- Summary

- Table Of Content

- Methodology

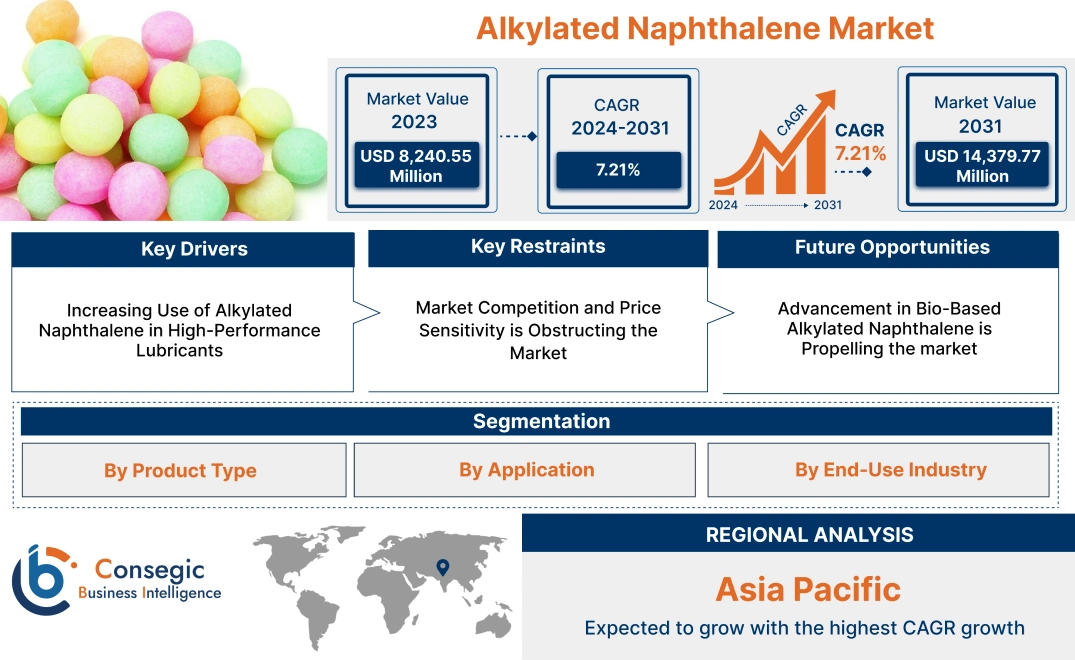

Alkylated Naphthalene Market Size:

Alkylated Naphthalene Market size is estimated to reach over USD 14,379.77 Million by 2031 from a value of USD 8,240.55 Million in 2023 and is projected to grow by USD 8,687.68 Million in 2024, growing at a CAGR of 7.21% from 2024 to 2031.

Alkylated Naphthalene Market Scope & Overview:

The alkylated naphthalene focuses on the production and application of alkylated naphthalene compounds, known for their exceptional thermal stability, oxidative resistance, and lubricating properties. These compounds are widely used as base oils and additives in industrial lubricants, automotive oils, and metalworking fluids. Key characteristics of alkylated naphthalene include a high viscosity index, superior load-bearing capacity, and excellent compatibility with various additive technologies. The benefits include enhanced equipment performance, extended oil life, and reduced maintenance costs in demanding industrial and automotive applications. Applications span gear oils, hydraulic fluids, compressor oils, and aviation lubricants, where reliability and performance under extreme conditions are critical. End-users include industrial machinery manufacturers, automotive companies, and aerospace firms, driven by increasing demand for high-performance lubricants, advancements in industrial processes, and the growing need for energy-efficient solutions.

