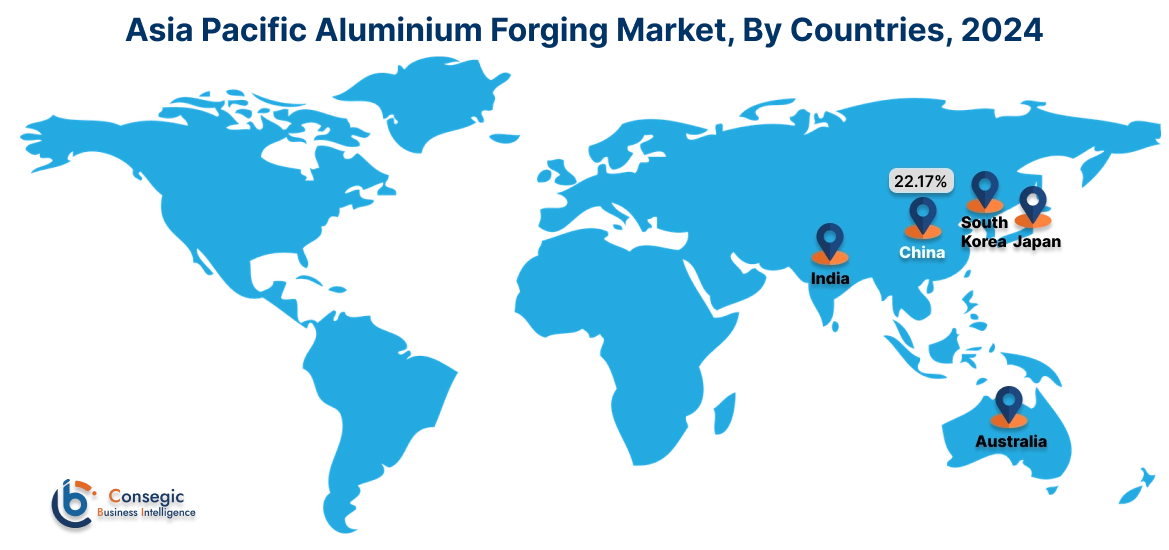

In 2024, Asia Pacific accounted for the highest market share at 34.26% and was valued at USD 4,638.80 Million and is expected to reach USD 7,529.72 Million in 2032. In Asia Pacific, China accounted for the highest market share of 22.17% during the base year of 2024. As per market analysis, the aluminium forging market share of the Asia-Pacific region is driven by rapid urbanization and industrial developments. The government in this region is also significantly investing in the aerospace and defense sector, driving the use of forged aluminium components in artillery gun platforms, missile parts, armored vehicles, and others. The automotive sector in the region is a major contributor, as aluminium forging components are used in critical parts such as engine blocks, suspension systems, wheel rims, and others. Companies in this region are also expanding aluminium production, to cater to the rising demand for forged aluminium components in commercial and passenger vehicles further propelling the markete.

- In 2024, NTPC partnered with NALCO Forge for aluminium production expansion in Odisha, India. It ensures a consistent supply of high-quality aluminium, supporting proliferation in the market in industries like automotive, construction, aerospace and defense, and others.

In conclusion, Asia-Pacific is leading in the market, supported by expanding aerospace and defense sectors and industrial developments.

North America is expected to witness the fastest CAGR of 6.9% over the forecast period during 2024-2031. According to market analysis, North America’s Aluminium forging market share is experiencing rapid proliferation in the market, driven by the well-established automotive aerospace and defense sector. The region benefits from a strong automotive sector, which remains a significant consumer of forged aluminium components in the control arm, drive shafts, yokes, suspension systems, and others. The region is also growing in terms of the aerospace and defense sector, driving the use of forged aluminium components in the production of aircraft, missiles, armored vehicles, and others. The region is also experiencing rapid construction and industrial developments, which is further driving the need for forged aluminium in beams, columns, and others.

Thus, North America is experiencing market growth, driven by the expanding aerospace defense sector and rapid industrial developments.

According to the aluminium forging market analysis, the European region is growing significantly in the market due to well-established automotive and manufacturing sectors. The European countries are leading in the manufacturing of engine blocks, suspension systems, wheel rims, and others, further fueling the market growth. Countries like France, the United Kingdom, and Norway are key contributors due to the major production and export of aluminium Forged components to other networks. The aerospace and defense industry is also expanding leading to demand for forged aluminium components in aircraft, armored vehicles, and others. Moreover, European manufacturers are investing heavily in research and development of high-quality and custom aluminium forging further driving the aluminium Forging market expansion.

According to the aluminium forging market analysis, the market is expanding in the Middle East and Africa region driven by rapid construction and the growing automotive sector. In countries like Dubai, UAE, and South Africa the market is propelling due to the rapid proliferation of industrial projects and the expanding manufacturing sector. Oil and gas remain significant contributors in this region, as aluminium forged components are critical for high temperatures and pressures in valves, fittings, pumps, and others. The governments in this region are also investing in the aerospace and defense sectors, further driving the market. The region is expected to grow significantly in the market, driven by industrial developments and government support as per market analysis.

According to market analysis, Latin America is witnessing moderate growth in the market, driven by expanding industrial activities, and rising construction and manufacturing development. Key countries like Brazil, Mexico, and Argentina lead the market due to their strong automotive and industrial sectors. The growing automotive market is a significant contributor, with increasing demand for aluminium forged components in engine blocks, suspension systems, wheel rims, and others. The region is also expanding in terms of construction, aerospace, and defense sectors, further accelerating the market. However, challenges such as supply chain complexities, rising raw material costs, and regulatory barriers impact the growth of the market in the region.

Top Key Players and Market Share Insights:

The aluminium forging industry is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global aluminium forging market. Key players in the aluminium forging industry include-

- All Metals & Forge Group (United States)

- Alcoa (United States)

- Farinia Group (France)

- Norsk Hydro (Norway)

- Bharat Forge (India)

- Scot Forge Company (United States)

- KOBE STEEL, LTD (Japan)

- Arconic (United States)

- ATI (Australia)

- Bons & Evers Group (Netherlands)

Recent Industry Developments :

Launches:

- In 2024, Ramkrishna Forgings launched an aluminium forging plant in Jamshedpur, India. The company will invest USD 6.78 million in the new plant, which will have an annual capacity of 3,000 tonnes and is slated to commence operations by the second quarter of the 2025-26 fiscal year. This will further expand the market.

Business Expansion:

- In 2024, ILJIN is expanding into the aluminium forging sector with a new facility in Alabama. It is investing nearly USD 100 million in a new operation to expand into the aluminium forging market.

Aluminium Forging Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 (USD Million) | USD 21,958.95 Million |

| CAGR (2025-2032) | 6.4% |

| By Forging Type |

|

| By End-Use Industry |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Aluminium forging market? +

In 2024, the Aluminium forging market is USD 13,540.00 Million.

Which is the fastest-growing region in the Aluminium forging market? +

North America is the fastest-growing region in the Aluminium forging market.

What specific segmentation details are covered in the Aluminium forging market? +

Forging type and end-use industry are covered in the Aluminium forging market.

Who are the major players in the Aluminium forging market? +

All Metals & Forge Group (United States), Alcoa (United States), and Scot Forge Company (United States) are some of the major players in the market.