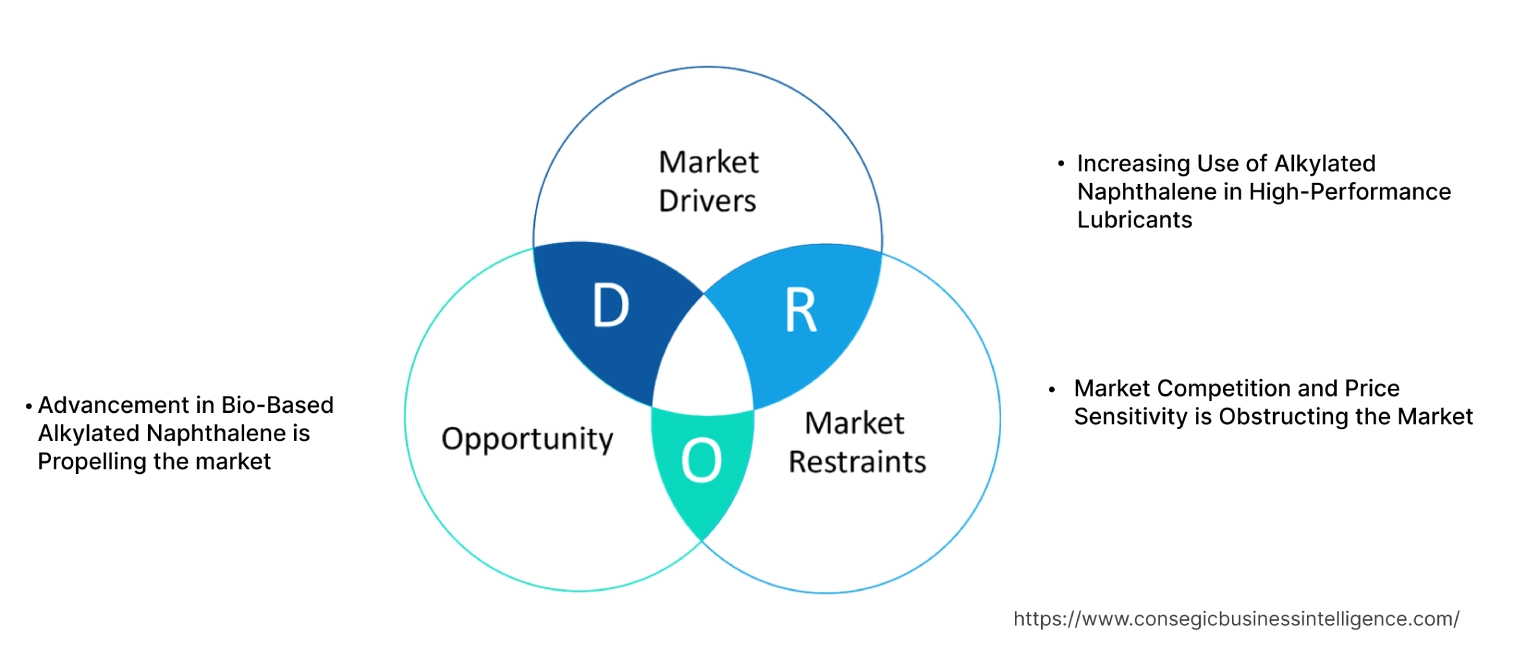

Key Drivers:

Increasing Use of Alkylated Naphthalene in High-Performance Lubricants

Alkylated naphthalene is widely utilized in high-performance lubricants due to its superior thermal stability, oxidative resistance, and compatibility with synthetic oils. These properties make it indispensable for applications in automotive engines, aerospace machinery, and industrial equipment, where extreme temperatures, high pressures, and prolonged operational cycles are common. The compound’s ability to maintain lubricant performance under such demanding conditions ensures the longevity and reliability of machinery.

Trends in energy efficiency and advanced manufacturing have further emphasized the importance of high-quality lubricants in reducing wear and enhancing the performance of critical components. Alkylated naphthalene is particularly valued in sectors such as electric vehicles (EVs), where thermal management and efficient lubrication are essential. Analysis highlights its growing role as industries focus on sustainability and advanced material performance in their operational workflows.

Key Restraints :

Market Competition and Price Sensitivity is Obstructing the Market

The alkylated naphthalene market is highly competitive, with numerous players offering similar products, leading to price pressures. This competition is further intensified by the availability of alternative lubricant additives that provide comparable performance at lower costs. Manufacturers are often required to balance quality with affordability to remain competitive, which can impact profit margins, particularly in cost-sensitive markets.

Price sensitivity is also influenced by the reliance on petrochemical-based raw materials, which are subject to price volatility due to fluctuating crude oil markets and supply chain disruptions. These challenges require producers to optimize manufacturing processes and explore cost-efficient sourcing strategies to mitigate financial risks while maintaining product quality.

Future Opportunities :

Advancement in Bio-Based Alkylated Naphthalene is Propelling the market

The growing emphasis on sustainability has spurred research into bio-based alkylated naphthalene as an eco-friendly alternative to traditional formulations. Innovations in green chemistry are enabling the development of renewable feedstocks and production methods that reduce environmental impact while retaining the high-performance characteristics of conventional alkylated naphthalene. These advancements align with industry trends prioritizing reduced carbon footprints and regulatory compliance with environmental standards.

Bio-based variants are particularly appealing in industries like automotive and aerospace, where the adoption of sustainable materials is becoming a key focus. Additionally, the ability to market bio-based alkylated naphthalene as a cleaner and greener option offers a competitive advantage for manufacturers aiming to differentiate themselves in the marketplace. As analysis highlights the increasing alkylated naphthalene market opportunities in the integration of sustainability in industrial processes, bio-based solutions are poised to play a significant role in the future of advanced lubricants.

Alkylated Naphthalene Market Segmental Analysis :

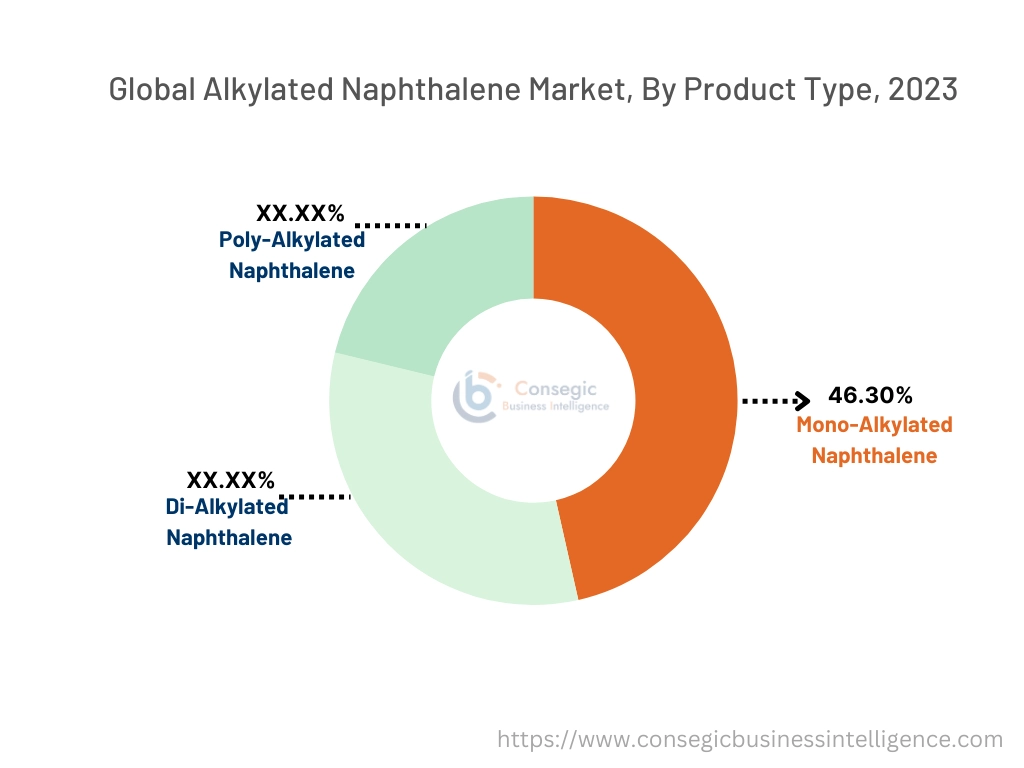

By Product Type:

Based on product type, the market is segmented into Mono-Alkylated Naphthalene, Di-Alkylated Naphthalene, and Poly-Alkylated Naphthalene.

Mono-alkylated naphthalene held the largest share of 46.30% alkylated naphthalene market share in 2023

- Due to its widespread use as a base fluid in lubricants. Its high thermal stability, excellent solvency, and oxidation resistance make it a preferred choice for applications in high-performance engines and industrial machinery.

- Additionally, mono-alkylated naphthalene offers enhanced viscosity control, making it essential in synthetic lubricants for automotive and aerospace applications.

- The increasing demand for high-performance lubricants across industries is further driving alkylated naphthalene market growth.

- Mono-alkylated naphthalene dominates the market trends analysis due to its superior performance characteristics and widespread use in high-performance lubricant formulations.

Poly-alkylated naphthalene is anticipated to register the fastest CAGR during the forecast period.

- Its ability to provide exceptional thermal stability, lower volatility, and enhanced lubricity under extreme pressure conditions drives its adoption.

- This product type is increasingly used in advanced greases and specialty lubricants for heavy machinery and aerospace applications.

- The growing focus on developing lubricants with superior load-carrying capacity and extended service life further boosts this segment's growth.

- Poly-alkylated naphthalene is expected to grow rapidly, driven by its superior thermal stability and applications in high-performance greases and lubricants.

By Application:

Based on application, the market is segmented into Lubricants, Greases, Metalworking Fluids, Hydraulic Fluids, and Others.

Lubricants accounted for the largest revenue share in 2023.

- It is supported by their extensive use across industries, including automotive and industrial machinery.

- Alkylated naphthalenes, as base fluids, enhance lubricants' oxidative stability, viscosity index, and high-temperature performance.

- They are particularly effective in synthetic and semi-synthetic formulations, providing excellent protection against wear and corrosion.

- The growing automotive sector and increasing adoption of energy-efficient systems in industries are driving alkylated naphthalene market demand for high-performance lubricants.

- Lubricants lead trends in the application segment due to their versatility and critical role in ensuring equipment efficiency and durability.

Greases are projected to grow at the highest CAGR during the forecast period.

- Alkylated naphthalene-based greases are favored for their ability to operate under extreme conditions, such as high temperatures, high pressures, and corrosive environments.

- Their use in industrial machinery, automotive components, and aerospace applications is expanding as industries seek long-lasting lubrication solutions.

- Additionally, advancements in grease formulations for specialized machinery and heavy-duty equipment contribute to this segment's growth.

- Greases are expected to grow rapidly, driven by increasing trends for long-lasting lubrication solutions in extreme operational environments.

By End-Use Industry:

Based on the end-use industry, the market is segmented into Automotive, Industrial Machinery, Aerospace, Energy, and Others.

The automotive segment held the largest alkylated naphthalene market share in 2023

- It is owing to the high trends for lubricants, greases, and metalworking fluids in vehicle manufacturing and maintenance.

- Alkylated naphthalenes play a vital role in enhancing the efficiency and longevity of automotive components by reducing friction and wear.

- The increasing production of electric vehicles (EVs) and the need for advanced lubricants to support their unique requirements further drive this segment's growth.

- The Automotive industry leads the alkylated naphthalene market trends due to its reliance on advanced lubricants and greases for vehicle manufacturing and maintenance.

The aerospace segment is projected to grow at the fastest CAGR during the forecast period.

- The stringent requirements for lubricants and fluids that can withstand extreme temperatures, pressures, and altitudes are driving the demand for alkylated naphthalenes in this industry.

- Their use in hydraulic fluids, high-performance greases, and engine oils ensures the efficient operation of aircraft systems.

- The growing aerospace sector, driven by increased air travel and defense investments, further supports this segment's expansion.

- The Aerospace industry is expected to grow rapidly, supported by the need for high-performance lubricants and fluids that meet stringent operational standards.

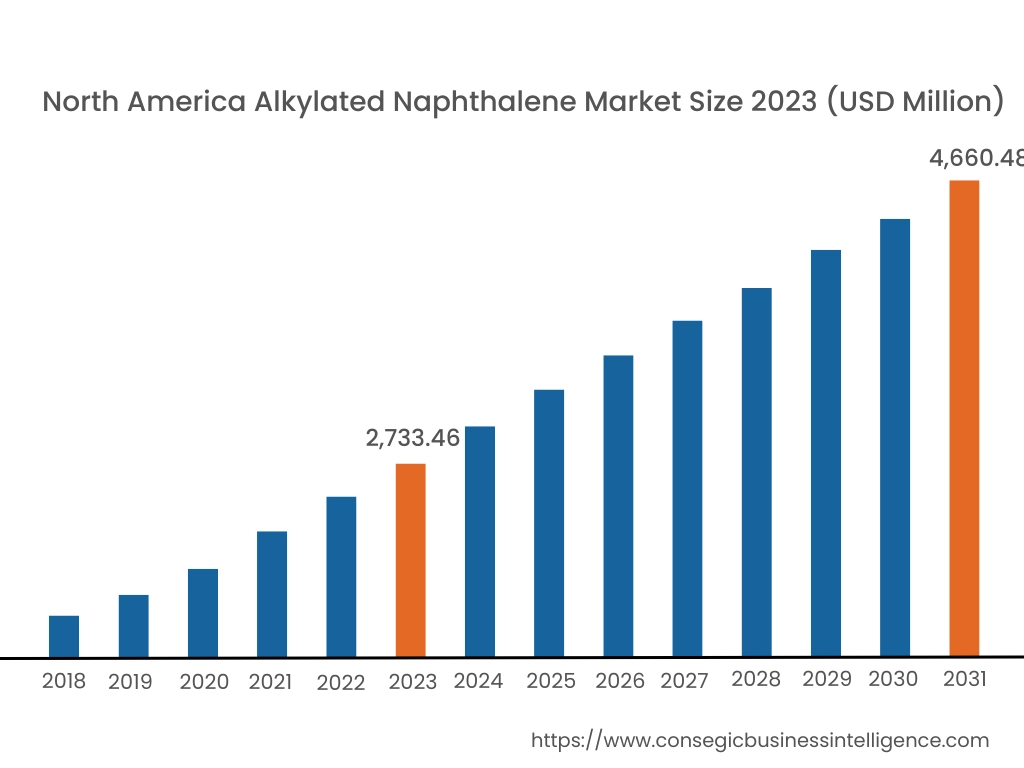

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2023, North America was valued at USD 2,733.46 Million and is expected to reach USD 4,660.48 Million in 2031. In North America, the U.S. accounted for the highest share of 72.60% during the base year of 2023. North America holds a significant share in the alkylated naphthalene market analysis, driven by its strong presence in the automotive, aerospace, and industrial sectors. The U.S. leads the region due to the extensive use of alkylated naphthalene as a high-performance lubricant additive in automotive and industrial machinery. The growing demand for durable lubricants in extreme temperature applications, particularly in aerospace and heavy-duty equipment, supports market expansion. Canada contributes to the market through increasing opportunities for adoption in industrial lubrication and metalworking fluids. However, strict environmental regulations on synthetic lubricants may pose challenges for manufacturers in the region.

In Asia Pacific, the market is experiencing the fastest growth with a CAGR of 7.7% over the forecast period. The market is fueled by rapid industrialization, urbanization, and increasing automotive production in China, India, and Japan. China leads the market with large-scale adoption in automotive and industrial lubrication, driven by its expanding manufacturing sector. India’s growing automotive and heavy equipment industries further boost demand for synthetic lubricant additives to enhance machinery efficiency and durability. Japan focuses on high-precision lubrication solutions for its advanced automotive and electronics industries, leveraging alkylated naphthalene for its superior thermal stability and oxidative resistance. However, cost sensitivity and limited awareness in emerging markets may hinder broader adoption in some parts of the region.

Europe is a prominent market for alkylated naphthalene, supported by the analysis of the region’s advanced automotive and manufacturing industries. Countries like Germany, France, and the UK are key contributors. Germany’s robust automotive sector drives alkylated naphthalene market demand for the market in high-performance engine oils and gear lubricants, while France focuses on its use in industrial applications requiring thermal stability and oxidative resistance. The UK emphasizes sustainable lubrication solutions, boosting interest in long-lasting synthetic additives like alkylated naphthalene. However, compliance with stringent EU regulations on lubricant additives and environmental sustainability creates challenges for manufacturers.

The Middle East & Africa region is experiencing steady development in the alkylated naphthalene market growth, primarily driven by increasing investments in industrial machinery and the oil and gas sector. Countries like Saudi Arabia and the UAE utilize alkylated naphthalene in lubricants for high-temperature industrial equipment and drilling operations. In Africa, South Africa is an emerging market, focusing on improving industrial and automotive lubrication systems for enhanced machinery performance. However, limited local production capabilities and reliance on imports for raw materials and synthetic additives may restrict market development in the region.

Latin America analysis shows it is an emerging market for alkylated naphthalene, with Brazil and Mexico leading the region. Brazil’s expanding industrial base and growing automotive sector drive the growth of high-performance lubricants incorporating alkylated naphthalene. Mexico’s strong focus on manufacturing and export-oriented industries supports the adoption of synthetic additives for lubrication in machinery and equipment. The region is also exploring sustainable and long-lasting lubricant solutions to reduce operational costs. However, economic instability and inconsistent regulatory frameworks may pose challenges to alkylated naphthalene market expansion across the region.

Top Key Players and Market Share Insights:

The alkylated naphthalene market is highly competitive with major players providing products and services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the global alkylated naphthalene market. Key players in the alkylated naphthalene industry include -

- MilliporeSigma (U.S.)

- Abcam plc (U.K.)

- Abnova Corporation (Taiwan)

- BioAssay Systems (U.S.)

- Randox Laboratories Ltd. (U.K.)

- Siemens Healthineers (Germany)

- Thermo Fisher Scientific Inc. (U.S.)

- Bio-Rad Laboratories, Inc. (U.S.)

- Bio-Techne Corporation (U.S.)

- GeneTex, Inc. (U.S.)

Alkylated Naphthalene Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 66,115.49 Million |

| CAGR (2024-2031) | 7.21% |

| By Product Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

What is the projected market size of the Alkylated Naphthalene Market by 2031? +

Alkylated Naphthalene Market size is estimated to reach over USD 14,379.77 Million by 2031 from a value of USD 8,240.55 Million in 2023 and is projected to grow by USD 8,687.68 Million in 2024, growing at a CAGR of 7.21% from 2024 to 2031.

Which product type dominates the market? +

Mono-alkylated naphthalene holds the largest market share due to its widespread use as a base fluid in high-performance lubricants for automotive and industrial applications.

What are the key growth drivers for the market? +

The increasing use of alkylated naphthalene in high-performance lubricants, driven by its superior thermal stability, oxidative resistance, and compatibility with synthetic oils, is a major growth driver.

What challenges does the Alkylated Naphthalene Market face? +

Market competition, price sensitivity, and the reliance on volatile petrochemical-based raw materials pose significant challenges for manufacturers.